You face a rapidly expanding PCBA industry in China, with the market projected to reach ¥1.1 trillion and hold about 40% of global share by 2025. Chinese manufacturers now account for nearly a third of worldwide PCB production. When you select a China pcba manufacturer, you need reliability, industry certifications, and a strong record of customer satisfaction. This curated list highlights the top 10 manufacturers, chosen for their market reputation, technological leadership, and consistent positive feedback. Use the detailed company profiles and comparison table to find the partner that best matches your project requirements.

Choosing a Reliable PCBA Manufacturer

- Focus on certifications like ISO 9001 and IATF 16949 when choosing a PCBA manufacturer. These ensure quality and safety standards.

- Evaluate a manufacturer’s experience and market presence. Companies with a long history often deliver better quality and reliability.

- Check customer feedback and testimonials. Positive reviews indicate a manufacturer’s ability to meet expectations and resolve issues.

- Request samples and detailed quotes before committing. This helps assess quality and ensures the manufacturer meets your specific needs.

- Strong after-sales support is crucial. Choose a partner who offers technical assistance and prompt issue resolution for long-term success.

Selection Criteria for Reliable China PCBA Manufacturer

Certifications & Standards

When you evaluate a china pcba manufacturer, certifications and standards should be your first checkpoint. These credentials prove that the company follows strict quality and safety protocols in PCB assembly. Look for certifications such as ISO 9001, which ensures consistent production through robust quality management systems. IPC-A-610 sets the industry standard for workmanship and visual criteria in PCB assembly. Automotive projects require IATF 16949, while RoHS and REACH demonstrate a commitment to eco-friendly manufacturing. Additional standards like IPC-A-600, IPC-6012, IPC-7711/7721, and IPC-J-STD-001 further guarantee reliable PCB results.

Tip: Always request documentation of certifications before starting a circuit board assembly project.

| Certification | Purpose |

|---|---|

| ISO 9001 | Quality management and consistency |

| IPC-A-610 | Industry-accepted workmanship |

| RoHS & REACH | Lead-free, eco-compliant manufacturing |

Experience & Market Presence

You should consider the manufacturer’s years in business and their reputation in pcb assembly and pcb fabrication. Companies with a long history often have refined processes and a proven ability to deliver high-quality pcba products. Market presence also indicates stability and the ability to handle large or complex orders.

Customer Feedback

Reliable pcb assembly partners value your opinion. Leading manufacturers collect and analyze customer feedback to identify problems and improve their services. When you see positive reviews and testimonials, you gain confidence in their ability to meet your expectations.

- Manufacturers use feedback to correct issues quickly.

- They strive to exceed customer expectations in every pcb assembly project.

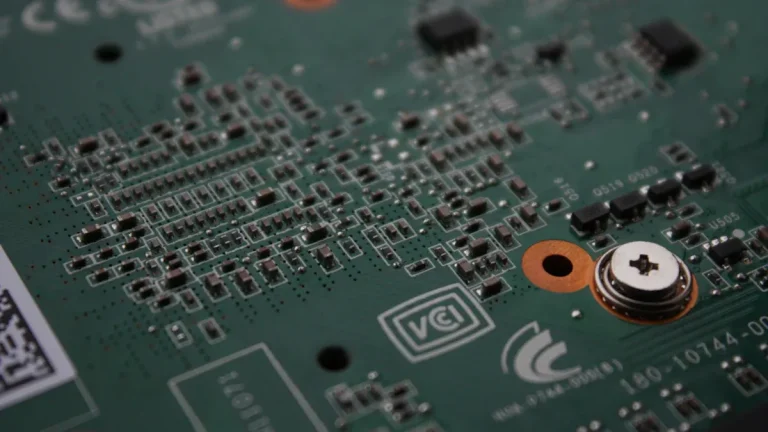

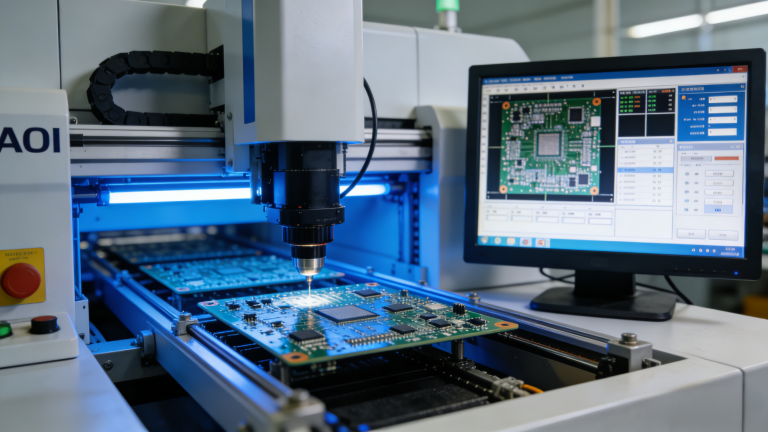

Quality Control Systems

Advanced quality control systems are essential for consistent pcb assembly results. Top manufacturers use automated inspection equipment such as AOI, SPI, and X-ray systems to detect defects early. Functional and circuit testing, including ICT and FCT, verify that each pcba meets performance standards. Real-time tracking systems like MES monitor production and ensure traceability.

- Automated Optical Inspection (AOI) identifies visual defects.

- In-Circuit Testing (ICT) checks component functionality.

- Rigorous supplier selection and real-time monitoring help maintain high first-pass yield.

Export & Global Reach

A reliable china pcba manufacturer should have a strong export record. China supplies about 67% of global PCB exports, serving markets in the U.S., Europe, and Asia. When you choose a manufacturer with global reach, you benefit from their experience in international logistics and compliance with worldwide standards.

Note: Global reach ensures your pcb assembly project meets international requirements and arrives on time.

Top 10 China PCBA Manufacturers for 2025

Qingdao SanShun Smart Technology Co., Ltd.

Qingdao SanShun Smart Technology Co., Ltd. stands out as a leading china pcba manufacturer with a strong focus on innovation and reliability. Since 2013, you have seen this company deliver advanced smart display solutions, intelligent lighting, and modular products from its 30,000-square-meter facility in Qingdao. SanShun integrates research, development, and manufacturing to provide customized pcb assembly solutions for industries such as home appliances, industrial control, and medical displays.

You benefit from their robust R&D team, which includes PhDs and master’s graduates. SanShun’s RTOS small-system display, developed in 2019, set a new benchmark for smart appliance displays, especially in Haier’s Casarte refrigerators. The company holds ISO/TS 22163 for rail transit and IATF 16949 for automotive electronics, ensuring high-quality pcb and circuit board assembly standards. Their commitment to social responsibility is evident in their smart factory project in Anqiu, which will create over 600 jobs.

Contact:

Website: sanshunsmart.com

Email: sales01@s-smart.cn

PCBway

PCBway has earned a reputation for comprehensive pcb assembly and pcb fabrication services, making it a preferred partner for both prototyping and full-scale production. You can rely on their 20 years of experience in pcb manufacturing, which includes collaborations with industry giants like Samsung and Siemens. PCBway’s expertise covers large-scale IoT solutions and custom pcb projects.

- You gain access to a 99% on-time PCB prototyping rate.

- PCBway offers a broad service portfolio, including CNC machining, 3D printing, and injection molding.

- Recognized among the Top 10 Custom PCB Companies for 2025.

Certifications include ISO 9001 and RoHS compliance, ensuring high-quality pcb assembly. Their global client base and advanced logistics make them a strong choice for international projects.

Flexium Interconnect

Flexium Interconnect delivers advanced pcb assembly solutions with a focus on technological innovation. You benefit from their specialization in high-density flex and hybrid stacks, which are essential for modern consumer electronics. Flexium partners with leading materials suppliers, using polyimide and LCP to enhance durability and performance.

- Controlled process windows ensure stable RF performance, which is crucial for devices that undergo repeated folding.

- Flexium’s customer service emphasizes rapid response and technical support throughout your project lifecycle.

Their certifications include ISO 9001 and IATF 16949, supporting applications in automotive, medical, and consumer electronics.

AVARY HOLDING

Avary Holding ranks as one of the largest printed circuit board manufacturers worldwide. You can trust their consistent leadership, as they have held the top position among Chinese PCBA manufacturers for seven consecutive years from 2017 to 2023. This achievement highlights their strong market presence and credibility in pcb assembly and pcb manufacturing.

Avary Holding’s capabilities span high-volume production, advanced pcb assembly, and support for diverse industries, including telecommunications, automotive, and consumer electronics. Their commitment to quality and innovation ensures you receive reliable and scalable solutions.

FS Technology

FS Technology offers a full spectrum of pcb assembly and circuit board assembly services, with a strong emphasis on process control and technical certifications. You benefit from their Capability Maturity Model Integration (CMMI-Dev) Maturity Level 3 certification, which demonstrates robust project management and process maturity.

| Category | Certification |

|---|---|

| Company Certifications | CMMI-Dev Maturity Level 3, ISO 20000:2008, Socio-economic certifications |

| Individual Certifications | ITIL v3, PMP, CISSP, Security+, Network+, RHCSA, MCSA, MCSE, VCP, Oracle, Java, Lean Six Sigma (Green & Black Belt) |

FS Technology’s team includes Lean Six Sigma-certified professionals, ensuring continuous improvement and high-quality pcb results. Their services cover everything from design to final assembly, making them a reliable partner for complex projects.

ELEPCB

ELEPCB provides end-to-end pcb assembly and pcb fabrication services, catering to both small-batch and mass production needs. You can expect rapid prototyping, competitive pricing, and a strong focus on quality control. ELEPCB’s advanced manufacturing lines support a wide range of applications, including industrial, automotive, and consumer electronics.

Their certifications include ISO 9001 and RoHS, ensuring compliance with international standards. ELEPCB’s customer support team helps you navigate every stage of your project, from design to delivery.

FC Electronic

FC Electronic specializes in high-quality pcb assembly and printed circuit board solutions for demanding industries. You benefit from their expertise in multilayer pcb fabrication, SMT assembly, and turnkey solutions. FC Electronic’s quality management system includes ISO 9001 and IATF 16949 certifications, supporting applications in automotive, medical, and industrial sectors.

Their global reach and flexible production capabilities make them a strong choice for clients seeking reliable and scalable pcb assembly services.

Unimicron Technology Corporation

Unimicron Technology Corporation delivers high-quality pcb and pcb assembly solutions by leveraging advanced technologies and a commitment to innovation. You can rely on their expertise in high-density interconnect (HDI) and flexible printed circuits, which are vital for modern electronics. Unimicron’s global operations span Taiwan, China, and the United States, enhancing their ability to meet diverse industry needs, including automotive and medical sectors.

Their certifications include ISO 9001, ISO 14001, and IATF 16949, ensuring consistent quality and environmental responsibility.

Zhen Ding Tech. Group

Zhen Ding Tech. Group holds the title of the world’s largest printed circuit board manufacturer. You benefit from their focus on high-end substrates, AI servers, and automotive electronics. Zhen Ding works closely with leading global customers to obtain certifications and has earned recognition for its technical capabilities.

- The company’s expertise covers advanced pcb assembly and pcb fabrication for complex, high-reliability applications.

- Zhen Ding’s global partnerships ensure you receive solutions that meet the highest industry standards.

JLCPCB

JLCPCB is known for its efficient pcb assembly and pcb manufacturing services, supporting both prototyping and large-scale production. You can take advantage of their impressive production capacity, which ranges from 1 to over 1 million units. JLCPCB maintains a customer satisfaction rate of 95% and an expert rating of 9.5 out of 10.

| Metric | Value |

|---|---|

| Expert Rating | 9.5/10 |

| Customer Satisfaction Rate | 95% |

| Production Capacity | 1–1M+ units |

JLCPCB’s streamlined online ordering system and fast turnaround times make them a popular choice for engineers and businesses worldwide.

Manufacturer Comparison Table

Features & Differentiators

You want to compare the leading china pcba manufacturer options quickly. The table below highlights what sets each company apart in pcb assembly, pcb fabrication, and circuit board assembly. You see companies like Qingdao SanShun Smart Technology Co., Ltd. excel in smart display integration and custom solutions. PCBway stands out for rapid prototyping and a broad service portfolio. Flexium Interconnect specializes in high-density flexible stacks, while AVARY HOLDING leads in large-scale printed circuit board production. FS Technology brings process maturity and Lean Six Sigma expertise. ELEPCB focuses on fast turnaround and competitive pricing. FC Electronic delivers multilayer pcb assembly for demanding sectors. Unimicron Technology Corporation offers advanced HDI and flexible pcb manufacturing. Zhen Ding Tech. Group dominates in high-end substrates and AI server applications. JLCPCB impresses with its streamlined online ordering and high-volume capacity.

| Manufacturer | Key Features & Differentiators |

|---|---|

| Qingdao SanShun Smart Technology | Smart display integration, custom solutions, strong R&D |

| PCBway | Rapid prototyping, broad service portfolio, high on-time rate |

| Flexium Interconnect | High-density flexible stacks, RF performance, technical support |

| AVARY HOLDING | Large-scale production, industry leadership, diverse applications |

| FS Technology | Process maturity, Lean Six Sigma, end-to-end project management |

| ELEPCB | Fast turnaround, competitive pricing, quality control |

| FC Electronic | Multilayer pcb assembly, turnkey solutions, global reach |

| Unimicron Technology Corporation | Advanced HDI, flexible pcb manufacturing, global operations |

| Zhen Ding Tech. Group | High-end substrates, AI server focus, global partnerships |

| JLCPCB | Streamlined online ordering, high-volume capacity, fast delivery |

Certifications

Certifications play a crucial role in pcb assembly and pcb manufacturing. You should always check for ISO 9001, IATF 16949, and RoHS compliance. Many top manufacturers also hold industry-specific certifications, such as ISO/TS 22163 for rail transit or CMMI-Dev for process maturity. These credentials ensure you receive high-quality pcb and reliable circuit board assembly.

| Manufacturer | Certifications |

|---|---|

| Qingdao SanShun Smart Technology | ISO/TS 22163, IATF 16949 |

| PCBway | ISO 9001, RoHS |

| Flexium Interconnect | ISO 9001, IATF 16949 |

| AVARY HOLDING | ISO 9001, IATF 16949 |

| FS Technology | CMMI-Dev Level 3, ISO 20000:2008, ITIL, PMP |

| ELEPCB | ISO 9001, RoHS |

| FC Electronic | ISO 9001, IATF 16949 |

| Unimicron Technology Corporation | ISO 9001, ISO 14001, IATF 16949 |

| Zhen Ding Tech. Group | ISO 9001, IATF 16949 |

| JLCPCB | ISO 9001, RoHS |

Export Markets

You need a partner with proven export experience. The top manufacturers serve clients in North America, Europe, and Asia. Companies like AVARY HOLDING, Zhen Ding Tech. Group, and Unimicron Technology Corporation have a global footprint. Others, such as PCBway and JLCPCB, support international projects with efficient logistics and compliance with worldwide standards. This global reach ensures your pcb assembly project meets international requirements and arrives on time.

| Manufacturer | Export Markets |

|---|---|

| Qingdao SanShun Smart Technology | Asia, expanding to global markets |

| PCBway | North America, Europe, Asia, Oceania |

| Flexium Interconnect | North America, Europe, Asia |

| AVARY HOLDING | Global |

| FS Technology | North America, Europe, Asia |

| ELEPCB | North America, Europe, Asia |

| FC Electronic | North America, Europe, Asia |

| Unimicron Technology Corporation | Global |

| Zhen Ding Tech. Group | Global |

| JLCPCB | North America, Europe, Asia, Oceania |

Tip: Use this table to match your project needs with the right manufacturer. You can focus on features, certifications, or export experience to find the best fit for your pcb assembly or printed circuit board requirements.

How to Choose a China PCBA Manufacturer

Assessing Project Needs

Start by defining your project requirements for pcb assembly. You should clarify your target production volume, delivery deadlines, and technical specifications. Consider the lead times for both pcb fabrication and delivery. Reliable manufacturers provide accurate estimates and adhere to agreed schedules, which helps you avoid costly delays. Evaluate scalability and ensure the manufacturer can support your growth. Effective communication and customer support also play a vital role in successful pcb services.

Tip: Use the table below to review key factors when assessing your project needs.

| Factor | Description |

|---|---|

| Supplier management | Build strong supplier relationships and have backups to prevent shortages. |

| Inventory management | Use just-in-time strategies to control costs and ensure component supply. |

| Lead time optimization | Collaborate to reduce lead times and improve delivery schedules. |

| Quality assurance | Implement continuous testing and feedback to meet specifications. |

| Technology utilization | Leverage advanced software for project tracking and analytics. |

Evaluating Capabilities

You need to verify the technical strengths of your chosen china pcba manufacturer. Define your pcb assembly requirements, including compliance standards and production volume. Research and shortlist candidates based on their certifications and technical expertise. Request prototypes to test quality and confirm certifications. Consider virtual or in-person facility audits to observe quality control processes. Negotiate clear terms before finalizing your partnership.

Checking References

Check references to confirm the reliability of your pcb assembly partner. Contact previous clients and review third-party feedback. Ask about their experience with design for testability, such as the use of test points and AOI after soldering. For high-volume circuit board assembly, ensure the manufacturer balances speed and thorough testing.

Requesting Samples & Quotes

Request samples and detailed quotes before committing to a large order. Identify manufacturers who can handle low-volume and complex pcb assembly. Verify their qualifications and understand their delivery cycles. Assess sample quality and responsiveness. Evaluate costs and confirm if they can deliver a one-stop pcb solution for your needs.

After-Sales Support

Strong after-sales support is essential for long-term success in electronic manufacturing services. Choose a partner who offers technical assistance, warranty coverage, and prompt issue resolution. Reliable support ensures your pcb assembly project runs smoothly from start to finish.

You now have a clear overview of the top 10 reliable PCBA manufacturers in China, each offering unique strengths such as advanced technology, strong certifications, and global reach.

- Use the selection criteria and comparison table to guide your decision.

- Evaluate your project needs and contact manufacturers directly for tailored solutions.

Remember: Careful research and direct communication help you choose the best PCBA partner for your business.

FAQ

What certifications should you look for in a reliable PCBA manufacturer?

You should check for ISO 9001, IATF 16949, and RoHS certifications. These prove the manufacturer meets international quality and safety standards. Always request to see valid certificates before starting your project.

How can you verify a manufacturer’s experience?

You can review their client list, project case studies, and years in business. Ask for references or testimonials from previous customers. This helps you confirm their expertise and reliability.

What is the typical lead time for PCBA orders from China?

Lead times vary by project complexity and order size. Most manufacturers deliver prototypes in 5–10 days. For mass production, expect 2–4 weeks. Always confirm timelines before placing your order.

How do you ensure product quality during production?

You should request regular updates and inspection reports. Many manufacturers offer real-time tracking and quality control data. You can also ask for sample testing before full production.