When you search for a trusted China pcba manufacturer, you want proven names like Sanshun, PCBasic, and PCBA Store. You need suppliers who deliver consistent quality, hold recognized certifications, and support your business with flexible service options. For international buyers in regions like Vietnam, Thailand, and Mexico, these pcb manufacturers in china stand out for their strong track record and dedication to reliability.

How to Choose a Quality PCBA Supplier

- Choose a PCBA manufacturer with recognized certifications like ISO 9001 and RoHS to ensure quality and compliance.

- Request quality metrics and customer references to verify the reliability of your chosen supplier.

- Evaluate manufacturers based on their technical capabilities and responsiveness to meet your business needs.

- Consider the range of services offered, such as quick-turn production and box-build assembly, to support your project requirements.

- Maintain clear communication with your supplier to build trust and ensure smooth project execution.

China PCBA Manufacturer Comparison

Choosing the right China pcba manufacturer can make a significant difference for your business, especially if you operate in Vietnam, Thailand, or Mexico. You need a partner who delivers consistent quality, meets international standards, and supports your growth with reliable service.

Features

When you compare top PCB manufacturers in China, focus on these essential features:

- Certifications and audit records: Always request audit summaries and process maps.

- Traceability and MES: Ensure the supplier links board serials to component lot IDs.

- Engineering and DFM depth: Ask for recent DFM reports to evaluate their expertise.

- Test strategy and coverage: Match their test scope to your risk profile.

- Supply chain resilience: Look for dual-source options and short lead times.

- Quality metrics: Review trends for FPY, DPM, and NCR.

- Small-batch policy and pricing: Confirm clear pricing for prototypes and small runs.

- Box-build competencies: Check for sub-assembly and firmware capabilities.

- Communication and PM structure: Clarify your point of contact and update frequency.

These features help you identify a supplier who can handle complex fabrication projects and adapt to your changing needs.

Reliability

You want a China pcba manufacturer with a proven track record. Sanshun stands out for its strong R&D team and robust supply chain, which ensures timely delivery and consistent quality. PCBasic has earned positive customer reviews for its responsive service and technical support. PCBA Store offers reliable order fulfillment and flexible production options, making it a solid choice for international buyers.

Tip: Always ask for quality metrics and customer references before making a decision.

Certifications

Certifications show a supplier’s commitment to quality and safety. Here’s how the leading pcb manufacturers in China compare:

| Manufacturer | IATF 16949 | ISO 13485 | ISO 9001 | ISO 14001 | RoHS |

|---|---|---|---|---|---|

| Sanshun | ✔ | ✔ | ✔ | ✔ | ✔ |

| PCBasic | ✔ | ✔ | ✔ | ✔ | ✔ |

| PCBA Store | ✔ | ✔ | ✔ | ✔ | ✔ |

These certifications align with international standards for automotive, medical, and environmental management, giving you confidence in your supplier’s capabilities.

Contact

You need clear and direct communication channels. Here’s how you can reach each manufacturer:

- Sanshun: www.sanshun.com/contact

- PCBasic: www.pcbasic.com/contact

- PCBA Store: www.pcbastore.com/contact

Quick response times and dedicated account managers help you resolve issues and keep your projects on track.

Why Choose These PCB Manufacturers in China

Selection Criteria

When you select a China pcba manufacturer, you need to focus on the criteria that matter for large B2B clients in Vietnam, Thailand, and Mexico. You want technical capabilities, certifications, quality validation, responsiveness, and scalability. The table below summarizes the most common selection criteria used by international buyers:

| Selection Criteria | Description |

|---|---|

| Technical Capabilities | Ability to meet design requirements, including layer count and material expertise. |

| Certifications and Compliance | Recognized certifications like ISO 9001 and RoHS that validate quality management systems. |

| Quality Validation | Methods to ensure quality, such as requesting samples and conducting factory audits. |

| Responsiveness | Supplier’s ability to respond quickly to requests and maintain delivery performance. |

| Scalability | The manufacturer’s capacity to handle volume fluctuations and reorder rates indicates reliability. |

Tip: Use B2B platforms such as Alibaba, Global Sources, and Made-in-China to research and vet suppliers before making a commitment.

Quality & Certifications

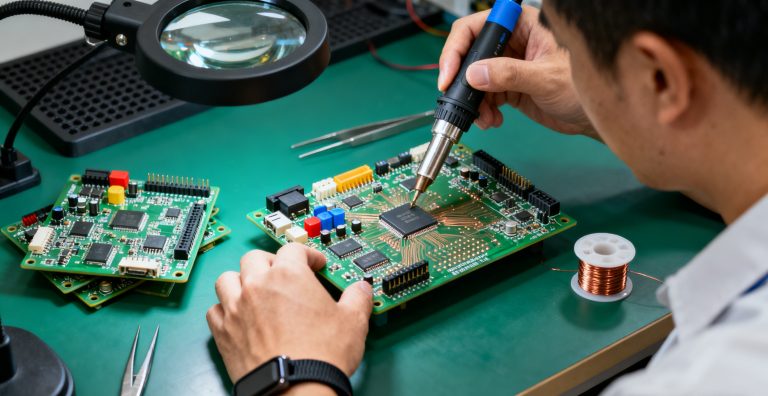

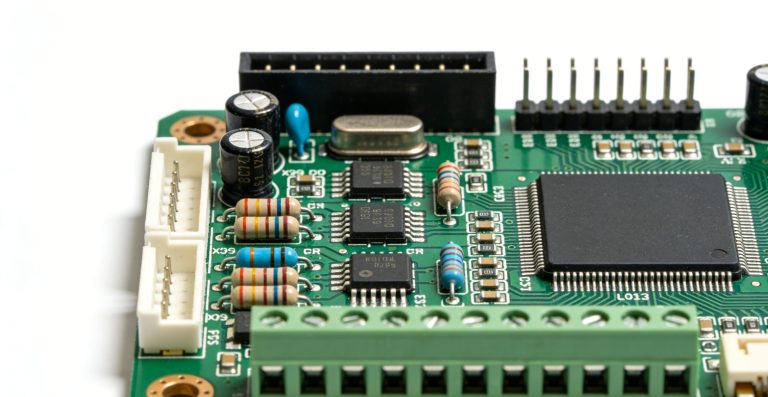

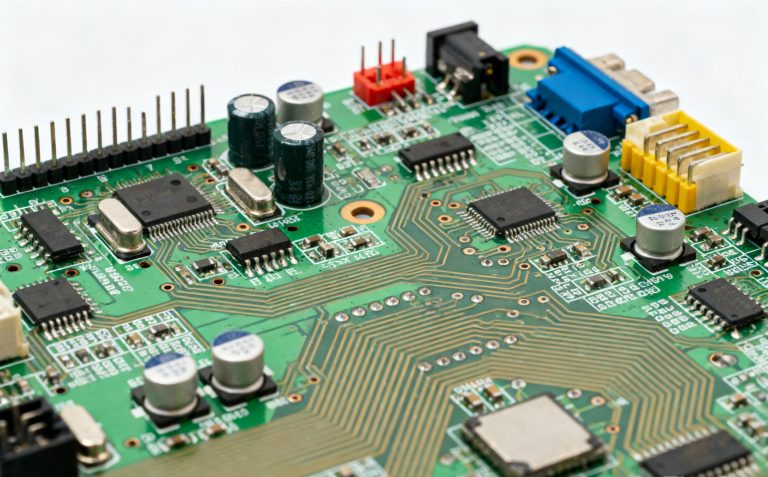

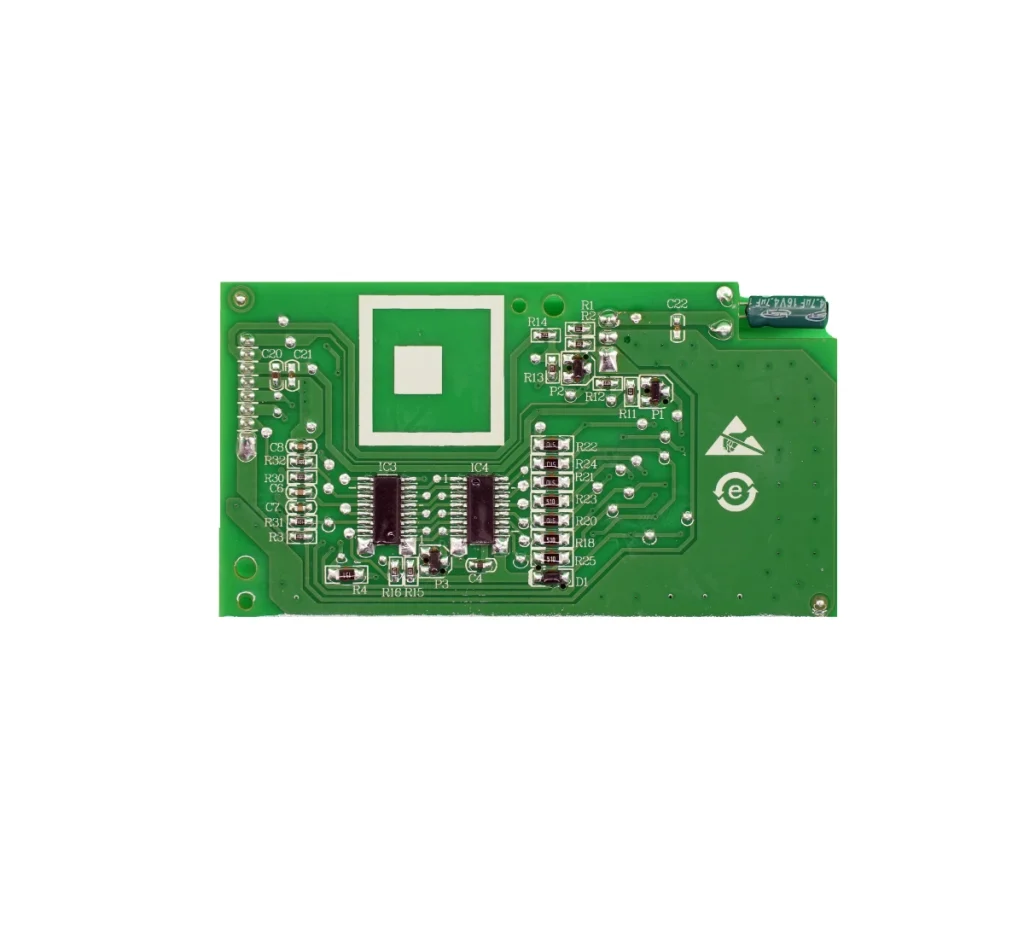

You need assurance that your chosen pcb manufacturers in China meet global standards. The top pcb manufacturers in China implement rigorous quality assurance processes. These include Automated Optical Inspection, X-ray Inspection, In-Circuit Testing, and Functional Testing. You can expect incoming quality control, solder paste inspection, and shipment inspection to prevent defects. Leading PCB assembly manufacturer options like Sanshun, PCBasic, and PCBA Store hold certifications such as ISO 9001, ISO 13485, IATF 16949, and RoHS. These certifications demonstrate compliance with automotive, medical, and environmental standards.

Customer Reviews

You should always check customer reviews before selecting a leading PCB assembly manufacturer. International buyers praise PCBasic for quick-turn services and high-quality standards. You will find that positive feedback often highlights reliability and technical support. Negative reviews in the industry mention delays and inconsistent quality, so you must verify supplier performance through references and sample orders.

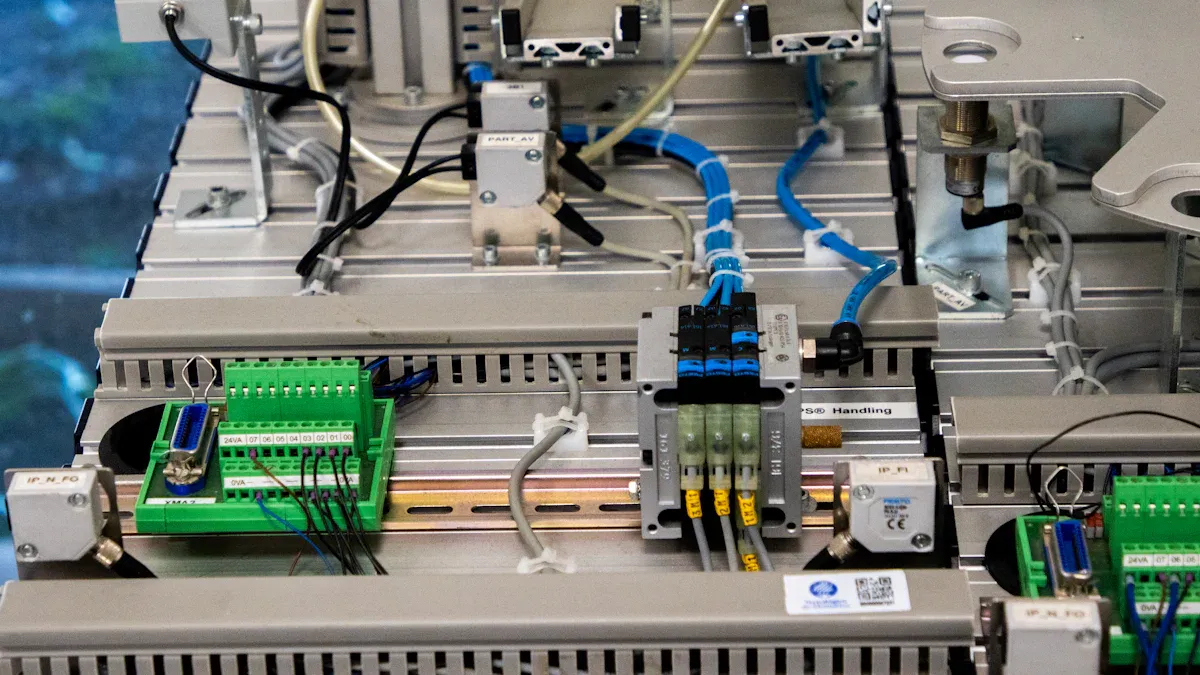

Service Scope

A leading PCB assembly manufacturer must offer a wide range of services to support your business needs. Sanshun, PCBasic, and PCBA Store provide PCB manufacturing, SMT soldering, DIP assembly, electrical and functional testing, and conformal coating. You can benefit from box-build assembly, digital management platforms, and advanced intelligent production lines. Professional customer support ensures project feasibility and smooth communication. These service offerings help you manage complex fabrication projects and scale production efficiently.

Manufacturer Profiles

Sanshun Overview

You want a partner with a proven track record and robust infrastructure. Sanshun, officially known as Qingdao SanShun Smart Technology Co., Ltd., has delivered advanced PCBA solutions since 2013. The company operates from Qingdao’s West Coast New Area, China, with a manufacturing facility spanning 30,000 square meters. Over a decade of industry experience positions Sanshun as a trusted supplier for international clients seeking innovation and reliability.

| Detail | Information |

|---|---|

| Company Name | Qingdao SanShun Smart Technology Co., Ltd. |

| Founding Year | 2013 |

| Headquarters | Qingdao’s West Coast New Area, China |

| Manufacturing Facility Size | 30,000 square meters |

| Industry Experience | Over a decade |

Sanshun Reliability

You need a supplier who delivers consistent quality and meets tight deadlines. Sanshun stands out for its strong R&D capabilities, with over 60 engineers, including PhDs and industry veterans. The company’s robust supply chain and multi-channel procurement strategy ensure timely delivery, even during global disruptions. Sanshun’s collaboration with industry leaders like Haier demonstrates its ability to meet demanding requirements and deliver innovative solutions. You can rely on Sanshun for stable production, advanced technology integration, and strict quality control.

Note: Sanshun’s proprietary RTOS-based display modules for smart appliances showcase its commitment to reliability and technological advancement.

Sanshun Service Offerings

You benefit from a comprehensive suite of PCBA services at Sanshun. The company specializes in:

- Custom hardware and software development for smart home modules.

- Integration with Android, RTOS, Linux, and MCU platforms.

- Advanced display technologies through partnerships with leading LCD manufacturers.

- End-to-end support, from R&D to mass production.

- Box-build assembly and firmware development for complete solutions.

These offerings help you streamline your supply chain and accelerate your product development cycles, especially if you operate in fast-growing markets like Vietnam, Thailand, or Mexico.

Sanshun Contact

You can reach Sanshun through their official website for direct inquiries and project consultations:

A dedicated account manager will guide you through the process, ensuring clear communication and timely updates.

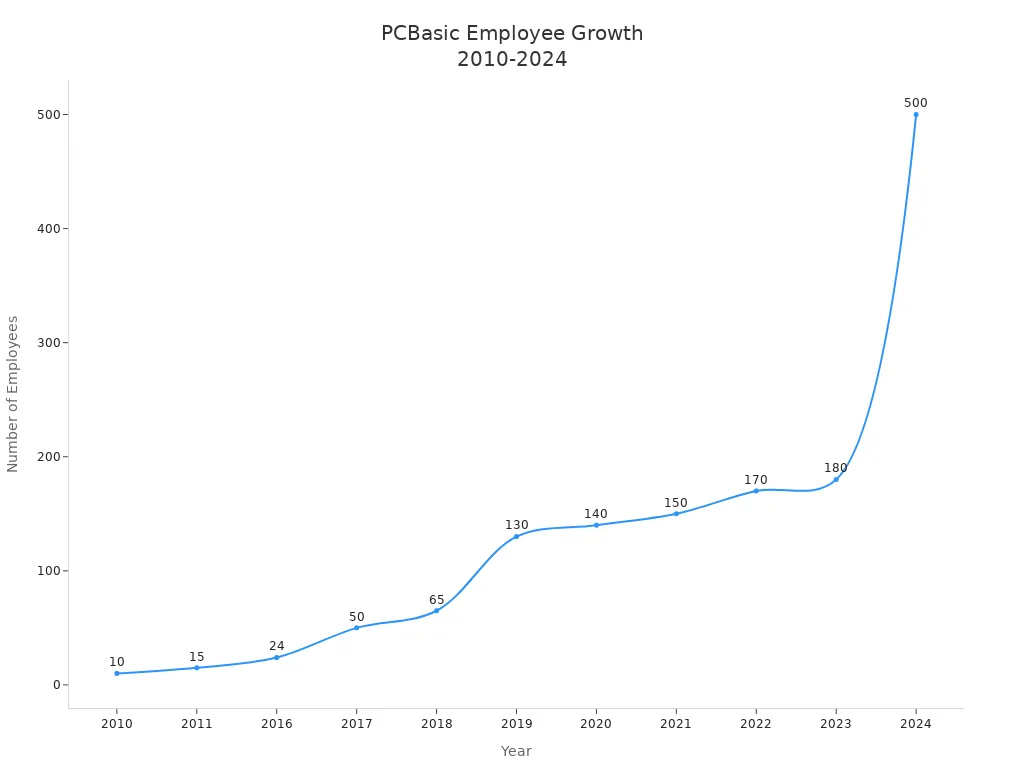

PCBasic Overview

You want a manufacturer with steady growth and a commitment to innovation. PCBasic began operations in 2010 with a small facility and just 10 employees. Over the years, the company expanded its capacity, workforce, and technological capabilities. By 2024, PCBasic employs over 500 people and operate multiple factories, including a new facility in Huizhou. This growth reflects the company’s ability to scale and adapt to the evolving needs of international clients.

| Year | Key Developments |

|---|---|

| 2010 | Established a 500-square-meter facility in Xixiang; 10 employees. |

| 2011 | Area expanded to 800 square meters; Staff increased to 15 people. |

| 2016 | Developed an online self-service quoting system; Staff increased to 24 people. |

| 2017 | Independently developed the first-piece testing device; Staff increased to 50 people. |

| 2018 | Established the IT department; Staff increased to 65 people. |

| 2019 | Relocated to a 3000m² factory; Staff increased to 130 people. |

| 2020 | Monthly shipment capacity: 1000+ orders; Staff increased to 140 people. |

| 2021 | Smart warehouse established; Staff increased to 150 people. |

| 2022 | Established the stencil and fixture business division; Staff increased to 170 people. |

| 2023 | Established CNC business division; Staff increased to 180 people. |

| 2024 | Total number of employees exceeds 500; New factory added in Huizhou. |

PCBasic Reliability

You can trust PCBasic for consistent delivery and technical excellence. The company maintains an on-time delivery rate of up to 96.15%, which is critical for B2B clients managing tight production schedules. PCBasic invests in advanced SMT production lines and in-house stencil manufacturing, reducing lead times and enhancing quality control. The company’s continuous growth and investment in smart warehousing and IT infrastructure demonstrate a commitment to reliability and scalability.

Tip: PCBasic’s flying probe testing and first-piece inspection devices help you minimize defects and ensure product quality before mass production.

PCBasic Service Offerings

You receive a full spectrum of PCBA services from PCBasic, designed to support international buyers:

| Service Feature | Description |

|---|---|

| Quick-turn printed circuit boards | On-time delivery rate of up to 96.15%, ensuring timely receipt of boards for urgent needs. |

| One-stop solution | Comprehensive support from design to production, covering prototype making to batch assembly. |

| Advanced SMT production lines | Utilizes advanced technology for efficient and quick-turn PCB assembly. |

| In-house Stencil Manufacturing Workshop | Customizes steel quickly to shorten production cycles and reduce delivery times. |

| Flying Probe Testing | Quickly detects function and performance, ensuring rigorous quality testing for each board. |

These services help you manage urgent orders, streamline procurement, and maintain high quality across all production stages.

PCBA Store Overview

You need a supplier with a long-standing reputation and a focus on innovation. PCBA Store, founded in 2006, operates as a high-tech enterprise specializing in PCB design, manufacturing, and assembly. The company aims to lead the electronic circuit interconnection industry, serving clients worldwide with a comprehensive range of services.

- PCBA Store was founded in 2006.

- It is a high-tech enterprise focused on PCB design, manufacturing, and assembly services.

- The company aims to be a leader in electronic circuit interconnection services.

PCBA Store Reliability

You can count on PCBA Store for quality and environmental responsibility. The company holds ISO 9000 and ISO 14001:2015 certifications, reflecting its commitment to quality management and environmental standards. These certifications assure you that PCBA Store meets international benchmarks for reliability and sustainability, which is essential for large B2B clients in Vietnam, Thailand, and Mexico.

| Certification Name | Description |

|---|---|

| ISO 9000 | Quality management systems |

| ISO 14001:2015 | Environmental management systems |

PCBA Store Service Offerings

You gain access to a wide array of PCBA solutions at PCBA Store, supporting every stage of your product lifecycle:

| Service Type | Description |

|---|---|

| PCB Design | Design services for printed circuit boards. |

| PCB Manufacturing | Mass fabrication of PCBs. |

| PCB Assembly | Assembly of electronic components onto PCBs. |

| Electronic Components Sourcing | Sourcing of necessary electronic components. |

| Box Build Assembly | Complete assembly of electronic boxes. |

| Flex PCB | Flexible printed circuit boards. |

| Custom PCB | Custom-designed printed circuit boards. |

| Prototype PCB | Prototyping services for PCBs. |

| Turnkey PCB Assembly | Comprehensive assembly services from start to finish. |

| Low Volume PCB Assembly | Assembly services for low-volume production. |

These offerings allow you to consolidate your supply chain, reduce costs, and accelerate time-to-market for new products.

How to Verify PCB Assembly Supplier Reliability

Selecting reliable PCB fabrication manufacturers is essential for large B2B clients in Vietnam, Thailand, and Mexico. You must verify that your circuit board suppliers meet international standards and deliver consistent quality. Use the following steps to ensure you partner with a trustworthy manufacturer.

Check Certifications

You should always confirm that your suppliers hold recognized certifications. Look for ISO 9001 for quality management, UL for safety, and RoHS for environmental compliance. These certifications demonstrate that the supplier follows strict standards and can meet the requirements of global markets. For automotive or medical applications, IATF 16949 and ISO 13485 are also important. You can find certification details on B2B platforms like Alibaba, Global Sources, and Made-in-China.

Assess Quality Control

Quality control processes separate trusted pcb fabrication manufacturer options from less reliable ones. Review the supplier’s testing protocols and ask for documentation. Common quality control methods include:

| Quality Control Method | Description |

|---|---|

| In-Circuit Testing (ICT) | Tests integrated circuits for performance and detects open/short circuits. |

| Flying Probe Test | Identifies loose connections using a probe aligned to a CAD grid. |

| Functional Test | Verifies PCB functionality under industry standards. |

| Automated Optical Inspection (AOI) | Uses cameras to detect missing or misplaced components. |

| X-Ray Inspection | Examines internal PCB structures for defects. |

| Electrical Testing | Checks output signals against performance requirements. |

| Visual Inspection | Manual checks for physical damage and misalignment. |

You should request recent quality control reports and ask about their defect rates.

Review Feedback

Customer feedback provides valuable insights into supplier reliability. You can review third-party audit reports, sample testing results, and production documentation. Reliable PCB fabrication manufacturers often share testimonials and case studies from previous clients. Look for customer reviews that mention product quality, delivery performance, and after-sales support.

Request Samples

Requesting samples helps you evaluate the supplier’s capabilities before committing to large orders. Follow these steps:

- Define your product specifications and intended use.

- Vet potential suppliers using B2B platforms.

- Request samples, clarifying fees and shipping options.

- Inspect the samples for quality and adherence to specifications.

- Provide feedback and request adjustments if needed.

- Negotiate pricing and confirm lead times for future orders.

Samples can include factory samples, customized samples, or pre-production samples for final approval.

Communication

Effective communication builds trust with your suppliers. Learn basic WeChat functions to facilitate daily engagement. Use a step-by-step approach during negotiations and maintain regular follow-ups throughout production. Finalize details early to avoid misunderstandings. Building rapport with your supplier leads to better collaboration and prompt issue resolution, which is crucial for international buyers.

Tip: Consistent communication and clear expectations help you establish long-term partnerships with trustworthy manufacturers.

You gain a competitive edge by choosing Sanshun, PCBasic, or PCBA Store for your PCBA needs. Each manufacturer offers proven reliability, global certifications, and a broad service scope.

- Sanshun delivers advanced R&D and robust supply chain support.

- PCBasic excels in quick-turn services and technical innovation.

- PCBA Store provides comprehensive solutions and environmental responsibility.

Use the criteria and verification tips from this guide to select a supplier that matches your business goals in Vietnam, Thailand, or Mexico.

FAQ

What is the difference between PCB assembly and PCBA?

You may see both terms used. pcb assembly refers to the process of placing and soldering components onto a bare board. PCBA describes the finished board after all components are mounted and tested. Both terms are important when you evaluate suppliers for your business.

How do I ensure quality when sourcing PCB assembly from China?

You should request certifications like ISO 9001 and IATF 16949. Ask for sample pcba units and review quality control reports. Reliable suppliers provide detailed test data. For B2B clients in Vietnam, Thailand, and Mexico, these steps help you avoid costly issues.

What services should I expect from a top pcba supplier?

A leading supplier offers PCB assembly, component sourcing, functional testing, and box-build services. You should also expect engineering support and fast response times. These services help your business in Vietnam, Thailand, or Mexico streamline production and reduce lead times.

How can I verify a pcba manufacturer’s reliability?

You can check certifications, request recent customer references, and review on-time delivery rates. Ask for sample pcb assembly orders before committing to large volumes. Consistent communication and clear documentation also indicate a trustworthy supplier for your B2B needs.

Why do international buyers choose China for PCB assembly and PCBA?

China offers advanced manufacturing, competitive pricing, and strong supply chains. You benefit from experienced pcba engineers and scalable PCB assembly lines. For B2B clients in Vietnam, Thailand, and Mexico, these advantages support growth and ensure reliable product delivery.