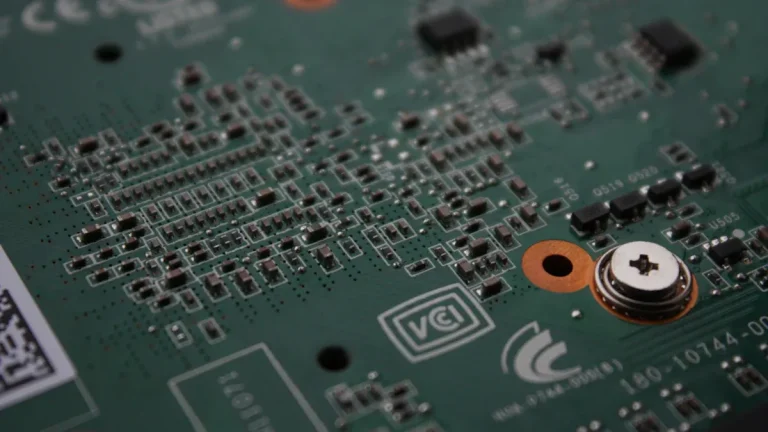

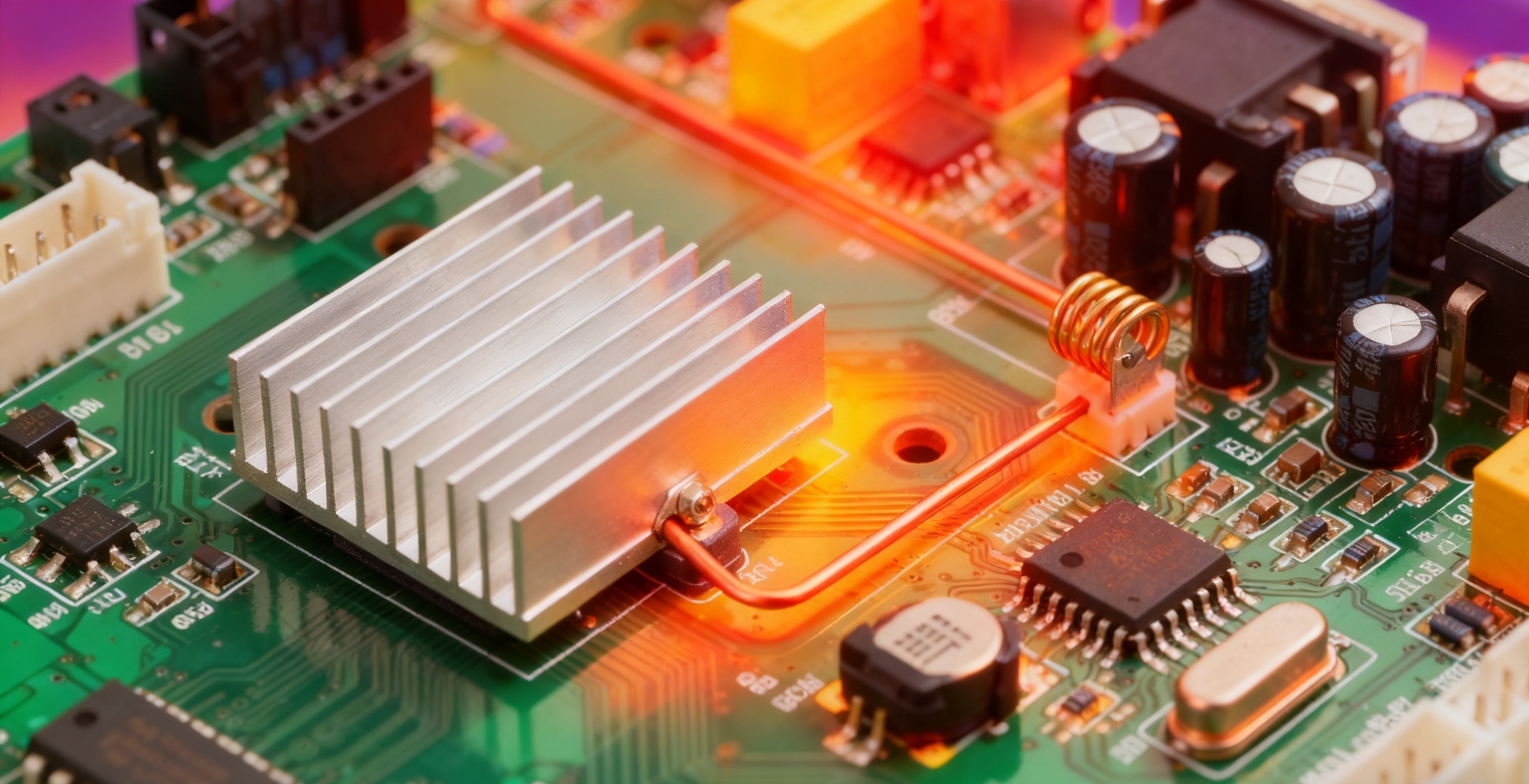

You play a crucial role in the electronics industry when you demand quality in every PCBA you produce. Quality certifications like ISO, RoHS, and IPC set clear standards that drive consistent reliability and safety. Manufacturers achieve robust results with certifications that validate their processes and reduce failure rates, as shown below:

| Certification | Impact on Product Quality and Failure Rates |

|---|---|

| ISO 9001 | Validates a robust quality management system for consistent processes. |

| IPC-A-610 Class 3 | Ensures the highest standard for PCB assembly, crucial for mission-critical applications. |

| UL Certification | Guarantees electrical safety and fire resistance for products in North America. |

| IATF 16949 | Focuses on defect prevention and continuous improvement in automotive PCBAs. |

With these standards, you gain more than compliance—you build trust, open new markets, and protect the environment while advancing innovative manufacturing.

PCBA Certifications Ensure Quality, Compliance, and Global Market Competitiveness

- Quality certifications like ISO, RoHS, and IPC ensure safety and reliability in electronics manufacturing.

- Certified manufacturers reduce defects and improve product quality, leading to higher customer satisfaction.

- Holding certifications opens access to new markets and meets global regulatory requirements.

- Staying updated with certification standards helps avoid legal issues and enhances competitiveness.

- Using certified components protects the environment and promotes safer recycling practices.

Why Quality Certifications Matter in PCBA

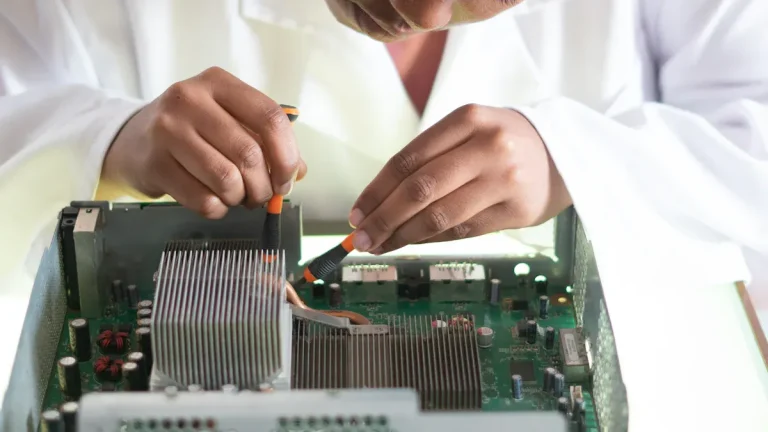

Reliability and Safety

You rely on quality certifications to ensure every PCBA meets the highest standards for reliability and safety. When you choose certified manufacturing partners, you gain confidence that each assembly will perform as expected, even in demanding environments. Certifications like UL, ISO, RoHS, and IPC standards confirm that manufacturers use documented processes and skilled teams. This approach guarantees that materials and procedures meet strict reliability requirements, which is especially important in regulated industries such as medical electronics and automotive systems.

- UL certification ensures PCBA safety and performance, which is crucial for creating reliable products.

- Understanding standards like UL 796 and UL 94 helps engineers design compliant products, enhancing reliability.

- Staying updated with trends like sustainability and EMC testing further improves PCBA quality.

- Certifications confirm that manufacturers have documented processes and skilled teams, ensuring reliability.

- They guarantee that materials and processes meet established reliability standards, which is vital for regulated industries.

- UL PCBA marking indicates compliance with strict safety standards, enhancing consumer trust.

- It ensures that products have passed rigorous testing, focusing on fire resistance and electrical efficiency.

Certified PCBA products undergo rigorous quality assurance and comply with regulatory standards. This process significantly reduces the likelihood of safety incidents compared to non-certified products. Using uncertified components can lead to device failures and pose risks to users, especially in critical applications.

Note: When you see a UL mark or IPC standards compliance on a product, you know it has passed strict tests for fire resistance, electrical efficiency, and overall safety. This assurance builds trust with your customers and end-users.

Market Access and Compliance

You face a complex global market where access depends on meeting specific certification requirements. Quality certifications such as ISO, RoHS, and IPC open doors to new regions and industries by demonstrating your commitment to global standards. Regulatory bodies enforce compliance to ensure that only safe, reliable, and environmentally responsible products reach consumers.

| Benefit | Description |

|---|---|

| Regulatory Readiness | Compliance with global regulations prevents legal risks and facilitates market access. |

| Higher Safety Standards | Strict risk management protocols reduce the likelihood of product failures. |

| Competitive Advantage | Certification enables manufacturers to enter the highly regulated medical electronics sector. |

| Stronger Quality Control | Enforces more rigorous testing, validation, and compliance processes. |

| Customer Trust | Medical device companies prefer working with ISO 13485-certified electronics manufacturers to ensure product reliability. |

| Expanded Market Access | Many businesses and government contracts require manufacturers to hold ISO 9001 and ISO 13485 certifications before entering into agreements. |

| Improved Process Control | Standardized procedures help manufacturers optimize workflows, increase efficiency, and minimize production waste. |

You can only sell your products in many countries if you meet local certification requirements. For example, the US requires FCC certification, the EU mandates CE certification, and Asia has fragmented regulations by country. Companies must understand and adapt to these diverse requirements to succeed in each market.

| Region | Certification Requirements |

|---|---|

| US | FCC certification |

| EU | CE certification |

| Asia | Fragmented regulations by country |

When you hold certifications like ISO 9001:2015, UL, and RoHS, you demonstrate your commitment to quality management, safety, and environmental responsibility. These certifications enhance your reliability and appeal to international customers who prioritize sustainability and compliance. As a result, you gain access to more markets and increase your export potential.

Tip: Staying informed about changing regulations and maintaining up-to-date certifications helps you avoid legal penalties and ensures your products remain competitive worldwide.

Key Certifications for PCBA Quality

ISO Standards Overview

You rely on ISO standards to set the foundation for quality in electronics manufacturing. These standards guide you through every step, from process control to continual improvement. When you follow ISO 9001, you create a robust quality management system that reduces defects and increases reliability in your printed circuit board assembly. For specialized sectors, ISO 13485 addresses medical device requirements, while AS 9100 focuses on aerospace, and ISO/TS 16949 targets automotive applications.

| ISO Standard | Focus Area | Certification Process |

|---|---|---|

| ISO 9001 | Quality Management | Two-phase audit, reevaluation every three years, continual improvement. |

| ISO 13485 | Medical Devices | Two-stage assessment, inspection every 6-12 months, no continual improvement. |

| AS 9100 | Aerospace | Three-stage audit, external auditor visits every 6-12 months. |

| ISO/TS 16949 | Automotive | Two-stage audit, reassessment every three years, and a defect prevention focus. |

You see the impact of ISO standards in lower defect rates and reduced rework costs. For example, ISO 9001 can cut defect rates from 5% to 1%, saving time and money on every printed circuit board.

RoHS Compliance

RoHS compliance plays a vital role in protecting both the environment and human health. When you choose RoHS-compliant printed circuit boards, you help reduce hazardous substances like lead and mercury in electronics. This action prevents toxic materials from contaminating soil and water, making recycling safer and more sustainable. RoHS compliance also protects workers and consumers from exposure to dangerous chemicals, supporting safety throughout the electronics industry. Many global markets require RoHS certification programs, so you gain access to new regions by meeting these electronics manufacturing standards.

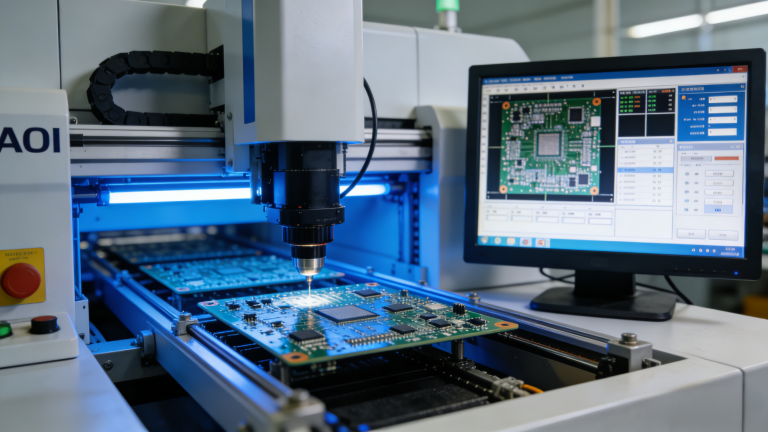

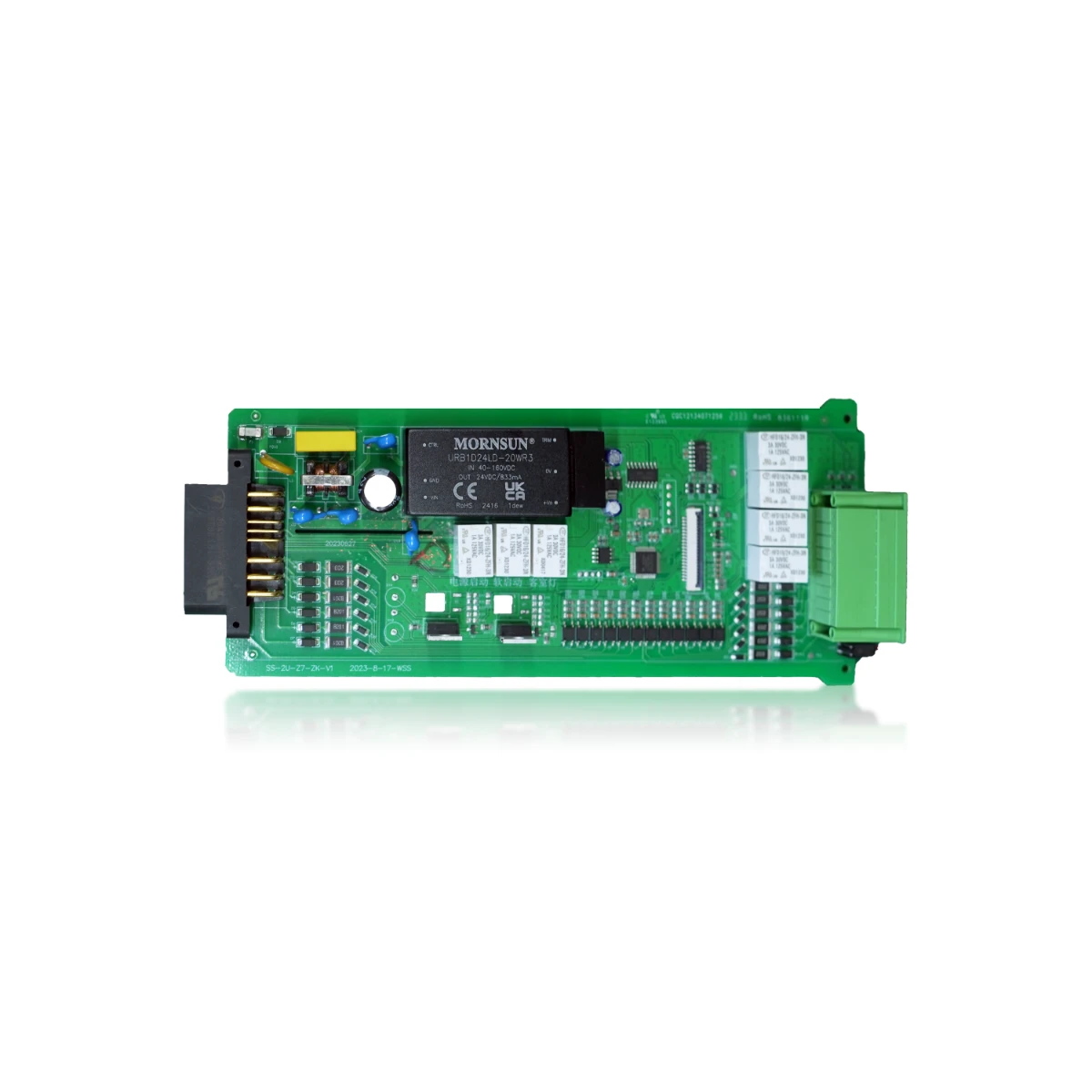

IPC Standards in PCBA

IPC standards shape every aspect of your PCBA processes. You use these guidelines to select materials, control manufacturing, and ensure proper inspection. IPC standards help you maintain consistent workmanship and quality, reducing errors and miscommunication during assembly. They also support documentation and traceability, which are essential for safety and reliability in electronics manufacturing. By following IPC standards, you meet customer expectations and achieve global compatibility for your products.

Tip: Adopting IPC standards in your assembly process leads to improved product consistency and long-term success in the competitive electronics market.

Benefits of IPC Standards and Certification

Enhanced Manufacturing Quality

You improve your manufacturing results when you follow ipc standards in pcba production. These standards guide your assembly process, helping you achieve consistent quality and reduce errors. When you implement IPC certification, you see measurable improvements in your electronics output:

- You experience significant enhancements in production quality.

- You notice a reduction in assembly rework, which saves time and resources.

- You benefit from lower costs and increased customer satisfaction.

Manufacturers who adopt IPC standards consistently outperform those who do not. The table below shows how IPC-certified manufacturers compare to non-certified ones:

| Evidence Type | Description |

|---|---|

| Higher Product Reliability | Products built to IPC standards have lower failure rates, leading to fewer defects in the field. |

| Consistent Quality and Yield | Adherence to IPC standards reduces variance in manufacturing processes, improving overall yield. |

| Reduced Reworks and Scrap | Following IPC guidelines minimizes defects, resulting in lower costs associated with non-quality. |

You gain a competitive edge by reducing defects and improving yield. This approach leads to better products and stronger business results.

Meeting Customer Expectations

You meet and exceed customer expectations when you use IPC standards in your manufacturing process. These standards assure your customers that you follow recognized quality definitions. They guide every step of the electronics manufacturing process, from design to inspection, enhancing overall product quality.

- You achieve better cost projections and reduce rework.

- You ensure quality and reliability in PCBA manufacturing.

- You provide a structured approach to the entire process, which builds trust with your customers.

- You reduce risks associated with manufacturing defects and improve confidence in the products you deliver.

- You lower the risk of field failures and strengthen communication with suppliers.

By committing to IPC standards, you show your dedication to quality and reliability. Customers value this commitment and prefer working with manufacturers who prioritize certified processes.

Real-World Impact of Quality Certifications

Success Stories in PCBA

You see the difference that quality certifications make when you look at leading manufacturers in the electronics industry. These companies invest in standards like ISO 9001:2015, ISO 13485:2016, IATF 16949, and UL Certification. Their commitment to quality management and safety opens doors to new markets and drives growth. The table below shows how these certifications support increased sales and market share:

| Certification | Description |

|---|---|

| ISO 9001:2015 | International standard for quality management systems |

| ISO 13485:2016 | Medical devices quality management system |

| IATF 16949 | Automotive industry quality standard |

| UL Certification | Safety standards for North American markets |

You notice that top PCBA manufacturers combine advanced technologies with these certifications to serve diverse market segments. The North American PCBA hard board industry focuses on sustainability, meeting global environmental standards. Regulatory frameworks like RoHS push manufacturers to innovate with eco-friendly materials and processes. When you choose certified partners, you gain access to reliable assembly and global opportunities.

Tip: Certifications like IPC standards help you build trust with customers and ensure consistent quality in every PCBA project.

Risks of Non-Compliance

You face serious consequences if you ignore quality certifications in electronics manufacturing. Non-compliance with standards such as ISO, RoHS, or IPC can lead to financial and reputational losses. You may encounter legal penalties, product recalls, and increased scrutiny from regulatory bodies. These issues disrupt your operations and damage your reputation.

- Legal penalties and fines can accumulate quickly.

- Product recalls result in lost revenue and wasted resources.

- Delayed product launches prevent you from reaching the market on time.

- Lost clients and contracts hurt your long-term business relationships.

- Negative online reviews and reduced customer loyalty make it harder to attract new customers.

You protect your business and reputation by prioritizing compliance. When you follow recognized standards, you minimize risks and strengthen your position in the electronics industry.

You strengthen your position in the electronics industry when you prioritize quality certifications. These standards drive consistency, support quality management, and guarantee high reliability. You benefit from verification of acceptable workmanship and gain access to global markets.

- Certifications like ISO, RoHS, and IPC ensure product safety and reliability.

- Buyers value certified partners for reduced risks and enhanced reputation.

| Standard | Key Benefit |

|---|---|

| ISO 9001 | Consistent quality management |

| RoHS | Environmental safety |

| IPC-6012 | Acceptable workmanship |

FAQ

What is the main benefit of ISO certification in PCBA production?

You gain a structured quality management system with ISO certification. This system helps you reduce defects, improve consistency, and meet customer requirements in every project.

How does RoHS compliance affect your products?

You ensure your products are free from hazardous substances. RoHS compliance protects the environment and supports safer recycling practices in the electronics industry.

Why should you follow IPC standards?

You achieve higher product reliability and consistent assembly quality when you follow IPC standards. These guidelines help you meet customer expectations and reduce manufacturing errors.

Can you sell uncertified PCBA products internationally?

You face restrictions in many markets if your products lack certification. Most countries require proof of compliance before you can sell electronics there.

How often should you renew your quality certifications?

You should review and renew your certifications regularly. Most standards require reassessment every one to three years to maintain compliance and quality.