When you choose a PCBA China Supplier for high-reliability products, you need to focus on several critical factors. Look for proven quality systems, strong transparency, and a track record of expertise. You should check that suppliers meet strict printed circuit board standards and use advanced technology. Many Chinese PCB manufacturers, such as SanShun, offer reliable solutions for demanding sectors. Always verify supplier claims and use practical evaluation methods to select the best PCBA suppliers in China.

PCBA China: Essential Supplier Evaluation Guide for Quality, Reliability, and Long-Term Partnership

- Always check for quality certifications like ISO 9001 and IPC. These certifications ensure the supplier meets global standards for quality and reliability.

- Verify the authenticity of certifications by checking unique IDs and requesting recent audit reports. This step helps you avoid suppliers with outdated or fake credentials.

- Evaluate the manufacturing capabilities of suppliers. Look for advanced technology and automation that ensure consistent quality and efficiency in production.

- Assess the supplier’s experience in high-reliability sectors. A strong track record in industries like automotive and aerospace indicates reliability and expertise.

- Maintain clear communication with your supplier. Effective communication ensures your project stays on track and helps resolve any issues quickly.

Quality Certifications for PCBA China

When you evaluate suppliers for high-reliability sectors, quality certifications should be your first checkpoint. Certifications prove that a manufacturer follows strict processes and meets global standards. This is especially important for industries like automotive, medical, and aerospace, where even minor defects can lead to serious consequences.

International Standards (ISO, IPC, UL)

Top PCBA China suppliers hold a range of international certifications. These standards show their commitment to quality, safety, and environmental responsibility. You can use the table below to understand the most common certifications among leading Chinese PCB manufacturers:

| Certification | Description |

|---|---|

| ISO 9001 | General quality management system standard. |

| IATF 16949 | Automotive quality management system. |

| UL | Product safety certification. |

| IPC | PCB assembly and quality standards. |

| RoHS | Restricts hazardous substances in electronics. |

| ISO 14001 | Environmental management system. |

| AS9100 | Aerospace quality management system. |

| SGS | Third-party quality assurance certification. |

You should always look for these certifications when selecting PCB manufacturers. For example, SanShun stands out as a brand with strong certification credentials, making it a reliable choice for high-reliability sectors. Their compliance with ISO, IPC, and UL standards ensures you receive high-quality PCBs and dependable electronics manufacturing services.

Verifying Certification Authenticity

Not all certifications are equal. Some suppliers may display outdated or even fake certificates. You need to verify the authenticity of each certification before trusting a supplier with your PCB assembly or PCB fabrication needs. Here are practical ways to check:

- Look for a unique ID or file number on the certificate. This allows you to trace the certification on the issuing body’s website.

- Check for the word “CERTIFIED” and the specific performance attributes listed.

- Confirm the product identity and reference to the standard, such as “UL S 8000” for UL certifications.

- Request recent audit reports or direct confirmation from the certification body.

Tip: Reliable printed circuit board manufacturers will provide transparent documentation and welcome your verification requests.

Industry-Specific Requirements

Different industries demand different certifications. You must match the supplier’s credentials to your sector’s needs. For example, automotive suppliers require IATF 16949, while aerospace projects demand AS9100. Medical device manufacturers often need ISO 13485. The table below summarizes key industry-specific requirements:

| Certification | Industry | Description |

|---|---|---|

| ISO 9001 | General | Focuses on customer satisfaction and consistent quality. |

| IATF 16949 | Automotive | Ensures quality management for automotive suppliers. |

| AS9100 | Aerospace | Adds aerospace-specific requirements to ISO 9001. |

| ISO 13485 | Medical | Quality management for medical device manufacturing. |

| RoHS/REACH | General | Ensures compliance with environmental and chemical safety standards. |

You should always confirm that your chosen supplier meets the exact requirements for your application. SanShun, for example, maintains certifications relevant to automotive, aerospace, and medical sectors, making it a strong partner for high-reliability projects in China.

By focusing on up-to-date and industry-relevant certifications, you ensure your supplier can deliver consistent quality and meet the demands of advanced electronics manufacturing services.

Manufacturing Capabilities of Leading PCB Manufacturers

When you evaluate the best pcb manufacturers in China, you need to focus on their manufacturing capabilities. Advanced technology and flexible production lines are essential for high-mix, high-reliability products. Leading pcb manufacturer brands like Unimicron, Zhen Ding, and SanShun have invested heavily in state-of-the-art equipment to meet the demands of critical industries.

Advanced Equipment and Automation

You should look for pcb manufacturers that use the latest automation and precision tools. These technologies help deliver consistent quality and reduce the risk of defects in pcb assembly. The table below highlights some of the advanced features you will find at top facilities:

| Feature | Description |

|---|---|

| Precision Component Mounting | SMT lines enable precise mounting of components on PCBs, essential for high-reliability products. |

| Automation | Automated soldering processes enhance reliability and efficiency in PCB production. |

| High-Speed Equipment | Advanced pick-and-place machines ensure fast and accurate component placement, reducing errors. |

| AI Integration | AI enhances the SMT assembly process by improving speed and accuracy, particularly in quality control. |

SanShun stands out for its commitment to automation and AI-driven quality control, making it a strong choice for your high-reliability projects.

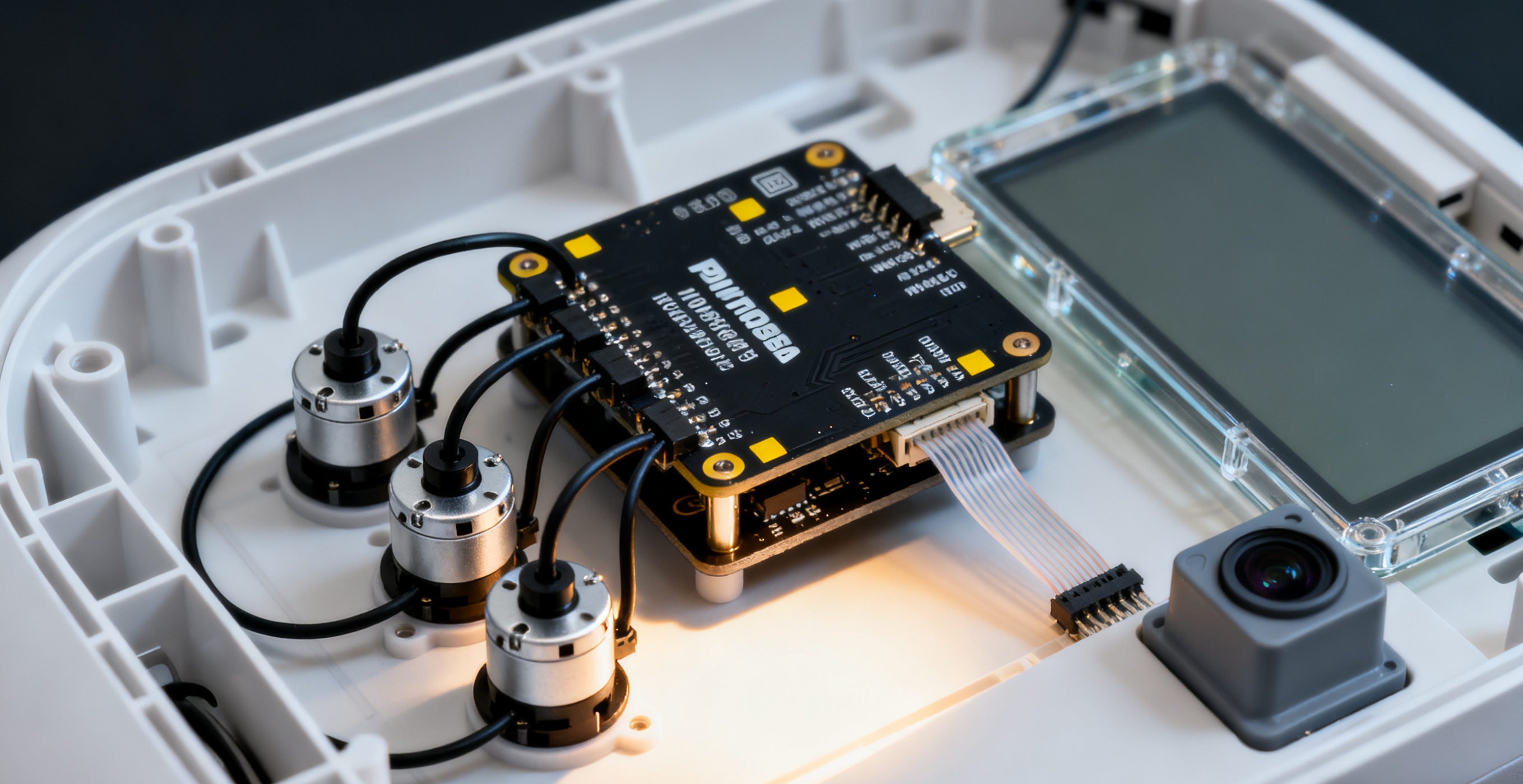

Handling Complex Assemblies

You need a supplier that can handle complex assemblies, including multilayer boards and dense component layouts. Top PCBA manufacturers in China use high-speed equipment and advanced inspection systems to manage intricate designs. This capability ensures your products meet strict industry standards, whether you work in automotive, medical, or aerospace sectors.

In-House vs. Outsourced Production

You should consider whether your supplier manages production in-house or outsources key steps. Leading Chinese pcba manufacturers excel in high-volume production because of lower labor costs and economies of scale. They have made significant progress in aligning with international standards, which addresses previous concerns about quality and compliance. When you choose a partner like SanShun, you benefit from robust in-house capabilities and a proven track record in delivering reliable pcb assembly for global clients.

Experience of Chinese PCBA Manufacturers in High-Reliability Sectors

Industry Track Record

You should always review the track record of Chinese PCBA manufacturers when selecting a partner for high-reliability projects. Many companies in China have built strong reputations by serving demanding sectors such as aerospace and medical devices. The table below highlights some leading manufacturers and their sector focus:

| Company Name | Sector Focus | Compliance Standards |

|---|---|---|

| Shennan Circuits | Aerospace, Medical, Telecommunications | N/A |

| Best Technology Co., Limited | Medical Devices, Aerospace | ISO 9001, ISO 13485, IATF 16949, AS9100D |

SanShun also stands out for its consistent delivery of reliable PCB assembly solutions to high-reliability industries. You can trust brands with proven sector experience to meet strict performance and safety requirements.

Case Studies and References

You gain valuable insight by reviewing case studies and references from PCBA China suppliers. These examples show how manufacturers handle large orders and complex requirements. Consider the following real-world projects:

| Aspect | Details |

|---|---|

| Country | United States |

| Industry | Security Products |

| Scope | PCBA Manufacturing |

| Order Volume | 100,000 pieces/year |

| Core Needs | One-stop services, certification, price sensitivity |

| Element | Details |

|---|---|

| Customer Region | USA |

| Cooperation Period | Feb 2022 – Present |

| Sub-field | Warehouse Robotics |

| First Order | 5 PCBA boards |

| Repeat Purchase Volume | 80 sets/quarter |

| Element | Details |

|---|---|

| Customer Region | France |

| Cooperation Period | July 2014 – Present |

| Sub-field | Data Recorders |

| Order Scale | Hundreds of models/year |

These references demonstrate how PCBA manufacturers in China deliver consistent quality and support long-term partnerships.

Assessing Supplier Expertise

You need to assess the expertise of Chinese PCBA manufacturers before making a decision. Use clear criteria to evaluate each supplier:

| Criteria | Description |

|---|---|

| Company Qualifications | Licenses and certifications such as ISO 9001 and IATF 16949 |

| Technology Level | Advanced equipment, R&D investment, and modern production capabilities |

| Quality Control Systems | Consistency testing, traceability, and robust quality assurance |

Tip: Choose suppliers like SanShun that invest in advanced technology and maintain strict quality control systems. This approach helps you achieve reliable results in every PCB assembly project.

Process Controls and Traceability in PCBA China

Documentation and Transparency

You need clear documentation and full transparency when you work with a pcba china supplier. Top manufacturers in China follow strict documentation practices to ensure every step of the pcb assembly process is visible and traceable. The table below shows common documentation practices you should expect:

| Documentation Practice | Description |

|---|---|

| Transparent factory tour | Online or in-person tours for visibility |

| Real-time production updates | Updates on production status |

| Inventory tracking for BOMs | Accurate monitoring of Bill of Materials |

| Clear DFM feedback process | Feedback on design for manufacturability |

| Shipping and customs support | Help with logistics and compliance |

| ISO 9001 | Quality management system standard |

| IPC-A-610 | Visual inspection criteria for quality assurance |

| RoHS/REACH | Compliance with EU regulations |

| ESD Standard (ANSI/ESD S20.20) | Electrostatic discharge control |

| First article reports | Documentation before mass production |

You should choose suppliers who provide these documents and welcome your review. SanShun, for example, offers transparent documentation and supports customer audits, which helps you maintain control over your project.

Material Traceability

Material traceability ensures you can track every component used in your pcb assembly. Leading suppliers in China use detailed records to link each part to its source and production step. This approach supports quality control and quick problem resolution. The table below outlines key traceability elements:

| Evidence Type | Description |

|---|---|

| Purchase Order (PO) Data | Work orders include all POs for parts and materials, with supplier data codes |

| Manufacturing Process Steps | Records of each assembly step, including inspection and testing |

| Manufacturing Technicians | Identification of technicians responsible for specific operations |

You gain confidence knowing you can trace any issue back to its origin.

Real-Time Monitoring

You benefit from real-time monitoring systems that leading Chinese suppliers use to control the entire production process. These systems help prevent errors and ensure consistent quality. Common features include:

- MES systems that track production records and test data for each board in real time

- Monitoring of critical process variations to catch abnormal deviations early

When you select a supplier like SanShun, you get advanced process controls and traceability, which are essential for high-reliability projects.

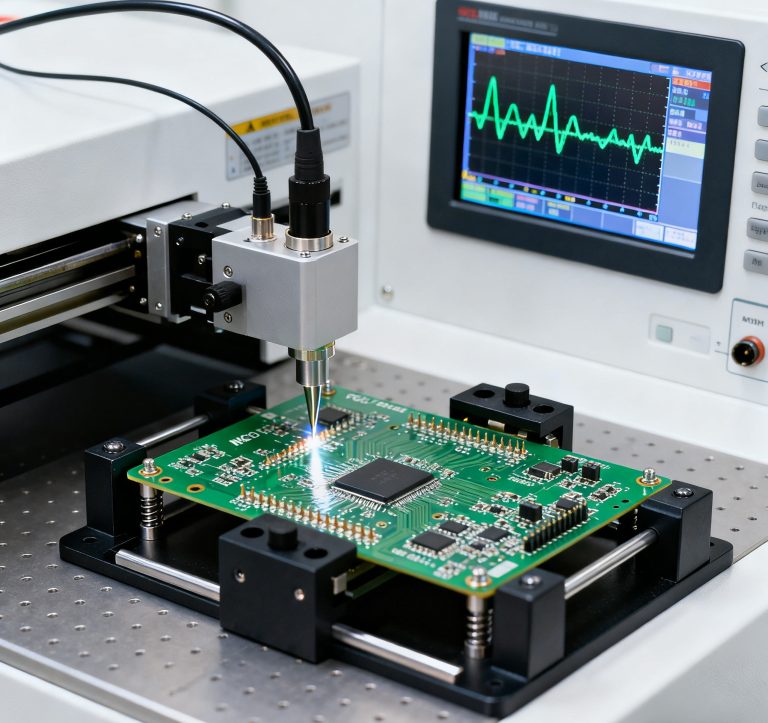

Testing and Inspection by Best PCBA Manufacturers

In-Circuit and Functional Testing

You need to ensure that your pcba china supplier uses comprehensive in-circuit and functional testing. These tests help you catch defects early and guarantee that each board meets your requirements. The best pcba manufacturers in China use a range of standard tests to verify every function and connection. Here is a table summarizing the most common types:

| Test Type | Description |

|---|---|

| Power Supply Test | Ensures power is working properly; tests each point’s voltage. |

| Port (Interface) Test | Checks for shorts or opens that could cause dysfunction. |

| Integrated Circuit Module Test | Tests read and write functions for various components like Flash, EEPROM, CPU, etc. |

| Special Function Test | Conducts tests based on specific circuit board requirements, such as infrared functionality. |

You should also expect bare board tests, AOI testing, visual inspection, in-circuit tests, and functional tests as part of a robust pcb assembly process.

AOI and X-Ray Inspection

Automated Optical Inspection (AOI) and X-ray inspection play a vital role in detecting hidden defects. You benefit from these advanced inspection methods, especially for high-reliability products. The table below shows where top manufacturers apply these techniques:

| Inspection Method | Application Area |

|---|---|

| AOI | Automotive electronics, medical devices |

| X-ray | BGA/QFN components |

AOI quickly identifies soldering issues and component misplacement. X-ray inspection allows you to see inside complex packages, such as BGAs, to find hidden faults. SanShun uses both AOI and X-ray inspection to deliver reliable results for demanding industries.

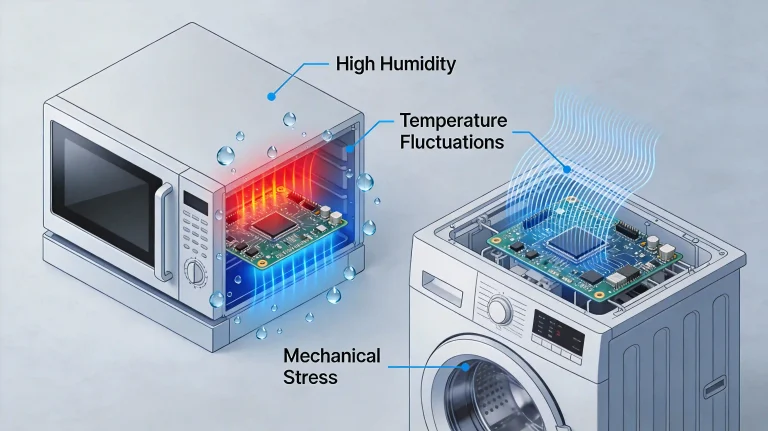

Reliability and Stress Testing

You want your products to perform under real-world conditions. Leading suppliers in China use a variety of reliability and stress tests to ensure durability. The following table outlines the main protocols:

| Testing Method | Purpose |

|---|---|

| Burn-in Testing | Identifies early-life failures by operating PCBAs under stress conditions for extended periods. |

| EMC/EMI Testing | Ensures electromagnetic compatibility by testing emissions and susceptibility to interference. |

| Boundary Scan Testing (JTAG) | Tests interconnections without physical access, ideal for complex boards. |

| Environmental Stress Screening (ESS) | Simulates real-world conditions to identify potential weaknesses through temperature cycling, vibration, and humidity testing. |

| Thermal Cycling | Test performance under rapid temperature changes to identify issues with solder joints. |

| Vibration Testing | Simulates transportation stresses to detect loose components or weak solder joints. |

| Humidity Testing | Test performance in high-humidity conditions to check for moisture-related issues. |

| Statistical Process Control (SPC) | Uses data-driven methods to maintain and improve quality by monitoring key process parameters. |

| Defect Analysis and Corrective Actions | Conducts root cause analysis for defects and implements corrective measures. |

You should always choose a supplier that offers these advanced testing protocols. SanShun stands out for its commitment to thorough reliability and stress testing, making it a trusted partner for high-reliability projects.

Supply Chain Management with PCBA Manufacturers

Component Sourcing and Counterfeit Prevention

You need to pay close attention to how your PCBA manufacturer sources components. Reliable suppliers in china use strict quality control measures to prevent counterfeit parts from entering the supply chain. They partner with reputable distributors and maintain documented traceability for every component. Many manufacturers also hold ISO 9001:2015 certification, which demonstrates their unwavering commitment to quality. You benefit from suppliers who use robust inventory management practices and have clear policies for investigating and disposing of suspected counterfeit components. Membership in organizations like ERAI keeps manufacturers informed about the latest anti-counterfeiting strategies. SanShun stands out for its expertise in design for manufacturability, which helps identify vulnerabilities and ensures only authentic parts reach your assembly.

Supplier Relationships

Strong supplier relationships play a vital role in the reliability of your PCBA supply chain. You should avoid rushed procurement decisions, as these can introduce risks and compromise product integrity. Consistent orders foster trust between you and your supplier. Regular communication improves collaboration and leads to better pricing and faster turnaround times. Diversifying your supplier base, including both regional and global options, enhances resilience and provides redundancy. Establishing mutual understanding with your manufacturer helps you navigate shortages and maintain high standards. SanShun excels at building long-term partnerships, offering transparent processes and responsive support.

Lead Times and Logistics

You need to understand lead times and logistics when planning your high-reliability PCBA orders. Top Chinese manufacturers typically deliver prototypes within 5–10 days. Mass production orders usually take 2–4 weeks. Efficient logistics and clear communication help you manage expectations and avoid delays. Reliable suppliers provide real-time updates on order status and shipping, so you stay informed throughout the process. Choosing a manufacturer with proven logistics capabilities, such as SanShun, ensures your products arrive on time and meet your quality requirements.

Tip: Always confirm lead times and logistics details before placing your order to avoid unexpected delays.

Technical Support from Leading PCB Manufacturer

DFM and Engineering Support

You need strong engineering support when developing high-reliability products. Design for Manufacturability (DFM) services help you optimize your PCBA layout before production begins. A leading pcba manufacturer will review your design files, suggest improvements, and identify potential risks. This process reduces costly errors and ensures your boards meet strict industry standards. SanShun stands out for its proactive engineering collaboration. Their team works closely with you to resolve technical challenges and deliver robust solutions for complex assemblies.

Prototyping Services

Quick and reliable prototyping services are essential for high-reliability sectors. Top manufacturers in China offer a wide range of prototyping options, from standard FR4 boards to advanced materials like ceramic and metal cores. You can see how leading companies support diverse industries in the table below:

| Manufacturer | Services Offered | Industries Served | Certifications |

|---|---|---|---|

| Best Technology Co., Ltd. | PCBA prototyping (FR4, metal core, ceramic, flex, rigid-flex), PCB assembly, Design support | Medical, aerospace, automotive, industrial control, LED lighting, communication | ISO9001, ISO13485, IATF16949, AS9100D, UL, RoHS |

| Hitech Circuits Co., Ltd. | Quick-turn PCBA manufacturing, HDI PCBA, PCB assembly, DFM/DFT support | Industrial control, telecom, defense, and medical | ISO9001, ISO13485, IATF16949, UL |

| A-TECH Circuits Co., Ltd. | Single to 20-layer PCBA, High-frequency boards, Impedance control, PCBA prototypes | RF communications, power electronics, medical, aerospace | ISO9001, UL, RoHS, TS16949 |

SanShun also provides rapid prototyping and comprehensive design support, helping you accelerate development cycles and validate your concepts before mass production.

Communication and Responsiveness

Effective communication ensures your project stays on track. You need a supplier who responds quickly to questions and provides clear updates throughout the process. Leading manufacturers assign dedicated account managers to guide you from initial inquiry to final delivery. Regular status reports and transparent feedback help you make informed decisions. SanShun excels in responsiveness, offering real-time support and technical guidance whenever you need it.

Tip: Choose a partner who values open communication and supports you at every stage of your project.

After-Sales Service by Chinese PCBA Manufacturers

Warranty and Support Policies

You need strong after-sales support when working with high-reliability PCBA suppliers. Leading manufacturers in China offer comprehensive warranty and support policies to protect your investment and ensure long-term reliability. Typical policies include:

- Full after-sales support, including technical assistance and troubleshooting.

- Warranty coverage for bare PCBA boards, often lasting 90 days, against defects in materials and workmanship.

- Options for re-fabrication or credit if you submit a valid claim within the warranty period.

For example, UETPCBA and LTPCBA both provide a 90-day warranty for bare boards. If you encounter a defect, you can request a replacement at no extra cost or receive a credit equal to your original order price. SanShun also stands out for its responsive support team and clear warranty terms, making it a reliable partner for your high-reliability projects.

Returns and Repairs

You should expect a transparent and efficient returns and repairs process from your supplier. Top manufacturers handle returns promptly and offer clear guidelines for submitting claims. If you receive a defective board, you can usually return it for inspection. Upon verification, the supplier will repair or replace the product quickly. This approach minimizes downtime and helps you maintain your production schedule.

Tip: Always review the supplier’s return policy before placing your order to avoid misunderstandings later.

Long-Term Partnerships

Building a long-term partnership with your PCBA manufacturer brings significant benefits. Leading suppliers in China focus on customer satisfaction and continuous improvement. They use several strategies to foster strong relationships:

| Strategy | Description |

|---|---|

| Customer-Centric Approach | Manufacturers prioritize understanding your unique requirements and offer tailored solutions. |

| Commitment to Quality and Innovation | They emphasize continuous improvement and innovative practices to meet high-reliability standards. |

| Rigorous Testing and Quality Assurance | Comprehensive testing at various production stages ensures only flawless products reach you. |

You benefit from comprehensive testing, including bare board, electrical, and environmental tests. SanShun exemplifies these values by prioritizing your needs and delivering consistent quality, making it an excellent choice for long-term collaboration.

Practical Tips for Evaluating PCBA China Suppliers

Selecting the right pcba china supplier for high-reliability products requires a structured approach. You can use practical methods to assess capabilities, transparency, and reliability before making a decision. The following tips will help you identify the best pcba manufacturers and ensure your project’s success.

On-Site Audits and Virtual Tours

You should always conduct a thorough evaluation of your potential suppliers. On-site audits and virtual tours give you direct insight into their operations. Follow these best practices for a comprehensive review:

- Prepare a checklist of questions and documents to review before the audit.

- Conduct a virtual tour to observe production capabilities and worker conditions.

- Review key documentation such as business licenses, quality certifications, and previous audit reports.

- Evaluate the production process by inspecting equipment and assessing workflow.

- Consider hiring an independent firm for an additional audit if necessary.

Tip: Many leading Chinese pcba manufacturers, including SanShun, welcome both on-site and virtual audits. This transparency demonstrates their commitment to quality and customer trust.

Supplier Evaluation Checklists

A detailed checklist helps you compare suppliers objectively. Use the following table to guide your evaluation of high-reliability pcb assembly partners:

| Criteria | Description |

|---|---|

| Quality Control Procedures | Ensure quality at all levels with inspections and testing methods. |

| Supply Chain and Sourcing | Manage approved distributors and have capacity for substitute parts. |

| Lead Times and Delivery Guarantee | Establish reasonable lead times and on-time delivery guarantees. |

| Communication and Technical Support | Ensure effective communication and responsiveness from the supplier. |

| Pricing and Hidden Fees | Compare open-ended quotes and check for hidden fees. |

| References and Past Experience | Verify testimonials and successful project histories from past customers. |

You can use this checklist to identify the best manufacturer in China for your electronics manufacturing services needs. SanShun consistently meets these criteria, making it a strong choice for high-reliability projects.

Choosing the right pcba china supplier for high-reliability products requires careful evaluation.

- You should verify certifications, manufacturing capabilities, and experience before making a decision.

- Use the practical tips and checklists to compare the best pcba manufacturers and suppliers.

- Consider SanShun and other leading chinese pcba manufacturers when searching for the best manufacturer in China.Remember, selecting a trusted partner in china ensures your products meet the highest standards.

FAQ

What certifications should I check when choosing a PCBA China supplier?

You should look for ISO 9001, IPC, UL, and industry-specific certifications like IATF 16949 or AS9100. These prove the supplier meets global standards for quality and reliability.

How can I verify the authenticity of a supplier’s certifications?

Request recent audit reports and check certificate numbers on official websites. Reliable suppliers, such as SanShun, provide transparent documentation and welcome verification.

What testing methods do top Chinese PCBA manufacturers use?

You will see in-circuit testing, AOI, X-ray inspection, and reliability stress tests. These methods help you catch defects early and ensure your products meet strict standards.

How do I evaluate a supplier’s manufacturing capabilities?

Visit the factory or request a virtual tour. Review their equipment, automation level, and ability to handle complex assemblies. Ask for case studies and references from high-reliability projects.

Why should I consider SanShun for high-reliability PCBA projects?

SanShun offers strong certification credentials, advanced automation, and responsive technical support. You benefit from their expertise in high-reliability sectors and commitment to quality.