You must set clear requirements before you select a reliable pcba supplier. Define your technical specifications, quality standards, and budget for your PCBAs project. China handles about 51% of global pcb manufacturing, making it vital to choose a reliable pcb supplier in China with proven reliability. Common challenges include material compatibility, quality control, communication, and pricing. Use a checklist to compare manufacturers and make sure to verify certifications and supply chain reliability. This approach helps you select a reliable pcba manufacturer and build a strong partnership with your chosen China pcba manufacturer.

5 Steps for PCBA Supplier Selection

- Define your PCBA needs clearly. Set technical specifications and quality standards to ensure the supplier meets your project requirements.

- Research suppliers using trusted online directories. Check certifications and customer reviews to gauge reliability and quality.

- Evaluate the quality control systems of potential suppliers. Look for advanced inspection methods and a strong commitment to maintaining high standards.

- Request samples and conduct a factory audit. This helps verify the supplier’s capabilities and ensures the product meets your expectations.

- Negotiate clear terms and confirm after-sales support. A solid agreement protects your interests and ensures ongoing assistance after production.

Define Your PCBA Needs

Set Technical and Quality Standards

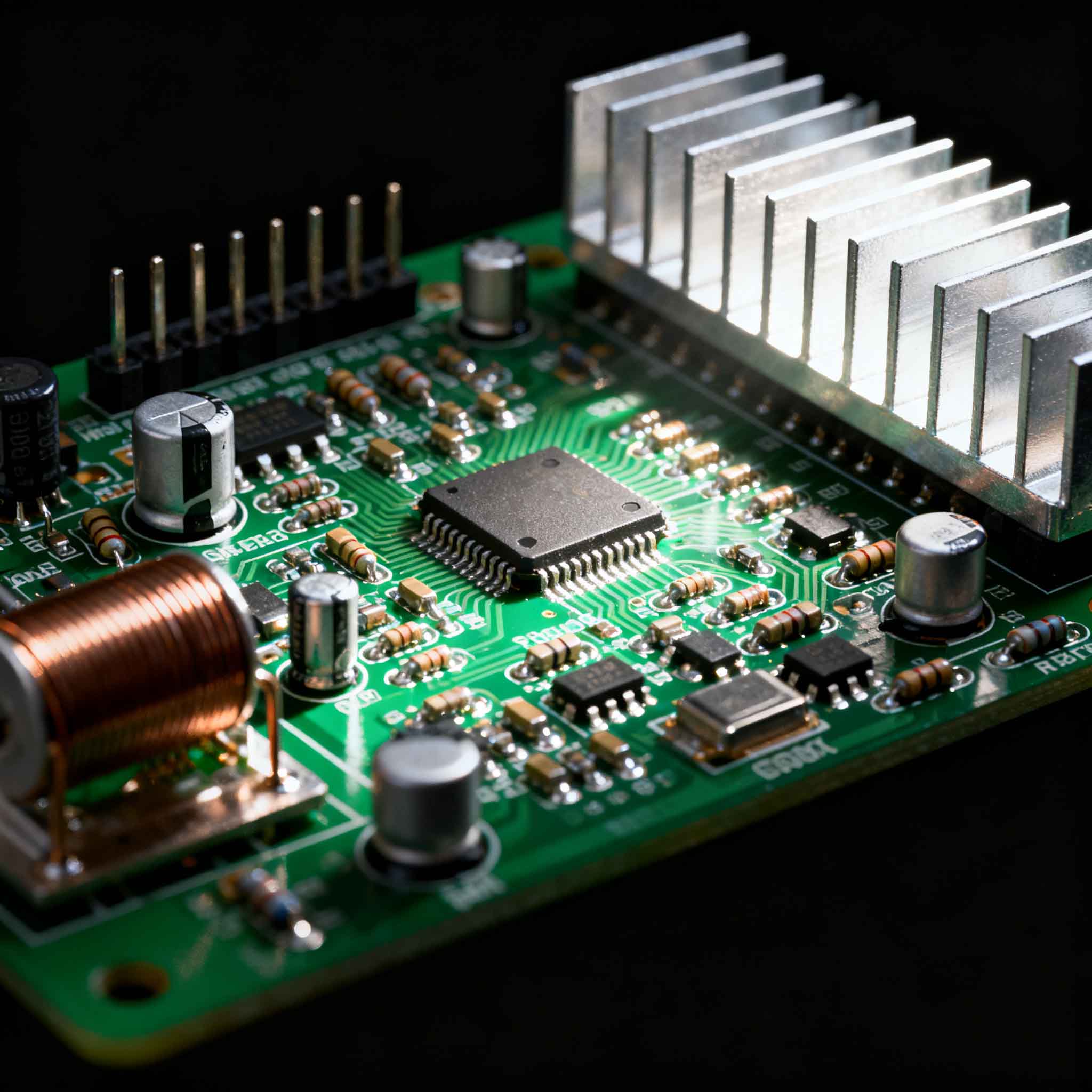

You should start by identifying the technical requirements for your PCBAs project. If your boards are intended for temperature control applications, focus on specifications that support accurate and reliable performance in varying environments. Consider the following table to help clarify your needs:

| Specification Type | Details |

|---|---|

| Electrical Requirements | Voltage rating, current rating, frequency response, tolerance, and rating accuracy. |

| Environmental Factors | Temperature range, vibration resistance, and humidity protection. |

| Cost Considerations | Performance vs. cost trade-off, availability and obsolescence. |

For temperature control, you must ensure the pcb can operate within the required temperature range and maintain stability. Pay close attention to environmental factors, as these directly affect the quality and reliability of your PCBAs.

When evaluating quality, look for suppliers who follow international standards. Common certifications include:

- IPC standards, which ensure best practices in pcb assembly.

- ISO certifications, such as ISO 9001 for quality management.

- RoHS compliance, which guarantees safe and environmentally friendly manufacturing.

- UL certification, which confirms the safety and reliability of your PCBAs.

These standards help you achieve consistent quality and reduce the risk of defects in your temperature control systems.

Plan Budget and Timeline

You need to set a clear budget for your pcba project. Costs can vary based on the complexity of your PCB. Here is a quick overview:

| Project Complexity | Estimated Cost Range |

|---|---|

| Simple, Single or Double-Sided PCB | $200 – $1000 |

| Intermediate, Multi-Layer PCB (4-6 Layers) | $1000 – $3000 |

| Complex, Multi-Layer PCB (8+ Layers) | $3000 – $10,000+ |

| Highly Complex, High-Density Interconnect (HDI) | $8,000 – $20,000+ |

You should also plan your timeline. Standard lead time for pcba projects in China is about 20 working days. For urgent needs, some suppliers offer quick-turn PCB delivery in less than 20 days. Prototypes can be ready in as little as 24 hours for simple boards.

Tip: Always communicate your quality expectations and delivery deadlines clearly to your supplier. This helps avoid misunderstandings and ensures your temperature control application performs as intended.

Research Reliable PCBA Suppliers in China

Use Online Directories and Reviews

You can start your search for a reliable PCBAs supplier by exploring trusted online directories. These platforms help you compare Chinese PCB manufacturers and review their offerings. Popular choices include:

- Alibaba.com

- Globalsources.com

These directories list many pcb suppliers for electronics and pcba manufacturers in China. You should check each manufacturer’s profile for certifications and quality standards. Customer reviews and feedback provide valuable insights into reliability and industry reputation. When you read reviews, focus on details such as production speed, communication, and technical help. You can also look for information about adaptability and transparency in pricing. Reliable pcb supplier in China often responds quickly to inquiries and offers flexible order sizes for prototypes.

Experts recommend evaluating reviews using these criteria:

- Certifications like ISO 9001 and IPC-A-610.

- Testing protocols such as AOI and X-ray inspections.

- Experience in demanding industries.

- Clear lead time details and shipping options.

- Technical capabilities and support.

Shortlist Based on Certifications and Experience

You should create a shortlist of pcba manufacturers based on certifications and experience. Certifications and quality standards show a manufacturer’s commitment to reliability. Common certifications include ISO 9001, ISO 14001, and IPC-A-610. The table below shows examples of reputable suppliers and their certifications:

| Supplier Name | Certifications |

|---|---|

| PCBasic | ISO9001, ISO13485, IATF 16949, ISO45001, ISO14001, RoHS, CE, FCC |

| DSBJ | ISO9001, ISO13485, IATF16949 |

| Kaifa | ISO9001, IATF16949, ISO13485 |

You should also verify business licenses and environmental permits. These documents confirm that the manufacturer operates legally and responsibly in China. Experience matters when you select a reliable pcba manufacturer. Top-rated suppliers like BESTFPC and Best Technology have over 18 years of experience in pcb manufacturing in China. Long-standing manufacturers often have a strong industry reputation and proven reliability.

When you research pcba suppliers, focus on certifications, experience, and reviews. This approach helps you find a reliable pcba manufacturer for your temperature control application.

Evaluate PCBA Supplier Quality and Capabilities

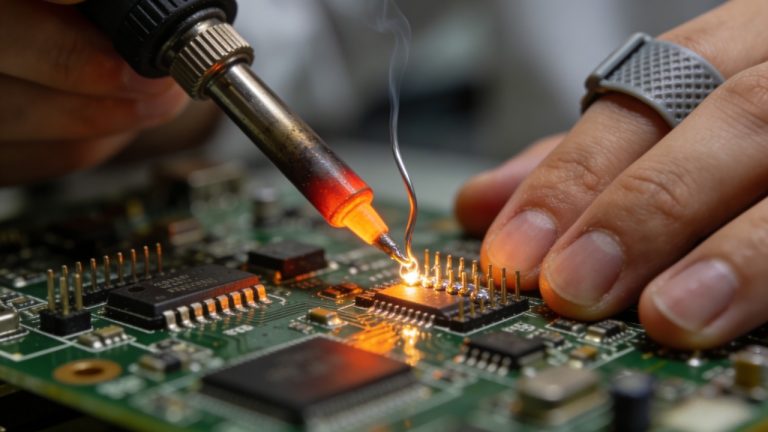

Check PCBA Quality Control Systems

When you select a reliable pcba manufacturer in China, you must examine their quality control process. A strong system ensures your temperature control pcba boards meet strict standards. Reliable pcba manufacturers use global certifications and document every step for consistency. They focus on critical stages in production to catch errors early. Advanced inspection methods like AOI and X-ray testing help detect both surface and hidden defects. Well-trained teams play a key role in maintaining quality. They use inspection data and customer feedback to improve processes. The table below shows the main components of an effective quality control system:

| Key Component | Description |

|---|---|

| Standardize for Consistency | Use ISO, IATF, UL standards and document processes for uniform quality. |

| Control Critical Stages | Focus on high-risk phases to catch errors early. |

| Leverage Advanced Inspection | Use AOI, X-ray, and functional checks for defect detection. |

| Invest in People | Train teams on protocols and defect recognition. |

| Iterate with Data | Use inspection data and feedback to optimize processes. |

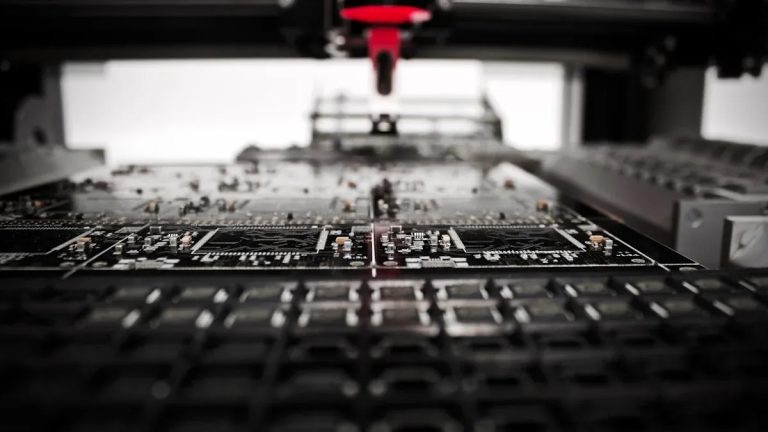

Assess PCBA SMT Assembly and Technical Expertise

You should always assess the SMT assembly capabilities of any manufacturer. Leading manufacturers in China use advanced equipment like YAMAHA and Panasonic surface mounters. They can handle a wide range of pcb sizes and component types, including the smallest 01005 packages. Reliable pcba manufacturers also use 3D AOI, X-ray, and SPI for thorough inspection. These tools ensure high quality and reliability for your temperature control applications. You can request samples or prototypes to verify the manufacturer’s quality before full production. Top manufacturers provide dedicated engineering support and clear communication throughout the project. Their reputation often comes from successful projects in demanding industries.

Review PCBA Supply Chain and Sourcing PCBs from China

Sourcing pcbs from China brings both opportunities and risks. Reliable pcba manufacturers source components from trusted distributors like Mouser and DigiKey. This reduces the risk of counterfeit parts and supports consistent quality. You should ask about their supply chain management and how they handle disruptions. Common risks include delays, cybercrime, and ESG violations. Manufacturers with strong capabilities diversify their supplier base and keep safety stock. When you select a reliable pcba manufacturer, always verify their credentials and track record in sourcing pcbs from China. This step protects your production schedule and ensures ongoing quality.

Final Verification and Agreement with Reliable PCBA Manufacturer

Request Samples and Factory Audit

Before you select a reliable pcba manufacturer in China, you should always request samples. This step lets you inspect the quality of the pcba and verify that the product matches your requirements. When you receive samples, check the materials, dimensions, and performance. Use this opportunity to refine your product before full production. Reliable pcba suppliers in China will provide clear sample requests and respond quickly.

A factory audit gives you a deeper look at the manufacturer’s capabilities. You can visit the facility or request a virtual tour. During the audit, review the following areas:

| Audit Check | Purpose |

|---|---|

| Certifications | Confirm compliance with industry standards |

| Soldering process control | Ensure quality in assembly |

| AOI/X-ray inspections | Detect defects in soldering |

| Traceability system | Track components and materials |

| Staff training | Assess skill levels and procedures |

This process helps you select a reliable pcba manufacturer who can deliver consistent quality and reliability.

Negotiate Pricing, Terms, and IP Protection

When you negotiate with a reliable pcba manufacturer, focus on more than just the unit price. Assess total costs, including hidden fees and possible rework. Build trust through clear communication and understanding of cultural practices in China. Always sign a detailed contract that covers product quality, delivery timelines, and payment terms. This reduces misunderstandings and protects your interests.

Key contract terms to include:

- Agreement term and exclusivity

- Quantities and delivery schedules

- Payment terms and pricing structure

- Quality standards and testing procedures

- Product inspections and warranty

- Confidentiality and intellectual property protection

You should also use agreements like NNN (Non-Disclosure, Non-Use, Non-Circumvention) to safeguard your designs and data.

Confirm After-Sales Support

After you select a reliable pcba manufacturer, confirm their after-sales service. Reliable pcba suppliers in China offer services such as delivery guarantees, quality assurance, and technical support. They provide warranty periods and handle repair or replacement if issues arise. You should expect quick responses to inquiries and regular feedback to improve your products. After-sales service ensures your pcba production runs smoothly and your temperature control applications remain reliable.

Tip: Ongoing communication with your manufacturer builds a strong relationship and helps you address any challenges quickly.

You can select a reliable pcba manufacturer in China by following a clear process. Start by defining your pcb needs and verifying supplier qualifications. Focus on quality control and technical strength. Maintain strong relationships for long-term benefits such as cost-effectiveness, supply chain integration, and speed to market. Use regular monitoring strategies like factory tours, real-time updates, and inventory tracking to ensure ongoing quality. Avoid common mistakes by checking production capacity, service level, and reputation. Investing time in supplier selection improves your pcba project outcomes and reduces risks.

| Key Monitoring Criteria | Description |

|---|---|

| Company Qualifications | Licenses and certifications for quality assurance |

| Technology Level | Advanced equipment and R&D investment |

| Quality Control Systems | Consistency testing and traceability |

Choosing the right pcb supplier can make a big difference in meeting deadlines and ensuring reliable quality for your pcba boards.

FAQ

What certifications should you look for in a PCBA supplier?

You should check for ISO 9001, IPC-A-610, and RoHS certifications. These show the supplier meets international quality and safety standards. Certifications help you trust the supplier’s process and product reliability.

How do you verify a supplier’s experience with temperature control PCBA boards?

Ask for case studies or references from similar projects. Review their technical documentation and request samples. You can also check if they have worked with temperature-sensitive applications before.

Why is a factory audit important before choosing a supplier?

A factory audit lets you see the supplier’s production process and quality control. You can confirm their capabilities and spot any risks. This step helps you select a reliable pcba manufacturer.

What after-sales support should you expect from a Chinese PCBA supplier?

You should expect warranty coverage, technical support, and quick responses to any issues. Good after-sales service ensures your PCBA boards work well in your application.

Can you request prototypes before full production?

Yes, you can request prototypes. Prototypes help you test the design and quality before starting mass production. This step reduces the risk of costly mistakes.