You need a systematic approach to identify a reliable PCBA manufacturer in China. China PACB accounts for approximately 51% of global PCBA production, making it a key destination for PCBA sourcing. You should prioritize strict quality control and reliability testing. Leading manufacturers such as Sanshun and Next PCBA have earned customer trust through their consistent service and proven reliability. You can evaluate trust and quality by checking for comprehensive inspections, IPC-certified staff, and adherence to industry standards. Use practical verification steps to ensure you work with a trustworthy PCBA manufacturer.

| Quality Control Aspect | Description |

|---|---|

| AOI Inspection | Inspect 100% of boards |

| Operator Training | IPC-certified staff logs |

| Reflow Oven Maintenance | Daily temperature profile checks |

| Compliance | RoHS and lead-free soldering for EU products |

Key Criteria for Selecting a Reliable China PCBA Manufacturer

- Prioritize manufacturers with strong experience and high reorder rates. This indicates reliability and customer satisfaction.

- Verify certifications like ISO 9001 and IPC-A-610 to ensure quality assurance and compliance with industry standards.

- Request samples and conduct reliability testing before placing large orders. This helps confirm product quality and performance.

- Evaluate communication practices. Quick and clear responses from manufacturers indicate good support and reduce project risks.

- Conduct facility visits or virtual tours to assess quality control practices and transparency in operations.

Key Criteria for a Reliable PCBA Manufacturer

Experience and Track Record

You should always consider the experience and track record of any PCBA manufacturer. Years of operation and a proven history of on-time delivery show reliability. Companies with high client retention rates demonstrate consistent quality and service. For example, Sanshun stands out as a reliable and trustworthy manufacturer in the China PCBA manufacturer market. You can look at reorder rates to gauge customer trust and satisfaction:

- Shenzhen Ulite Precision Technology Limited maintains a 70% reorder rate.

- King Field Electronic Co., Ltd. and Shenzhen Moko Technology Ltd. have reorder rates between 21% and 51%.

A high reorder rate signals that customers receive consistent quality and responsive support. You should always ask about the on-time delivery rate and past project examples to verify reliability.

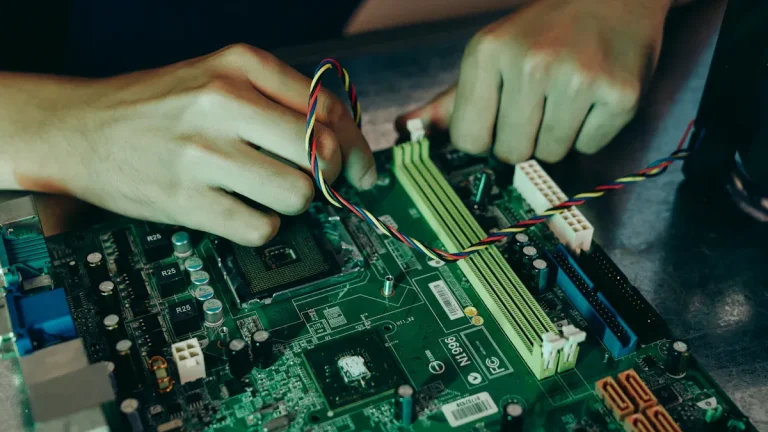

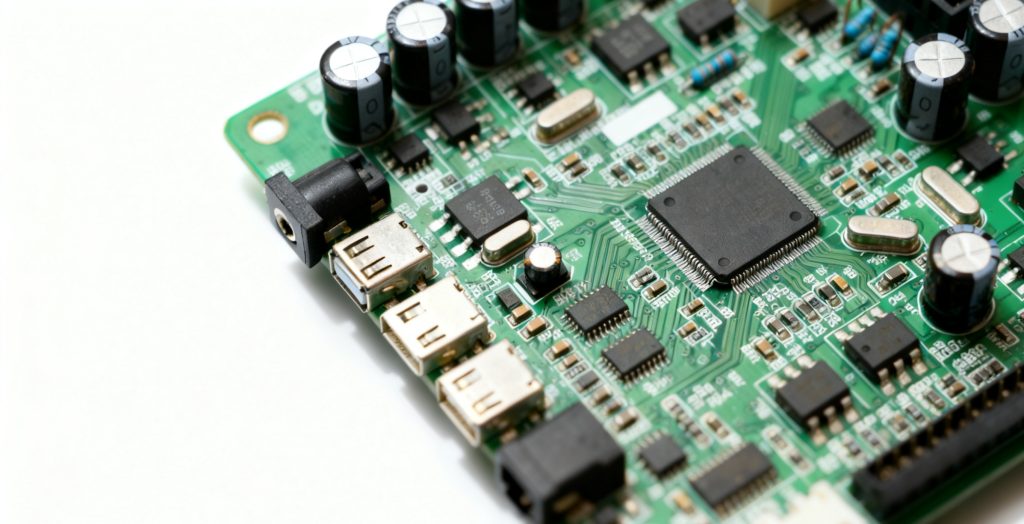

Technology and Equipment

Advanced technology and modern equipment play a crucial role in delivering high-quality PCBA and reliable PCBA assembly. Leading PCBA manufacturers in China invest in state-of-the-art machinery and smart robotics. Automation reduces production time and labor costs, while enhancing quality control and minimizing human error. You should expect the following capabilities from a trustworthy PCBA manufacturer:

| Technology/Equipment | Description |

|---|---|

| PCBA Fabrication | Supports 1-64 layers for prototypes, 1-40 layers for mass production, including complex rigid-flex hybrids. |

| Material Choices | Offers FR-4, high-frequency laminates (Rogers RO3003), and aluminum substrates for specialized uses. |

| Advanced Features | Provides buried/blind vias, laser-drilled microvias, and heavy copper for high-power designs. |

| Prototyping Speed | Delivers two-layer boards in 24 hours; multilayers in 2-4 days. |

| Equipment Origin | Uses equipment from Japan, the US, and Europe for various PCBA types. |

| Assembly Technologies | Supports SMT, THT, and mixed-technology assemblies. |

| Quality Checks | Implements AOI and functional circuit testing for strict quality control. |

Automated assembly lines and AI-powered systems ensure high precision, consistency, and cost savings. These features are essential for maintaining reliability and trustworthiness in fast-paced markets like PCBA China.

Certifications and Quality Assurance

Certifications reflect a manufacturer’s commitment to quality assurance and reliability. You should always verify that your chosen PCBA manufacturer holds internationally recognized certifications. These standards guarantee strict quality control and compliance with industry requirements.

| Certification | Description |

|---|---|

| ISO 9001:2015 | General quality management |

| ISO 13485:2016 | Medical device quality management |

| IATF 16949:2016 | Automotive quality management |

| IPC-A-610 Class 2 and 3 | Assembly workmanship standards |

| UL Certified | US safety compliance |

| RoHS Compliant | Environmental compliance |

A manufacturer with these certifications demonstrates a robust quality control system and a commitment to delivering high-quality PCBA products. You should also check for regular audits and transparent communication about quality processes.

Customer Trust and Reputation

Customer trust and reputation are vital indicators of a trustworthy PCBA manufacturer. You should look for verified customer reviews and transparent communication. Stable quality, smooth communication, and ethical sourcing practices build customer trust. Sanshun and Next PCBA have earned strong reputations for reliability, responsive support, and consistent quality in the PCBA China market.

Tip: Always verify English communication abilities to avoid misunderstandings and hidden issues that could increase costs.

Responsible material acquisition and ethical sourcing further enhance trustworthiness. You should prioritize manufacturers who offer responsive support and maintain transparency throughout the service and delivery process. A strong reputation for on-time delivery and quality service ensures long-term customer satisfaction.

How to Verify a Trustworthy PCBA Manufacturer

Checking Certifications and QA Processes

You need to confirm that your chosen PCBA manufacturer follows strict quality assurance procedures. Start by verifying their quality management system. Check if certifications like ISO 9001, RoHS, and IPC-A-610 are active and up to date. Ask for documentation that proves these certifications have not expired. Confirm that internal quality procedures are consistently followed, not just listed on paper.

A trustworthy PCBA manufacturer will implement multiple layers of quality control throughout the PCBA assembly process. You should expect to see these measures:

| Quality Assurance Measure | Description |

|---|---|

| Pre-fabrication Engineering Review | Analysis of design files to ensure manufacturability and identify potential issues. |

| Incoming Quality Control | Inspection and testing of all incoming materials to meet high standards. |

| In-process Quality Control | Continuous monitoring and testing during manufacturing to catch issues early. |

| Electrical Test | Comprehensive testing of electrical connections and functions. |

| Automated Optical Inspection (AOI) | High-speed, high-accuracy inspection of PCB and PCBA surfaces. |

| Final Quality Control (Outgoing Inspection) | Final check of products before shipment to ensure specifications and standards are met. |

You should also look for evidence of third-party audits. These audits help verify that the manufacturer maintains high standards for quality and reliability. The table below shows the types of audits and their focus areas:

| Audit Type | Focus Areas |

|---|---|

| Supplier Quality Audits | Management, Engineering, Quality Control, Incoming Receiving Inspection, Manufacturing, Packaging, Non-Conforming Materials, Corrective Action, Inspection & Test Equipment |

| Quality Management System Audits | Management, quality control methods, non-conforming materials, corrective action, inspection and test equipment |

| ISO 9001 Audits | Verification of quality management systems to ensure compliance and support continuous improvement |

Tip: Always request recent audit reports and certification documents. This step builds trust and demonstrates the manufacturer’s commitment to quality assurance.

Reviewing Customer Feedback

You should review customer feedback to assess the reputation and reliability of a pcba manufacturer. Look for verified reviews on independent platforms and industry forums. Positive feedback about on-time delivery, service quality, and responsive support signals strong customer trust. Negative reviews about missed deadlines or poor communication can indicate potential risks.

Consider these points when evaluating feedback:

- Consistent praise for on-time delivery and reliable service shows a manufacturer values customer satisfaction.

- Detailed reviews about PCBA quality and support help you understand the manufacturer’s strengths and weaknesses.

- Feedback about after-sales support and problem resolution demonstrates the manufacturer’s commitment to long-term relationships.

Note: Reliable manufacturers often share case studies or testimonials from satisfied customers. These stories highlight their trustworthiness and reputation in the pcba market.

Assessing Communication and Responsiveness

Effective communication plays a critical role in project success. You should evaluate how quickly and clearly the manufacturer responds to your inquiries. Regular meetings, clear documentation, and digital tools for real-time updates improve alignment and reduce misunderstandings.

| Key Practices for Effective Communication | Impact on Project Success |

|---|---|

| Regular meetings to review project status | Improves alignment and addresses concerns |

| Clear documentation of requirements | Reduces misunderstandings and risks |

| Use of digital tools for real-time updates | Enhances efficiency and responsiveness |

| Defined points of contact | Facilitates fast decision-making |

| Open feedback channels | Resolves problems early and fosters collaboration |

You should expect defined points of contact and open feedback channels. These practices support fast decision-making and early problem resolution. Strong communication builds trust and supports on-time delivery throughout the PCBA assembly process.

Callout: If a manufacturer provides prompt, clear answers and maintains transparency, you can expect better support and fewer delays in delivery.

Verifying Business Legitimacy

You must verify the business legitimacy of any pcba manufacturer before entering a partnership. Obtain the company’s Unified Social Credit Code (USCC), which is a unique identifier assigned by the Chinese government. This code helps you confirm the correct entity, even if the company changes its name.

You can use the National Enterprise Credit Information Publicity System, an official government website, to check the company’s legal status. Enter the company’s name or registration number to confirm their registration and compliance with local laws.

Tip: Always cross-check business registration details and legal status. This step protects you from fraud and ensures you work with a trustworthy pcba manufacturer.

By following these steps, you strengthen your ability to select a manufacturer with proven reliability, strong customer trust, and a solid reputation for quality and on-time delivery. These actions help you build long-term partnerships and achieve consistent results in pcba and pcba projects.

Practical Steps to Evaluate PCBA Reliability

Requesting Samples and Reliability Testing

You should always request samples before committing to a large order with any pcba manufacturer. Samples allow you to verify consistent quality and assess the reliability of the pcba assembly process. Leading manufacturers offer comprehensive reliability testing to demonstrate their commitment to strict quality control. You can expect the following types of tests:

| Type of Testing | Description |

|---|---|

| Electrical Performance Testing | Verifies continuity of conductive paths and insulation resistance, crucial for high-voltage applications. |

| Mechanical Performance Testing | Assesses structural integrity through peel strength, flexural, and thermal stress testing. |

| Environmental Adaptability Testing | Evaluates performance under extreme conditions, including high-temperature aging and damp heat tests. |

These tests help you build trust in the manufacturer’s quality control system and ensure the high-quality pcba meet your requirements for on-time delivery and long-term performance.

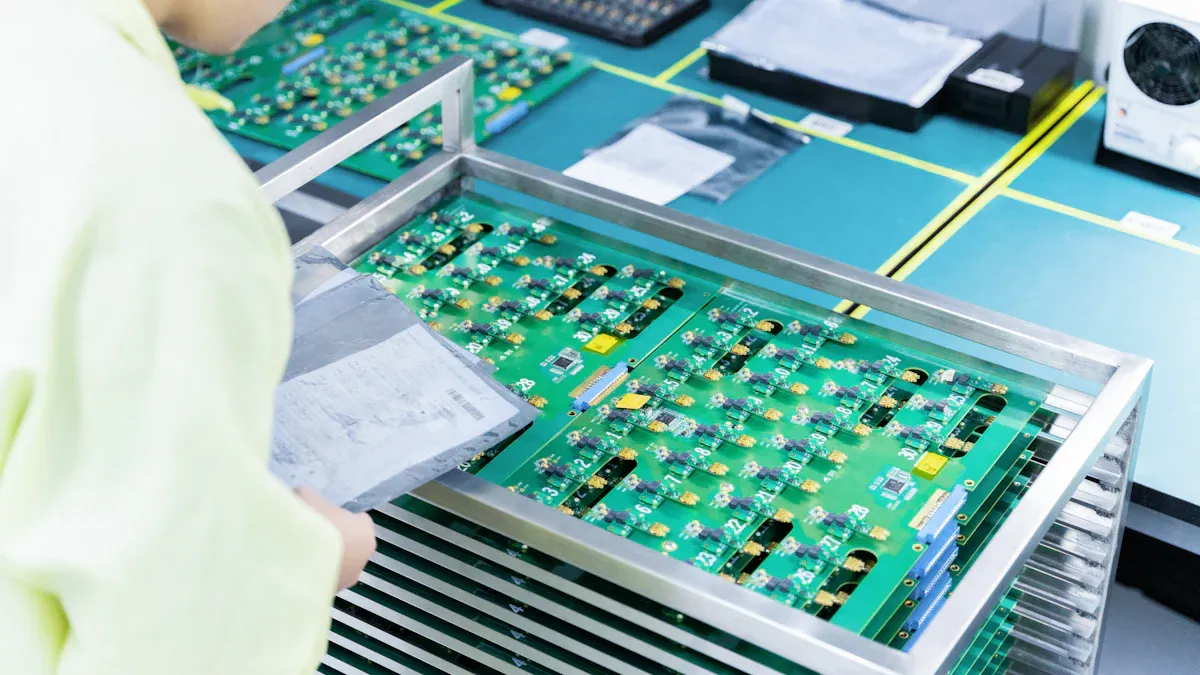

Facility Visits or Virtual Tours

You gain valuable insights into a manufacturer’s reputation and quality standards by visiting their facility or arranging a virtual tour. On-site visits provide direct observation of product quality, company culture, and strict quality control practices. Virtual tours offer a convenient alternative, but limit your ability to verify transparency and physical conditions. Compare the two approaches:

| Aspect | On-Site Visits | Virtual Tours |

|---|---|---|

| Product Quality Evaluation | Direct observation of product quality and on-time delivery | Limited to visual representation |

| Company Culture | Personal interaction with staff and understanding company values | No personal interaction |

| Facility Condition | Assessment of the cleanliness, organization, and safety of the manufacturing floor | No physical assessment |

| Machinery Inspection | Direct evaluation of machinery condition and calibration | No hands-on inspection |

| Environmental Testing | Opportunity to see testing capabilities in action | No real-time evaluation |

| Documentation Review | Access to manufacturing work instructions and processes | Limited documentation access |

| ITAR Compliance | Verification of ITAR registration and access control measures | No verification possible |

| Material Control | Walkthrough of component ordering and tracking processes | No insight into material control |

| Certifications | Review of necessary certifications and qualifications | No verification of certifications |

During a facility visit, you should focus on supplier expertise, documentation practices, material traceability, and testing methods. These steps help you confirm the manufacturer’s commitment to transparency and consistent quality.

Comparing Quotes and Services

You need to compare quotes and services from multiple PCBAs to ensure you receive the best value and quality. Pricing varies based on order volume and complexity:

| Order Volume | Price Range |

|---|---|

| Prototype (1–10 pcs) | $50 – $110 |

| Low Volume (50–500 pcs) | $0.90 – $1.50/pc |

| Mass Production (1000+ pcs) | $0.35 – $0.80/pc |

You should review what each service includes, such as testing, packaging, and delivery timelines. Reliable manufacturers provide clear quotes with no hidden fees and maintain a reputation for on-time delivery and responsive support.

Evaluating After-sales Support

You must assess after-sales support to protect your investment and maintain trust in your pcba supplier. Leading manufacturers offer warranties, technical support, and fast responses to customer inquiries. For example:

- Kingsheng provides free repairs within a 5-year warranty period and replaces defective products caused by quality issues.

- JHYPCB delivers 24/7 engineering support, quality tracing, and continuous improvement.

- PCBWay offers exclusive customer support and multi-language assistance, ensuring quick solutions for complaints.

- Hemeixinpcb warrants bare boards for 90 days, offering free replacements or credits for valid claims.

Strong after-sales service demonstrates a manufacturer’s commitment to quality and customer satisfaction. You should prioritize suppliers who offer reliable support and maintain transparency throughout the delivery process.

Avoiding Common PCBA Manufacturer Pitfalls

Hidden Costs and Quality Issues

You may encounter hidden costs when working with a PCBA manufacturer in China. These costs often include rework expenses, material waste, and production delays. Missed deadlines can lead to penalties or lost contracts, especially if your industry demands on-time delivery. Defective pcba products can damage your customer relationships, resulting in returns and warranty claims. These issues may cost more than the original order and can harm your reputation. Processing returns for defective pcba assemblies often involves extra shipping, replacements, and the intangible cost of customer dissatisfaction.

| Quality Issue Description | Details |

|---|---|

| Recurring Quality Issues | Ongoing problems without solutions, leading to unpredictable quality. |

| Lack of Quality Processes | Skipped quality checks or fabricated inspection records. |

| Immature Operational Practices | Reliance on operators instead of dedicated inspectors for quality checks. |

Tip: Always clarify all costs and request a detailed breakdown before you confirm your order. This step helps you avoid surprises and supports your project’s reliability.

Red Flags in Communication

You should watch for poor communication from your manufacturer. Delayed responses, vague answers, or inconsistent updates signal potential problems. Reliable service requires clear, prompt communication and defined points of contact. If you struggle to get timely support or accurate information, your project may face delays or quality issues. Strong communication builds trust and ensures on-time delivery.

Supply Chain Transparency

You need transparency in the supply chain to maintain quality and reliability. A trustworthy manufacturer shares information about component sourcing, inventory management, and delivery timelines. Lack of transparency can lead to counterfeit parts, missed deadlines, or unexpected changes in service. You should request documentation and regular updates to ensure your project stays on track.

Overreliance on Online Listings

You should not rely solely on online listings when choosing a PCBA manufacturer. Many listings exaggerate capabilities or hide negative reviews. Direct engagement, sample requests, and facility visits provide a clearer picture of the manufacturer’s true service quality and reliability. This approach helps you avoid disappointment and supports long-term success.

PCBA Manufacturer Selection Checklist

Step-by-step Process

You can streamline your search for a reliable PCBA manufacturer in China by following a clear process. Start by evaluating the manufacturer’s experience and expertise in the type of pcba you need. Assess their technology and equipment to confirm they can handle your production requirements. Establish effective communication channels to ensure smooth collaboration. Verify their quality assurance processes to maintain high standards in every pcba project.

- Identify manufacturers with proven experience in your industry.

- Review their technology, equipment, and production capabilities.

- Set up direct communication to discuss your project needs.

- Request documentation on quality control and certifications.

- Compare service offerings, delivery timelines, and customer support.

Tip: A systematic approach helps you avoid unstable quality and ensures on-time delivery.

Key Questions to Ask

When you contact a potential manufacturer, you should ask targeted questions to uncover their strengths and weaknesses. These questions help you evaluate their reliability and the level of service you can expect.

- How do you handle emergency sample requests?

- What technical support or DFM advice do you provide?

- Can you share details about your quality control process?

- Are your quotations transparent, with no hidden charges?

- How do you manage information feedback and project updates?

Note: Clear answers to these questions reveal the manufacturer’s commitment to customer satisfaction and reliable service.

Final Verification Steps

Before you sign a contract, complete several final checks to protect your project and intellectual property. Review your design files and requirements with the manufacturer. Request a detailed quote that includes lead time and all costs. Sign a non-disclosure agreement to safeguard your designs. Confirm that the manufacturer holds all necessary quality certifications.

- Conduct a design verification to ensure your pcba meets specifications.

- Check the manufacturing process for DFM compliance and inspect the board during production.

- Require final testing of the finished product to guarantee quality and performance.

Callout: These steps help you build trust and secure a long-term partnership with a reliable manufacturer.

You can find a reliable pcba partner in China by following a systematic approach that prioritizes quality, reliability testing, and customer trust. Focus on proven brands like Sanshun to build trust and ensure your pcba projects succeed. Use the checklist to evaluate each pcba and supplier. When searching for a china pcba manufacturer or pcba china, you improve your chances of connecting with a reputable customer-focused company that values quality and long-term relationships.

FAQ

What certifications should a reliable PCBA manufacturer in China have?

You should look for ISO 9001, IPC-A-610, and RoHS certifications. These show the manufacturer follows strict quality standards and environmental regulations.

Tip: Always request to see valid certificates before placing an order.

How can you verify a manufacturer’s reputation?

Check independent reviews, request customer references, and look for case studies.

- Reliable manufacturers share testimonials.

- Consistent positive feedback signals trustworthiness.

Why is sample testing important before mass production?

Sample testing lets you confirm product quality and reliability. You can identify issues early and avoid costly mistakes in large orders.

| Step | Benefit |

|---|---|

| Request sample | Verify quality |

| Test sample | Ensure reliability |

What after-sales support should you expect?

You should expect clear warranty terms, technical support, and fast responses to issues.

Reliable manufacturers provide ongoing support and resolve problems quickly to protect your investment.