You see many European SMEs turning to Asia-based PCBA Suppliers because they seek lower costs, enhanced production flexibility, and superior quality. Rising labor expenses in Europe and unpredictable supply chain risks have forced you to rethink your manufacturing strategies. The pandemic changed how you approach outsourcing, pushing you to favor efficiency and innovation. Brands like Sanshun, with international standards and proven expertise, help you achieve reliable results and maintain agility in a rapidly evolving market.

How Partnering with Asia-Based PCBA Suppliers Helps European SMEs Cut Costs and Boost Competitiveness

- Outsourcing to Asia can reduce manufacturing costs by up to 60%, allowing European SMEs to invest more in innovation and growth.

- Asian PCBA suppliers offer flexible small-batch pricing, enabling businesses to adapt quickly to market changes without large upfront investments.

- Fast turnaround times from Asian suppliers help you meet tight deadlines, giving you a competitive edge in the market.

- Choosing suppliers with international certifications ensures high-quality standards and reliable product performance.

- One-stop solutions from Asian suppliers simplify your supply chain management, reducing overhead and improving efficiency.

Cost Benefits with PCBA Suppliers

Lower Labor and Production Costs

You face high labor costs when you manufacture in Europe. These expenses often make it difficult for your business to compete globally. PCBA Suppliers in Asia, especially in Southeast Asia and China, help you reduce these costs. You benefit from lower wages and streamlined production processes. This cost advantage allows you to allocate more resources to innovation and growth.

Tip: Choosing the right supplier can help you cut costs by up to 60% compared to Western manufacturers.

Here is a comparison of labor costs across regions:

| Region | Labor Cost Description |

|---|---|

| North America | Higher due to higher wages and overheads. |

| South Asia (China) | Lower due to lower labor costs and scale. |

| Western Europe | Moderate, varies by country. |

Sanshun stands out among PCBA Suppliers by offering competitive pricing and efficient logistics. You gain access to high-quality manufacturing without the burden of excessive labor expenses.

Small-Batch Pricing Advantages

You often need flexibility in your production runs. Asian PCBA Suppliers provide small-batch pricing models that suit your needs. These models help you adapt to niche markets and respond quickly to changing demands. You avoid large upfront investments and reduce financial risk.

Here are some key benefits of small-batch pricing:

| Benefit | Description |

|---|---|

| Flexibility in production | Small-batch models allow you to adapt to niche markets and changing demands, leading to cost savings. |

| Customized services | Tailored offerings can enhance customer satisfaction and loyalty, improving your cash flow. |

| Rapid prototyping | Quick response to market needs reduces time to market, enhancing your competitiveness. |

- In Asia, especially China, many PCBA Suppliers offer no minimum order quantity (MOQ) for small-batch production.

- You enjoy competitive pricing for low-volume orders, which is rare among European manufacturers.

- Some suppliers, such as Best Technology, implement a zero MOQ policy and waive Non-Recurring Engineering (NRE) fees for custom designs or prototyping.

Sanshun provides flexible small-batch solutions, helping you manage costs and scale production as your business grows.

Logistics and Overhead Savings

You save more than just labor costs when you work with PCBA Suppliers in Asia. Efficient logistics networks and streamlined supply chains reduce your overhead. You avoid high setup costs and benefit from integrated shipping solutions.

- Asian suppliers often have established logistics partnerships, ensuring timely delivery and lower transportation expenses.

- You minimize management overhead by relying on suppliers who handle procurement, assembly, and shipping.

- Choosing manufacturers in China can make small-batch production more affordable and accessible.

Sanshun leverages its expertise in logistics to help you optimize your supply chain. You receive your products faster and at a lower cost, allowing you to focus on your core business.

Production Flexibility

Fast Turnaround Times

You need your products delivered quickly to stay ahead in the market. Asian PCBA Suppliers excel at fast turnaround times, giving you a competitive edge. Their streamlined processes and high production capacities allow you to receive completed assemblies much faster than you would from European manufacturers.

- Asian suppliers, especially in China, are recognized for rapid delivery and efficient production cycles.

- European manufacturers often struggle with declining profits and increased competition, which can slow down their response times.

- You benefit from suppliers who prioritize speed and reliability, helping you meet tight deadlines.

Note: Sanshun’s efficient workflow ensures you receive your orders on time, reducing delays and keeping your projects on schedule.

Rapid Prototyping

You often need prototypes to test new ideas or launch products quickly. Asian PCBA Suppliers support rapid prototyping, helping you move from concept to reality in days rather than weeks.

- Simple projects can be completed in as little as 1 to 10 days.

- Complex designs may take up to 4 weeks, but effective communication and planning with your supplier can prevent delays.

- Companies like myProto offer fast PCB assembly services, with standard delivery in five working days. If you need even faster results, expedited options are available.

| Project Type | Typical Completion Time |

|---|---|

| Simple Prototype | 1-10 days |

| Complex Prototype | Up to 4 weeks |

Tip: Sanshun’s prototyping services help you validate designs quickly, so you can launch products faster and minimize risk.

Adaptable Scheduling

You must adjust your production schedules to respond to market changes and customer demands. Asian PCBA Suppliers offer adaptable scheduling, allowing you to scale production up or down as needed.

- You can request changes to order quantities or delivery dates without facing heavy penalties.

- Flexible scheduling helps you manage inventory and cash flow more effectively.

- You gain the ability to respond to urgent orders or seasonal fluctuations with ease.

Callout: Sanshun’s customer support team works with you to create a production plan that fits your business needs, ensuring flexibility at every stage.

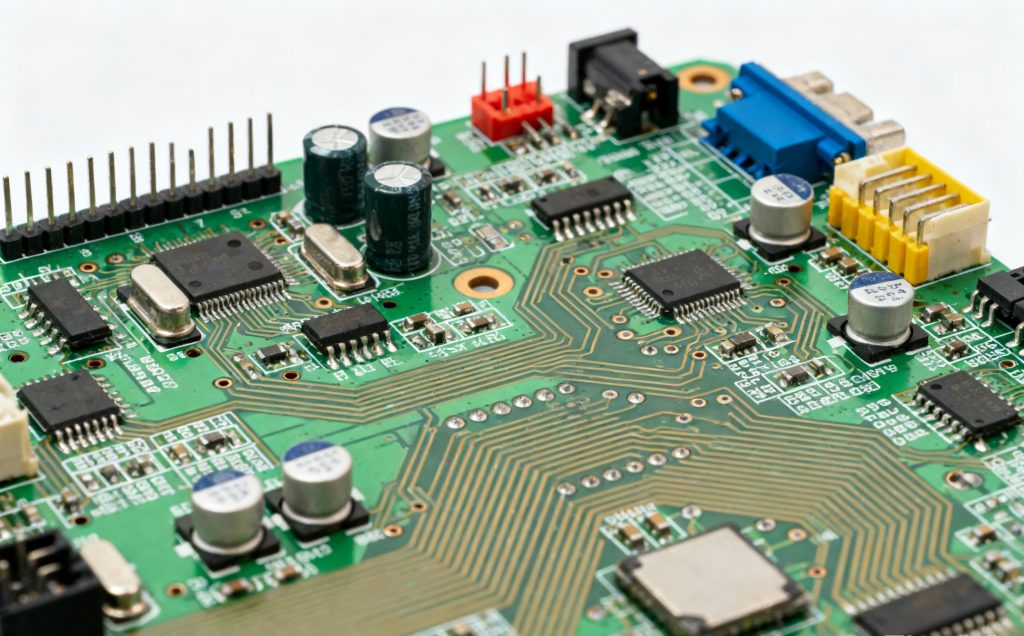

Quality Assurance from PCBA Suppliers

You want assurance that your products meet the highest quality standards. Leading PCBA Suppliers in Asia address your concerns by following strict international guidelines and using advanced testing methods. You can trust that your assemblies will perform reliably in demanding applications.

International Standards Compliance

You benefit when your supplier holds recognized certifications. These certifications show a commitment to quality and process management. Most top suppliers meet the following standards:

| Certification | Description |

|---|---|

| ISO 9001 | Reflects commitment to quality and process management. |

| ISO 13485 | Ensures reliability and safety in medical devices. |

| IPC-A-610 | Defines quality requirements for PCBA assembly. |

You should always check for these certifications. They guarantee that your supplier follows best practices for manufacturing and inspection.

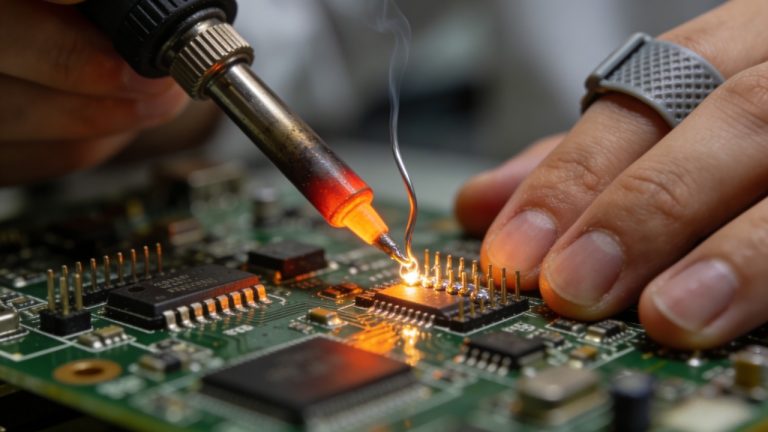

Advanced Testing Processes

You need your products to work right the first time. Asian suppliers use advanced testing to catch defects early and ensure reliability. Common testing methods include:

- Burn-in testing to identify early-life failures.

- EMC/EMI testing for electromagnetic compatibility.

- Boundary scan (JTAG) for complex boards.

- Environmental stress screening (ESS) to simulate real-world conditions.

- Thermal cycling and vibration testing for durability.

- Statistical process control (SPC) to monitor quality trends.

Tip: Ask your supplier about their inspection methods. Automated Optical Inspection (AOI), X-ray, and In-Circuit Testing (ICT) are essential for fast, accurate results.

Quality Commitment by Sanshun

You gain peace of mind when you choose a supplier like Sanshun. Sanshun matches or exceeds industry benchmarks for quality control:

| Quality Control Aspect | Description |

|---|---|

| Zero-Defect Production | Automated inspection and skilled technicians ensure flawless boards. |

| Real-Time Monitoring | Continuous oversight prevents errors during assembly. |

| Staff Training | Ongoing training keeps teams up to date on best practices. |

| Root Cause Analysis | Systematic elimination of recurring issues. |

You can rely on Sanshun’s robust quality systems and international certifications to deliver consistent, high-quality results for your business.

Integrated Services and Supply Chain Control

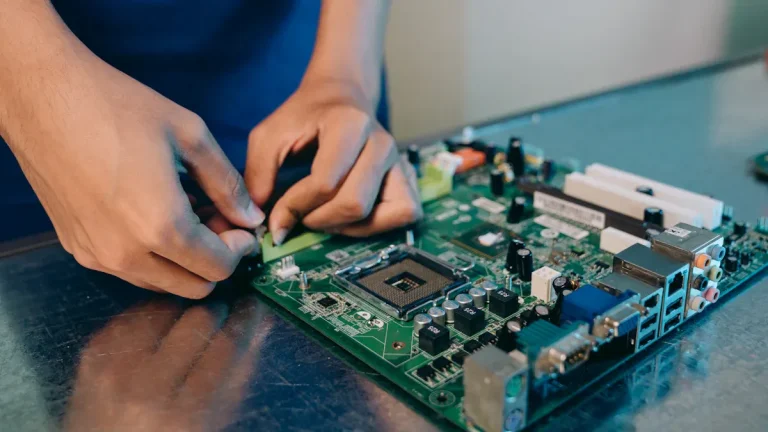

One-Stop PCBA Solutions

You want a supplier who can handle every step of your project, from design to delivery. Asian PCBA Suppliers offer one-stop solutions that simplify your workflow and reduce management overhead. You gain access to a full suite of services, including PCB manufacturing, component sourcing, assembly, and testing. This approach streamlines your process and minimizes the need to coordinate with multiple vendors.

| Component/Service | Details |

|---|---|

| Assembly Types | Surface mount (SMT), Through-hole (DIP), Mixed technology (SMT & Thru-hole) |

| Quality Grade | IPC-A-610 |

| SMT Capacity | 3 Million~4 Million Soldering Pad/day |

| DIP Capacity | 100 Thousand Pins/day |

| Lead Time | 24-hour expedited service; 3-4 days for PCBA prototype orders |

| Quality Assurance | ISO 9001:2015 and IATF 16949 compliant; UL, REACH, RoHS, and CQC certified |

| Testing Services | AOI, Function Testing, In-Circuit Testing, X-Ray for BGA Testing, etc. |

| Shipping | 99% on-time shipping by DHL; 24-hour online customer service; delivery in 3-5 days |

Sanshun delivers end-to-end solutions, allowing you to focus on your core business while they manage the technical details.

Simplified Supply Chain Management

You need efficient supply chain control to avoid delays and reduce costs. Integrated services from Asian suppliers help you manage your supply chain with advanced tools and platforms. You benefit from digital supply networks, predictive analytics, and smart manufacturing systems that optimize material flow and minimize risks.

| Tool/Platform | Description |

|---|---|

| Benchmark | Data-driven systems to manage materials effectively, minimizing costs and supporting customer requirements. |

| Jabil | Global sourcing teams identify optimal suppliers and components, leveraging market intelligence for cost efficiency and risk mitigation. |

| Auspi | Local presence for consignment agreements, allowing quick reaction to requirement fluctuations. |

| BestPCBs | End-to-end solutions from design assistance to functional testing, improving project efficiency and reducing multi-supplier coordination costs. |

Note: The COVID-19 pandemic forced many European SMEs to rethink their supply chain strategies. You now rely on collaboration, multi-sourcing, and supplier diversification to build resilience against disruptions.

Skilled Labor and Technology Access

You want your products built by skilled professionals using advanced technology. Major Asian hubs offer competitive labor markets and invest heavily in workforce training. You benefit from government incentives and partnerships with educational institutions that enhance employee skills. Companies like Sanshun adopt English as their working language and position engineers fluent in Chinese on the production floor to ensure smooth communication.

- Asian suppliers invest in technical training programs to address skill gaps.

- Ongoing equipment upgrades keep pace with rapid technological changes.

- Advanced manufacturing capabilities in regions like South Korea and Japan support high-quality production, while China and India focus on cost efficiency.

Tip: When you choose a supplier with strong training and technology programs, you ensure your products meet global standards and stay competitive.

You choose Asia-based PCBA suppliers for several key reasons:

- Cost advantages, especially for small-batch production.

- Flexible delivery and rapid turnaround.

- Controllable quality through rigorous inspection.

- One-stop service that streamlines your management.

Outsourcing to Asia helps you save up to 30% on manufacturing costs, letting you offer competitive prices and expand your market share. Diversifying your supply chain also protects your business from disruptions. Advanced technologies used by suppliers like Sanshun ensure consistent quality and reliability. You stay competitive and resilient in a changing global market when you partner with trusted experts.

FAQ

What is PCBA outsourcing?

You hire a supplier to assemble printed circuit boards for your products. This process saves you time and money. You focus on design and sales while experts handle manufacturing.

How do Asian PCBA suppliers ensure quality?

You receive products that meet strict international standards. Suppliers use advanced testing, such as AOI and X-ray inspection. You can request certifications like ISO 9001 or IPC-A-610.

Why should you choose Sanshun for PCBA services?

You benefit from Sanshun’s proven expertise and global certifications. Their team delivers reliable quality, fast turnaround, and flexible solutions. You gain a trusted partner for your manufacturing needs.

Can you order small batches from Asian PCBA suppliers?

You can order small quantities without high costs. Many suppliers offer no minimum order requirements. You test new products or serve niche markets with ease.

How does outsourcing PCBA help you manage supply chain risks?

You diversify your supply chain and reduce disruptions. Asian suppliers provide integrated services and strong logistics. You build resilience against global events and market changes.