You gain a clear advantage when you choose PCBA China for your manufacturing needs in 2025. Global OEMs rely on this region because it leads the world, holding 59% of the global PCB production market. When you partner with top suppliers such as Sanshun, you benefit from:

- Competitive cost efficiency and flexible pricing

- Advanced technical capabilities and fast turnaround

- Robust, integrated supply chain and proven quality standards

PCBA assembly in China stands out for its ability to deliver reliable results, driven by experience and international certifications. You can trust China PCBA suppliers to help you meet market demands and manage your PCBA cost effectively.

Why PCBA China Strengthens Your Manufacturing Competitiveness

- Choosing PCBA China offers significant cost savings, with prices 30%–80% lower than other regions, enhancing your product’s competitiveness.

- Chinese suppliers provide fast turnaround times and flexible production capabilities, allowing you to respond quickly to market demands.

- Partnering with leading PCBA factories in China ensures access to advanced technology and skilled labor, improving product quality and efficiency.

- Reliable logistics and proximity to global manufacturing centers streamline your supply chain, reducing transportation costs and delivery times.

- Building long-term partnerships with trusted Chinese suppliers secures consistent quality and support for your manufacturing needs.

PCBA Cost and Scalability

Competitive Pricing in PCBA China

You gain a significant advantage when you choose pcba assembly China for your projects. The region offers unmatched competitive pricing, which directly impacts your bottom line. When you compare average PCBA cost across major regions, the difference becomes clear:

| Region | Cost Range (Total) | Cost per Unit (pc) | Cost per Unit (Assembly) |

|---|---|---|---|

| China | $60–$110 | $0.90–$1.50 | $0.35–$0.75 |

| Germany | $120–$180 | $2.00–$3.20 | $1.20–$2.20 |

| USA | $150–$250 | $2.50–$3.80 | $1.50–$3.00 |

You benefit from cost reductions of 30%–80% compared to other regions. This cost efficiency allows you to improve your product’s competitiveness and increase profit margins. Chinese PCBAs achieve these results through systematic automation and a skilled workforce. Even as labor rates rise, they remain lower than in Western countries, supporting affordable manufacturing for global OEMs.

High-Mix, High-Speed Production

You need flexibility and speed to stay ahead in today’s market. PCBA assembly china delivers both. The advanced infrastructure in China supports high-mix, high-speed production, meeting the needs of diverse industries. The global pcba market is projected to reach $79.95 billion by 2025, with China holding a 50% share. You can rely on china pcba suppliers to handle complex, multilayer pcba orders efficiently. Automation and optimized production flows ensure that you receive fast turnaround without sacrificing quality or standards.

Tip: Choosing a pcba factory in China gives you access to advanced technology and rapid scaling for new product launches.

Large-Scale Capacity for OEMs

You can trust PCBA assembly China to manage large-scale orders with ease. Chinese manufacturers have expanded their capacities to meet rising global demand. They invest in automation, high-precision equipment, and regional supply chains to reduce lead times. This approach ensures that you receive consistent quality and timely delivery, even for high-volume projects. The skilled workforce and robust quality management systems, including rigorous testing and international certifications, guarantee that your products meet the highest standards.

- OEM production in China is known for speed, cost-effectiveness, and scalability.

- Low labor costs and advanced automation support large orders without compromising efficiency or quality.

When you partner with leading China PCBA suppliers, you secure a reliable foundation for your global manufacturing strategy.

Advanced Technology in PCB Assembly China

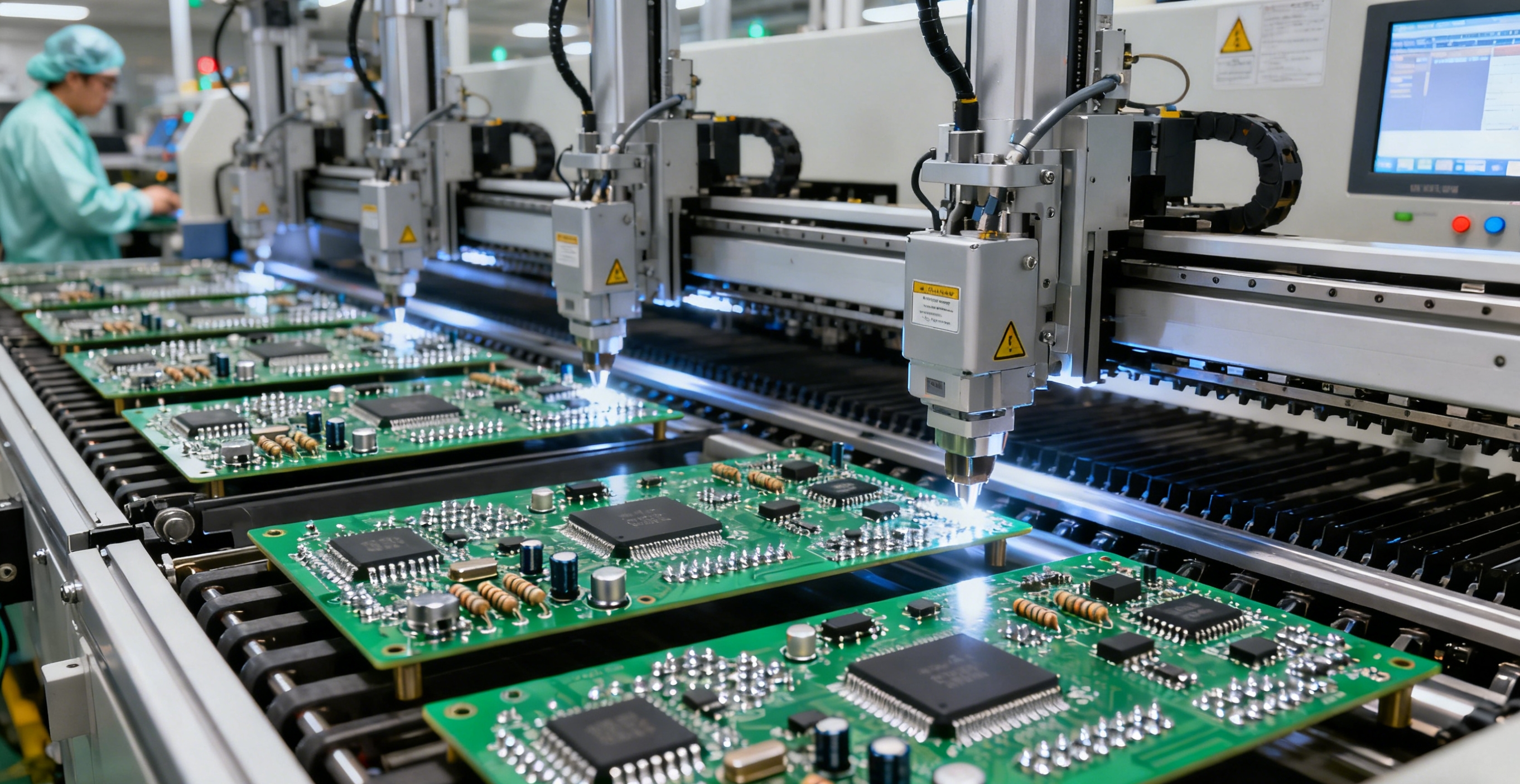

Cutting-Edge Manufacturing

You experience the benefits of cutting-edge manufacturing when you choose PCBA assembly in China. Leading PCBA China suppliers invest in advanced technology to deliver precise and efficient assembly. The latest advancements drive the global pcba industry forward. You see improvements in speed, accuracy, and sustainability. The table below highlights key innovations adopted by top China PCBA factories:

| Advancement Type | Description |

|---|---|

| Automation and AI in SMT Assembly | AI enhances the speed and accuracy of SMT assembly, improving precision and reducing errors. |

| Miniaturization and High-Density PCBs | Smaller, high-density PCBs are now prevalent in smartphones, healthcare, and wearables. |

| Green Manufacturing & Sustainability | Focus on eco-friendly production methods, including recyclable materials and reduced hazardous chemicals. |

| Industry 4.0 & Smart Factories | IoT and data analytics are making PCB factories smarter, allowing for real-time monitoring and efficiency. |

Note: Automation and smart manufacturing practices in pcb assembly china help you reduce pcba cost and improve product quality.

Skilled Labor Force

You benefit from a skilled labor force in pcba assembly China. Chinese pcba factories invest in training and development, ensuring workers master advanced assembly techniques. Nearly half of the world’s robot installations occur in China, reshaping the industrial landscape. You gain faster production, improved quality, and reduced lead times. The shift toward automation supports consistency and speed, making China PCBA Suppliers highly competitive.

- Chinese pcba factories use robotics and automation to deliver reliable results.

- Rising labor costs drive innovation and efficiency in assembly processes.

Innovation in the Global PCB Industry

You see continuous innovation in pcba assembly china. Chinese pcba companies invest in R&D, producing high-density interconnect and multilayer boards. Flexible pcba meet the demand for smaller, more efficient electronics. You benefit from quick line changeover, NPI capability, and DFM services, which accelerate production and optimize design. Government policies in Shenzhen and across China support the development of new pcba technologies, making the region a leader in the global pcba industry.

Tip: Partnering with a pcba factory in china gives you access to advanced technology, skilled labor, and innovative solutions for your assembly needs.

Supply Chain Strength

Integrated Logistics

You benefit from integrated logistics when you choose pcba assembly china for your manufacturing needs. China’s efficient manufacturing processes and robust infrastructure enable you to bring products to market faster. This speed is essential for global OEMs who need timely delivery and flexibility. The well-established logistics network in China supports quick turnaround times for pcba assembly china, helping you respond rapidly to changing market demands. You can rely on a dense network of suppliers, manufacturers, and logistics providers that offer end-to-end pcba production solutions. This network ensures you receive reliable pcba assembly and consistent quality, even when you face sudden increases in demand.

Here are some logistics solutions commonly used by Chinese suppliers:

| Logistics Solution | Description |

|---|---|

| Advanced Tracking Systems | Integration of MES systems and full digital tracking ensures every batch is traceable, reducing miscommunication and improving product consistency. |

| EMS Models | The use of build-to-stock (BTS), build-to-order (BTO), and configure-to-order (CTO) models helps optimize production and delivery. |

| Lean Production Practices | Implementation of RFID tracking and barcode scanning minimizes waste and accelerates output. |

| Global Shipping Support | Services like DHL are utilized for timely deliveries worldwide, ensuring efficient logistics. |

Proximity to Global Centers

You gain a strategic advantage from the geographic proximity of Chinese pcba assembly suppliers to major global manufacturing centers. This location reduces transportation costs and shortens delivery times for your products. You can easily source raw materials and components because of the concentration of suppliers in the region. Factories in these areas have experience with international standards and demands, so you receive high-quality and timely production. The close connections between suppliers and manufacturers help you maintain a smooth supply chain and meet your project deadlines.

Tip: Choosing a pcba china partner near global hubs helps you optimize your logistics and reduce overall pcba cost.

Reliable Partnerships with China PCBA Suppliers

You secure long-term value when you build reliable partnerships with leading china pcba suppliers. Companies like Sanshun set the benchmark for quality and service in the industry. These suppliers hold quality system certifications and offer strong engineering and technical support. You benefit from robust supply chains and comprehensive testing capabilities that ensure your products meet strict standards. Many global OEMs, including Fortune 500 electronics companies, maintain long-term cooperation with top Chinese suppliers. They address common challenges such as supply chain disruptions and quality assurance by diversifying their supplier base, conducting regular audits, and working with experienced freight forwarders. When you choose a trusted pcba factory in China, you gain a partner committed to your success and the delivery of reliable pcb assembly.

Quality and High-Quality Standards

Quality Control in PCBA China

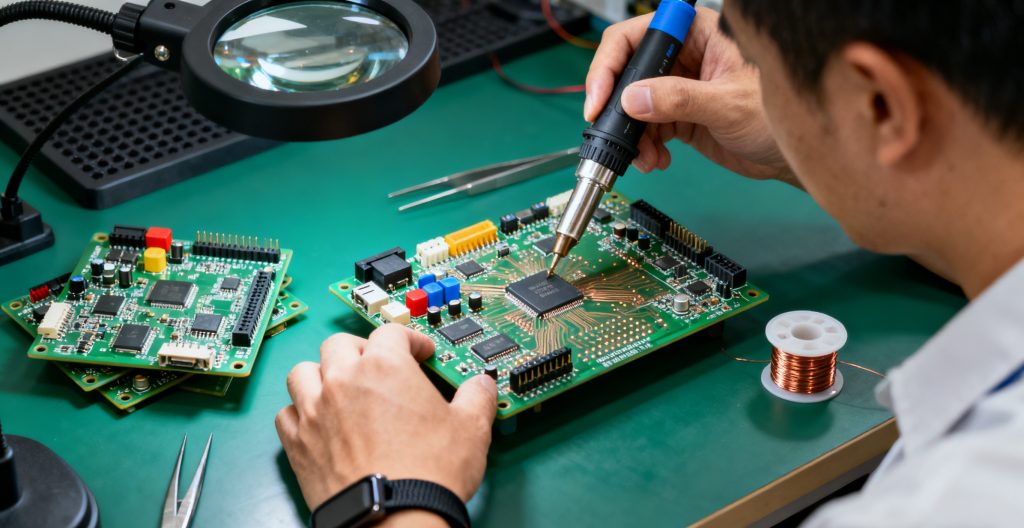

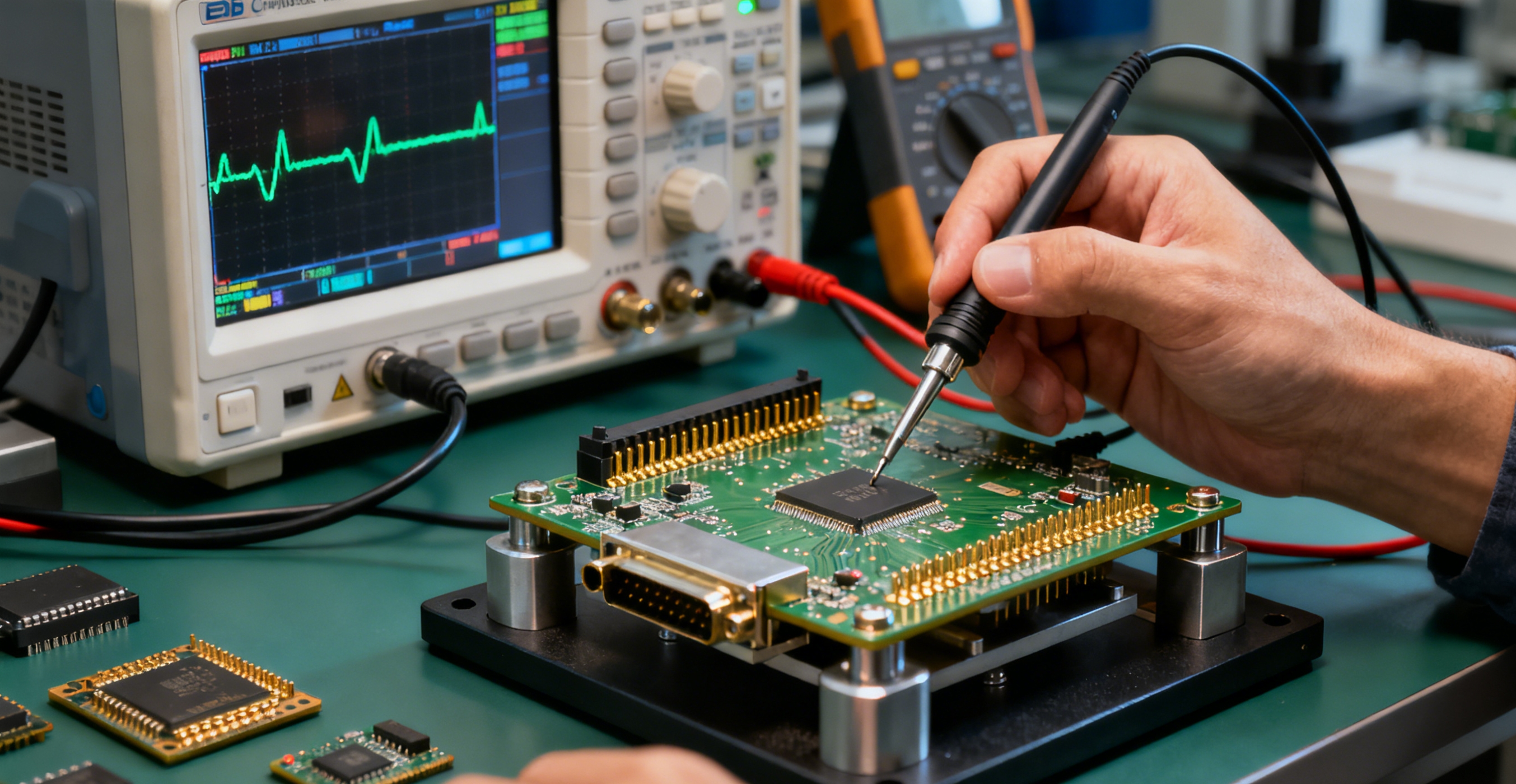

You expect high-quality standards when you choose pcba assembly china for your projects. Leading pcba china suppliers use advanced technology and strict processes to guarantee quality. You see automatic printing presses and high-speed placement machines in every modern PCBA factory. These facilities implement AOI and X-ray detectors for thorough testing. You benefit from long-term cooperation with suppliers, which ensures reliable procurement of components and consistent assembly results.

- Strict SOP specifications and IPC electronic acceptance standards guide every step.

- ESD anti-static control requirements protect sensitive printed circuit boards during production.

- Common issues like welding and material shortages receive careful attention.

Note: Real-time tracking systems and MES platforms monitor every stage, improving efficiency and quality.

| Quality Control Method | Description |

|---|---|

| Automated Inspection Equipment | AOI, SPI, and X-ray systems detect soldering quality and internal defects. |

| Functional and Circuit Testing | ICT and FCT confirm every pcba functions as designed. |

| International Certification Systems | Compliance with ISO, IPC, and RoHS standards ensures high-quality production. |

| Real-time Tracking Systems | MES systems trace production records and support quality audits. |

International Certifications

You gain confidence in pcb assembly china because suppliers comply with international quality standards. Top china pcba suppliers hold certifications such as ISO 9001, ISO 14001, ISO 45001, ISO 13485, and IATF 16949. These standards support high-reliability programs in the global pcba industry. You see compliance with RoHS and WEEE regulations, which ensures environmental safety and product quality. Suppliers adopt lead-free soldering processes and eco-conscious materials to meet global requirements.

- Compliance with international environmental regulations like RoHS.

- Adoption of lead-free soldering to reduce health risks.

- Use of recyclable materials and advanced waste management practices.

Tip: Regular environmental awareness training and safety culture programs help maintain high-quality standards and protect your investment.

| Compliance Area | Practices |

|---|---|

| Personnel Safety | Training and PPE for safe handling of hazardous materials. |

| Equipment Safety | Routine maintenance and safety signage in production areas. |

| Chemicals and Materials Management | Proper labeling, storage, and disposal of chemicals. |

| Static Electricity Control | ESD protection measures for sensitive pcba components. |

| Standards Compliance | Adherence to RoHS, IPC, and ISO standards for quality and safety. |

| Documentation and Tracking | Detailed records for traceability and quality audits. |

Consistency in PCB Assembly China

You rely on pcba assembly china for consistent quality and reliable results. Advanced soldering techniques ensure robust connections and prevent heat-related damage. Comprehensive inspection systems, including AOI, X-ray, and functional testing, deliver defect-free assemblies. Digital MES and traceability systems assign unique IDs to every pcba, tracking materials, operators, and inspections. Multi-stage quality control, from IQC to final inspection, guarantees every board meets specifications.

- China pcba suppliers maintain high-quality standards through continuous improvement.

- You benefit from consistent assembly results, reduced pcba cost, and efficient production cycles.

- The global pcba industry recognizes China for its commitment to quality and reliability.

Callout: Choosing a pcba factory in China gives you access to high-quality production, advanced technology, and proven testing methods.

Speed and Flexibility

Quick Turnaround Times

You need fast delivery to stay ahead in the global market. Chinese pcb assembly china suppliers excel at quick turnaround times, thanks to advanced infrastructure and streamlined processes. When you compare average delivery times, you see that leading Chinese providers like PCBWay and JLCPCB offer some of the fastest results in the industry.

| Supplier | Total Time |

|---|---|

| OSHPark | 13 days |

| PCBWay | 16 days |

| JLCPCB | 20 days |

You benefit from this efficiency, which helps you reduce time-to-market and respond quickly to customer needs. These short lead times, combined with cost-effective solutions, give you a strong competitive edge.

Agile Response to OEM Needs

You face changing requirements and tight deadlines in every project. China pcba suppliers demonstrate agility by using advanced technology and strong engineering support. They work closely with you to resolve technical challenges and optimize your designs before production. Effective communication ensures you receive regular updates and quick responses, keeping your projects on track.

- Customer-centric approach

- Commitment to quality and innovation

- Rigorous testing and quality assurance

You can rely on their expertise and flexible processes to adapt to your evolving needs. This agility supports your business growth and helps you maintain high standards in every assembly.

Customization from China PCBA Factories

You require tailored solutions to meet your unique product goals. Leading china pcba factories offer a wide range of customization options, from minor adjustments to full turnkey pcb assembly. You can request custom logos, packaging, and graphics with minimum order requirements as low as 300 pieces.

| Customization Type | Minimum Order Requirement |

|---|---|

| Customized logo | 300 pieces |

| Customized packaging | 300 pieces |

| Graphic customization | 300 pieces |

| Supplier’s customization ability | N/A |

| Minor customization | N/A |

| Drawing-based customization | N/A |

| Sample-based customization | N/A |

| Full customization | N/A |

You also gain access to specialized services such as PCB layout and schematic design, wireless charger ODM, multi-layer pcba board production, and final product assembly. These options ensure you receive cost efficiency, substantial cost savings, and competitive pricing while maintaining high quality and compliance with international standards.

Tip: Partnering with a pcba factory in China gives you the flexibility to scale production and customize products for different markets.

You secure a competitive edge when you choose a China PCBA partner. Leading global electronics brands benefit from proven technical capabilities, integrated supply chains, and consistent quality. Recent case studies show that a medical device manufacturer achieved zero-defect assembly of a 14-layer rigid-flex PCB in just 10 days, while a large-format LED project demonstrated adaptability and high standards.

| Case Study Description | Key Takeaway |

|---|---|

| Medical device manufacturer achieving zero-defect assembly of a 14-layer rigid-flex PCB in 10 days | Precision and efficiency in meeting stringent quality requirements and tight deadlines |

| Large-format LED lighting panel project with custom equipment modifications | Expertise and adaptability in handling complex requirements while maintaining high-quality standards |

You should evaluate pcba cost, technical capabilities, and supplier reliability when selecting among china pcba suppliers or a pcba factory for your next project.

FAQ

What factors influence PCBA cost in China?

You see PCBA cost is affected by order volume, board complexity, component sourcing, and testing requirements. Choosing a reliable china pcba supplier helps you optimize expenses and maintain quality.

How do I select the right PCBA factory for my project?

You should evaluate technical capabilities, certifications, turnaround times, and customer support. Leading pcba factories in China offer advanced automation and strict quality control, ensuring consistent results for global OEMs.

Can China PCBA suppliers handle high-mix, low-volume orders?

You benefit from flexible production lines in China. Top china pcba suppliers use smart manufacturing to manage high-mix, low-volume projects efficiently, supporting rapid prototyping and product launches.

What certifications should I look for in a PCBA factory?

You should check for ISO 9001, ISO 14001, IPC, and RoHS compliance. These certifications confirm that the pcba factory meet international standards for quality, safety, and environmental responsibility.

How fast can I expect delivery from China PCBA suppliers?

You typically receive PCBA orders within 7–20 days, depending on complexity and customization. Efficient logistics and integrated supply chains help China PCBA suppliers deliver quick turnaround times.