When you choose a partner for your PCBA project, you need to weigh several critical factors. Focus on the process each PCBA manufacturer uses to ensure quality, from inspection and testing to advanced engineering controls. The table below shows how leading companies manage this process at every time point:

| Criteria | Description |

|---|---|

| Inspection and Testing Processes | Quality checks at every time to maintain consistent results. |

| Incoming PCB Lot Testing | Verifies copper and surface finish thickness each time for reliability. |

| Environmental Stress Screening | Identifies failures ahead of time to protect your brand and reduce risk. |

| Advanced Metrology and Engineering | Maintains accuracy every time to prevent defects and ensure your design fits perfectly. |

Your process should start with clear communication about your needs every time. Take time to align your expectations and set a process that ensures success from the first time you engage with a manufacturer.

Key Guidelines for Choosing a Reliable PCBA Manufacturer

- Define your project needs clearly. This includes understanding the type of electronics, production volume, and technical requirements to avoid misunderstandings.

- Evaluate potential manufacturers based on quality and certifications. Look for industry standards like ISO 9001 and IPC-A-610 to ensure reliability.

- Assess assembly capabilities. Ensure the manufacturer can handle your design complexity and offers comprehensive testing to meet your project demands.

- Consider cost versus value. Focus on the overall value provided by the manufacturer, including quality, timely delivery, and support, rather than just the lowest price.

- Prioritise strong customer support. Choose a manufacturer that communicates effectively and responds quickly to your inquiries to keep your project on track.

Define Your Electronics Project Needs

Before you select a PCBA manufacturer, you must clearly define your project requirements. This step ensures you communicate your expectations and avoid costly misunderstandings.

PCBA Type and Volume

Start by identifying the type of electronics you plan to produce. Different industries require different assembly approaches. For example, a prototype circuit board for a medical device will have different requirements than one for a consumer gadget. The table below highlights common applications across industries:

| Industry | Examples of Applications |

|---|---|

| Consumer Electronics | Smartphones, tablets, laptops, and game consoles |

| Automotive | Engine control units, infotainment systems, and ADAS sensors |

| Industrial Automation | PLCs, motor drives, robotics controllers |

| Telecommunications | 5G base station modules, network routers, optical transceivers |

| Aerospace & Defense | Avionics, radar systems, and missile guidance |

| Medical Devices | Patient monitors, infusion pumps, diagnostic equipment |

You should also estimate your production volume. Manufacturers often categorise orders as prototype circuit board runs, medium batches, or high-volume production. This distinction affects both pricing and process.

Timeline and Delivery

Set a realistic timeline for your project. You need to match your schedule with the manufacturer’s capabilities. The table below outlines typical lead times based on order volume:

| Order Volume | Typical Lead Time |

|---|---|

| Prototypes (5–10 units) | 1–5 business days |

| Medium Runs (100–500 units) | 7–10 business days |

| High-Volume (1,000+ units) | 14–20 business days |

Tip: Always confirm the manufacturer’s delivery reliability. Delays can disrupt your launch and increase costs. Ask about their track record for on-time delivery and how they handle urgent requests.

Technical Requirements

List your technical needs in detail. These requirements guide the manufacturer’s process and ensure your product meets industry standards. Common technical considerations include:

- Thermal stability and mechanical strength

- Selection of passive and active components

- Solder and flux types

- Design for manufacturability and testability

- Signal integrity and quality assurance

- Environmental compliance

| Requirement Type | Description |

|---|---|

| Thermal stability | Materials must withstand assembly and operational temperatures. |

| Mechanical strength | Supports heavy or high-density components. |

| Cost considerations | High-performance substrates are more expensive but necessary for advanced applications. |

| Passive components | Resistors, capacitors, and inductors that do not require power to operate. |

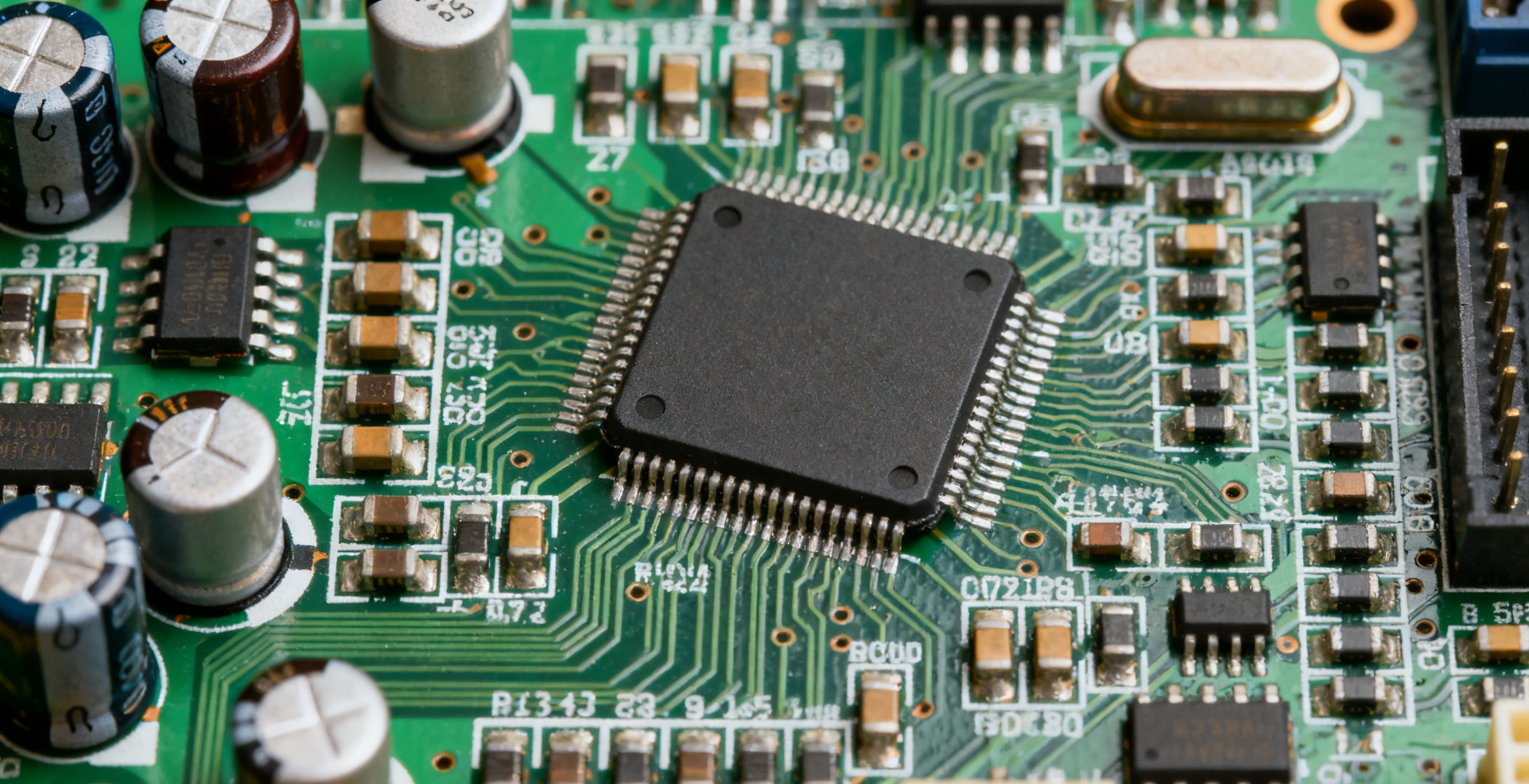

| Active components | ICs, transistors, diodes, and microcontrollers that require power and perform functions such as amplification or computation. |

| Solder and flux types | Essential for creating strong electrical and mechanical connections. |

| Design for Manufacturability | Focuses on creating PCB designs that are easy and cost-effective to manufacture while minimising assembly errors. |

| Design for Testability | Ensures that boards can be easily tested and troubleshooted during production and maintenance. |

| Signal Integrity | High-frequency or high-speed boards require careful design to maintain signal integrity. |

| Quality Assurance | High-quality PCBA requires rigorous quality assurance practices. |

| Environmental Compliance | Adhering to environmental and regulatory standards ensures legal compliance and sustainability. |

By defining these needs, you set a strong foundation for successful collaboration and timely delivery.

Key Criteria for PCBA Manufacturer Selection

Choosing the right PCBA manufacturer for your electronics project requires a systematic approach. You need to evaluate several core criteria to ensure your project achieves high quality, meets deadlines, and stays within budget. Prioritise your project’s unique needs and communicate them clearly to your manufacturing partner. This section outlines the most important factors to consider.

Quality and Certifications

You should always start by assessing the quality and certifications of a potential PCBA manufacturer. High-quality standards are non-negotiable if you want to avoid costly failures and ensure your product’s reliability. Leading manufacturers implement rigorous quality control processes at every stage of production.

| Quality Control Process | Description |

|---|---|

| AQL Testing | Involves testing a sample from a batch to determine if it meets acceptable quality limits. |

| First Article Approval | The manufacturer inspects the first unit produced to ensure the manufacturing process is functioning correctly. |

| Quality Engineer On-Site | A dedicated engineer oversees the assembly process to prevent mistakes and ensure high-quality output. |

| Risk Management | Involves planning for potential problems to avoid costs associated with fixing issues. |

| Choosing a PCB Team with Standards | Ensures the manufacturer has a commitment to quality assurance, fostering trust in the client-manufacturer relationship. |

Certifications serve as proof of a manufacturer’s commitment to quality and industry best practices. Look for the following certifications when evaluating a PCBA manufacturer:

| Certification | Description |

|---|---|

| ISO 9001 | Quality management system |

| IATF 16949 | Automotive quality management |

| UL | Safety certification |

| IPC-A-610 | Acceptability of electronic assemblies |

A manufacturer with these credentials demonstrates experience and industry reputation. You can trust them to deliver high-quality pcba and maintain compliance with global standards.

Assembly Capabilities

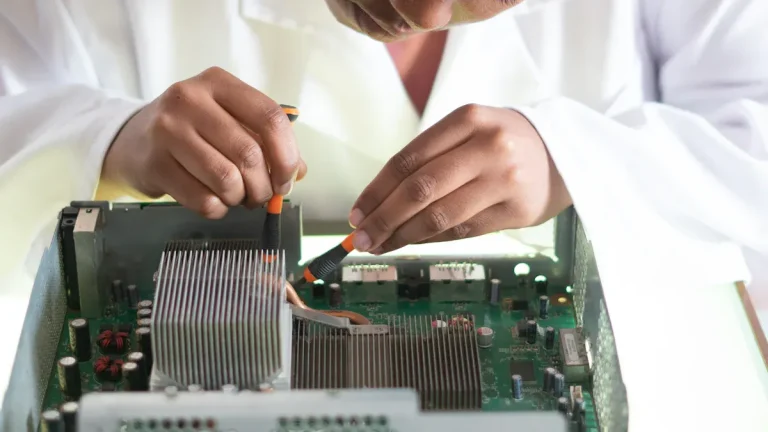

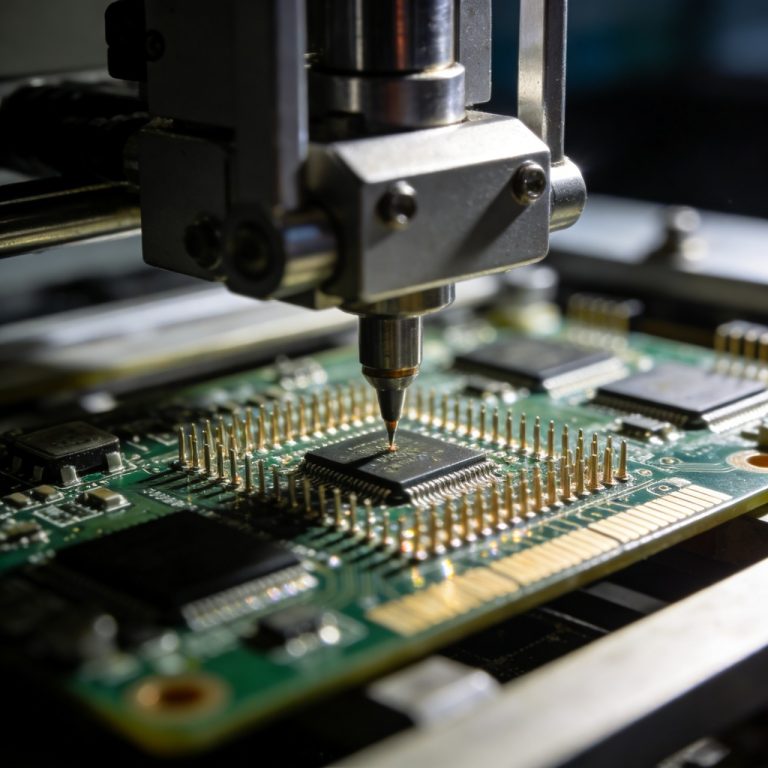

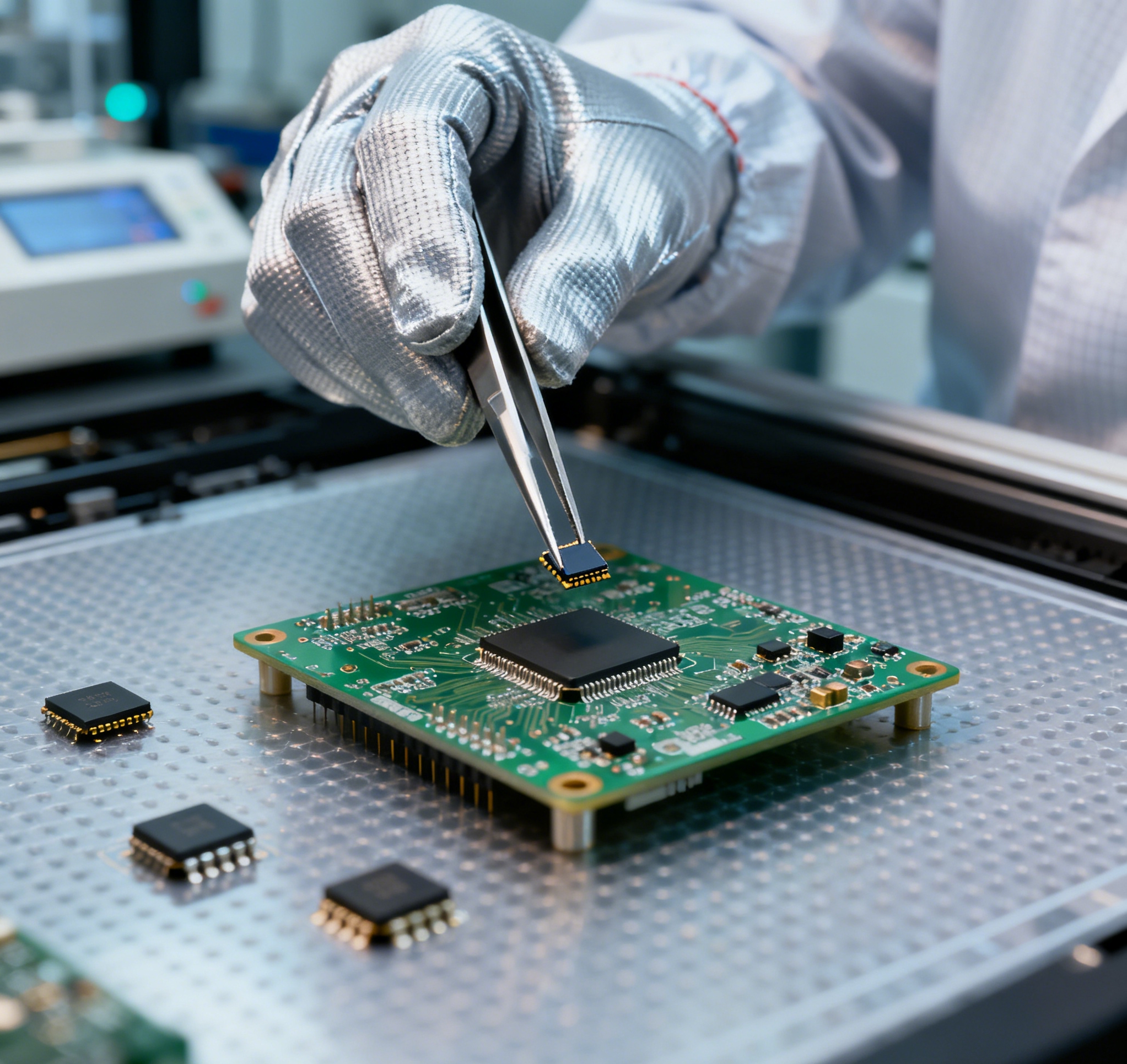

Evaluate the assembly capabilities of each PCBA manufacturer you consider. Your project may require advanced techniques or specialised equipment, especially if you need a high-reliability pcba or quick-turn pcbas for rapid prototyping.

Celestica offers advanced reverse engineering services for high-complexity applications, utilizing state-of-the-art equipment like 3D scanning and high-resolution imaging. Advanced Circuits combines software tools and manual inspection for PCB analysis and reproduction, excelling in high-density and multi-layer designs. TTM Technologies employs tools like 3D X-ray and optical inspection for detailed PCB analysis, particularly beneficial for aerospace and automotive sectors.

You should also check if the manufacturer can handle your design’s complexity and provide comprehensive testing. Best practices include:

- Evaluate complexity to minimise unnecessary features while maintaining functionality.

- Standardise components and sizes to streamline procurement and assembly.

- Partner with proven assemblers to ensure high-quality standards across all processes.

- Design for testability from the outset to facilitate effective testing during production.

- Implement a mixed testing methodology to achieve high test coverage and identify issues early.

A manufacturer with robust assembly capabilities can deliver quick-turn pcba and adapt to your evolving technical requirements.

Cost vs. Value

Cost and pricing transparency play a major role in your decision. However, you should not focus solely on the lowest price. Instead, weigh the value you receive for your investment.

- The cost for PCB assembly typically ranges from $0.02 to $0.05 per square inch.

- Overall assembly prices can vary between $5 and $50 per board, depending on:

- Design complexity

- Component types

- Assembly quantity

- Assembly options (manual vs. automated)

- Additional services (testing, quality control)

- Lead time

- Quality

- Functionality

- Quantity

You gain more value from a manufacturer who offers high quality and affordable pricing, even if the initial quote is higher. Timely delivery, lead time reduction, and supplier quality all contribute to the total value. High-quality pcba prevent delays and reduce the risk of expensive rework or legal issues.

Lead Time and Logistics

Production and lead times directly impact your project’s success. You need a PCBA manufacturer who can meet your schedule and adapt to urgent requests. Reliable turnaround ensures you launch on time and keep your supply chain moving.

| Assembly Type | Lead Time |

|---|---|

| Prototype Assembly | 1–5 working days |

| Low-Volume Production | 5–10 working days |

| Medium to High Volume | 10–20 working days or more |

| Turnkey with Component Sourcing | 10–25 working days |

Manufacturers offer flexible production services and real-time visibility into your order status. Optimised supply chain management ensures seamless transitions from prototype to full-scale production.

| Logistics Solution | Description |

|---|---|

| Flexible Production Services | Tailored production services that maximise efficiency and reliability for various volume needs. |

| Real-Time Visibility | Proven supply chain execution that meets delivery schedules without compromise. |

| Optimised Supply Chain Management | Collaboration with clients to ensure seamless transitions from prototype to full-scale production. |

Integrated ERP and MES systems provide real-time order tracking and production scheduling. Centralised communication platforms enhance visibility and trust. Nearshoring options can further reduce disruptions and ensure a consistent production cycle.

Customer Support

Strong customer support sets top PCBA manufacturers apart. You need a partner who responds quickly to your questions and adapts to changes in your project. Fast turnaround on inquiries and technical support requests helps you avoid costly delays.

| Feature | Description |

|---|---|

| Response Time | Technical and Sales support requests are handled within 1 business day. |

| Urgent Requirements | Expedite options are often available for urgent requirements. |

| Service Type | Description |

|---|---|

| Turnaround Time | Rapid turnaround times without compromising on quality. |

| Urgent Needs | Services designed to meet urgent needs with speed and efficiency. |

| Delivery Option | Description |

|---|---|

| Rapid Prototyping | 24-hour rapid prototyping available. |

| Standard Delivery | Standard delivery time of 72 hours. |

| Expedited Delivery | Urgent orders can be delivered within 48 hours. |

A manufacturer with a strong reputation for customer support will help you navigate challenges and keep your project on track. Prioritise partners who offer clear communication, fast turnaround, and flexible solutions.

Tip: Always evaluate the manufacturer’s expertise, assembly capabilities, and quick-turn options. Prioritize your project’s unique requirements and communicate them clearly to ensure a successful partnership.

Questions for PCBA Manufacturer

When you evaluate a pcba manufacturer, you need to ask targeted questions that reveal their strengths and reliability. These questions help you understand their processes and ensure your project receives the attention it deserves.

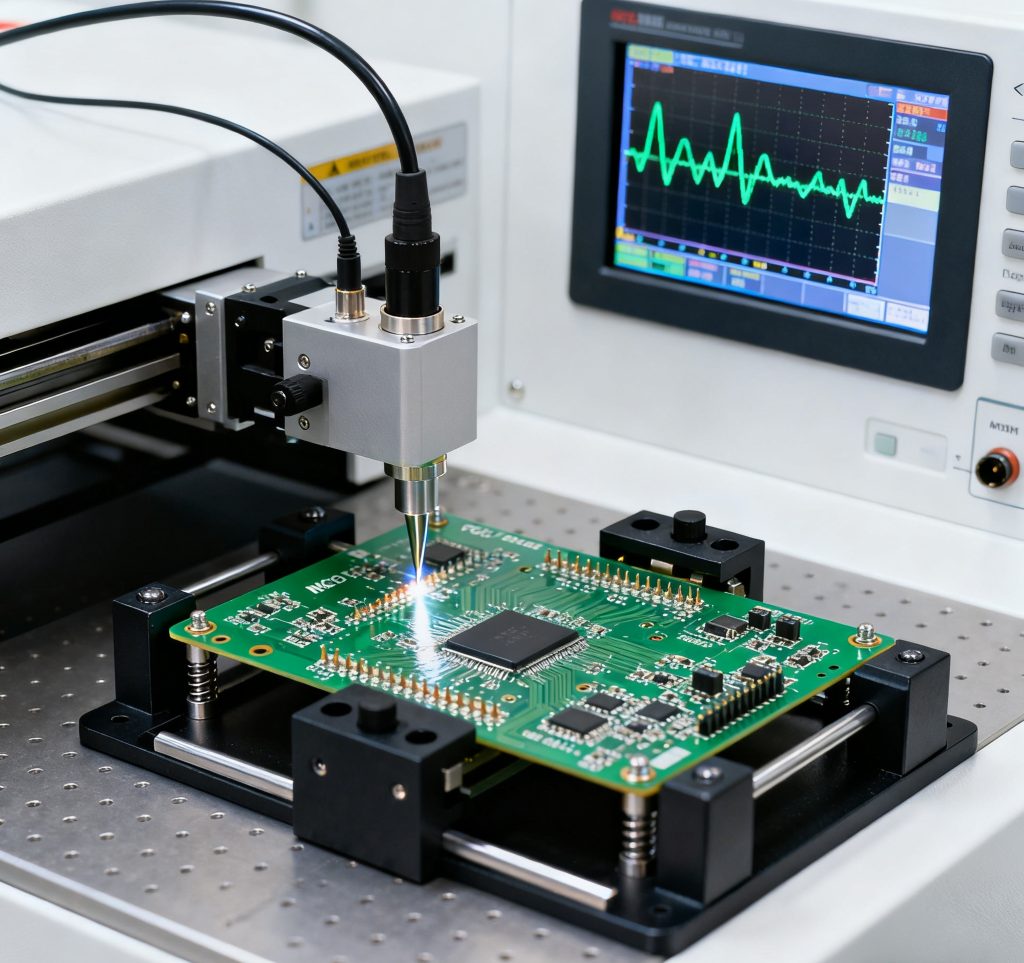

Quality Assurance Practices

Ask about the manufacturer’s approach to quality assurance. You want to know how they measure and control defects. The best companies use a combination of metrics and advanced testing methods.

| Quality Control Metric | Description |

|---|---|

| Defects Per Unit (DPU) | Measures the total number of defects found on a given board. |

| Defects Per Million Opportunities (DPMO) | Normalises the total amount of defects on one million boards of differing complexities. |

You should also inquire about their testing procedures:

- In-Circuit Testing (ICT)

- Flying Probe Test

- Functional Test

- Automated Optical Inspection (AOI)

- X-Ray Inspection

- Electrical Testing

- Visual Inspection

Request documentation on their quality assurance results. Leading manufacturers provide detailed reports, including pre-fabrication engineering reviews, incoming and in-process quality control, and final outgoing inspections.

Production Capacity

Determine if the manufacturer can handle your order volume and adapt to changes. Ask how they scale production for prototypes, medium batches, and high-volume runs. Top manufacturers use flexible toolkits and optimise design processes to transition smoothly from prototype to production. Effective supply chain management reduces risks and helps them respond quickly to market changes.

Communication and Responsiveness

Strong communication and customer service are essential for a successful partnership. Ask how the manufacturer keeps you updated on project status. Reliable companies provide regular progress reports and maintain transparency throughout the project lifecycle. You should also check their response time and support channels. Quick replies and proactive updates minimise delays and keep your project on track.

Tip: Multiple support channels and timely communication show a manufacturer’s commitment to your project.

Handling Design Changes

Design changes often occur during development. Ask about their change management procedures. The best manufacturers follow formal processes for evaluating, approving, and implementing changes.

| Process | Description |

|---|---|

| Change Management Procedure | Outlines steps for change requests, evaluations, approvals, and implementation. |

| Documentation Practices | Uses standardised templates and centralised repositories for change records. |

| Cross-Functional Collaboration | Holds regular meetings and uses collaboration tools for information sharing. |

| Change Control Mechanisms | Develops plans and conducts impact assessments for production. |

| Compliance and Quality Assurance | Reviews procedures to meet regulatory requirements and engages quality teams. |

| Leveraging Technology | Invests in change management software and data analytics to monitor impacts. |

Quick-turn assembly services allow manufacturers to adapt to last-minute modifications, reducing production timelines and supporting rapid product development.

Comparing the Best PCB Manufacturer Options

When you reach the stage of comparing the best pcba manufacturer options, you need a structured approach. Using a reliable benchmark like Sanshun Smart helps you set high standards for reliability and service. This section guides you through evaluating proposals, conducting site visits, and checking references to make the right choice.

Evaluating Proposals

You should compare proposals from each best pcba manufacturer using clear criteria. A side-by-side review helps you see which partner aligns with your project goals. Use the table below to organise your assessment:

| Criteria | Description |

|---|---|

| Quality | Check if the manufacturer meets industry standards and holds key certifications. |

| Cost | Review the pricing structure and look for transparency in all fees. |

| Delivery | Evaluate lead times and the reliability of delivery schedules. |

| Capabilities | Assess technical strengths and any limitations in assembly or testing. |

| Customer Reviews | Read feedback from previous clients to gauge satisfaction and long-term reliability. |

You should also consider factors like manufacturer capability limits, price versus lead time, and available materials. This process ensures you select the best pcba manufacturer for your specific needs.

Site Visits and Audits

A site visit gives you firsthand insight into the operations of each best pcba manufacturer. During your visit, pay attention to:

- First impressions and facility cleanliness

- Condition of machinery and equipment

- Certifications displayed on-site

- Quality control processes in action

- Material control and storage

- Environmental testing areas

- Walkthrough of the full manufacturing process

You gain confidence in your choice when you see strong quality systems and modern equipment in person.

Reference Checks

Before you make a final decision, contact references provided by each best pcba manufacturer. Ask about their experience with delivery times, communication, and problem-solving. Reliable partners like Sanshun Smart often have a track record of positive feedback. Reference checks help you confirm that your chosen pcba manufacturer can deliver consistent results and support your project from start to finish.

Tip: Always use a checklist to compare each best pcb manufacturer on the same criteria. This method helps you make an informed, objective decision.

Turn-Key PCB Manufacturer Services

Full-Service Capabilities

When you select a turn-key pcba manufacturer, you gain access to a partner who manages every stage of your project. Top providers stand out by offering:

- Quality management systems that meet strict industry standards.

- Flexible assembly capabilities for both small prototype runs and large-scale production.

- Effective parts management that keeps your project on schedule.

- Customer service teams are available during North American business hours, ensuring you receive timely updates and support.

You can rely on these full-service capabilities to streamline pcba fabrication and assembly, reduce risks, and simplify your supply chain. This approach allows you to focus on innovation while your manufacturer handles the details of circuit board manufacturing.

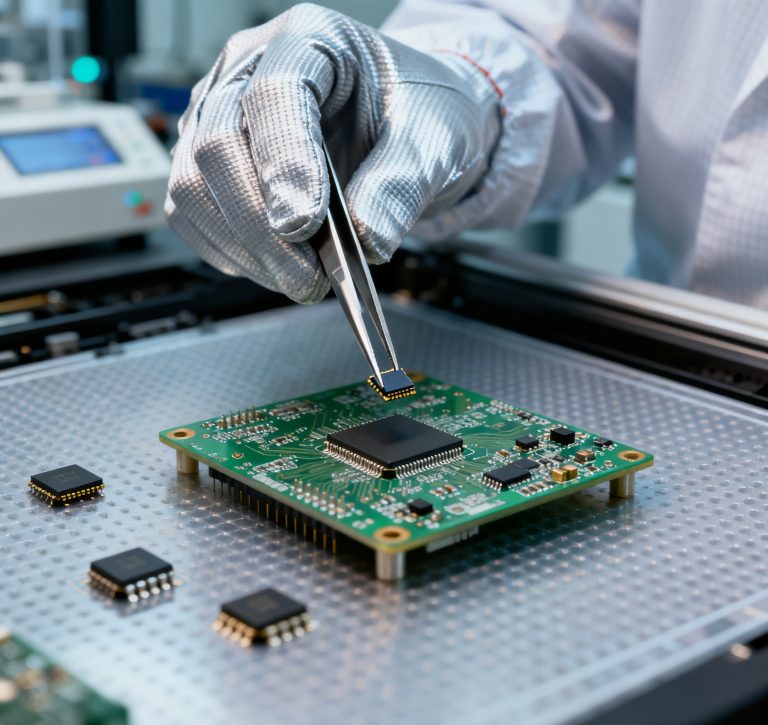

Rapid Prototyping

Rapid prototyping services play a critical role in accelerating your product development. These services transform your designs into functional units quickly, allowing you to test and validate concepts early in the process.

| Benefit | Explanation |

|---|---|

| Faster Iterations | You can refine your designs more often, catching errors and optimising layouts. |

| Reduced Development Costs | Shorter feedback loops lower your overall development expenses. |

| Mitigated Design Risks | Early validation helps you identify and address potential flaws before full production. |

| Accelerated Certification | Quick prototypes speed up certification, especially in regulated industries like medical devices. |

You benefit from quick-turn services that optimise every step, ensuring a smooth transition from prototype to volume production.

After-Sales Support

After your boards leave the factory, strong after-sales support becomes essential. You should expect:

- Technical troubleshooting and engineering support for any issues that arise.

- Warranty coverage on workmanship or materials, including root cause analysis and rapid replacement if needed.

- Rework and repair services, especially for mission-critical applications.

- Lifecycle management consulting to help you plan updates or revisions as your product evolves.

A reliable partner will support you throughout the product lifecycle, giving you confidence in every aspect of your circuit board manufacturing project.

You can select the right PCBA manufacturer by following a clear process. Start by defining your needs, then compare manufacturers using a checklist like the one below:

| Factor | Description |

|---|---|

| Quality | High quality ensures long-term success. |

| Capabilities | Match production facilities to your project. |

| Quality Control | Look for certifications such as ISO 9001. |

| Pricing | Compare quotes for competitive rates. |

| Lead Time | Confirm delivery meets your schedule. |

| Additional Services | Seek comprehensive support for your project. |

Balance these factors for the best results. Consider trusted brands like Sanshun Smart. Begin your selection process today to ensure project success.

FAQ

What certifications should you look for in a PCBA manufacturer?

You should check for ISO 9001, IPC-A-610, and UL certifications. These show that the manufacturer follows strict quality standards. For automotive projects, IATF 16949 is essential.

How do you verify a manufacturer’s quality control process?

Ask for documentation on their inspection steps. Request sample quality reports. You can also visit the facility to see their testing equipment and procedures in action.

What is the typical lead time for PCBA production?

Lead times vary by order size. Prototypes usually take 1–5 days. Medium runs need 7–10 days. High-volume orders may require 14–20 days. Always confirm timelines before placing your order.

How can you handle urgent design changes during production?

Notify your manufacturer immediately. Provide updated files and clear instructions. Choose a partner with quick-turn capabilities and formal change management processes to minimize delays.

Why is customer support important when selecting a PCBA manufacturer?

Strong support ensures fast answers to your questions. You get help with technical issues and urgent requests. Good communication keeps your project on track and reduces costly mistakes.