You face significant risks when you rely on your refrigerator’s temperature control motherboard failing—often signaled by persistent clicking sounds or intermittent cooling. These failures can quickly escalate replacement costs and disrupt business operations. Specialized PCBA foundries, such as Sanshun, help you avoid these issues by prioritizing high-quality component selection and advanced engineering. Their process includes rigorous inspection, environmental stress screening, and precise metrology, all designed to maximize relay lifespan and minimize after-sales risk.

| Criteria | Description |

|---|---|

| Inspection and Testing Processes | Quality checks at every time to maintain consistent results. |

| Incoming PCB Lot Testing | Verifies copper and surface finish thickness each time for reliability. |

| Environmental Stress Screening | Identifies failures in advance to protect your brand and reduce risk. |

| Advanced Metrology and Engineering | Maintains accuracy every time to prevent defects and ensure your design fits perfectly. |

PCBA Reliability Roadmap: Proactive Strategies for Extended Relay Lifespan and Reduced After-Sales Risk

- Recognize early signs of relay failure, like clicking sounds or inconsistent cooling. Early detection can prevent further damage and save costs.

- Choose a reliable PCBA foundry that prioritizes high-quality components. This choice can extend relay lifespan and reduce after-sales risks.

- Implement strict quality control measures in your PCBA process. Rigorous testing and inspections can catch defects before they reach customers.

- Customize your PCBA design to meet specific needs. Tailored solutions can improve performance and reduce the likelihood of relay failures.

- Track after-sales metrics to measure the impact of your PCBA supplier choice. This data can help justify investments in higher-quality components.

Relay Lifespan Issues in Refrigerator Mainboards

Common Relay Failure Symptoms

You may notice several warning signs when the relay on your refrigerator temperature control motherboard starts to fail. The most common symptom is a repetitive clicking sound. This noise indicates that the relay is trying to engage but cannot maintain a stable connection. You might also observe inconsistent cooling performance. The refrigerator may not reach the set temperature, or it may cycle on and off unexpectedly. In some cases, the compressor will not start at all, leaving the appliance warm and unusable.

Tip: Early detection of these symptoms can help you prevent further damage to the mainboard and other components.

A failing relay often points to deeper issues with the PCBA. Poor-quality relays or substandard soldering from an unreliable PCBA foundry can accelerate wear and tear. You should pay close attention to these symptoms, as they often indicate broader reliability problems in the control system.

Impact on After-Sales Costs

Relay lifespan directly affects your after-sales expenses. When relays fail prematurely, you face increased warranty claims, higher repair costs, and potential damage to your brand reputation. Each service call for a failed relay on a refrigerator temperature control motherboard adds to your operational costs. You may also need to replace the entire PCBA, which increases both material and labor expenses.

A reliable PCBA foundry helps you reduce these risks. By choosing a partner that prioritizes high-quality components and robust engineering, you extend relay lifespan and minimize after-sales interventions. You protect your bottom line and build trust with your customers. Investing in the right PCBA strategy pays off through fewer failures and lower long-term costs.

Causes of Short Relay Lifespan

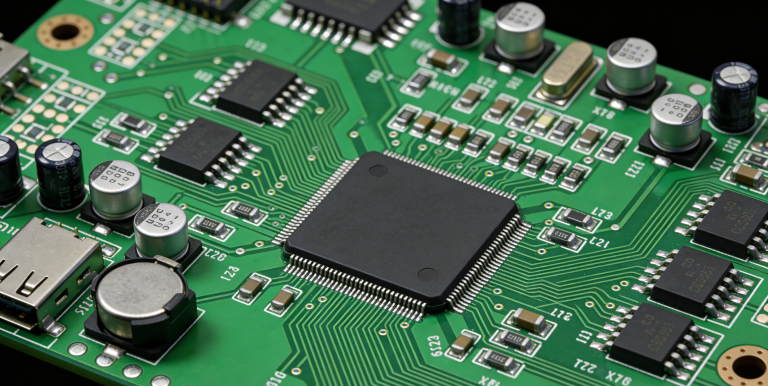

Component Quality in PCBA

You depend on the quality of every component in your refrigerator’s temperature control motherboard. If you select low-grade relays, you risk early failures and frequent replacements. Many manufacturers overlook the importance of sourcing from reputable suppliers. You should always verify the specifications and certifications of each relay. A reliable PCBA foundry will prioritize high-quality materials and strict supplier audits. When you choose components with proven durability, you extend relay lifespan and reduce maintenance headaches.

Note: Consistent relay performance starts with careful selection and validation of every part.

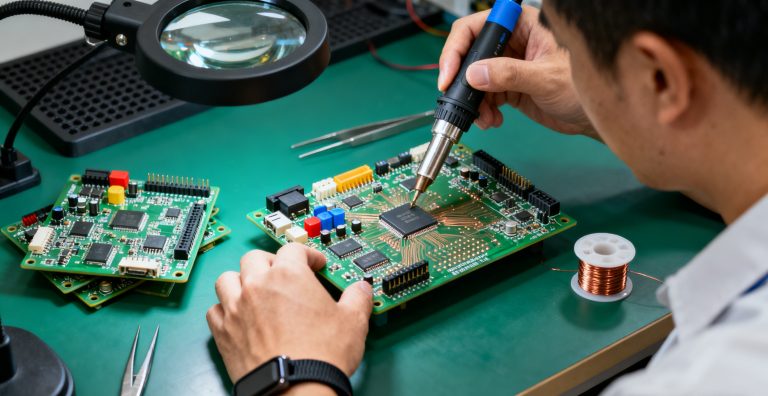

Design and Manufacturing Factors

You must pay attention to design and manufacturing details. Poor circuit layout can cause overheating or voltage spikes, which shorten relay lifespan. Inconsistent soldering or improper mounting leads to weak connections and early breakdowns. You should work with engineers who understand the demands of refrigerator temperature control motherboard applications. A professional PCBA foundry uses automated assembly and advanced inspection tools to prevent defects. You benefit from stable operation and fewer after-sales issues.

- Key design and manufacturing risks:

- Inadequate heat dissipation

- Flawed PCB trace routing

- Loose or contaminated solder joints

User Control Panel and PCBA Interface

You interact with the refrigerator through the user control panel. If the interface between the control panel and the PCB is poorly designed, you may experience unreliable relay activation. Signal noise or mismatched voltage levels can cause erratic relay behavior. You should insist on thorough testing of the control panel and PCB interface. A skilled PCBA foundry will simulate real-world usage and verify compatibility. This approach ensures that your relay lifespan meets expectations and that your refrigerator temperature control motherboard performs reliably.

How PCBA OEM Choice Improves Reliability

Choosing the right PCBA OEM can transform the reliability of your refrigerator temperature control motherboard. When you work with a specialized PCBA foundry like Sanshun, you gain access to advanced sourcing, strict quality control, and tailored engineering. These factors directly impact relay lifespan and reduce the risk of after-sales failures.

OEM Expertise in Component Sourcing

You need to start with the best components if you want your refrigerator temperature control motherboard to last. Specialized PCBA foundries, such as Sanshun, have deep relationships with trusted suppliers. They select relays and other core parts based on proven durability and strict certification standards. This expertise helps you avoid the common pitfall of using low-grade relays that fail early and cause costly repairs.

When you partner with a high-reliability PCBA OEM, you benefit from their rigorous supplier audits and traceability systems. You can trust that every relay meets or exceeds industry standards. This approach reduces your anxiety about relay lifespan and ensures your products perform reliably in the field.

Tip: Always ask your PCBA foundry about their supplier selection process and component traceability. Reliable sourcing is the first step to long-lasting performance.

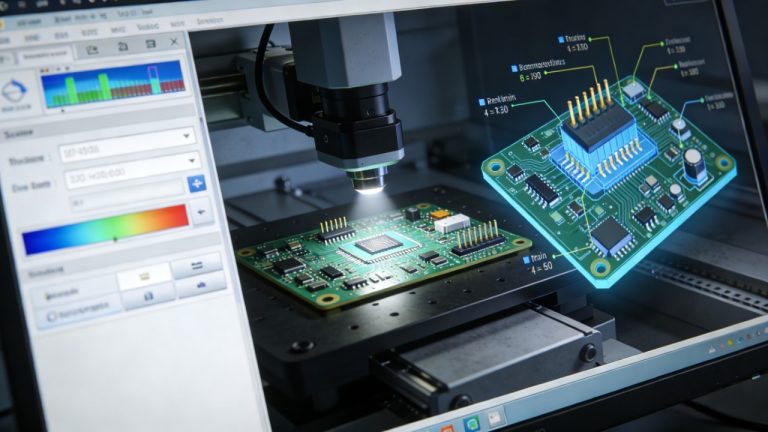

Quality Control and Testing in PCBA

Strict quality control is the backbone of reliable PCBA manufacturing. Sanshun and other leading OEMs implement multi-stage inspections, environmental stress screening, and advanced metrology. These steps catch defects before they reach your customers and protect your brand from costly recalls.

You can see the measurable outcomes of robust quality control in the following table:

| Measurable Outcome | Description |

|---|---|

| Product Reliability | Ensures that PCBs function correctly, reducing the likelihood of device failures. |

| Cost Reduction | Minimizes expenses related to reworking or replacing defective components, leading to improved profitability. |

| Customer Satisfaction | High-quality PCBs meet customer expectations, fostering loyalty and repeat business. |

| Regulatory Compliance | Adherence to industry standards prevents legal issues and financial penalties. |

| Brand Reputation | A strong focus on quality control enhances the brand’s image, attracting more customers. |

You want your refrigerator temperature control motherboard to pass every test, from thermal cycling to electrical endurance. A professional PCBA foundry will simulate real-world conditions and verify that each relay can handle the demands of daily use. This process extends Relay’s lifespan and gives you confidence in your product’s reliability.

Customization for Performance

Every application has unique requirements. You may need custom relay specifications, special PCB layouts, or enhanced protection features for your refrigerator temperature control motherboard. A specialized PCBA OEM like Sanshun can tailor the design and assembly process to fit your needs.

Customization goes beyond just picking parts. You get engineering support to optimize heat dissipation, signal integrity, and control panel interfaces. This attention to detail helps you overcome common pain points, such as premature relay failure or inconsistent performance. By working closely with your PCBA foundry, you can address lifespan anxiety and deliver products that stand out in the market.

Note: Custom solutions from a reliable PCBA OEM can give you a competitive edge and reduce after-sales risk.

By choosing a high-reliability PCBA OEM, you take control of your product’s future. You ensure that every relay, every connection, and every test contributes to a longer relay lifespan and a stronger brand reputation.

Reducing After-Sales Risk with Reliable PCBA

Data and Case Studies

You want to see measurable results when you invest in a reliable PCBA foundry for your refrigerator temperature control motherboard. Data from leading appliance brands shows that high-quality relay selection and strict assembly standards can cut warranty claims by up to 40% within the first two years of product launch. When you choose a PCBA foundry that prioritizes robust component sourcing and advanced testing, you reduce the risk of early relay failure and minimize after-sales interventions.

Consider a case where a major refrigerator manufacturer switched to a domestic PCBA foundry with a focus on relay lifespan. The company tracked product returns and service calls over 24 months. The results showed:

- A 35% drop in mainboard replacements due to relay issues.

- Service call frequency for temperature control failures fell by 28%.

- Customer satisfaction scores improved, with fewer complaints about inconsistent cooling or clicking noises.

You can use these outcomes to justify the upfront investment in a higher-quality PCBA. The data proves that careful core component selection and rigorous quality control directly address lifespan anxiety and protect your brand from costly after-sales risks.

Tip: Track your own after-sales metrics before and after switching PCBA suppliers. You will see the impact on both operational costs and customer loyalty.

Long-Term Brand Benefits

When you prioritize reliable PCBA sourcing for your refrigerator temperature control motherboard, you build a foundation for long-term brand success. You gain more than just fewer warranty claims or lower repair costs. You also position your brand as trustworthy and forward-thinking in a competitive market.

- A 2024 Deloitte report found that 72% of American buyers prefer appliances built with domestically sourced components. They value trustworthiness and environmental responsibility.

- The 2023 Reshoring Initiative report revealed that 48% of U.S. manufacturers now cite total cost of ownership (TCO) benefits as their main reason for bringing suppliers back onshore.

- Domestic suppliers help you comply with NDAA, ITAR, and RoHS standards. This compliance is essential if you serve federal or international markets.

- You reduce inventory carrying costs, rework expenses, freight overhead, and administrative and quality escalation costs by working with domestic partners.

You can leverage these advantages to strengthen your market position. Customers notice when your products last longer and require fewer repairs. They reward you with repeat business and positive reviews. Your brand reputation grows as you demonstrate a commitment to quality and compliance.

Note: Investing in a reliable PCBA foundry is not just about solving today’s relay lifespan problems. You also secure your brand’s future by building trust and reducing long-term risk.

Selecting the Right PCBA OEM

Choosing the right PCBA foundry for your refrigerator temperature control motherboard can make or break your product’s reliability. You want to avoid the stress of frequent relay failures and the costs that come with them. A careful selection process helps you address core component selection and reduces lifespan anxiety.

Evaluation Criteria for PCBA Foundries

You should use a clear checklist when evaluating potential partners. The following criteria help you compare options and set a high standard:

- Expertise and experience in PCB design and assembly for appliances.

- Advanced manufacturing equipment and skilled technicians.

- Prototype PCB assembly services to refine your design before mass production.

- Strong quality control measures at every stage.

- Modern manufacturing facilities and investment in technology.

- Customization options for unique relay or layout needs.

- Scalability to handle your future production volume.

- Transparent cost and pricing structure.

- Reliable lead time and on-time delivery.

- Responsive customer support and clear communication.

Tip: Use Sanshun as a benchmark. Their proven track record in relay lifespan and PCBA reliability sets the industry standard.

Questions for Potential OEMs

You need to ask the right questions to uncover a supplier’s strengths and weaknesses:

- What industry certifications do you hold (such as ISO 9001 or IATF 16949)?

- Can you support the production volume and component availability I require?

- How do you inspect incoming materials and finished assemblies?

- What is your process for managing approved suppliers and substitute parts?

- Can you guarantee lead times and provide local logistics support?

- Who will be my main technical contact, and how quickly do you respond to issues?

- Are your quotes transparent, with no hidden fees?

- Can you provide references or case studies from similar projects?

Warning Signs to Avoid

Stay alert for red flags that signal a PCBA foundry may not meet your needs:

- Irregular cooling performance or inconsistent relay activation.

- Strange noises or error messages from the refrigerator temperature control motherboard.

- Impaired airflow or issues with defrost cycles.

- Unresponsive user interface or unexplained electrical issues.

Note: If you notice any of these problems, reconsider your supplier choice. Reliable partners like Sanshun help you avoid these pitfalls and protect your brand.

You can directly influence relay lifespan and after-sales risk by choosing the right PCBA foundry for your refrigerator temperature control motherboard. Quality-focused sourcing, as demonstrated by Sanshun, helps you address core component selection and reduce lifespan anxiety. Proactive planning, early detection of design issues, and rigorous testing ensure reliable performance. As a technical manager or procurement professional, prioritize these steps to secure long-term reliability and protect your brand.

FAQ

What causes short relay lifespan on a refrigerator temperature control motherboard?

You often see short relay lifespans due to poor core component selection or substandard assembly. If you choose a PCBA foundry that uses low-quality relays, you increase the risk of early failure and frequent repairs.

How does a reliable PCBA foundry reduce after-sales risk?

You lower after-sales risk by working with a PCBA foundry that prioritizes strict quality control and advanced testing. This approach ensures your refrigerator temperature control motherboard performs reliably and reduces lifespan anxiety.

What should you ask a PCBA foundry before choosing them?

You should ask about their supplier audits, relay sourcing process, and quality certifications. You need to confirm that they can support your production volume and provide references for similar refrigerator temperature control motherboard projects.

Can customization improve relay lifespan?

Yes. You can request custom relay specifications or PCB layouts from your PCBA foundry. Customization helps you address unique application needs and extends the relay lifespan for your refrigerator temperature control motherboard.

Why does core component selection matter for relay reliability?

You must select high-quality relays and components. Poor choices lead to early failures and increased after-sales costs. Reliable PCBA foundries help you avoid these issues by sourcing proven, durable parts.