You face a critical challenge when designing an intelligent thermostat pcba: preventing signal interference that can compromise accuracy and reliability. EMC issues often arise during the R&D stage, causing unexpected failures in the PCBA assembly process. Inadequate attention to electromagnetic compatibility can lead to costly recalls and safety hazards. You must prioritize robust testing and precise layout early to ensure your system meets industry standards and avoids these hidden dangers.

PCBA Design Essentials for Ensuring EMI-Safe Intelligent Thermostat Performance

- Prioritize electromagnetic compatibility (EMC) during the design phase to prevent costly recalls and safety hazards.

- Implement effective grounding, shielding, and filtering techniques to protect your intelligent thermostat PCBA from electromagnetic interference (EMI).

- Carefully place sensors away from noise sources and use thermal shields to ensure accurate temperature readings.

- Minimize trace lengths and use direct routing to enhance signal integrity and reduce susceptibility to EMI.

- Conduct thorough testing and validation for EMI at every stage of the PCBA assembly process to ensure reliability and compliance.

Why Electromagnetic Interference Is a Critical Risk in PCBA

Impact on Thermostat Reliability

You must recognize that electromagnetic interference poses a direct threat to the reliability of the intelligent thermostat pcba. When you design or assemble a pcba, even minor EMI can disrupt sensor signal accuracy. This disruption often leads to incorrect temperature readings, which can compromise the entire system. For example, emi can cause measurement errors in RTD probes, making resistance readings unreliable. In high-emi environments, such as manufacturing plants, these errors can result in significant quality control issues. In medical settings, EMI from equipment like MRI machines can produce false temperature readings, which may lead to misdiagnosis. You need to address these risks early in the pcba assembly process to ensure consistent performance.

System Safety Concerns

Electromagnetic compatibility challenges become especially critical during the R&D stage. If you overlook EMI risks, you may introduce vulnerabilities that threaten system safety. Research shows that EMI can affect smart power high-side switches, which are essential in automotive and industrial applications. Under EMI conditions, these devices may fail to diagnose faults like overtemperature, increasing the risk of undetected failures. You should understand that similar vulnerabilities can exist in an intelligent thermostat pcba, where undetected signal interference can lead to unsafe operating conditions. Proactive attention to electromagnetic compatibility during design and assembly helps you prevent these hidden dangers.

Common EMI Failure Scenarios

You encounter several failure scenarios when EMI is not properly managed in PCBA design:

- emi disrupts the operation and functionality of intelligent thermostat pcba assemblies.

- Both natural and man-made sources can introduce EMI, affecting pcba performance.

- Poor grounding or shielding in the pcba layout increases susceptibility to EMI.

- Inadequate filtering allows unwanted EMI to reach sensitive signal paths.

- Failure to follow EMC best practices during the pcba assembly process can reduce long-term reliability.

Tip: Implement filtering, shielding, and grounding techniques to enhance electromagnetic compatibility and protect your intelligent thermostat pcba from emi-related failures.

You must prioritize EMI mitigation strategies throughout the pcba assembly process to maintain system reliability and safety.

Main Sources of PCBA Interference in Intelligent Thermostat PCBA

EMC and EMI Challenges

You face significant challenges from EMC and EMI during the intelligent thermostat pcba assembly process. These challenges include both common and differential mode radiations, which can disrupt the performance of your pcba. You must address conduction interference, which enters through power circuits, and crosstalk interference, which occurs when one signal line affects another. Radiation interference, especially from cables and internal lines, can also compromise your system. You need to consider conducted and radiated emissions, as these can enter through power input lines and switching devices. Effective electronic circuit design, careful component selection, and optimized pcba layout design help you meet EMC standards.

Tip: Always reference international emc standards during your design phase. The table below highlights key organizations and their focus areas:

| Standard/Organization | Description |

|---|---|

| IEC | Develops global standards for EMC compliance in pcba design. |

| CISPR | Focuses on radio frequency interference standards. |

| FCC | Establishes regulations for electromagnetic emissions in the U.S. |

| EU EMC Directives | Mandates compliance for products sold in EU member countries. |

| CISPR 32 | Sets emission requirements for information technology equipment. |

| IEC 61000 Series | Provides comprehensive EMC requirements, including immunity testing methods. |

Crosstalk and Signal Coupling

Crosstalk remains a major source of pcba interference in the intelligent thermostat pcba. When one signal line couples energy onto another, you see a decline in sensor signal integrity. Common-mode crosstalk can have a more severe impact than differential mode, leading to compromised sensor performance. You must keep key signals separate from noisy signals to maintain accuracy. Use differential pair routing and impedance matching to minimize these effects. Shielding sensitive circuits and using filtering at power entry points further reduces unwanted coupling.

- Crosstalk allows one signal to affect another, causing noise and interference.

- Energy from an aggressor signal can couple onto a victim signal, degrading performance.

- Keeping critical traces apart and using shielding measures are essential.

Power Supply and Environmental Noise

Power supply noise can disrupt sensor signals in your intelligent thermostat pcba. Fluctuations in the power supply may cause erratic sensor behavior and inaccurate readings. This risk increases in high-speed digital circuits, where power integrity is crucial. Environmental noise, such as return currents from harmonic noise and induced currents from magnetic fields, can also propagate across your pcba. You can mitigate these effects by optimizing grounding and pcba layout. 3D electromagnetic field simulations help you understand how noise currents travel along transmission lines and ground.

| Key Insights on Noise Propagation and Mitigation | Description |

|---|---|

| Noise Propagation Mechanisms | Noise can spread due to the return current of harmonic noise and induced currents from magnetic fields. |

| Importance of Grounding and Layout Optimization | Proper grounding and layout can significantly reduce noise effects on pcbas. |

| Simulation Insights | 3D electromagnetic field simulations reveal how noise current propagates along transmission lines and ground. |

Sensor Placement Issues

Sensor placement plays a critical role in minimizing pcba interference during the pcba assembly process. You should position the SMT temperature sensor near heat-generating components, such as power ICs, but maintain a safe distance of 2-3 mm to prevent damage. Avoid placing sensors in areas with strong airflow, as this can distort temperature readings. If airflow is unavoidable, use a thermal shield to protect the sensor. Proper sensor placement ensures accurate readings and reduces the risk of signal interference in your intelligent thermostat pcba.

Note: Careful sensor placement and shielding are essential for reliable operation and long-term performance.

| Type of Interference | Description |

|---|---|

| Layout interference | Caused by the unsuitable placement of components on pcba. |

| Stacking interference | Noise interference caused by unscientific stacking strategies. |

| Routing interference | Caused by improper distance settings between signal, power, and grounding lines. |

PCBA Design and Assembly Strategies to Prevent Signal Interference

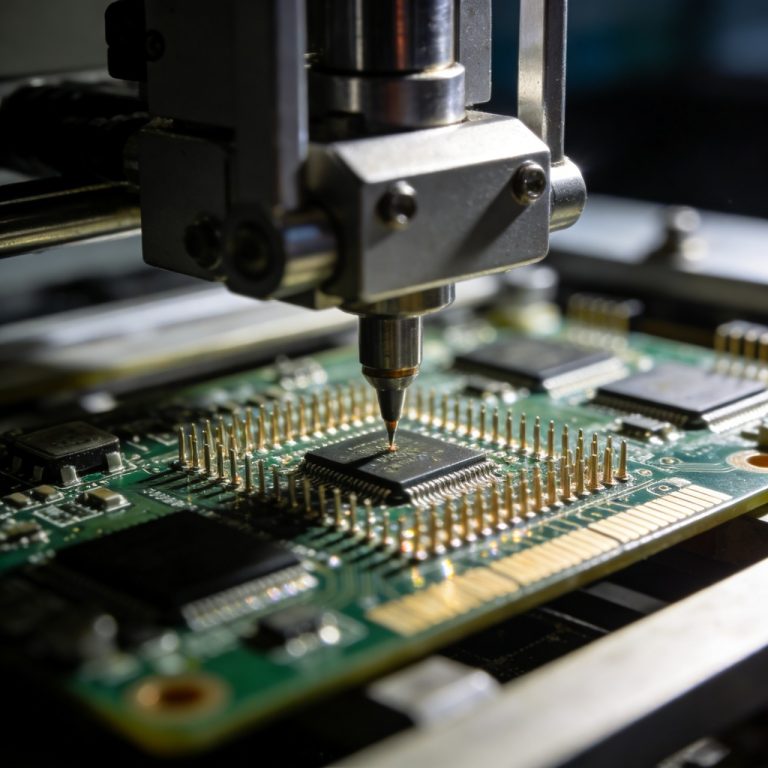

Component Placement and Trace Routing

You must prioritize precise component placement and effective trace routing in every stage of PCBA design. Proper placement reduces the risk of component placement errors and thermal management errors, which often lead to signal interference and EMI. When you arrange components, keep sensitive signal lines away from high-speed signals and noisy power circuits. This separation maintains signal integrity and reduces crosstalk.

- Place thermal sensors close to heat sources, but maintain a safe distance to avoid thermal management errors.

- Avoid routing signal lines under or near components that generate significant noise.

- Use short, direct routing for key signal lines to minimize EMI.

- Prevent sharp bends in traces, as these can cause signal reflections and increase electromagnetic interference.

- Separate high-speed and sensitive signal lines to reduce routing interference and maintain integrity.

Tip: Always review your PCBA design for component placement errors before moving to the PCBA assembly process. This step helps you catch issues that could compromise thermal performance and signal integrity.

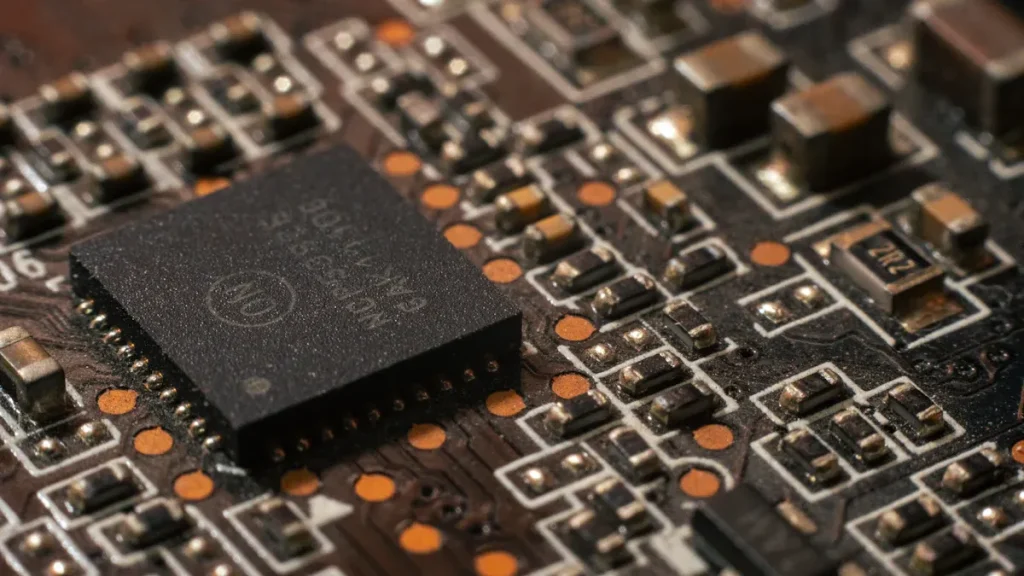

Grounding, Shielding, and Filtering

You need to implement robust grounding, shielding, and filtering strategies to protect your intelligent thermostat PCBA from EMI and noise. A dedicated ground plane under signal layers provides a low-impedance path for return currents, which shields signal lines from electromagnetic interference and maintains signal integrity.

- Use uniform ground planes to minimize voltage drops and improve integrity.

- Separate ground planes for high- and low-voltage sections to prevent noise from spreading.

- Place the ground plane directly below the signal plane to reduce the return path and minimize EMI.

- Add stitching capacitors when signal lines change ground reference, which stabilizes the signal.

- Employ multi-point grounding to ensure consistent ground voltage across the PCBA.

- Use guard traces parallel to sensitive signal lines to block EMI and reduce crosstalk.

- Install shielding cans over critical areas to create a physical barrier against EMI.

- Apply copper pours around sensitive traces for additional shielding.

- Integrate passive filtering components, such as ferrite beads and capacitors, at power entry points to block noise.

Note: Shielded connectors and proper filtering techniques are essential best practices for maintaining signal integrity in the PCBA assembly process.

Minimizing Trace Lengths and Signal Paths

You should always minimize trace lengths and signal paths in your PCBA design. Long traces act as antennas, increasing EMI susceptibility and reducing signal integrity. Keeping traces short and direct is a fundamental best practice for intelligent thermostat PCBA design.

| Condition | Maximum Trace Length |

|---|---|

| Standard Electrode (C_electrode ~ 3 pF) | 210 mm |

| Larger Electrode (C_electrode ~ 8 pF) | 120 mm |

Minimizing signal path length reduces the loop area, which decreases electromagnetic radiation and interference. This approach is especially important for high-speed signals, where maintaining signal integrity is critical. Route high-speed traces over uninterrupted ground planes and keep current loop areas as small as possible. This strategy helps you avoid routing interference and ensures robust thermal performance.

- High-frequency signals require a clear, low-impedance return path to prevent EMI.

- Direct routing over ground planes supports signal integrity and reduces noise.

- Avoid unnecessary vias and layer changes, as these can disrupt the return path and increase EMI.

Tip: Regularly check your PCBA design for excessive trace lengths and unnecessary routing complexity. This review helps you prevent signal interference and maintain the reliability of your intelligent thermostat PCBA.

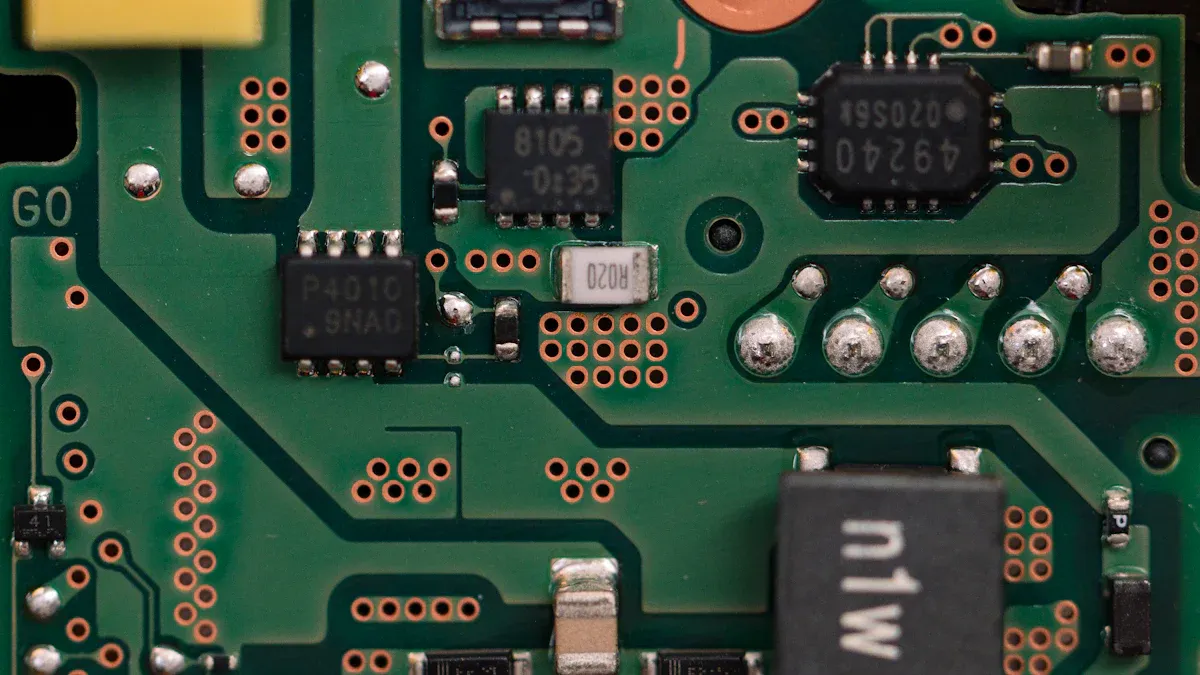

Testing and Validation for EMI

You must conduct thorough testing and validation for EMI throughout the PCBA assembly process. Early detection of EMI issues allows you to address problems before they affect the final product. Use a combination of pre-test, emission test, sensitivity test, and spectrum analysis to ensure your intelligent thermostat PCBA meets industry standards.

| Testing Method | Description |

|---|---|

| Pre-test | Conducted during design to identify EMI issues early, using simulations or actual test equipment. |

| Emission test | Measures electromagnetic waves emitted by equipment to ensure compliance with EMI standards. |

| Sensitivity test | Evaluates the equipment’s resistance to interference through radiation and conduction sensitivity tests. |

| Spectrum analysis | Analyzes electromagnetic wave characteristics to identify interference sources. |

You should perform pre-tests during the design phase to catch EMI problems before assembly. Emission tests confirm that your PCBA does not exceed regulatory limits for electromagnetic interference. Sensitivity tests help you understand how your intelligent thermostat PCBA responds to external noise. Spectrum analysis pinpoints the sources of EMI, allowing you to refine your PCBA design and assembly process.

Best Practice: Integrate EMI testing at every stage of the PCBA assembly process. This approach ensures that your intelligent thermostat PCBA remains reliable and free from signal interference throughout its lifecycle.

By following these best practices in component placement, trace routing, grounding, shielding, filtering, and testing, you can significantly reduce the risk of EMI and signal interference in your intelligent thermostat PCBA. Consistent attention to detail in PCBA design and the PCBA assembly process will help you avoid component placement errors, routing interference, and thermal management errors, ensuring optimal performance and long-term reliability.

You can prevent signal interference in your intelligent thermostat PCBA by focusing on a few key actions:

- Place components carefully to minimize noise.

- Use effective routing techniques and controlled impedance for clear signals.

- Manage thermal conditions to avoid signal degradation.

You improve safety and reliability when you address EMI risks early. Ongoing testing during the PCBA assembly process ensures your system remains robust and compliant.

FAQ

What causes signal interference in the Intelligent Thermostat PCBA?

Signal interference often results from poor trace routing, inadequate grounding, or improper component placement. You may also encounter issues from environmental noise or power supply fluctuations during the PCBA assembly process.

How can you test for signal interference during the PCBA assembly process?

You can use pre-tests, emission tests, and spectrum analysis. These methods help you identify and resolve signal interference in your Intelligent Thermostat PCBA before final production.

Why is sensor placement important in Intelligent Thermostat PCBA design?

Sensor placement affects temperature accuracy and system reliability. You should position sensors away from strong airflow and noisy components to reduce signal interference and ensure optimal performance.

What are the best practices for minimizing signal interference?

- Use short, direct trace routing.

- Implement robust grounding and shielding.

- Separate sensitive signals from noisy circuits.

- Test your Intelligent Thermostat PCBA at every stage of the PCBA assembly process.

Can signal interference impact long-term reliability?

Yes. Signal interference can cause inaccurate readings and system failures over time. You must address these risks early in the PCBA assembly process to maintain the reliability of your Intelligent Thermostat PCBA.