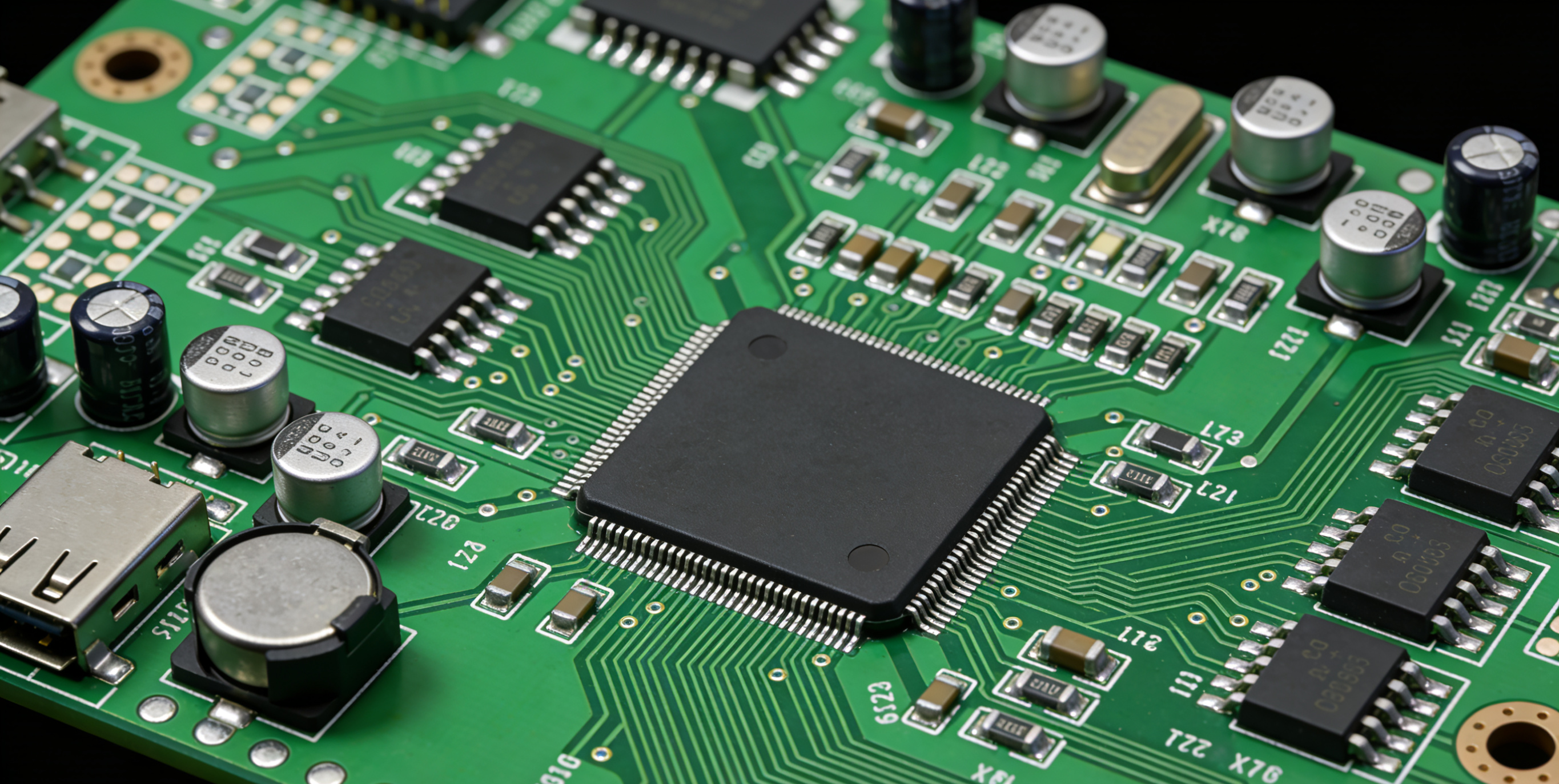

To ensure on-time PCBA delivery during ongoing shortages, you must act quickly and decisively. Today’s supply chain faces persistent instability, especially for temperature control components. Pricing shifts and sourcing delays disrupt production, while high demand from industries like AI and automotive increases competition for critical parts.

You can limit delays by adopting proactive planning, building strong supplier relationships, and creating resilient supply chain processes. These steps help you navigate fluctuating lead times and reduce the risk of missing delivery targets.

Optimizing PCBA Production with Proactive Planning and Resilient Supply Chain Strategies

- Proactive planning is key. Anticipate shortages by forecasting demand accurately to avoid unexpected delays.

- Early procurement secures components before shortages hit. Place orders as soon as forecasts are ready to lock in pricing.

- Build strong supplier relationships. Open communication and collaboration help you navigate sourcing challenges effectively.

- Implement agile scheduling. Adjust production plans in real-time to respond to component availability and minimize disruptions.

- Utilize vendor-managed inventory (VMI) to enhance supply chain resilience. This strategy ensures you have the right components available when needed.

Proactive PCBA Planning

You can strengthen your PCBA delivery timelines by focusing on proactive planning. This approach helps you anticipate electronic component shortages and respond quickly to supply chain disruption risk. When you plan, you reduce delays and improve your shortage management process.

Demand Forecasting

Accurate demand forecasting gives you a clear view of future requirements. You can use several methods to predict supply chain risks and avoid unexpected shortages. The table below summarizes the most effective forecasting methods in the PCBA industry:

| Forecasting Method | Description |

|---|---|

| Supply forecasting | Evaluates the supplier base to predict available products and quantities. |

| Demand forecasting | Analyzes potential customer demand over a specified period, considering trends and seasonality. |

| Price forecasting | Assesses how supply and demand shifts may influence component prices, factoring in external events. |

You should analyze historical data, market trends, and seasonality. This process helps you anticipate demand spikes and plan your sourcing strategy. By forecasting accurately, you can minimize supply chain management risks and maintain steady PCBA delivery.

Early Procurement

You need to buy components early to secure inventory before shortages impact your production. Early procurement allows you to lock in pricing and avoid last-minute sourcing challenges. This strategy supports your shortage management process and helps you maintain control over costs.

Tip: Place orders as soon as your demand forecast is ready. Early action gives you access to a wider range of components and reduces the risk of paying premium prices during shortages.

Aligning bill of materials (BOM) reviews with agile scheduling further improves your ability to source components efficiently. The table below highlights the benefits of this approach:

| Benefit | Description |

|---|---|

| Cost-effective components | Agile BOM management enables teams to secure components in advance, ensuring better pricing and availability. |

| Lock in pricing | Early orders or supply agreements help stabilize costs and reduce last-minute purchasing. |

| Risk reduction | Proactive management minimizes the chance of needing expensive alternatives during shortages. |

You can follow these steps to optimize your shortage management process:

- Utilize agile BOM management to access real-time data on component availability.

- Take early action to secure pricing and order parts before shortages occur.

- Reduce redesigns and last-minute searches by maintaining a proactive approach.

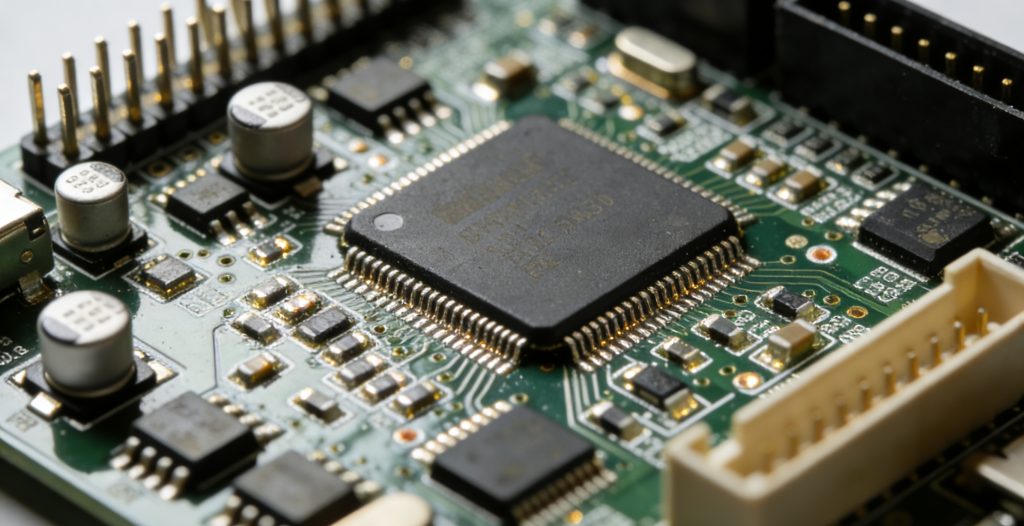

Design for Shortages

Flexible design helps you adapt to supply chain risks and electronic component shortages. You should select alternative components and design your PCBA to accommodate substitutions. This strategy ensures that your production continues even when preferred parts are unavailable.

- Review your BOM regularly to identify at-risk components.

- Work with your engineering team to approve alternate parts.

- Update your design files to support quick changes during sourcing disruptions.

Agile scheduling allows you to adjust production timelines based on component availability. This flexibility is crucial for minimizing disruptions and keeping your PCBA delivery on track.

Note: Agile PCBA production scheduling adjusts in real-time to component shortages, which helps maintain delivery timelines. This flexibility is essential for effective supply chain management.

By combining accurate forecasting, early procurement, and flexible design, you build a resilient supply chain. These strategies help you manage sourcing challenges and ensure on-time PCBA delivery, even during periods of shortages.

Supplier Collaboration for Component Shortages

Building strong relationships with your electronic component supplier is essential for overcoming shortages and maintaining on-time PCBA delivery. You can improve supply chain management by adopting multi-source procurement and conducting regular supplier reviews. This approach helps you secure critical components and reduces the risk of supply chain disruption.

Alternate Sourcing Lists

You should maintain alternate sourcing lists for temperature control components. This strategy supports dual sourcing and gives you flexibility when your primary supplier faces shortages. The table below highlights the key benefits of alternate sourcing lists:

| Benefit | Description |

|---|---|

| Risk Mitigation | Provides backup options to continue operations during supply disruptions or supplier issues. |

| Shorter Lead Times | Allows for faster procurement from suppliers with shorter lead times, keeping production on schedule. |

| Cost Management | Offers more cost-effective solutions and negotiation leverage when primary parts become expensive. |

| Avoiding Internal Stockouts | Helps prevent production downtime from missing parts, aiding in inventory management. |

| Mitigation of Obsolescence | Ensures production continuity by quickly shifting to alternatives when parts are discontinued. |

| Flexibility in Design | Accommodates engineering changes without overhauling the supply chain. |

| Supplier Diversification | Supports a multi-sourcing strategy, enhancing supply chain resilience. |

| Business Continuity Planning | Ensures minimal downtime during unforeseen events with a list of alternate parts. |

| Quality Control | Improves quality through competition and ensures compliance with industry standards. |

| Scalability and Production Expansion | Allows for more responsive capacity management during rapid production volume increases. |

You can use dual sourcing and supplier diversification to strengthen your supply chain. This method helps you respond quickly to electronic component shortages and keeps your PCBA delivery on track.

Open Supplier Communication

You need to communicate openly and frequently with your electronic component supplier. This practice supports joint problem-solving and helps you resolve sourcing challenges. Consider these strategies:

- Identify alternative components quickly when shortages occur.

- Adjust your bill of materials with supplier input to keep projects moving.

- Manage inventory proactively through regular updates and discussions.

- Secure high-quality parts and streamline procurement by maintaining open dialogue.

- Monitor part lifecycles and transition smoothly from prototype to production.

Transparent communication with your supplier reduces supply chain disruption risk and improves your ability to source critical components.

Agile Scheduling

You should implement agile scheduling to adapt to the fluctuating availability of temperature control components. Dynamic scheduling allows you to adjust production plans in real time. This approach supports just-in-time manufacturing and helps you optimize costs and lead times. By integrating real-time events and maximizing production capacity, you ensure work orders finish on schedule and at the lowest possible cost.

Dual sourcing, open supplier communication, and agile scheduling work together to build a resilient supply chain. These strategies help you overcome electronic component shortages and maintain reliable PCBA delivery.

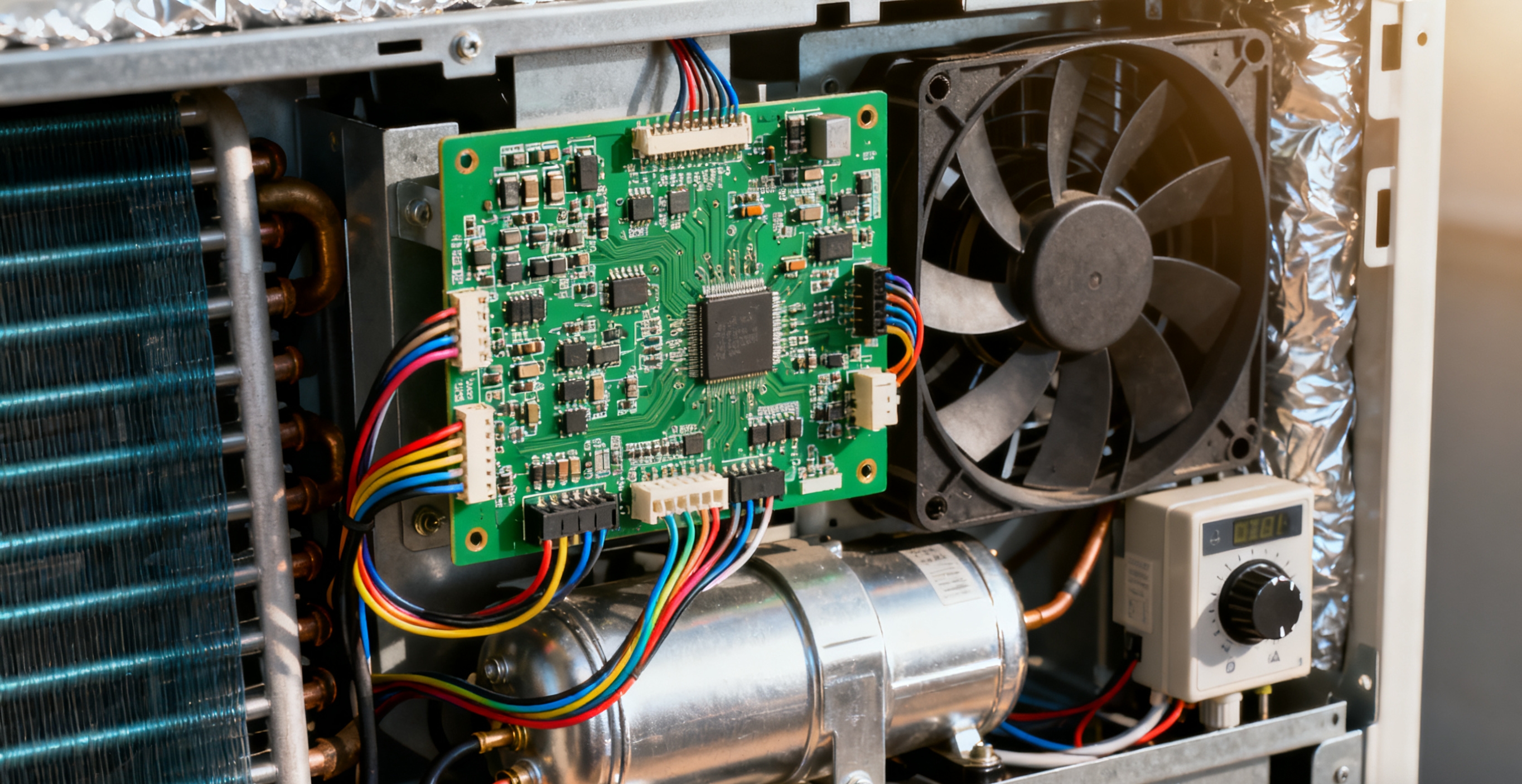

Inventory and Supply Chain Resilience

Building supply chain resilience is essential for on-time PCBA delivery, especially during electronic component shortages. You can strengthen your supply chain management by adopting strategies like vendor-managed inventory, safety stock, and domestic sourcing. These methods help you respond quickly to supply chain disruption risk and maintain a steady flow of high-quality components.

Vendor Managed Inventory (VMI)

Vendor-managed inventory gives you a powerful tool for supply chain resilience. With VMI, your supplier takes responsibility for monitoring and replenishing your inventory. This approach ensures you have the right components available, even when shortages threaten your production schedule.

The table below shows how VMI supports resilience for temperature control electronic components:

| Benefit | Description |

|---|---|

| Inventory management | Identifies additional sources for critical components, ensuring availability during shortages. |

| Forecasting | Manages database software to alert manufacturers about lifecycle changes of components. |

| Warehousing | Accumulates materials to prevent delays and mitigate costs during supply shortages. |

| Franchise pricing | Secures discounts that can be passed on to customers, enhancing competitiveness. |

| Turnkey services | Offers additional services like component kitting, which can expedite the manufacturing process. |

| Supplier relationships | Strong relationships with suppliers are crucial for prioritization during component shortages. |

You benefit from improved forecasting and warehousing, which help you avoid costly delays. VMI also strengthens your supplier relationships, giving you priority access to critical components when supply chain disruption risk is high.

Safety Stock Strategies

Safety stock acts as a buffer between your forecasted and actual demand. This strategy protects your PCBA production from unexpected shortages and supply chain disruptions. You need to calculate safety stock levels carefully to avoid both stockouts and excess inventory.

- Safety stock provides a cushion against demand variability.

- Proper calculation of safety stock levels prevents both shortages and overstock.

- A broad distribution network supports better inventory management.

You should review your safety stock policies regularly. Adjust your buffer levels based on changes in demand, lead times, and supply chain risk. This proactive approach helps you maintain supply chain resilience and ensures you always have high-quality components ready for production.

Domestic Sourcing

Domestic sourcing increases your supply chain resilience by reducing your dependence on overseas suppliers. When you source temperature control electronic components locally, you shorten lead times and minimize the impact of global disruptions. Domestic suppliers can respond faster to your needs, helping you avoid delays in PCBA delivery.

You also gain better visibility into your supply chain. Local suppliers often provide more reliable communication and faster shipping. This advantage helps you manage supply chain disruption risk and maintain a steady flow of components.

Tip: Combine domestic sourcing with VMI and safety stock strategies to create a robust, multi-layered approach to supply chain resilience.

Daily Shortage Reporting and BOM Health Reviews

You can further strengthen your supply chain resilience by implementing daily shortage reporting and regular bill of materials (BOM) health reviews. These practices help you identify risks early and take corrective action before they impact your PCBA delivery.

| Best Practice | Description |

|---|---|

| Daily Material Reviews | Maintain daily or weekly shortage reports and review meetings to track at-risk components and plan alternative actions. |

| Structured Processes | Develop structured, repeatable workflows to ensure risks are identified early and resolved efficiently. |

| Use of Technology | Implement real-time connectivity and advanced analytics for supply chain visibility and efficiency. |

Daily reviews keep you informed about at-risk components. Structured processes ensure you address issues quickly and consistently. Advanced technology gives you real-time insights, supporting your supply chain management and resilience efforts.

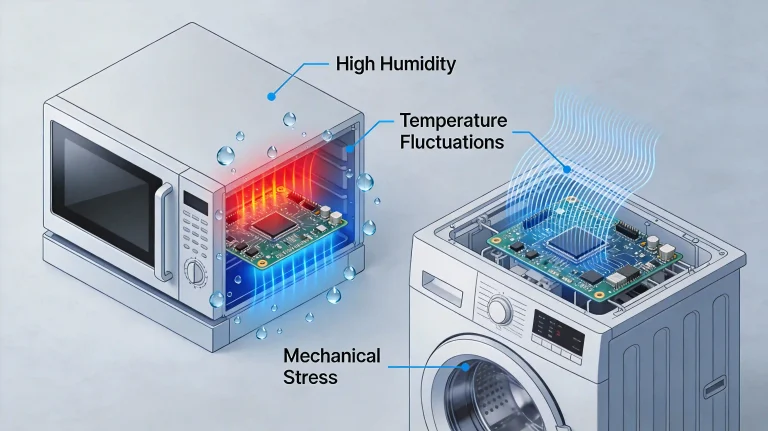

You may face challenges when building supply chain resilience for temperature-controlled electronic components. Complex supply chains, the need for supplier diversification, and external factors like geopolitical events can all impact your strategy. You must also consider careful material selection and robust thermal management to prevent product failure.

By combining VMI, safety stock, and domestic sourcing with daily reporting and BOM health reviews, you build a resilient supply chain. These strategies help you overcome electronic component shortages and ensure on-time PCBA delivery, even in the face of ongoing supply chain disruption risk.

Technology and Quality Control

Real-Time Supply Chain Tools

You can improve PCBA delivery by using real-time visibility tools. These systems help you track electronic component lead times and respond quickly to shortages. Online portals and EDI connections synchronize inventory and order status, giving you instant updates. Stock and risk analysis platforms, such as SiliconExpert and Z2 Data, identify alternative sources before shortages escalate. ERP integration with supplier data ensures accurate purchasing and production schedules. AI systems analyze large datasets to predict shortages early, assess supplier performance, and flag at-risk components. Machine learning models suggest alternative sourcing strategies, helping you avoid delays caused by supply chain disruption risk.

| Feature | Description |

|---|---|

| Accurate Inventory | Real-time monitoring of stock levels through ERP systems. |

| Climate Controlled | Regulates humidity and temperature for sensitive items. |

Quality Assurance

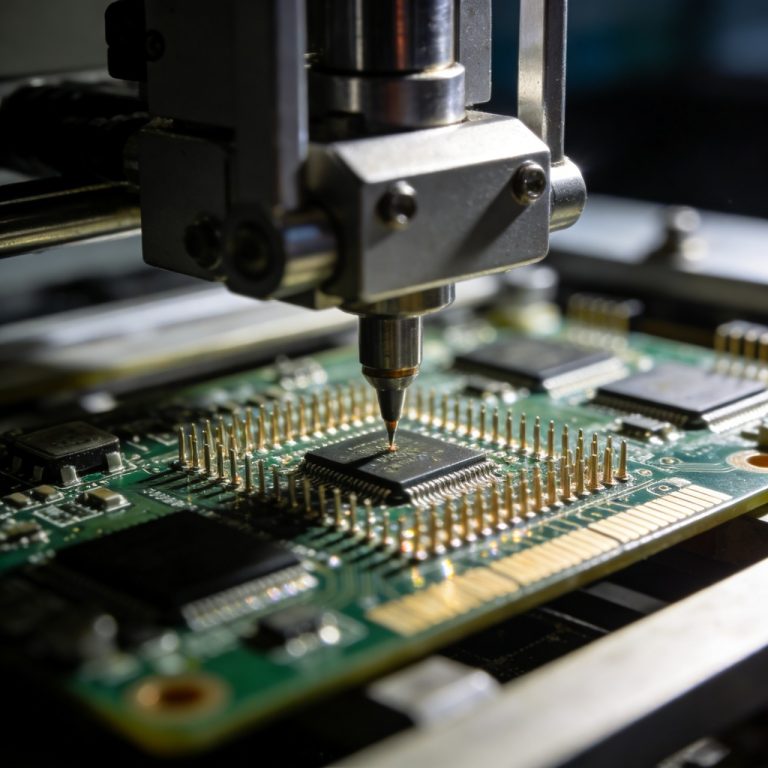

You must maintain strict quality assurance to keep electronic component lead times on track. Supplier audits verify capabilities, evaluate factory conditions, and assess risk. These audits identify improvements and build confidence in your supply chain. You should conduct pre-fabrication engineering reviews to ensure manufacturability. Incoming quality control inspects and tests materials, while in-process checks catch issues early. Final quality control confirms specifications before shipment. Digital production management and full traceability reduce risks and improve delivery times. Rigorous process control enhances reliability and supports consistent PCBA delivery.

Counterfeit Prevention

Counterfeit prevention protects your supply chain management and ensures the integrity of temperature control components. You should source from verified suppliers and use layered testing. Strict adherence to industry standards, supplier audits, and advanced material analysis helps you detect counterfeit items. X-ray scanning and electrical validation add extra layers of protection. You can partner with trusted manufacturers and maintain an accurate BOM to safeguard your production. Batch tracking and material traceability ensure compliance and readiness for recalls. Electronic data management and barcode labeling streamline quality assurance and traceability.

Tip: Conduct visual inspections, review documentation, and verify quantities for every incoming batch. Test electrical parameters and assess durability under stress conditions to maintain high standards.

You can reduce supply chain disruption risk by combining technology-driven quality control, real-time visibility, and robust counterfeit prevention. These strategies help you manage electronic component shortages and keep electronic component lead times predictable, ensuring on-time PCBA delivery.

You can achieve on-time PCBA delivery even during electronic component shortages by following proven industry steps:

- Partner with reliable suppliers who maintain a steady flow of components.

- Diversify your sources to reduce dependency and minimize supply chain disruptions.

- Use inventory management systems for real-time tracking and proactive reordering.

- Design your PCBA with flexibility to accept alternative components.

| Strategy | Benefit |

|---|---|

| Standardization | Reduces dependency on hard-to-find parts by using widely available components. |

| Modular Design | Allows for easier substitutions if a particular component becomes unavailable. |

Proactive planning, supplier collaboration, and technology adoption help you respond quickly to supply risks. You should leverage digital monitoring, accelerate prototyping, and embed risk management into daily operations. Take immediate action and continue improving your supply chain management practices. Stay vigilant and adaptable to maintain time advantages and overcome ongoing challenges.

FAQ

What is the most effective strategy to avoid PCBA delivery delays during electronic component shortages?

You should combine early procurement, flexible design, and alternate sourcing lists. This strategy helps you respond quickly to supply chain disruption risk and maintain steady PCBA delivery. You can also strengthen your supply chain management by working closely with each supplier.

How do you select reliable sourcing partners to minimize sourcing slowdowns?

You need to evaluate each supplier’s track record, audit their quality systems, and review their inventory management. Strong sourcing partners offer transparent communication and rapid response to shortages. You should prioritize suppliers with proven supply chain management and robust monitoring capabilities.

Why is daily monitoring important for supply chain management in PCBA delivery?

Daily monitoring helps you identify risks early and take corrective action. You can track supplier performance, review shortage reports, and adjust your strategy. This approach reduces supply chain disruption risk and supports on-time PCBA delivery, even during electronic component shortages.

How can you ensure supplier collaboration improves supply chain management?

You should maintain open communication with every supplier, share forecasts, and review alternate sourcing lists together. Joint problem-solving and agile scheduling allow you to adapt quickly. This strategy builds trust and resilience, helping you overcome sourcing slowdowns and electronic component shortages.

What role does supplier diversification play in mitigating supply chain disruption risk?

Supplier diversification spreads risk across multiple sources. You can secure critical components from different suppliers, reducing dependency and improving supply chain management. This strategy ensures you maintain PCBA delivery schedules, even when facing electronic component shortages or unexpected sourcing slowdowns.