You need low-volume PCBA assembly for prototype PCBA China, product validation, or small-batch PCBA assembly runs. High-volume PCBA manufacturing works best for established products with stable designs and large market demand. Aligning your production volume with project needs, budget, and speed-to-market will help you achieve greater success in PCBA in China.

- Fast turnaround times reduce waiting periods and support rapid development cycles.

- Choosing a manufacturer with strong quality control can improve outcomes and help you compete in a fast-paced industry.

- SMT dominates high-volume production, while mixed technology is growing due to complex designs.

Considering the China PCBA cost at each stage helps you maximize efficiency and value.

Low-Volume vs. High-Volume PCBA China: Navigating the Strategic Choice for Your Project

- Low-volume PCBA assembly is ideal for prototyping and small batches, allowing for cost-effective testing and quick design adjustments.

- High-volume PCBA assembly suits established products with stable designs, offering significant cost savings and consistent quality through automation.

- Choose low-volume assembly for flexibility and rapid development, especially in innovative sectors like IoT and technology startups.

- Select high-volume assembly when you need large quantities and reliable output, particularly in industries like automotive and medical devices.

- Evaluate your project needs, budget, and timeline to align your production strategy with the right assembly approach.

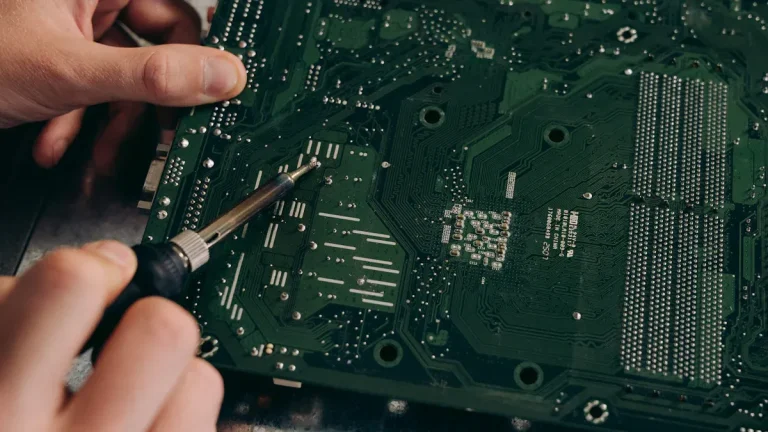

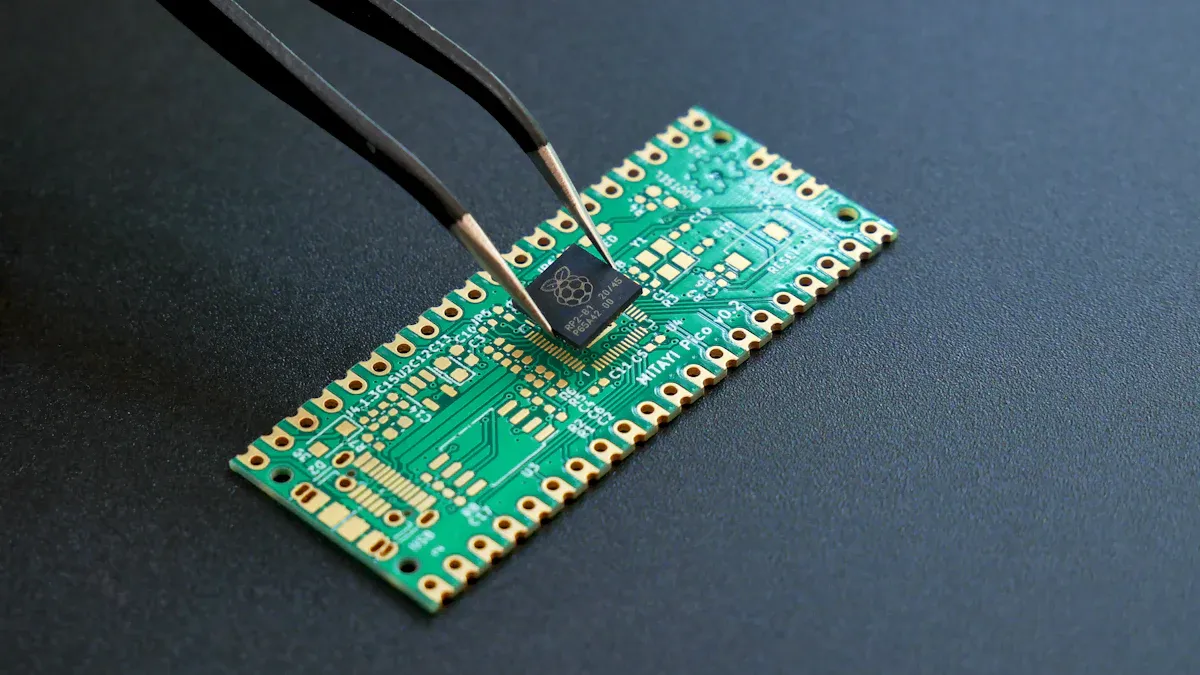

What Is Low-Volume PCBA Assembly?

Definition and Unit Range

You encounter low-volume pcba assembly when you need to produce a limited number of printed circuit boards for testing or market entry. In the Chinese manufacturing industry, low-volume pcba assembly typically refer to production runs that consist of fewer than 1,000 units. The range can extend from a single prototype to approximately 10,000 units.

- You may request just one board for the prototype PCBA China validation.

- You might order several hundred units for small batch PCBA assembly during early product launches.

- Flexible low-volume approaches allow you to scale production as your project evolves.

Key Benefits for Prototyping and Small Batches

Low-volume pcba assembly offers significant advantages when you need cost-effective prototyping or small batch PCBA assembly.

- You save money during the testing phase, since small batch production is budget-friendly and enables you to test designs without incurring high costs.

- You reduce waste and fix design errors before committing to larger manufacturing runs.

- You minimize overhead and storage costs associated with faulty prototypes.

- You benefit from a low-cost testing method, making adjustments without large-scale production.

- You experience faster completion times, which is essential for meeting tight deadlines. Many manufacturers deliver test boards in just a few days, supporting rapid development cycles.

This cost-effectiveness for prototyping helps you validate concepts and refine designs efficiently. You gain the flexibility to iterate quickly, which is crucial for prototype PCBA China projects and small batch PCBA assembly.

When to Choose Low-Volume PCB Assembly

You should select low-volume pcba assembly in several scenarios. The following table highlights common situations and reasons for choosing this approach:

| Scenario | Reason for Low-Volume PCB Assembly |

|---|---|

| Technology Innovators | Require flexibility and speed in product development cycles |

| Startups in the IoT Sector | Need quick validation of design concepts and performance |

| Iterative Design Modifications | Essential for adapting to changes during the development |

Low-volume pcba assembly supports you when you need to adapt quickly, validate new ideas, or manage risk before scaling up manufacturing. You gain control over your project timeline and budget, making this approach ideal for early-stage development and market testing.

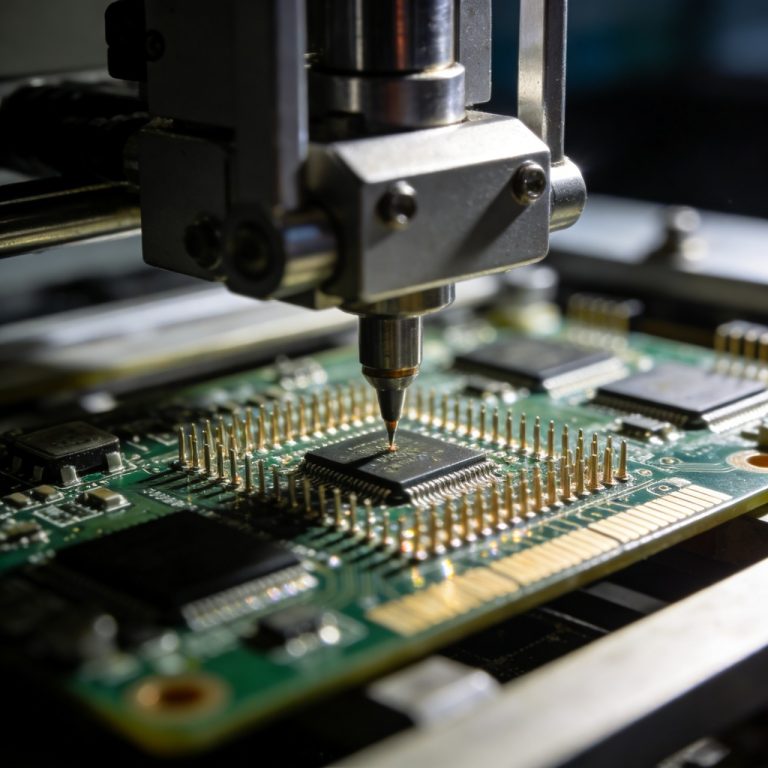

What Is High-Volume PCBA Assembly?

Definition and Scale

High-volume PCBA assembly refers to the process of producing printed circuit boards in large quantities, often for established products with steady demand. You may think that high-volume PCB assembly always requires a large minimum order, but leading Chinese providers such as PCBA Store and PCBasic offer flexible solutions.

- PCBA Store can start with as few as 10 pieces, allowing you to scale up quickly.

- PCBasic also provides high-volume PCB assembly with no strict minimum order quantity.

You benefit from high-volume PCB assembly when your project requires long production runs or consistent output for mass production. High-volume PCB manufacturing supports your business as you move from prototype to full-scale manufacturing.

Advantages of Mass Production

High-volume PCB assembly delivers several key benefits for mass production. You gain cost efficiency, consistent quality, and scalability. The following table highlights the main advantages:

| Advantage | Description |

|---|---|

| Cost Efficiency | Mass production allows for significant cost reductions per unit through bulk purchasing and optimized workflows. |

| Consistent Quality | Automated processes reduce variability, ensuring products are uniform in appearance and functionality. |

| Scalability | Manufacturers can easily increase production to meet rising demand without disruptions. |

| Faster Delivery | Optimized assembly services lead to reduced lead times, enhancing overall delivery speed. |

You achieve lower costs per unit and faster delivery times with high-volume PCBA manufacturing. Automated systems ensure that every board meets strict quality standards. You can scale your output to match market demand, making high-volume PCB assembly ideal for mass production.

Tip: High-volume PCB assembly helps you maintain product consistency and meet tight delivery schedules, especially when your business is growing rapidly.

When to Choose High-Volume PCB Assembly

You should choose high-volume PCB assembly when your project moves beyond prototyping and enters the mass production phase. Industries that rely on high-volume PCB assembly include:

| Industry | Applications |

|---|---|

| Aviation | Aviation electronics and systems |

| Drones | Drone technology and components |

| Electronics | General electronic devices |

| Automotive | Automotive electronics and systems |

| Medical | Medical devices and equipment |

| Telecommunications | 5G base stations, communication devices |

| Industrial | Industrial equipment and machinery |

You need high-volume PCB assembly for products with stable designs and large market demand. This approach suits you if you work in sectors such as automotive, telecommunications, or medical devices. High-volume PCB assembly supports your business when you require reliable, repeatable results and efficient manufacturing for long production runs.

Low-Volume vs High-Volume PCB Assembly: Key Differences

Process and Workflow Comparison

You face distinct process steps when you choose between low-volume pcba assembly and high-volume pcba assembly in China. Low-volume projects focus on stringent testing and prototyping. You often see smaller manufacturing batches and frequent design changes. You benefit from rigorous testing and troubleshooting, which helps you refine your product before scaling up. The workflow relies on parallel and sequential prototyping, allowing you to adapt quickly.

High-volume PCBAs emphasize speed, automation, and cost efficiency in bulk production. You work with larger manufacturing batches and stable designs. The process uses high-speed automated assembly lines, which streamline testing and minimize manual intervention. You achieve consistent results and rapid output, which supports large-scale manufacturing.

Here is a table that highlights the main differences in process and workflow:

| Aspect | Low-Volume PCBA Assembly | High-Volume PCBA Assembly |

|---|---|---|

| Production Focus | Stringent testing and prototyping | Speed, automation, and cost efficiency |

| Batch Size | Smaller manufacturing batches | Larger manufacturing batches |

| Design Flexibility | Frequent design changes and testing | Stable designs with fewer frequent changes |

| Testing Approach | More rigorous testing and troubleshooting | Streamlined testing processes |

| Production Method | Parallel and sequential prototyping | High-speed automated assembly |

| Cost | Higher cost per unit due to lower volume | Lower cost per unit due to mass production |

You can visualize the difference in workflow by using a flowchart. The flowchart would show how low-volume pcb assembly involves multiple feedback loops for design changes and testing, while high-volume pcb assembly follows a linear, automated path from design to finished product.

Cost, Lead Time, and Flexibility

You must consider cost, lead time, and flexibility when deciding between low-volume and high-volume PCBAs. China PCBA cost varies significantly based on production quantities and scale. Low-volume PCBAs usually have a higher cost per unit because you produce fewer boards. You pay more for specialized attention and frequent design changes. For example, prototype PCB boards (5–10 units) cost between $50 and $300 per board in 2025. Mass production (1000+ units) costs only $1 to $20 per board, which demonstrates the cost efficiency in bulk production.

Lead time also differs. You receive low-volume orders (1–50 units) in just 3–5 days. High-volume pcba assembly orders (10,000+ units) take 7–14 days, but automation and vertical integration in Chinese manufacturing facilities help speed up delivery for large batches.

Flexibility is another key factor. You enjoy high flexibility with low-volume PCBA assembly. Providers like PCBasic offer adaptable solutions for low to medium-volume projects. You can make frequent design changes and test new concepts. High-volume PCB assembly offers less flexibility. Providers such as Flex and Sanmina focus on large-scale enterprise projects with strict minimum order quantities and standardized designs.

Here is a comparison table for cost, lead time, flexibility, and quality:

| Feature | Low-Volume PCBA Assembly | High-Volume PCBA Assembly |

|---|---|---|

| Cost per Unit | $50–$300 (2025, 5–10 units) | $1–$20 (2025, 1000+ units) |

| Lead Time | 3–5 days (1–50 units) | 7–14 days (10,000+ units) |

| Flexibility | High (frequent design changes) | Low (stable designs) |

| Quality | Rigorous testing, high control | Automated, consistent output |

- Low-volume PCBAs assembly is ideal for specialized applications such as communication equipment, industrial control, medical health, and automotive electronics. You benefit from a smaller average order area, around 10 square meters, which requires more orders to reach significant sales revenue.

- High-volume PCBAs suit general consumer electronics and some automotive electronics, where demand is greater, and PCBs are more standardized.

Tip: If you need rapid prototyping and frequent design changes, choose low-volume pcb assembly. If you require large quantities and consistent quality, high-volume pcb assembly is the better option.

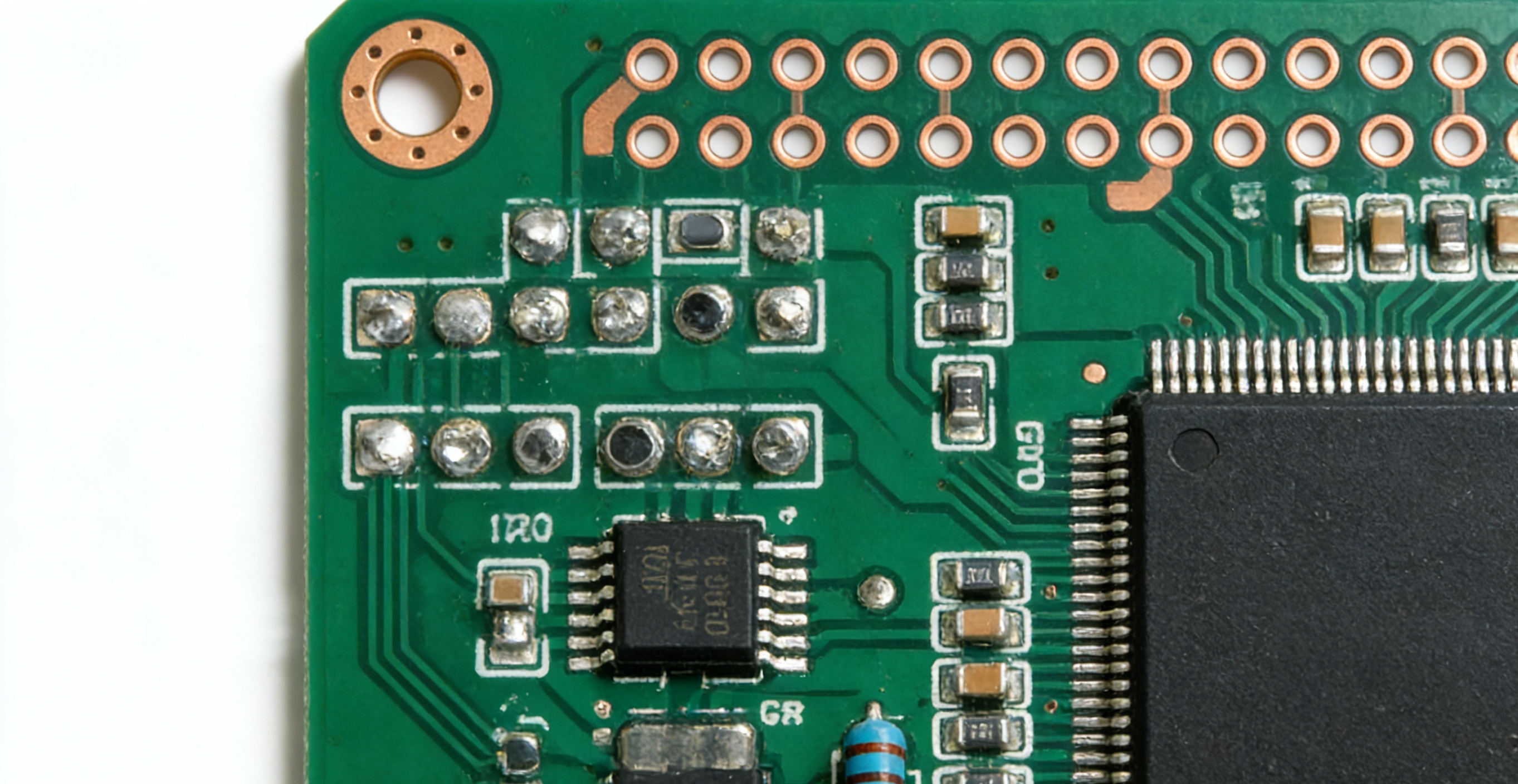

Quality and Consistency

You experience different levels of quality and consistency depending on your choice. Low-volume PCB assembly provides rigorous testing and troubleshooting. You catch design errors early and ensure each board meets your specifications. You have more control over quality, which is crucial for prototypes and specialized products.

High-volume PCBA assembly relies on automated processes. You achieve consistent quality across thousands of units. Automation reduces variability and ensures uniform appearance and functionality. You benefit from streamlined testing, which supports efficient manufacturing and reliable results.

- Low-volume PCBAs give you high control and adaptability, but at a higher cost per unit.

- High-volume PCBAs deliver uniformity and cost savings, making them ideal for mass production.

Note: You should evaluate your project requirements and market demand before choosing between low-volume and high-volume pcb assembly. The right choice helps you balance China PCBA cost, speed, flexibility, and quality.

Decision Factors for PCBA China Projects

Cost Considerations

You must evaluate cost at every stage of your project. Low-volume PCBA assembly often brings a higher per-unit cost because fixed engineering preparation costs are spread over fewer units. High-volume PCBA assembly reduces cost per unit through economies of scale. The following table shows how cost factors compare:

| Cost Factor | Low-Volume Assembly | High-Volume Assembly |

|---|---|---|

| Per-Unit Cost | Higher due to fixed costs | Lower due to economies of scale |

| Engineering Preparation | Spread over fewer units, increasing the cost | Spread over many units, reducing cost |

| Component Pricing | Less favorable, no bulk discounts | More favorable, benefits from bulk discounts |

| Labor Cost Allocation | Higher proportion per unit | Lower proportion per unit |

| Quality and Testing | May vary, often less automated | Consistent quality with automated processes |

You see the same machine setup time for both low-volume and high-volume runs, but only high-volume runs benefit from bulk discounts. China PCBA cost becomes more competitive as you scale up. For more details, visit our PCBA Assembly Services.

Flexibility and Customization Needs

You gain significant advantages with low-volume PCB assembly if your project demands customization and flexibility in design. Providers like PCBasic and Seeed Fusion offer tailored solutions for complex requirements. They support rapid prototyping, competitive pricing, and fast turnaround. High-volume PCBA assembly focuses on standardized processes, which limit customization options. If you need unique features or frequent design changes, low-volume is the better fit. Learn how we help clients adapt quickly in See Our Success Stories.

Lead Time and Delivery

You benefit from reduced lead times for small orders with low-volume PCBA assembly. Quick delivery supports rapid development and market entry. High-volume PCBA assembly offers fast output for large batches, but initial setup and procurement may extend lead times. Choose low-volume for urgent prototypes and high-volume for established products with predictable schedules.

Quality Assurance and Risk Management

You must prioritize quality assurance to manage risk in pcba China projects. Define design specifications, maintain updated reference files, and document procedures for each job. Assign quality inspectors and work with verified suppliers to ensure consistency. Regular audits and root cause analysis tools like the 5 Whys technique help you identify and fix issues. High-volume PCBAs rely on automated testing for consistent quality, while low-volume PCBAs allow for more hands-on inspection. For tailored guidance, Contact Us.

Scalability and Future Growth

You need a partner who supports your growth from prototype to mass production. Chinese PCBA providers offer unmatched flexibility, handling both small batches and large-scale runs. PCBasic specializes in high-mix, small-to-medium batch production, helping you scale as your project evolves. Strong supplier relationships also improve component pricing and availability, making it easier to expand. Consider including a case study image from a real China project to visualize this journey.

How to Choose the Right PCBA China Partner

Supplier Selection Criteria

You need to evaluate several factors when selecting a partner for your PCBA China project. The right supplier will help you achieve consistent quality, reliable delivery, and cost efficiency. Consider the following criteria:

| Criteria | Description |

|---|---|

| Quality of PCBA Production | Ensures the dimensions, drilling, and overall quality of the PCBA meet specifications. |

| Quality of Service | Involves responsiveness, customization capabilities, and turnaround times. |

| Supplier Experience | The supplier’s history and expertise in the industry. |

| Market Sector Expertise | Knowledge of specific industry requirements and best practices. |

| Certification Standards | Compliance with relevant industry certifications to ensure quality and reliability. |

| Problem-Solving Approach | The supplier’s ability to address issues and improve processes. |

| Supply Chain Management | Effective sourcing and management of components to prevent delays. |

| Design for Manufacturability (DFM) | Identifying design flaws and inefficiencies before production to save costs. |

| Industry Reputation | Trustworthiness based on customer feedback and reviews. |

| Cost vs Quality Balance | Evaluating the trade-off between cost and the quality of services provided. |

| Equipment Capabilities | Modern equipment and the capacity to handle complex orders efficiently. |

| Overall Improvement Commitment | The supplier’s dedication to continuous improvement and employee training. |

You should prioritize suppliers who demonstrate strong quality control, fast response times, and experience with both small batch PCBA assembly and high-volume PCBA manufacturing. This approach helps you avoid costly errors and ensures your product meets market standards.

Transitioning from Low-Volume to High-Volume

You may start with prototype PCBA China runs and later scale to mass production. Successful transitions require careful planning. In early stages, your designs may not be optimized for cost or function. As you move to high-volume PCBA manufacturing, you need to refine your design for manufacturability and cost efficiency. You should work with suppliers who offer both prototyping and mass production services. This ensures a smooth handoff and consistent quality.

| Prototyping/Low Volume | High Volume |

|---|---|

| High per-unit cost | Low per-unit cost |

| Sourcing by the design team | Sourcing by the procurement team and the manufacturer |

| QC varies by vendor | Specific QC programs by assembly vendor |

| Programming by designers | Programming on the line or pre-programmed parts |

You benefit from suppliers who provide design feedback, stable sourcing, and robust quality control throughout the transition. This reduces China PCBA cost and minimizes production risks.

Protecting IP and Ensuring Quality

You must protect your intellectual property and ensure product quality when working with PCBA China partners. Leading suppliers use strict NDA agreements and secure data handling to safeguard your designs. They implement automated inspection equipment, such as AOI and X-ray systems, to detect defects. Functional and circuit testing confirm that every board works as intended. International certifications like ISO and RoHS demonstrate compliance with global standards.

Tip: Regular factory audits, bilingual project managers, and real-time tracking systems further enhance quality and communication. You should choose partners who commit to continuous improvement and transparent processes.

By focusing on these strategies, you can confidently manage China PCBA cost, protect your innovations, and deliver reliable products to market.

You achieve rapid innovation and flexibility with small batch PCBA assembly and prototype PCBA China projects. High-volume PCB manufacturing delivers cost efficiency for stable designs and large-scale production. Align your strategy with business goals, budget, and timeline to optimize China PCBA cost.

- Consult experienced suppliers early to leverage technical expertise.

- Define clear requirements and review manufacturer capabilities.

- Prioritize quality control and effective communication.

Selecting the right partner ensures your project succeeds. Request a quote or explore case studies to guide your next steps.

FAQ

What factors influence China PCBA cost?

You see China PCBA cost change based on order volume, component selection, and assembly complexity. High-volume PCB manufacturing lowers per-unit cost. Small batch PCBA assembly often has higher setup fees. Material quality and testing requirements also impact your final price.

When should you choose Prototype PCBA China services?

You select prototype PCBA China services when you need to test new designs, validate concepts, or refine product features. Rapid prototyping helps you identify errors early. You gain flexibility and speed, which supports faster market entry and design improvements.

How does small batch PCBA assembly benefit startups?

You benefit from small batch PCBA assembly by reducing upfront investment and minimizing risk. You can test products in the market before scaling. This approach lets you adjust designs quickly and control China PCBA cost during early development stages.

What quality checks do high-volume PCBA manufacturing providers offer?

You receive automated inspections, such as AOI and X-ray testing, from high-volume PCBA manufacturing providers. These checks ensure consistent quality across large orders. You also see functional testing and strict process controls to meet industry standards.

Can you switch from low-volume to high-volume PCBA manufacturing easily?

You transition smoothly when you work with suppliers who support both prototype PCBA China and mass production. You refine your design for manufacturability. You benefit from stable sourcing, consistent quality, and lower China PCBA cost as you scale up.