Before you approach any China PCBA manufacturer, you need to clarify your project’s complexity and technical requirements. List every customization, required engineering support, and your quality standards. Request upfront verification of certifications such as ISO 9001, IPC-A-610, RoHS, and more. You should also assess technical capabilities, production capacity, and lead time. The following table highlights the most common certifications international clients require from a reliable PCBA manufacturer or a reliable PCBA manufacturer in electronics manufacturing and PCBA assembly service projects:

| Certification | Description |

|---|---|

| ISO 9001 | Quality Management Systems |

| ISO 13485 | Medical Device Quality Management |

| RoHS | Restriction of Hazardous Substances |

| REACH | Chemical substance regulation |

| ISO 14001 | Environmental Management |

| UL | Fire and safety compliance |

| IPC-A-610 | Global workmanship standard |

| IPC-7711/7721 | Precision rework standard |

| IATF 16949 | Automotive Quality Standard |

| ISO 45001 | Occupational Health & Safety |

| CE Marking Support | Compliance for the European market |

| FCC Compliance Support | Compliance for the US market |

| ISO/IEC 17025 | Laboratory Testing Competence |

5 Essential Criteria for Vetting a China PCBA Manufacturer in 2025

- Define your project requirements clearly. List all customization needs, engineering support, and quality standards before contacting manufacturers.

- Verify certifications like ISO 9001 and IPC-A-610. These certifications ensure the manufacturer meets quality and safety standards essential for complex designs.

- Assess the manufacturer’s technical capabilities. Look for advanced equipment and experience with multi-layer and rigid-flex boards to ensure they can handle your project.

- Request samples and prototypes. Comparing prototypes from different suppliers helps you evaluate quality and make an informed decision.

- Ensure strong communication and post-production support. A reliable manufacturer should provide timely responses and comprehensive defect handling after delivery.

Why Complex Designs Need Special Vetting for Chinese PCBA Manufacturer

Consumer vs. Advanced China PCBA Manufacturer

You will notice a clear difference between consumer-grade and advanced manufacturers when you move into complex PCB assembly. Consumer-focused suppliers often handle simple, single- or double-layer boards for everyday devices. These projects do not require advanced process control or tight tolerances. In contrast, advanced manufacturers specialize in high-density interconnect (HDI), multi-layer, and fine-pitch BGA designs. They invest in precision equipment, robust engineering support, and strict quality systems. This expertise is essential for industries like aerospace, automotive, and medical devices, where reliability and performance cannot be compromised.

When you select a China PCBA manufacturer for complex projects, you must consider several risks:

- Design complexity can lead to errors in HDI and multi-layer PCB designs.

- Material selection may not meet the required quality standards, impacting performance.

- Technical challenges in manufacturing processes can result in production delays and increased costs.

- Quality assurance issues can arise, leading to defective products.

- Supply chain management challenges may affect the availability of necessary components.

- High-density designs require innovative tactics to balance performance and cost, which can be difficult to achieve.

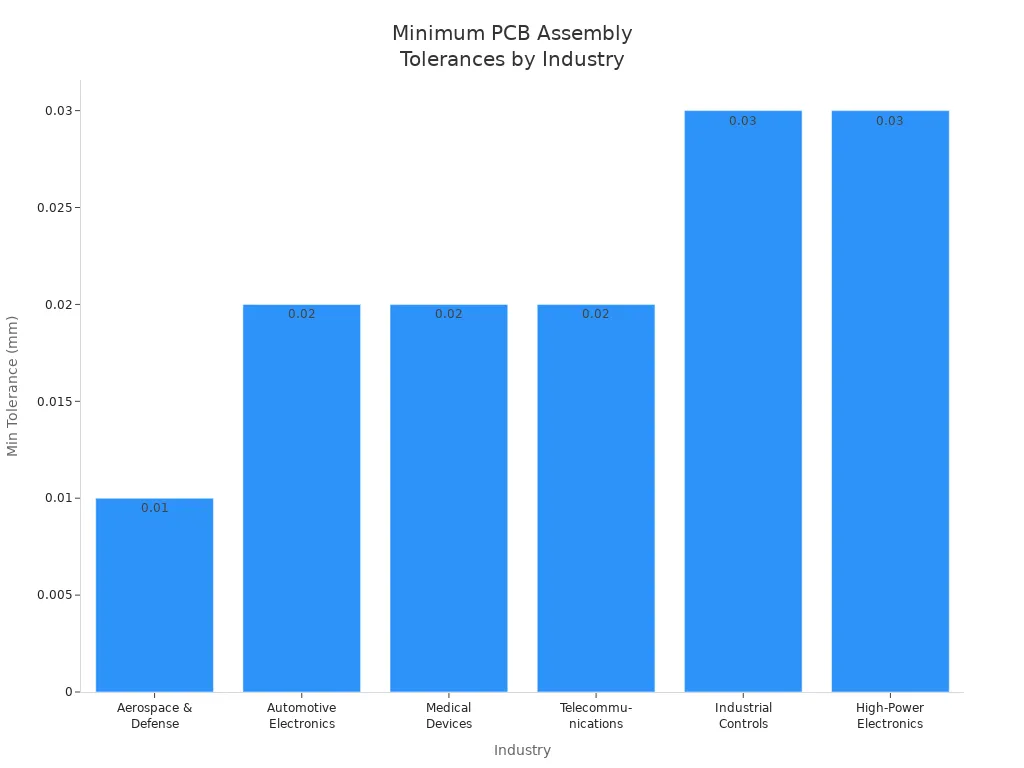

Error Tolerance in HDI and Multi-layer Assembly

Error tolerance becomes critical in advanced electronics manufacturing. For HDI and multi-layer PCB assembly, you must demand tighter tolerances and higher IPC class standards. The following table shows typical tolerances for different industries:

| Industry | IPC Class | Typical Tolerances | Key Considerations |

|---|---|---|---|

| Aerospace & Defense | Class 3 | ±0.01–0.03 mm (±0.4–1.2 mil) | High reliability under extreme vibration, temperature, and radiation. |

| Automotive Electronics | Class 2–3 | ±0.02–0.05 mm (±0.8–2 mil) | Critical systems must perform under harsh thermal/mechanical stress. |

| Medical Devices | Class 3 | ±0.02–0.03 mm (±0.8–1.2 mil) | Ensures accurate functionality and patient safety. |

| Telecommunications | Class 2 | ±0.02–0.04 mm (±0.8–1.6 mil) | Maintains signal integrity for high-frequency circuits. |

| Industrial Controls | Class 2 | ±0.03–0.05 mm (±1.2–2 mil) | Reliable operation under vibration and temperature variations. |

| High-Power Electronics | Class 2 | ±0.03–0.05 mm (±1.2–2 mil) | Supports efficient current flow and thermal dissipation. |

You should always verify that your supplier can meet these standards before starting production.

Advanced Features: Blind/Buried Vias, Fine-pitch BGA

Complex PCBA designs often require advanced features such as blind and buried vias or fine-pitch BGA components. These features demand specialized equipment and strict process control. For example, precise drilling and plating operations are essential for buried vias. Designers must also consider the aspect ratio of the vias to ensure reliability. Blind and buried vias increase the cost of PCBs due to the extra work and testing required. You should use these features only when necessary to maintain efficiency and control costs.

Tip: Always ask your supplier about their experience with advanced features and request examples of previous projects with similar complexity.

Choosing the right partner for complex PCBA projects means looking beyond basic capabilities. You need a manufacturer with proven expertise, advanced technology, and a strong track record in high-reliability sectors.

Auditing Technical Capabilities for Turnkey PCBA Assembly

Selecting the right partner for turnkey pcba assembly requires a thorough audit of technical capabilities. Complex projects demand more than basic assembly skills. You need a manufacturer who can support your design from the earliest engineering review through to final testing and delivery. This section guides you through the critical areas to evaluate.

DFM Review and Engineering Support

A robust Design for Manufacturability (DFM) review forms the foundation of successful turnkey pcb assembly. You should expect your China PCBA manufacturer to provide comprehensive engineering support, including DFM checks, as a standard part of their service. Many leading suppliers, such as Suntak, offer DFM reviews at no extra cost. This proactive approach helps you optimize your design before production, reducing the risk of costly errors and delays.

When you audit a potential partner, ask about their DFM process. Engage their engineering team in a technical discussion to assess their expertise. A reliable pcba manufacturer will not only review your Gerber files but also suggest improvements for manufacturability, component placement, and testability. You should also inquire about their quick-turn prototyping flow. Fast and agile prototyping demonstrates their commitment to new product introduction (NPI) and their ability to prioritize your project.

Tip: Always request a sample DFM report. This document reveals the depth of their analysis and their attention to detail.

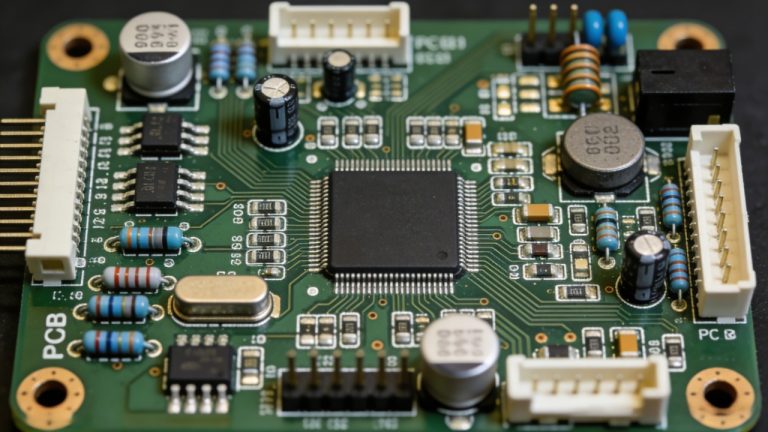

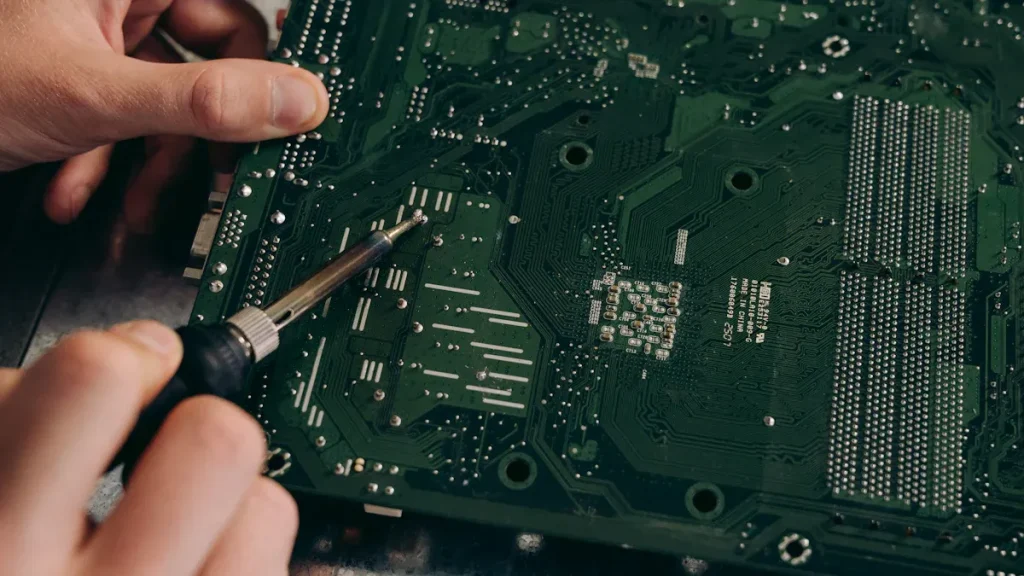

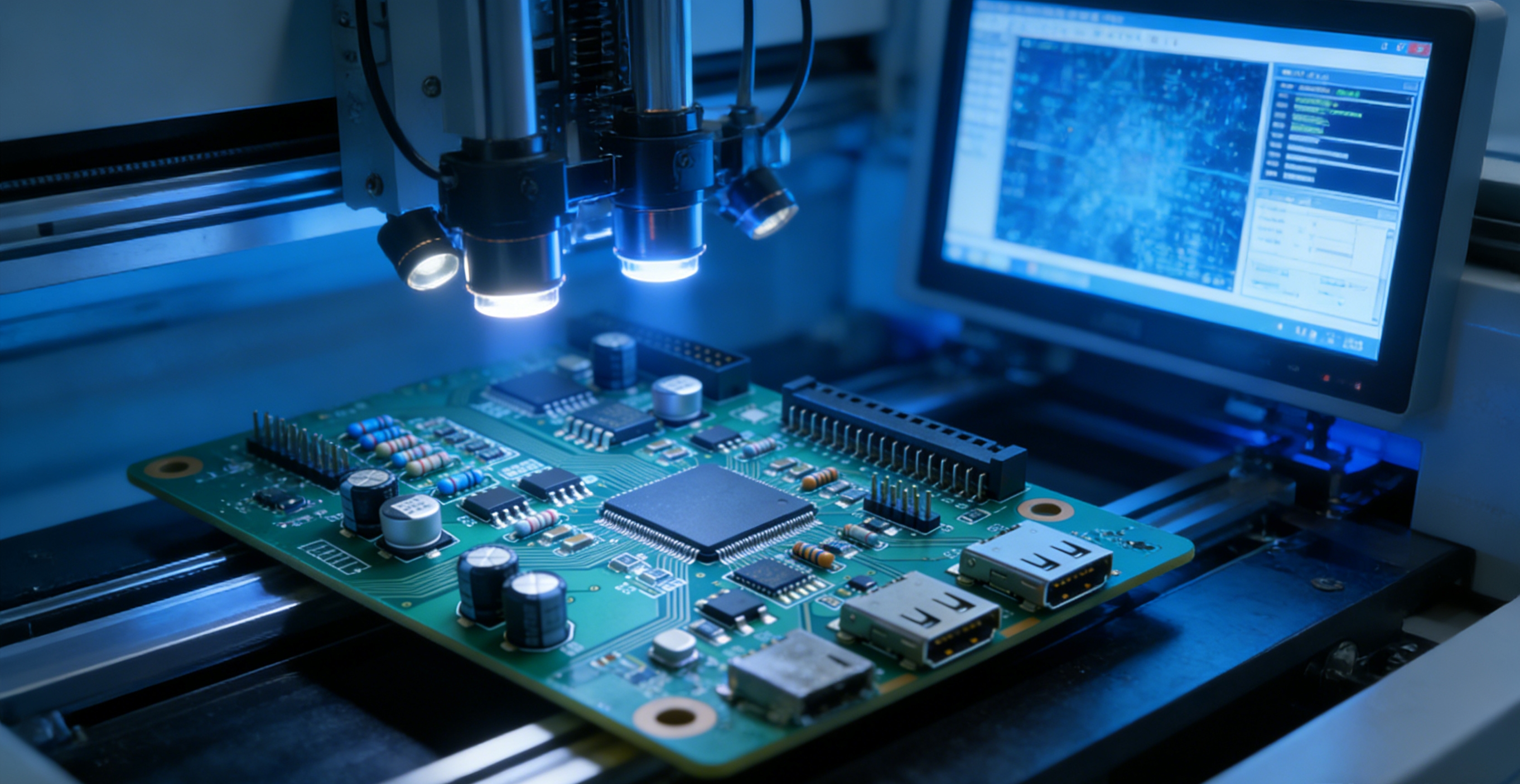

Precision Equipment: 3D AOI, X-Ray, SMT

Advanced turnkey pcb assembly relies on state-of-the-art inspection and assembly equipment. You should verify that your supplier uses 3D Automated Optical Inspection (AOI), X-ray inspection, and high-precision Surface Mount Technology (SMT) lines. These tools play a vital role in detecting and preventing defects that can compromise complex assemblies.

3D AOI and X-ray systems identify a wide range of issues, including:

- Solder joint defects such as shorts, bridges, and voids

- Ball grid array (BGA) problems, such as uneven or missing solder balls

- Chip-scale package cracks and fractures

- Component placement errors

- Plated through-hole defects, including inadequate fill and poor plating

High-precision SMT lines enable accurate placement of 0201 components and 0.35mm pitch BGAs. This capability is essential for HDI, fine-pitch, and high-reliability applications. You should also confirm the presence of in-line Solder Paste Inspection (SPI), In-Circuit Testing (ICT), and Functional Circuit Testing (FCT) for comprehensive quality control.

Note: Request to see sample inspection reports or defect rate statistics. This data provides insight into their process control and commitment to quality.

Experience with Multi-layer and Rigid-Flex Boards

Complex designs often require multi-layer or rigid-flex PCBs. Not every pcb assembly service provider can handle these advanced substrates. You should audit the manufacturer’s experience by reviewing their factory capabilities and technical documentation.

Key indicators of technical capability include:

- Factory size, layout, and cleanliness

- Support for single-sided, double-sided, multilayer, HDI, flex, rigid-flex, and metal core PCBs

- Monthly and peak production capacity

- ESD-safe assembly zones and environmental controls

- Ability to fabricate up to 20+ layers with fine trace/space resolution

- Minimum drill/via size and aspect ratio for microvias, blind/buried vias, and via-in-pad

- Controlled impedance design and test capability

- SMT, THT, mixed, and BGA assembly support

- Automated optical inspection (AOI) and documented quality procedures

- Incoming material inspection and traceability

- Lead times for both fabrication and assembly

- NDA protection for all shared files and communications

You should also question the engineering team about their experience with high-frequency laminates and their processing guidelines. A reliable pcb manufacturer will have documented quality manuals, standard operating procedures, and a proven track record with multi-layer and rigid-flex projects.

Checklist for Supplier Audit:

- Can the manufacturer support your required PCB type and layer count?

- Do they have advanced inspection and assembly equipment?

- Will they provide DFM review and engineering support?

- Can they demonstrate experience with similar complex projects?

- Are their quality control and traceability systems robust?

- Do they offer quick-turn prototyping and transparent communication?

Finally, always request samples and prototypes before committing to full-scale production. Comparing prototypes from multiple suppliers allows you to verify their technical claims and select the most capable partner for your turnkey pcb assembly needs.

Component Sourcing and Traceability in Chinese PCBA Manufacturer Selection

Anti-counterfeit and BOM Optimization

You must ensure that every component in your assembly is genuine and traceable. Leading manufacturers use several methods to prevent counterfeit parts from entering the supply chain:

- Perform visual inspections for discrepancies in labeling and packaging.

- Verify part numbers against the manufacturer’s datasheet.

- Conduct electrical testing to confirm key parameters.

You should always source components from authorized distributors. Check manufacturer websites for approved distributor lists and request proof of authorization. Reliable pcba manufacturer partners also implement robust traceability systems, allowing you to track each part from origin to finished product.

| Method | Description |

|---|---|

| Certification | Suppliers should be ISO 9001:2015 certified, showing commitment to quality. |

| Traceability | Documented procedures track components from source to end-user. |

| Testing Services | Electrical and structural tests identify counterfeit parts. |

| Visual Inspection | Checks for inconsistencies in packaging and markings. |

Optimizing your bill of materials (BOM) is essential for controlling costs and ensuring reliability in electronics manufacturing. You can simplify designs, choose cost-effective materials, and leverage volume economics by partnering with a reliable pcb manufacturer. Effective BOM management supports accurate planning and a stable supply chain, which helps you meet your project’s lead time and production capacity targets.

Supply Chain Transparency and Vendor Management

Supply chain transparency protects your project from delays and quality issues. You should use vendor management solutions to monitor suppliers and ensure compliance. Adopt traceability systems, such as barcodes or RFID tags, to track components throughout the process. Partner with ethical suppliers and conduct regular audits to maintain high standards.

- Implement real-time tracking software for production status and shipments.

- Use IoT devices for live data on component locations and conditions.

- Train your team on transparency tools and best practices.

A reliable China PCBA Manufacturer will provide complete visibility into the production cycle, including real-time updates and open communication. This approach builds trust and ensures that your HDI, blind/buried vias, and fine-pitch BGA projects meet the highest standards.

Tip: Always compare multiple manufacturers by ordering prototypes. This step allows you to evaluate their sourcing practices, traceability systems, and overall quality before committing to full-scale production.

Quality Management Systems and Certifications

Beyond ISO 9001: IATF 16949, ISO 13485

You need to verify that your chosen partner operates a robust quality management system. While ISO 9001 forms the foundation, advanced projects require more. For automotive applications, IATF 16949 certification ensures your supplier meets strict process and traceability standards. For medical devices, ISO 13485 certification demonstrates compliance with regulatory requirements and risk management. These certifications show that the manufacturer can deliver consistent results for high-reliability sectors.

A high-quality manufacturer will also hold IPC-A-610 and RoHS certifications. IPC-A-610 sets the global standard for electronics manufacturing workmanship. RoHS compliance ensures your products meet environmental safety standards. When you audit suppliers, request documentation for each certification. This step protects your project from costly compliance issues and supports long-term stability.

Advanced quality management systems reduce defect rates, improve reliability, and increase customer satisfaction. You benefit from enhanced process control, better component handling, and comprehensive testing protocols.

In-Process Controls: SPI, ICT, FCT, Prototyping

You should evaluate the in-process controls your supplier uses during PCB assembly. These controls catch defects early and keep your project on track. The table below outlines the main controls and their roles:

| In-Process Control | Role in Quality Assurance |

|---|---|

| Solder Paste Inspection (SPI) | Ensures the correct application of solder paste, preventing defects in solder joints. |

| In-Circuit Testing (ICT) | Tests individual circuits for a comprehensive assessment of functionality. |

| Functional Circuit Testing (FCT) | Verifies that the entire circuit board functions as intended under real-world conditions. |

Identifying defects during solder paste application reduces rework costs. A fault found after reflow can cost ten times more to fix than one caught before. Delayed detection increases costs further. Functional Circuit Testing (FCT) confirms that all components work together as intended, which is vital for product reliability.

You should also ask about iterative prototyping. Leading Chinese PCBA manufacturers offer flexible iterations and rapid prototyping—sometimes delivering double-sided PCB prototypes in as little as eight hours. This approach allows you to optimize your design quickly and minimize risk.

Supplier Checklist for Complex PCBA Projects:

- Confirm all relevant certifications (ISO 9001, IATF 16949, ISO 13485, IPC-A-610, RoHS)

- Review in-process controls (SPI, ICT, FCT)

- Request sample inspection and test reports

- Assess rapid prototyping capabilities

- Ensure transparent communication and engineering support

For more details on HDI and complex PCB assembly, visit our [HDI/complex PCB assembly service page]. To learn about DFM best practices, see our [DFM engineering service introduction].

Communication and Support from a Chinese PCBA Manufacturer

Engineering Responsiveness and Project Dialogue

You need clear, responsive communication when working with a Chinese PCBA manufacturer on complex projects. Strong relationships and trust form the foundation of successful collaboration. In Chinese business culture, you build trust through consistent communication and mutual respect. Regular feedback loops help you and your supplier stay aligned, especially when handling advanced features like HDI, blind/buried vias, or fine-pitch BGA.

Effective project dialogue relies on structured systems. Leading manufacturers use documented change request systems to track every engineering update. This approach reduces errors and ensures that all parties understand the latest requirements. You benefit from electronic approval processes, which provide reliable records for audits and compliance.

| Best Practice | Description |

|---|---|

| Documented Change Request System | All change requests are formally recorded and tracked to prevent miscommunication. |

| Clear Communication | Open lines of communication keep everyone informed about project changes. |

| Electronic Approval Process | Digital documentation ensures compliance and traceability. |

A reliable pcba manufacturer will use a shared database to log engineering changes. You receive electronic summaries of each request, and the system archives all interactions for future reference. This level of transparency is essential for maintaining quality standards in your pcb assembly service.

Post-Production Support and Defect Handling

You should clarify expectations for post-production support before starting production. Reliable pcb manufacturer partners offer comprehensive defect handling and technical support after delivery. Standard procedures include functional testing, burn-in testing, automated and manual inspections, and soldering quality control. These steps ensure your assembled boards meet performance and reliability targets.

| Procedure Type | Description |

|---|---|

| Functional Testing | Simulates end-use conditions to verify PCBA performance. |

| Burn-in Testing | Powers the board for extended periods to detect early failures. |

| Automated Inspection | Uses AOI to catch assembly defects before shipment. |

| Manual Inspection | Adds human oversight to identify issues missed by machines. |

| Soldering Quality Control | Monitors solder joint quality through temperature and material checks. |

Top-tier suppliers respond to post-production support inquiries within 2–4 hours, with some replying in less than 2 hours. This rapid response helps you resolve issues quickly and maintain your project’s lead time. When you select a partner, confirm their support process and average response time. Fast, effective communication ensures that your complex designs receive the attention they deserve.

To select the right China PCBA manufacturer for complex designs, follow these steps:

- Define your project requirements, including HDI, blind/buried vias, and fine-pitch BGA needs.

- Verify certifications and audit technical capabilities, focusing on SPI, ICT, FCT testing, and iterative prototyping.

- Assess supply chain transparency and confirm the ability to meet your lead time.

- Request samples and compare prototypes for quality assurance.

Common pitfalls include poor communication, lack of certifications, and outdated equipment.

Supplier Checklist:

- Official licenses & certificates

- Advanced technology utilization

- Quality control metrics

- English communication fluency

- Responsiveness level

Have a complex PCBA design that others find challenging? Consult with our engineering experts at [Sanshun Smart] to ensure your project’s success from the prototype.

FAQ

What makes a Chinese PCBA manufacturer suitable for complex designs?

You need a manufacturer with proven experience in HDI, Blind/Buried Vias, and Fine-pitch BGA assembly. Look for advanced equipment, strong engineering support, and certifications like ISO 9001 and IPC-A-610. Reliable suppliers also offer SPI, ICT, and FCT testing for quality assurance.

How do you verify component authenticity in a turnkey PCB assembly?

Request documentation showing that components come from authorized distributors. Leading Chinese PCBA manufacturers use traceability systems and perform visual, electrical, and structural tests. This process helps prevent counterfeit parts from entering your supply chain.

Why is iterative prototyping important for complex PCBA projects?

Iterative prototyping lets you test and refine your design before mass production. You can catch errors early, optimize performance, and reduce costs. Top manufacturers offer rapid prototyping, which supports faster new product introduction and better project outcomes.

What in-process controls should you expect from a reliable PCBA manufacturer?

Expect Solder Paste Inspection (SPI), In-Circuit Testing (ICT), and Functional Circuit Testing (FCT). These controls help detect defects early, ensuring your complex PCB assembly meets strict quality standards.

How can you compare multiple Chinese PCBA manufacturers for your project?

Order prototypes from several suppliers. Evaluate their quality, communication, and technical capabilities. Use a supplier checklist to compare certifications, equipment, engineering support, and post-production services.