You face a complex global PCBA market in 2025. Tariffs, shifting regulations, and emerging competitors continue to reshape strategies. Many OEMs encounter challenges such as rising tariffs, operational costs, and supply chain disruptions:

| Challenge Type | Description |

|---|---|

| Rising Tariffs | Higher tariffs and trade restrictions impact sourcing decisions. |

| Increased Operational Costs | Energy shortages and compliance demands raise costs. |

| Supply Chain Disruptions | Logistics and sourcing face ongoing instability. |

| Compliance Uncertainty | Tighter regulations complicate compliance. |

| Intellectual Property Risks | IP enforcement remains a concern. |

Despite these hurdles, PCBA China continues to deliver unmatched cost efficiency, advanced technology, and rapid cluster response—benefits that extend far beyond labor costs.

Why PCBA China Remains the Strategic Choice for Global OEMs in 2025: Beyond Cost Efficiency

- Chinese PCBA manufacturing offers unmatched cost efficiency, with production costs significantly lower than in North America and Europe.

- Rapid response times from industry clusters in China ensure quick turnaround for urgent orders, helping you meet tight deadlines.

- Advanced technology and automation in Chinese factories enhance production quality and efficiency, providing reliable products.

- Strong government support and ongoing R&D investments position Chinese manufacturers as leaders in innovation and market adaptability.

- ISO certifications and rigorous quality control processes guarantee that products meet global standards, ensuring compliance and reliability.

Why PCBA China Leads in 2025

Cost Efficiency & Scalability

You see, PCBA China maintains its leadership in the global market by combining cost efficiency with unmatched scalability. In 2025, China holds approximately 60% of the global PCBA market share, far outpacing competitors in Southeast Asia and Mexico. This dominance stems from a strategic blend of advanced manufacturing, robust supply chain integration, and aggressive pricing.

- You benefit from lower overall manufacturing costs, especially for high-volume production. PCBA assembly in China typically costs around $545, whereas similar services in North America cost around $1,100.

- Labor costs in China remain about 10% to 20% of those in the USA and Europe. Average hourly wages range from $3 to $6, compared to $15 to $30 in the United States.

- Asian manufacturers, including those in PCBA China, leverage local material supply chains and proximity to suppliers. This reduces material costs by 5-10% and shortens delivery cycles.

- Western regions face higher overhead and regulatory compliance costs, making them less competitive for large-scale projects.

You gain access to rapid prototyping and mass deployment through China’s mature PCB industry clusters. These clusters enable a delivery cycle of 7-15 days for regular orders, which is significantly faster than the international average. Continuous R&D investment supports rapid technological iteration and customization, allowing you to optimize your BOM and benefit from turnkey PCBA solutions. One-stop services streamline the supply chain, ensuring you meet tight project deadlines.

Tip: When you choose PCBA China, you tap into a system designed for speed and flexibility. Industry clusters respond within 48 hours, minimizing risk and maximizing efficiency for your business.

| Evidence Type | Description |

|---|---|

| Cost Efficiency | Production costs for metal-based PCBs in China are 20%-40% lower than in Europe and the U.S. |

| Supply Chain Maturity | PCB industry clusters in China enable a delivery cycle of 7-15 days for regular orders. |

| Technological Capability | Continuous R&D investment allows for rapid technological iteration and customization. |

| Turnkey Services | One-stop solutions streamline the supply chain for faster prototyping and deployment. |

Market Penetration & Pricing

PCBA China continues to set the pace for global market penetration and pricing. You see Chinese manufacturers dominate with a market share of 20.66%, compared to 6.15% for Southeast Asia and 3.81% for Mexico. This leadership is not just about volume; it reflects a sophisticated balance of cost, quality, and scale.

| Region | Market Share (%) |

|---|---|

| China | 20.66 |

| Southeast Asia | 6.15 |

| Mexico | 3.81 |

You benefit from aggressive pricing strategies that do not compromise quality. Leading manufacturers in PCBA China, such as JLCPCB and PCBWay, offer competitive prices by leveraging economies of scale and advanced automation. These companies implement rigorous quality control processes, including DFM practices and ISO-certified inspections, to ensure reliability.

You also gain from BOM Optimization and integrated sourcing, which further reduce costs and enhance product quality. The large-scale operations in regions like Shenzhen allow manufacturers to deliver consistent results for both small and large orders. You can trust PCBA China to provide turnkey PCBA solutions that meet global standards while keeping your costs under control.

Note: PCBA China balances aggressive pricing with established quality control and certifications. You receive reliable products without sacrificing performance or compliance.

You find that, in 2025, PCBA China remains the preferred choice for global OEMs seeking cost efficiency, scalability, and market reach. The combination of advanced technology, supply chain maturity, and rapid cluster response ensures that you stay ahead in a competitive landscape.

Manufacturing Strengths & Technology

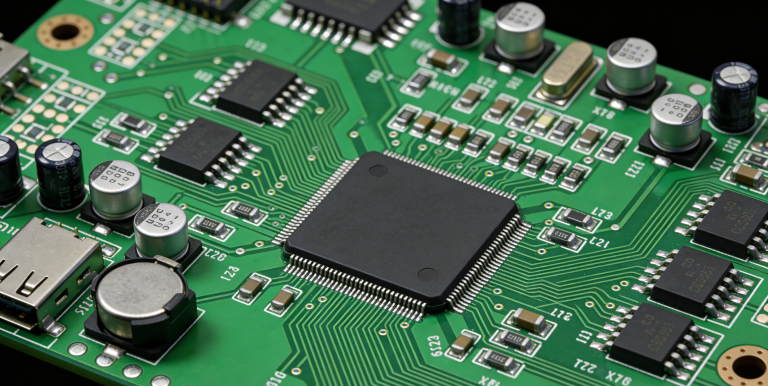

SMT & HDI Capabilities

You gain a significant advantage when you choose PCBA China for advanced SMT and HDI capabilities. Chinese manufacturers lead the industry with high-precision SMT lines and the ability to produce complex multilayer and HDI boards. You see these strengths reflected in the following technical capabilities:

| Capability Type | Description |

|---|---|

| Multilayer Rigid PCB | Specialized in high-performance, multilayer PCBs for diverse industries. |

| High-Difficulty & High-Density Interconnect (HDI) PCB | Advanced HDI with stacked microvia technology. |

| High Layer Count Constructions | Capable of producing PCBs with up to 70 layers. |

| High-Speed / Ultra Low-Loss Materials | Utilizes materials that support high-speed applications. |

| Thermal Solutions with Attached Copper Coins | Innovative thermal management solutions. |

| RF Materials and Hybrid Build-Ups | Expertise in RF applications and hybrid PCB constructions. |

| Blind and Buried Mechanical and Microvia Technologies | Advanced via technologies for complex designs. |

| Back-drilling | Techniques to improve signal integrity. |

| Epoxy-filled Via in Pad Plated Over (VIPPO) | Advanced via filling techniques for enhanced reliability. |

You notice that the PCB industry in China is projected to exceed $50 billion USD by 2025, driven by sectors such as 5G, electric vehicles, and AI. Strong supply chain integration, including copper foil and laminates, enhances manufacturing efficiency. In comparison, Southeast Asia and Mexico lag in the mass production of fine-line HDI circuits and multilayer boards. For example, 47.8% of PCB output value in China comes from middle and low-level boards, while the United States and Japan report only 31.4% and 19.6%, respectively.

Sanshun Smart stands out with expertise in PCBA assembly, component sourcing, and rigorous quality control. You benefit from ISO-certified processes and AOI inspection, ensuring consistent quality and reliability for every order.

Automation & Smart Manufacturing

You experience the benefits of automation and smart manufacturing when working with PCBA China. In 2025, leading Chinese PCBA factories have automated over 80% of their production processes. This high level of automation supports rapid prototyping, mass deployment, and BOM Optimization. You receive turnkey PCBA solutions that meet global standards and adapt quickly to market changes.

- AI-driven smart manufacturing enables real-time monitoring and DFM practices.

- Integrated supply chains allow for flexible sourcing and fast response to demand shifts.

- Industry clusters in China respond within 48 hours, minimizing risk and maximizing efficiency.

You see that PCBA China combines technical expertise, automation, and supply chain resilience to deliver unmatched manufacturing strengths. You stay ahead of competitors by leveraging these advanced capabilities for your projects.

Supply Chain & Delivery Speed

Cluster Response & Flexibility

You experience unmatched speed and flexibility when you work with Chinese PCBA industry clusters. These clusters respond to urgent OEM orders in record time, often within hours. The table below shows how leading suppliers in Shenzhen deliver rapid solutions:

| Supplier Name | Average Response Time |

|---|---|

| Shenzhen Changkeshun Technology Co., Ltd. | ≤1 hour |

| Shenzhen JS Technology Co., Ltd. | ≤2 hours |

| Shenzhen Pengzexiang Technology Co., Ltd. | ≤2 hours |

| Kinglisheng(Shenzhen) Electronic & Technology Co. | ≤2 hours |

| Shenzhen Fumax Technology Co., Ltd. | ≤3 hours |

| Shenzhen Yongchangtai Electronics Co., Ltd. | ≤2 hours |

You benefit from a mature supply chain ecosystem that enables rapid adaptation to market changes. Chinese PCBA manufacturers leverage multiple sourcing locations, which provide stability and reduce risks from political events or labor shortages. Diversified production helps you avoid unpredictable tariff fluctuations and price hikes. Flexible sourcing enables faster turnaround and scalable production, reducing transit times for your projects.

Tip: Rapid cluster response and supply chain flexibility help you mitigate risks and keep your production schedule on track, even during global disruptions.

Integrated Sourcing & Logistics

You gain a competitive edge through integrated sourcing and logistics solutions offered by Chinese PCBA manufacturers. These companies cooperate with leading delivery agencies to ensure quality and speed. Comprehensive component sourcing services leverage a reliable global supply chain, guaranteeing efficient sourcing and component quality. Professional R&D teams and intelligent production management systems drive quality control and production efficiency. Fully automated SMT lines with nine inspection processes ensure quality assurance throughout production.

| Evidence Description | Key Focus Areas |

|---|---|

| Cooperation with leading delivery agencies to ensure quality and speed of delivery. | Rapid delivery and logistics efficiency. |

| Comprehensive component sourcing services leveraging a reliable global supply chain. | Efficient sourcing and component quality. |

| Equipped with a professional R&D team and an intelligent production management system. | Quality control and production efficiency. |

| Fully automated SMT line with 9 inspection processes for quality assurance. | Quality assurance in production. |

You notice that Chinese PCBA manufacturers consistently outperform other regions in on-time delivery rates. They offer shorter lead times, faster prototyping, and strong supply chain support for material availability. For urgent projects, you receive faster turnarounds, keeping your business agile.

Supply chain resilience remains crucial for your decision-making. The COVID-19 pandemic and geopolitical uncertainties have shown the importance of diversification and agility. Chinese PCBA manufacturers invest in AI-driven smart manufacturing and collaborate with research institutions to enhance production efficiency and innovation. These strategies ensure you can adapt quickly to emerging industries and global market changes.

Note: When you choose Chinese PCBA manufacturing, you secure a resilient supply chain, rapid delivery, and the flexibility needed to stay ahead in a dynamic global market.

Quality Assurance in PCBA China

Global Standards & Certifications

You rely on PCBA China for strict adherence to international standards and certifications. Leading manufacturers implement ISO 9001 for quality management, ISO 13485 for medical devices, and IATF 16949 for automotive applications. You also see ISO 14001 and ISO 45001 supporting environmental and occupational health management. These certifications ensure your products meet global requirements and pass regulatory audits with confidence.

| Certification | Description |

|---|---|

| ISO 9001 | Quality management systems |

| ISO 13485 | Medical devices quality management |

| IATF 16949 | Automotive quality management systems |

| ISO 14001 | Environmental management systems |

| ISO 45001 | Occupational health and safety management |

You benefit from advanced SMT assembly lines that support components like 01005, BGA, and QFN. Full inspection processes, including SPI, AOI, 3D X-ray, and ICT/FCT, guarantee that every board meets your specifications. MES production traceability tracks each step, giving you complete visibility and control over your manufacturing process.

Tip: When you choose PCBA China, you secure traceability and reliability for every order, no matter the industry.

Consistent Quality Control

You experience consistent quality control across large production volumes. Leading Chinese PCBA factories incorporate AOI inspection and DFM practices as standard. These methods help you identify layout issues and testability gaps early, reducing defects and improving manufacturability. All components come from authorized channels, ensuring complete traceability.

- You see strict quality control at every stage:

- IQC material inspection

- Paste inspection (SPI)

- Reflow profiling

- AOI 100% inspection

- 3D X-ray for BGA and QFN

- ICT/FCT test coverage

- Environmental and reliability testing

You benefit from automated inspection equipment, functional and circuit testing, and real-time tracking systems. Companies like Unimicron use AI and SEM for defect detection, while Sunwoda Electronic employs pin testing and environmental durability tests. These practices ensure your products remain reliable and compliant with international standards.

Note: Consistent quality control and comprehensive testing in PCBA China help you deliver reliable products to global markets.

Innovation & Future-Readiness

R&D Investment

You see, Chinese PCBA manufacturers invest heavily in research and development. This commitment drives rapid advances in AI-driven manufacturing and smart factory automation. You benefit from continuous improvements in BOM Optimization, DFM practices, and turnkey PCBA solutions. The PCB industry in China is projected to reach $26.79 billion by 2024, with a 16.6% annual growth rate. You notice strong demand for AI servers and automotive electronics, which pushes companies to innovate faster. Firms specializing in networking, servers, and automotive markets outperform smaller competitors, giving you access to cutting-edge technology and reliable supply chains.

- China accounts for 51% of global PCB production, confirming its leadership in the market.

- Manufacturers invest overseas, especially in Thailand, to diversify supply chains and reduce risk.

- You benefit from advanced automation, real-time monitoring, and smart manufacturing guidelines that keep your products competitive.

Tip: When you choose a Chinese PCBA partner, you tap into a system that adapts quickly to new technologies and market demands.

Government Support & Upgrading

You gain a strategic advantage from robust government support and industry upgrading initiatives. The Chinese government allocated ¥12 billion in 2024 for PCB technology innovation. You benefit from tax incentives and standardized smart manufacturing guidelines, which help manufacturers localize 70% of core equipment by 2027. Upskilling programs aim to train 50,000 workers by 2026, ensuring a skilled workforce for advanced production.

- Government subsidies strengthen competitiveness, with 86% of global semiconductor industry subsidies from 2014 to 2018 going to Chinese firms.

- Some leading companies receive up to 40% of their revenues from direct government support, enabling aggressive investment in R&D and infrastructure.

- You see industry-wide adoption of smart manufacturing standards and rapid cluster response, which enhance supply chain resilience and delivery speed.

Note: You secure future-ready solutions and long-term reliability when you choose Chinese PCBA manufacturing, thanks to ongoing R&D investment and strong government backing.

You see China’s PCBA industry leading global OEMs in 2025 with cost efficiency, advanced technology, and supply chain resilience. The market grows to $79.95B, with China holding 50% of global production.

| Trend Description | Projected Value/Share |

|---|---|

| Global PCB market growth | $79.95B by 2025 |

| Market size for 8-16 layer PCBs | $45B by 2025 |

| Cost increase in copper | 15% increase in 2025 |

| China’s share of global production | 50% by 2025 |

You benefit from an ecosystem that competitors cannot easily replicate:

- Domestic technology adoption and R&D investments

- Strategic moves like Huawei’s Ascend chips

- Integrated, high-reliability services from leaders such as FR4PCB.TECH

You secure reliability, speed, and innovation with BOM Optimization, Turnkey PCBA, and DFM practices. China remains your best partner for PCBA needs.

FAQ

What makes Chinese PCBA manufacturing stand out in 2025?

You benefit from China’s 60% global PCBA market share, rapid cluster response, and advanced AI-driven smart manufacturing. These strengths deliver reliable quality, fast turnaround, and supply chain resilience for your projects.

How does BOM Optimization improve your PCBA results?

You achieve lower costs and higher reliability with BOM Optimization. Chinese manufacturers analyze your bill of materials, source components efficiently, and streamline assembly for better performance and faster delivery.

Can you trust the quality of Chinese PCBA products?

You receive consistent quality through ISO certifications, AOI inspection, and DFM practices. Leading factories use automated testing and traceability systems to ensure every board meets global standards.

How fast can you expect delivery from Chinese PCBA suppliers?

You experience rapid delivery thanks to mature industry clusters. Many suppliers respond within 48 hours and complete regular orders in 7-15 days, keeping your production schedule on track.

What is Turnkey PCBA, and why should you choose it?

You simplify your process with Turnkey PCBA. Chinese manufacturers handle component sourcing, assembly, and testing, providing you with a one-stop solution that saves time and reduces risk.