Selecting a China SMT PCBA factory for your oem project means you must evaluate quality, technical capability, and communication. You should always prioritize factories with recognized certifications and advanced equipment. Trust real factory partners who offer transparent processes. Request samples and verify quality control before you make any commitment. Understand the difference between oem and ODM services to avoid confusion. > Trust grows when you work with vetted, long-term partners who maintain robust sourcing and quality assurance systems.

Key Strategies to Evaluate a China SMT PCBA Factory

- Verify certifications like ISO9001 and IPC-A-610G to ensure quality and compliance.

- Invest in advanced equipment and inspection systems to enhance production reliability.

- Establish clear communication and transparency to build trust with your manufacturing partner.

- Request samples and conduct audits to assess quality control before mass production.

- Protect your intellectual property with strong contracts and non-disclosure agreements.

Key Criteria for Choosing a China SMT PCBA Factory

Choosing a China SMT PCBA factory for your oem project requires a clear understanding of the standards, equipment, expertise, and processes that drive reliable turnkey PCBA assembly. You need to evaluate each factory’s SMT PCBA assembly capabilities, quality guarantees, and transparent sourcing practices. The following criteria will help you select a trustworthy PCBA assembly partner for high-volume production and complex OEM PCBA assembly requirements.

Quality Certifications and Standards

You should always verify the certification status of any China SMT PCBA factory before starting your OEM PCBA assembly project. Recognized certifications such as ISO9001, IATF 16949, IPC-A-610G, and RoHS signal a commitment to global quality control and environmental compliance. These standards ensure that your turnkey pcb assembly meets international benchmarks for reliability and safety.

| Category | Certification | Primary Purpose |

|---|---|---|

| Quality Management | ISO 9001 | Fundamental quality management system |

| Manufacturing Process | IATF 16949 | Automotive electronics quality system |

| Industry & Product | IPC-A-610 | Global workmanship standard |

| Environmental Compliance | RoHS | Restriction of hazardous substances |

| Testing & Reliability | CE, FCC Support | Regulatory readiness |

Factories with these certifications demonstrate robust quality control and a strong reputation for delivering high-volume turnkey pcb assembly. You should also look for IPC-A-610G compliance, which sets the workmanship standard for electronic assemblies.

Tip: Always request documentation of certifications and audit reports to confirm the factory’s commitment to quality guarantees.

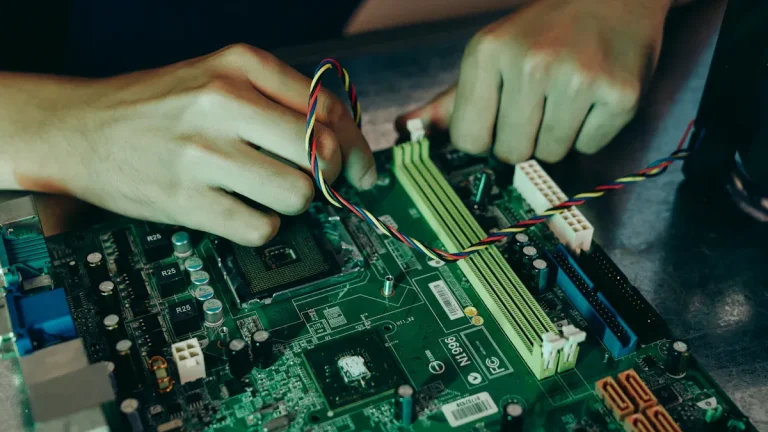

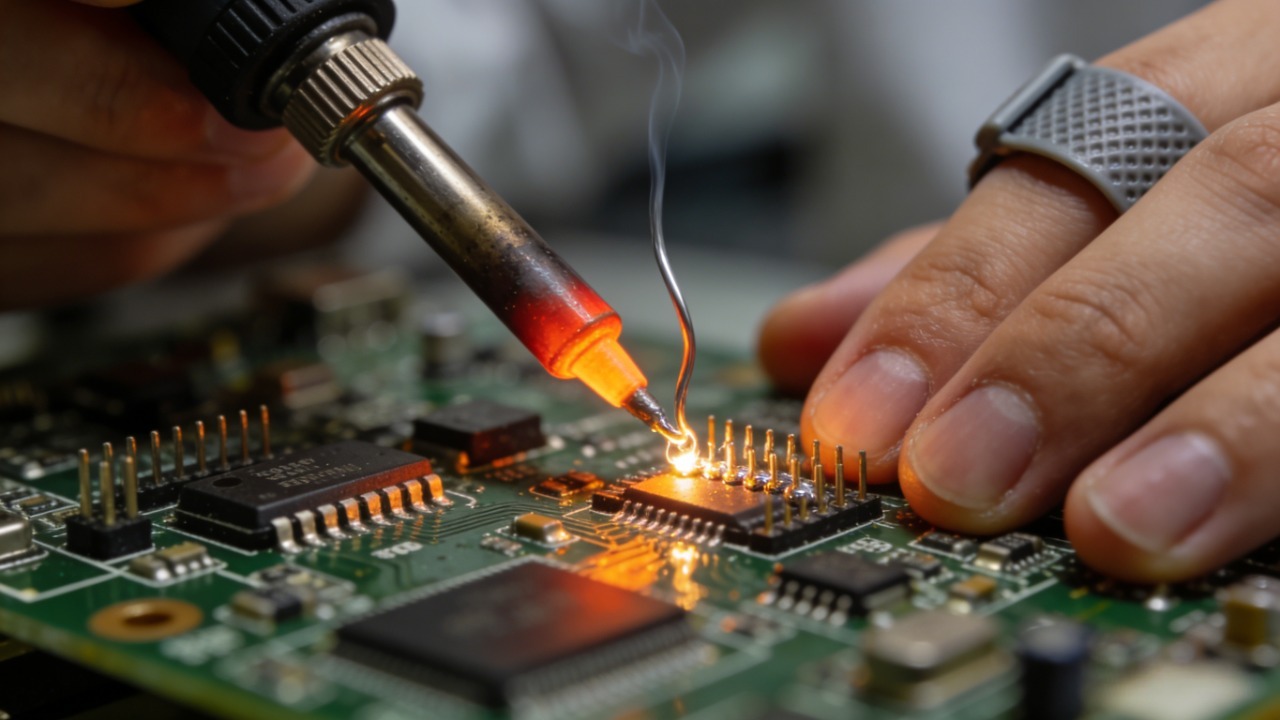

Advanced Equipment and SMT Lines

The backbone of any reliable China SMT PCBA factory is its investment in advanced SMT equipment. Leading factories use Yamaha and Panasonic SMT machines for high-speed, precise component placement. Automated Optical Inspection (AOI), Solder Paste Inspection (SPI), and X-ray systems are essential for detecting defects and ensuring quality control in high-volume production.

- AOI quickly identifies surface-level defects.

- SPI verifies solder paste volume and placement.

- X-ray inspection uncovers hidden issues in BGA, QFN, and LGA packages.

These technologies reduce defect rates and improve the yield of turnkey pcb assembly. You should prioritize factories with multiple SMT lines and modern inspection systems to support both prototyping and high-volume turnkey pcb assembly.

Technical Expertise for OEM PCBA Assembly

You need a PCBA assembly partner with deep technical expertise to handle complex OEM PCBA assembly requirements. Experienced engineers in R&D, hardware, software, and mechanical design ensure that your China turnkey PCBA assembly meets functional and reliability standards.

| Role | Experience and Skills |

|---|---|

| R&D Manager | 18 years in hardware, structural, and embedded software design |

| Software Engineer | 7 years in MCU and Linux software development |

| Mechanical Design Engineer | 8 years in 3D/2D product structure design |

| Hardware Engineer | 7 years in circuit design and PCB layout |

A strong engineering team supports DFM checks, BOM management, and quality control throughout the turnkey process. You should confirm that your China PCBA assembly partner has the right mix of skills and certifications, including IATF 16949 and IPC-A-610G.

Communication and Transparency

Effective communication is critical for building trust and ensuring project success in OEM PCB assembly. You should expect clear contracts, regular audits, and ongoing updates from your china smt pcba factory. Transparent sourcing and open dialogue help you address issues quickly and maintain quality guarantees.

- Clear contracts outline expectations and responsibilities.

- Regular audits verify compliance and quality control.

- Ongoing communication resolves problems before they escalate.

- Relationship-based partnerships foster trust and collaboration.

Language barriers and time zone differences can impact project timelines. You should choose a pcb assembly partner with proven communication practices and a reputation for transparency.

Supply Chain and Component Sourcing

Reliable component sourcing is essential for high-volume turnkey pcb assembly. Top China SMT PCBAs factories source only from authorized distributors, require certificates of conformity, and use advanced testing for high-value ICs. Diversified sourcing, buffer stock, and strong supplier relationships protect your oem project from delays and counterfeit risks.

- Source from authorized distributors

- Require CoC with shipments

- Use X-ray or decapsulation testing for critical components

- Diversify sourcing across regions

- Maintain buffer stock for key parts

- Engage logistics partners for global shipping

- Use Approved Vendor Lists (AVL)

- Embrace BOM management tools for real-time monitoring

You should verify your China PCB assembly partner’s sourcing strategies and ensure they maintain transparent sourcing and robust supply chain controls.

Intellectual Property and Data Security

Protecting your intellectual property is vital in any OEM PCBA assembly project. China’s first-to-file principle means you must register trademarks and patents early. Well-drafted contracts, including NDAs, define ownership and restrict unauthorized use. Recent legal amendments have increased penalties for counterfeiters and streamlined IP filings.

| Aspect | Description |

|---|---|

| First-to-file Principle | Early registration secures rights for foreign businesses |

| Importance of Contracts | Contracts define IP ownership and include NDAs |

| Legal Amendments | Increased penalties and streamlined filing processes |

You should review your pcb assembly partner’s reputation, draft robust contracts, and conduct regular audits to prevent breaches. Educate your team on IP protection and maintain oversight during critical manufacturing stages.

Note: The difference between OEM and ODM services matters. OEM means you provide the design and specifications, and the factory manufactures according to your requirements. ODM involves the factory designing and manufacturing the product, which may limit your control over IP and customization.

By focusing on these criteria, you can select a China SMT PCBA factory that delivers high-volume turnkey pcb assembly with quality guarantees, technical expertise, and strong IP protection.

Step-by-Step Evaluation of Reliable PCB Manufacturers

Choosing a reliable China SMT PCBAs factory for your oem project requires a systematic approach. You should begin by compiling a shortlist of reputable manufacturers such as PCBasic, Luxshare, Kaifa, and Sanshun Smart. The most effective ways to find PCBA manufacturers include using trusted industry directories and platforms. For example, SMTnet and Unit Circuits provide comprehensive listings and detailed company profiles.

Researching China PCB Assembly Partners

You need to evaluate each potential partner’s technical capabilities, production capacity, and reputation. Look for a supplier who offers complete services, including PCB fabrication, assembly, testing, and logistics. Prioritize manufacturers with advanced engineering skills, especially in high-density interconnect boards and complex multilayer designs. Review their quality control measures, certifications like ISO 9001 or IPC-A-610, and customer support responsiveness.

| Platform/Directory | Description |

|---|---|

| SMTnet | Source for SMT and PCB manufacturing companies |

| Unit Circuits | EMS provider specializing in turnkey PCB assembly |

Requesting Samples and DFM Checks

Requesting samples is essential for verifying quality control and process reliability. You should ask for Design for Manufacturability (DFM) checks to identify potential issues before mass production. DFM reviews help prevent delays, increase first pass yield, and lower total manufacturing costs. When you receive samples, assess equipment capability, soldering process control, component sourcing, and traceability. Confirm compliance with standards such as ISO 9001 and RoHS.

| Evaluation Criteria | Description |

|---|---|

| Equipment Capability | SPI, AOI, FCT |

| Soldering Process Control | Robust process measures |

| Traceability | Component tracking throughout production |

| BOM Validation | Sourcing risk assessment |

Checking References and Case Studies

You should always check references and review case studies from each China SMT PCBA factory. Ask for information about their quality control systems, supply chain strength, lead times, and delivery commitments. Evaluate their communication and technical support. Review testimonials and past project successes to gauge experience and reputation.

| Factor | Explanation |

|---|---|

| Low Cost | Cost-effective manufacturing |

| High Quality Guarantee | Focus on intelligent manufacturing |

| High Efficiency | Fast turnaround and market entry |

Facility Audits and Quality Control Review

Conduct a step-by-step smt factory audit to assess equipment capability, certification compliance, and workforce competencies. Review adherence to quality management systems and operator training programs. Check for humidity control and component traceability standards. An on-site or virtual audit helps you verify process consistency and quality control.

Tip: Facility audits provide direct insight into the manufacturer’s operational standards and help you avoid costly mistakes.

Contract and NDA Review for OEM Projects

Before finalizing your OEM PCB assembly agreement, review all contract clauses related to intellectual property. Use non-disclosure agreements to protect sensitive information. Limit access to design data and files. Clearly specify IP ownership to prevent unauthorized sharing. NDAs create a legal framework for confidentiality and reduce the risk of IP leakage in oem projects.

| Clause Type | Description |

|---|---|

| Non-Disclosure Agreement | Binds the manufacturer to confidentiality |

| Access Limitation | Restricts access to sensitive design files |

| IP Ownership Specification | Defines ownership and prevents unauthorized use |

By following these steps, you can select a China SMT PCBA factory that meets your OEM PCB assembly needs and ensures robust quality control throughout the project lifecycle.

Common Pitfalls in China SMT PCBA Factory Selection

When you select a China SMT PCBA Factory for your OEM project, you must recognize and avoid several industry pain points. These pitfalls can impact quality, cost, and delivery, especially if you do not implement robust qa and anti-counterfeit safeguards.

Counterfeit Components and Quality Risks

Counterfeit and refurbished components pose a major threat to product reliability. You can encounter recycled, remarked, out-of-specification, cloned, or tampered parts. These risks demand strict qa and supplier verification. The table below highlights common counterfeit types:

| Type | Description |

|---|---|

| Recycled | Reclaimed from old systems, sold as new |

| Remarked | Genuine part with forged markings |

| Out-of-Specification | Nonconforming part misrepresented as compliant |

| Cloned | Unauthorized reproduction |

| Tampered | Modified clone for sabotage or malfunction |

You should inspect for incorrect part numbers, impossible date codes, and misspelled logos. Visual inspection, X-ray, and decapsulation help you detect counterfeit ICs. Always compare labels with original manufacturer data and check packaging for moisture-sensitive components. Implement qa at every stage, including post-soldering qa, to ensure only genuine parts enter your assembly.

Hidden Costs and Ambiguous Quotes

Hidden costs often arise when you receive ambiguous quotes from a China SMT PCBA Factory. You must clarify all component procurement, testing, and auxiliary material expenses. The table below outlines typical hidden costs:

| Cost Type | Description |

|---|---|

| Component Procurement Costs | 40%-60% of total cost; high-end ICs and BGAs fluctuate |

| Testing and Quality Control Costs | AOI, flying probe, functional testing, fixtures, and development |

| Auxiliary Materials & Operating | Solder paste, flux, stencils, packaging, utilities, management |

Incomplete BOMs and design files can increase time and resources spent on qa and corrections. Always request transparent pricing and detailed documentation.

Documentation and Traceability Issues

Poor documentation and lack of traceability can lead to qa failures and costly recalls. You should demand clear process records, component tracking, and test reports. Use approved vendor lists and BOM management tools to maintain traceability throughout production.

Tip: Consistent documentation supports effective qa and helps you resolve disputes quickly.

Lead Time and Delivery Delays

Delivery delays can disrupt your supply chain and market entry. Common causes include component availability, production capacity, design complexity, and extended testing. You should select a China SMT PCBA Factory with efficient logistics, advanced machinery, and strong qa systems to minimize delays.

- Check component lead times before placing orders

- Assess factory workforce and equipment

- Review design complexity and required testing

- Confirm shipping routes and proximity to suppliers

By addressing these pitfalls, you strengthen your qa process and protect your OEM project from costly setbacks.

Why Sanshun Smart is a Reliable PCB Manufacturer

When you search for a reliable PCBA manufacturer in the China SMT PCBA Factory landscape, Sanshun Smart stands out as a trusted partner for OEM projects. You can count on their advanced SMT production lines, robust quality systems, and professional engineering support. Sanshun Smart delivers a pcb assembly service that meets the highest industry standards and supports your high-quality manufacturing goals.

Certifications and Advanced SMT Production Lines

You should always verify a manufacturer’s certifications before starting any oem project. Sanshun Smart holds ISO9001 and IATF16949 certifications. These credentials prove their commitment to high-quality pcb assembly and global compliance. This advanced setup ensures precise placement and reliable soldering for every pcb assembly service. You gain confidence knowing your products are built on state-of-the-art SMT production lines.

DFM and Engineering Support for OEM PCB Assembly

You benefit from Sanshun Smart’s strong engineering team. Their experts provide DFM checks and technical guidance throughout your oem project. You receive early feedback on your design, which helps you avoid costly errors and delays. The team reviews your BOM, layout, and process flow to optimize for manufacturability. This proactive approach makes Sanshun Smart a reliable pcba manufacturer for complex and high-mix assemblies.

Tip: Request a DFM review before mass production to maximize yield and minimize risk.

Quality Control and IPC-A-610G Compliance

You expect strict quality control from a reliable pcb manufacturer. Sanshun Smart uses AOI, SPI, and X-ray systems at every stage of the pcb assembly service. You can also request detailed inspection reports and traceability records for your oem orders.

Customer Success and Secure China PCB Assembly

If you need a reliable PCBA manufacturer for your next oem project, consider Sanshun Smart’s PCBA manufacturing service and advanced SMT production lines. You will experience high-quality manufacturing and dependable support at every stage.

Choosing a reliable China SMT PCBA Factory for your OEM project requires a structured approach. You should focus on certifications, advanced equipment, and technical expertise. Transparent communication and strong IP protection matter. Follow these steps:

- Request samples and audit quality control systems.

- Review contracts and NDAs for data security.

- Prioritize long-term partners like Sanshun Smart.

Tip: Careful evaluation helps you achieve consistent quality and secure project success.

FAQ

What is the average lead time for a China SMT PCBA Factory?

You can expect an average lead time of 2 to 4 weeks from a China SMT PCBA Factory. Lead time depends on order volume, component availability, and process complexity. Always confirm timelines before placing your order.

How do you verify the quality of a China SMT PCBA Factory?

You should request certifications like ISO9001 and IPC-A-610G. Ask for sample boards and inspection reports. Review their AOI, SPI, and X-ray testing capabilities. Reliable factories provide transparent quality control documentation.

What documents do you need to start an OEM PCB assembly project?

You need a Gerber file, BOM, assembly drawings, and test instructions. These documents help the China SMT PCBA Factory understand your requirements and ensure accurate production.

How do you protect intellectual property with a China SMT PCBA Factory?

You should sign NDAs and specify IP ownership in contracts. Limit access to sensitive files. Choose a factory with a strong reputation for data security and compliance.

Can you request small batch or prototype runs before mass production?

Yes, most Chinese SMT PCBA Factories offer prototype and small batch services. You can evaluate quality and process reliability before committing to large-scale production.