You face a critical decision when choosing between SMT PCBA and THT Assembly for your project. Review the following table to see how cost and application suitability differ:

| Factor | SMT (Surface Mount Technology) | THT (Through-Hole Technology) |

|---|---|---|

| Cost | More cost-effective for high-volume | Higher cost, ideal for durable, low-volume |

| Application Suitability | Best for compact electronics | Suited for heavy, robust components |

Consider these points:

- SMT PCBA supports higher component density, fitting 50-100 components per square inch.

- THT Assembly offers greater mechanical strength, preferred for demanding environments.

Evaluate your product’s size, weight, production volume, and durability needs before deciding.

SMT PCBA vs. THT: How to Choose the Right Process for Your Project Requirements

- Choose SMT PCBA for high-volume production. It offers lower costs and faster assembly speeds, making it ideal for compact electronics.

- Opt for THT Assembly when durability is crucial. It provides strong mechanical bonds, perfect for products exposed to stress or harsh environments.

- Evaluate your project’s needs carefully. Consider factors like component size, production volume, and environmental conditions to make the best choice.

- Understand the cost implications. SMT is more cost-effective for large runs, while THT may be better for low-volume, specialized projects.

- Consult with experienced manufacturers. They can help clarify technical requirements and optimize your PCB assembly process.

SMT PCBA and THT Assembly Overview

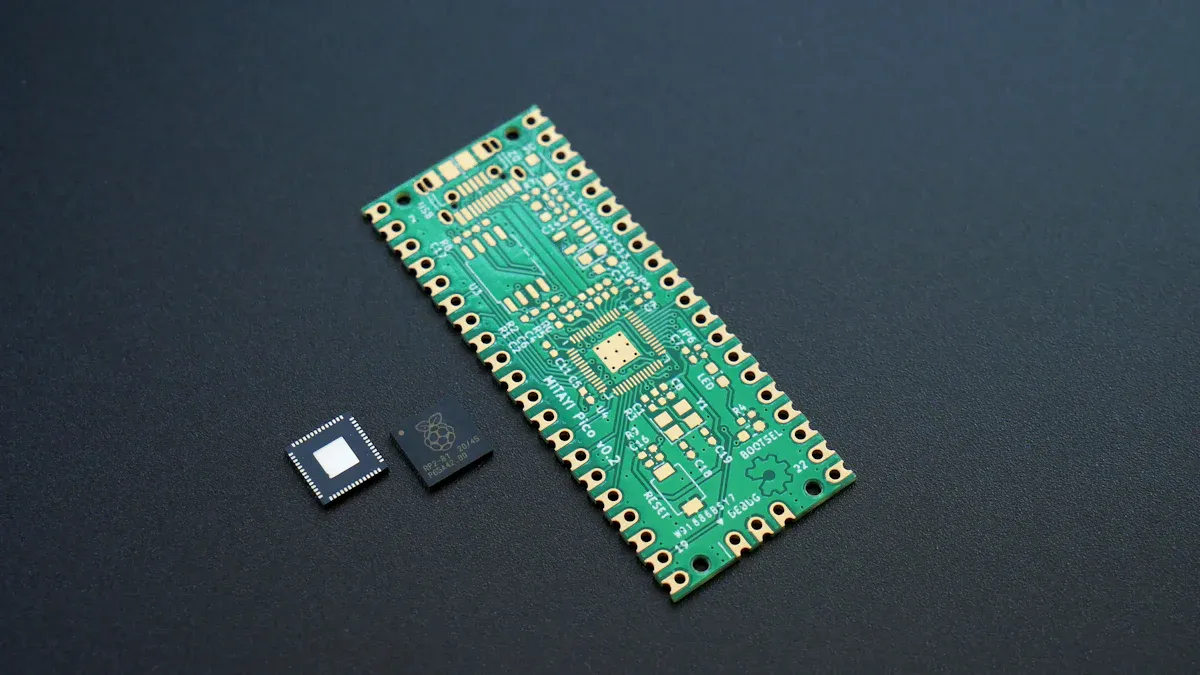

What Is SMT PCBA?

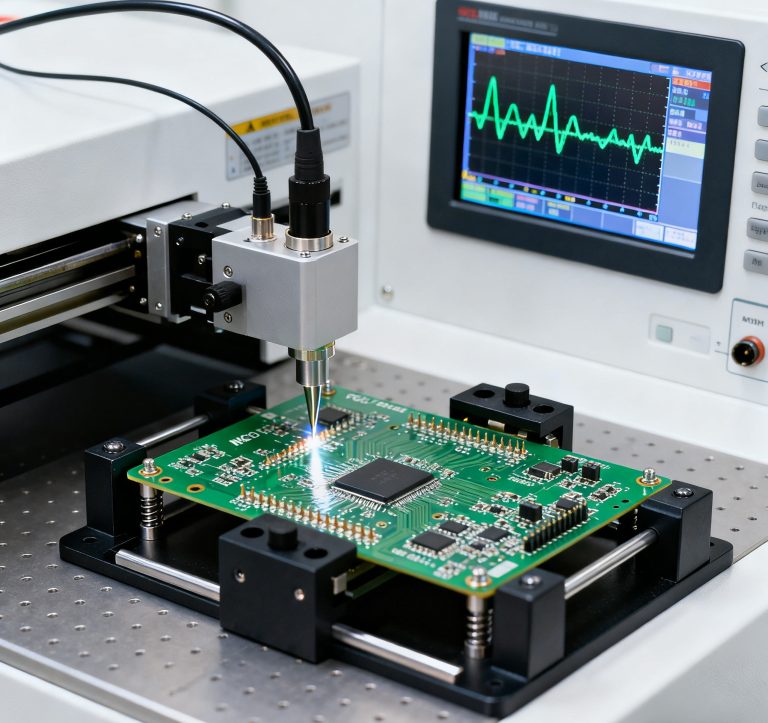

You use SMT PCBA when you need to mount electronic components directly onto the surface of a printed circuit board. This method relies on surface mount technology, which places small, lightweight devices called SMDs onto the board. The SMT process uses automated pick-and-place machines for component placement, followed by reflow soldering to secure each part. You benefit from high-speed assembly and the ability to fit many components in a compact space. Industry standards guide every step, from design and material selection to quality control and compliance. These standards ensure your SMT PCBA meets reliability and environmental requirements.

Tip: SMT PCBA supports double-sided mounting, which increases component density and allows for more complex circuit designs.

| Category | Description |

|---|---|

| Design Standards | Guidelines for PCB design to ensure manufacturability and reliability. |

| Material Selection Standards | Standards for selecting appropriate materials, including solder paste and components. |

| Manufacturing Process Standards | Detailed steps in the SMT manufacturing process, including solder paste printing and component placement. |

| Quality Control Standards | Systems are in place to ensure each PCB meets quality requirements through inspections and testing. |

| Compliance Standards | Adherence to international standards like IPC and RoHS to ensure quality and environmental safety. |

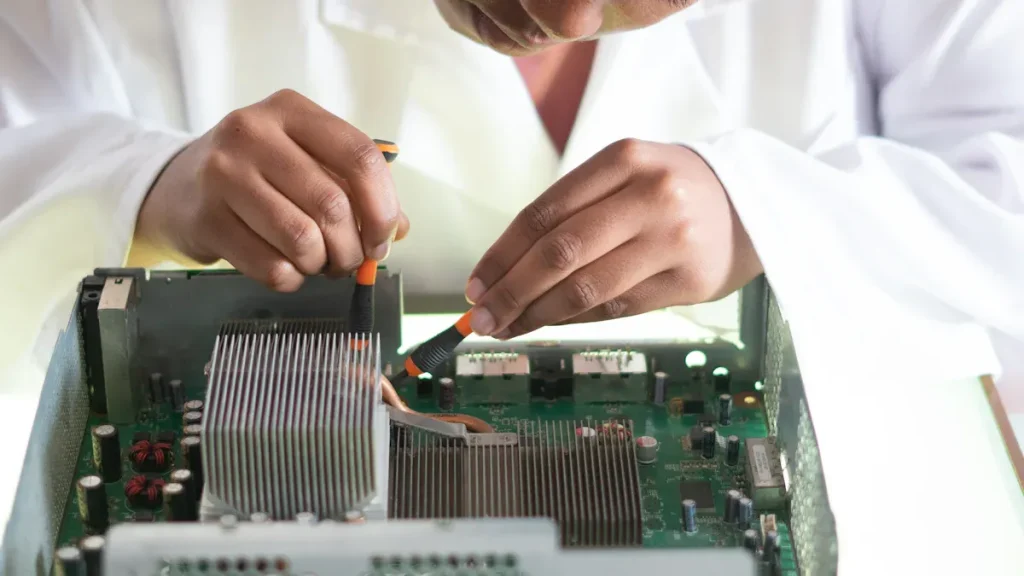

What Is THT Assembly?

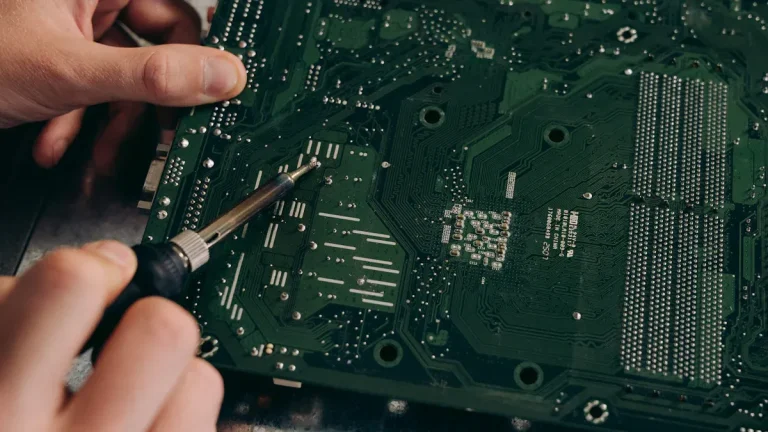

You choose THT assembly when your project requires strong mechanical bonds and high reliability. Through-hole technology involves inserting components with leads into holes drilled in the PCB. You then solder these leads, usually with wave soldering, to create robust connections. THT assembly suits larger components and products exposed to stress or vibration. The process often uses manual insertion, making it ideal for prototypes or low-volume production. IPC-A-610 sets the standards for quality and inspection, helping you achieve consistent results.

- THT assembly places larger components using pick & place solutions.

- Selective soldering targets specific points under the PCB.

- Depaneling separates individual boards using laser or milling cutters.

- Packaging uses blister packs and electric actuators for movement.

- IPC-A-610 provides clear criteria for quality assurance, with Class 3 for the most demanding applications.

SMT vs THT: Core Differences

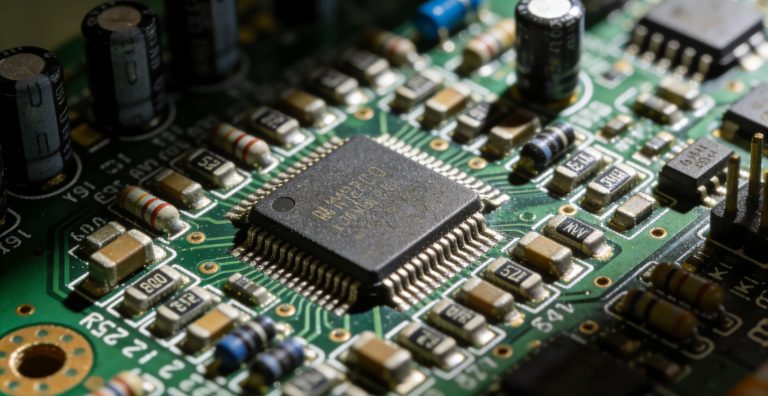

You need to understand the core differences between SMT PCBAs and THT assembly to make the right choice. SMT uses smaller components and automated processes, while THT relies on manual labor and larger parts. SMT offers higher PCB density and faster assembly, but rework can be complex. THT provides easier repair and stronger physical connections.

| Aspect | SMT Assembly | THT Assembly |

|---|---|---|

| Component Size | Smaller components (1-2mm) | Larger components (5-7mm) |

| PCB Density | Higher density, less wasted space | Requires more space for holes |

| Assembly Process | Automated with pick-and-place machines | Manual labor for insertion and soldering |

| Reworkability | More complex, requires specialized tools | Easier to replace faulty components |

| Automation | Highly optimized for automation | Complex, better for prototypes |

| Cost Considerations | Higher startup costs, faster assembly | Lower equipment investment, slower assembly |

You see that SMT PCBAs excel in high-volume, compact electronics, while THT assembly remains the best choice for products needing durability and strong bonds.

SMT Assembly vs THT Assembly: Key Factors

Cost Comparison

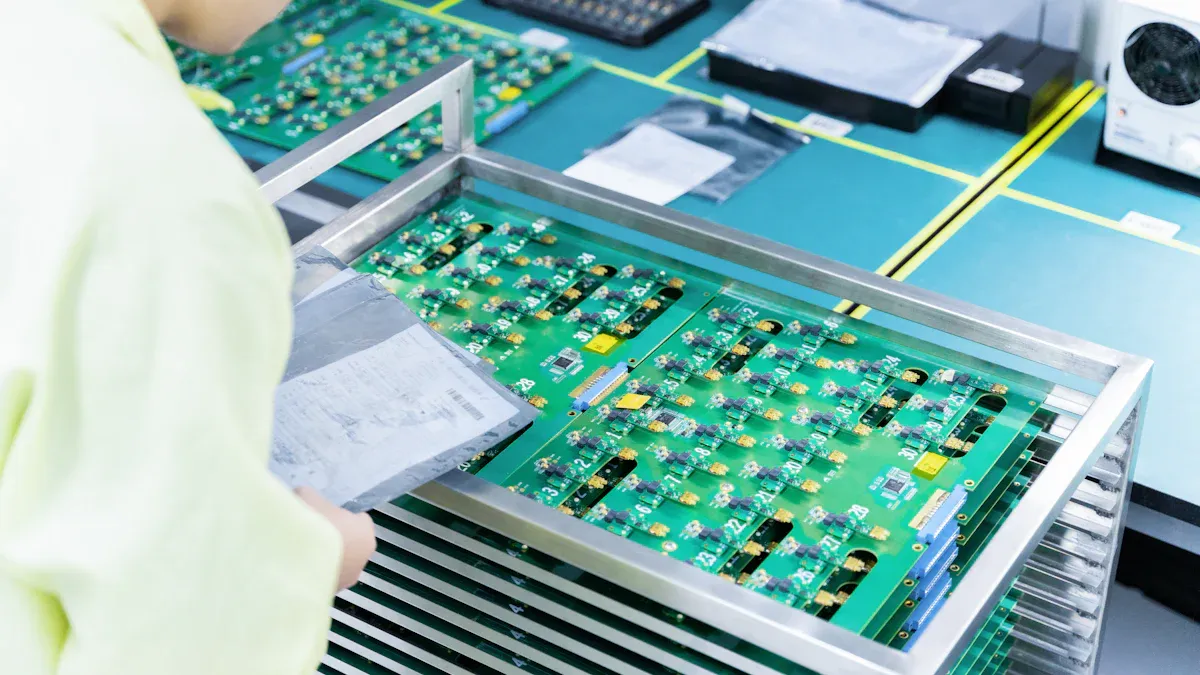

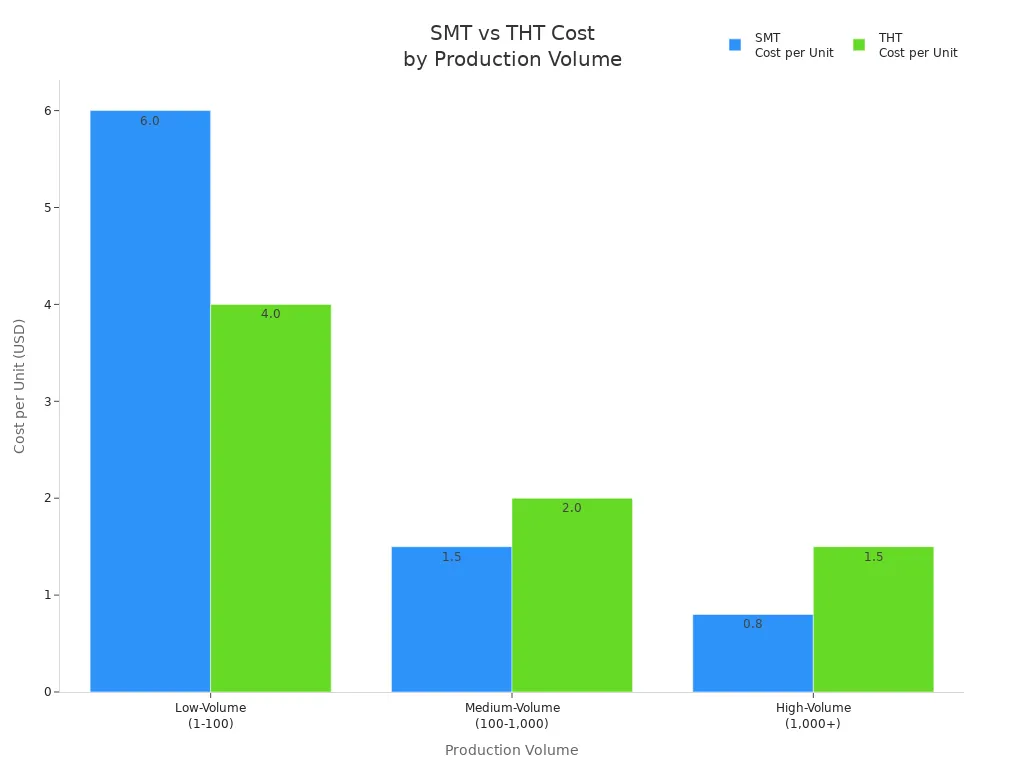

You need to evaluate THT vs SMT cost before selecting your PCB assembly process. SMT assembly uses automated machines, which reduce labor expenses and speed up production. THT assembly relies on manual insertion and soldering, leading to higher labor costs and slower throughput. The cost difference becomes more pronounced as production volume increases.

| Production Volume | SMT Cost per Unit | Total SMT Cost | THT Cost per Unit | Total THT Cost |

|---|---|---|---|---|

| Low-Volume (1-100) | $6.00 | $300-$500 | $4.00 | $200-$300 |

| Medium-Volume (100-1,000) | $1.50 | $750 | $2.00 | $1,000 |

| High-Volume (1,000+) | $0.80 | $8,000 | $1.50 | $15,000 |

- SMT achieves lower cost per unit at scale due to automation and reduced board complexity.

- THT assembly incurs higher labor costs and is slower to assemble.

- SMT is designed for efficiency and scalability, while THT is more labor-intensive.

You should consider the THT vs SMT cost for your specific production volume. SMT assembly is more cost-effective for high-volume runs, while THT assembly may suit low-volume, specialized projects.

Reliability and Strength

Reliability is a critical factor in the THT vs SMT reliability debate. SMT achieves excellent reliability in controlled environments, especially when you use underfill, conformal coating, or staking adhesives. THT assembly provides superior mechanical strength and withstands vibration better, making it ideal for harsh conditions.

| Reliability Metric | SMT (Surface Mount Technology) | THT (Through Hole Technology) |

|---|---|---|

| Mechanical Strength | Improved with underfill, conformal coating, or staking adhesives | Generally offers superior mechanical strength and withstands vibration better |

| Thermal Reliability | Can achieve excellent thermal reliability with proper design | Handles thermal cycling better due to stress distribution |

| Long-term Reliability | Achieves excellent long-term reliability in controlled environments | Better long-term performance in harsh environments |

- Environmental testing validates product reliability under real-world conditions.

- Temperature extremes and humidity variations are critical factors.

- THT components create robust mechanical bonds and provide exceptional resistance to mechanical stress and vibration.

- SMT can achieve high reliability with proper design, but THT assembly excels in environments with vibration, shock, or extreme temperatures.

You should select the THT assembly for applications where mechanical strength and long-term reliability are essential. SMT suits products used in stable, controlled environments.

Component Density

Component density is a major consideration in the THT vs SMT component density comparison. SMT components are much smaller than THT components, allowing you to place more parts in a given area. SMT supports double-sided mounting, which further increases density.

- SMT components like the 0402 resistor (0.4mm × 0.2mm) take up much less space than through-hole resistors.

- Achievable component densities with SMT can exceed 500 components per square inch.

- THT typically achieves only 50-100 components per square inch.

- SMT allows for the use of both sides of the PCB for component placement, enhancing density.

- The smaller size of SMT components directly contributes to higher achievable component densities compared to THT.

You should choose SMT assembly when your design requires high component density and compact layouts. THT assembly is better for boards with fewer, larger components.

Assembly Speed

Assembly speed impacts your production timeline and overall cost. SMT assembly can achieve speeds of up to 45,000 parts per hour, while THT assembly operates at about 200-400 components per hour. SMT processes are highly automated, leading to reduced setup times and faster production cycles.

| Assembly Type | Setup/Changeover Time | Production Time per Complex Board |

|---|---|---|

| Traditional THT | 1–2 hours | 1–2 hours |

| SMT PCBA | 5–10 minutes | 5–10 minutes |

- SMT is significantly faster than THT in high-volume production.

- THT assembly involves multiple steps, such as component insertion, soldering, and cleaning, contributing to longer production times.

- SMT automation leads to reduced assembly time and lower overall costs per unit.

You should select SMT assembly for projects with tight deadlines and high production volumes. THT assembly suits prototypes or low-volume runs where speed is less critical.

Application Suitability

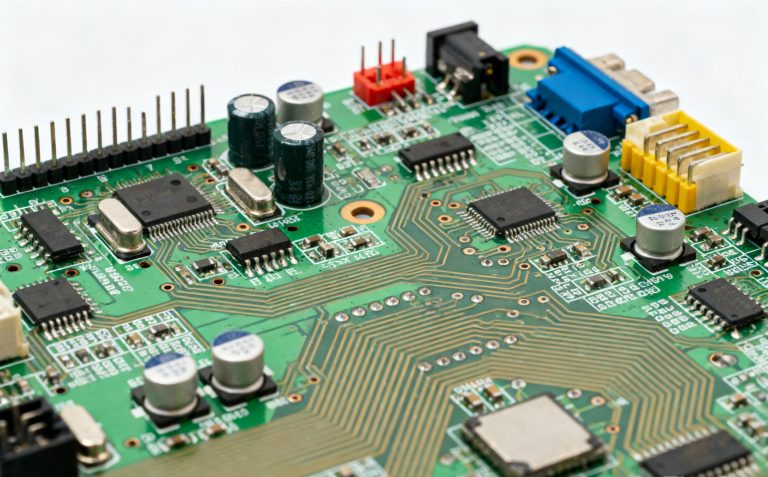

You must match your assembly method to your application requirements. SMT assembly is best for consumer electronics, mobile devices, and compact gadgets. THT assembly suits power electronics, transformers, connectors, industrial equipment, automotive systems, and military hardware.

| Assembly Method | Best Suited Applications |

|---|---|

| THT | Power electronics, transformers, connectors, industrial equipment, automotive systems, military hardware |

| SMT | Consumer electronics, mobile devices, compact gadgets |

- SMT assembly supports high-density, lightweight designs for modern electronics.

- THT assembly provides durability and reliability for products exposed to mechanical stress or harsh environments.

- Industry trends show automation increases production speed and quality, with SMT leading in consumer and wearable markets.

- THT remains essential for applications requiring robust mechanical connections.

You should analyze your product’s operating environment, size constraints, and durability needs before deciding between SMT and THT assembly.

SMT PCBA and THT Assembly: Pros & Cons

SMT PCBA Pros and Cons

When you consider surface mount technology for your PCB assembly process, you gain several advantages:

- Reduces production costs by streamlining manufacturing steps.

- Improves reliability through automated placement and consistent soldering.

- Supports high scalability, allowing you to increase output without sacrificing quality.

- Enables high component density and double-sided mounting for compact designs.

- Delivers fast assembly speeds, ideal for large-scale production.

However, you should also weigh the disadvantages:

- Requires advanced equipment and technical expertise, which can increase initial investment.

- Presents challenges in inspection and repair due to small component size and dense layouts.

- May not suit low-volume or prototype runs because of higher setup costs.

Note: SMT PCBA works best for high-volume, compact electronics where automation and density matter most.

THT Assembly Pros and Cons

Through-hole technology offers unique benefits for your PCB assembly process:

- Provides strong mechanical bonds, making it reliable in harsh environments.

- Simplifies repair and replacement; you can easily desolder and swap components.

- Facilitates straightforward identification of faulty parts during maintenance.

- Performs well in applications exposed to vibration, shock, or extreme temperatures.

You should also consider the drawbacks:

- Involves more manual labor, which can increase per-unit costs and slow production.

- Limits component density due to the need for drilled holes.

- Risks of damaging leads during insertion, which may cause defects.

Tip: THT assembly remains a preferred choice for industrial, automotive, and military electronics that demand durability.

THT vs SMT: Comparison Table

| Feature | Through-Hole Technology (THT) | Surface Mount Technology (SMT) |

|---|---|---|

| Component Mounting | Leads inserted through PCB holes, soldered on the opposite side | Components placed directly on the PCB surface, soldered via reflow oven |

| Mechanical Strength | Exceptional; resists vibration and thermal stress | Moderate; relies on solder paste adhesion |

| Automation Level | Low; manual insertion and wave soldering | High; automated pick-and-place machines |

| PCB Design Impact | Requires drilled holes; limits density | No holes needed; supports double-sided mounting |

| Cost Efficiency | Higher per-unit cost; ideal for low-volume | Lower per-unit cost in mass production |

| Ideal Applications | Industrial, automotive, aerospace | Consumer electronics, IoT, mobile devices |

| Repairability | Easy; components removed with basic tools | Difficult; requires specialized equipment |

When you compare the pros and cons of THT and SMT, you see that each method serves different project needs. Your choice depends on your priorities for cost, reliability, repairability, and production scale.

Application Scenarios for PCBA Assembly

Best Uses for SMT PCBA

You should select surface mount technology for projects that demand compact designs, high component density, and rapid production. SMT PCBA excels in applications where miniaturization and automation drive efficiency. Common scenarios include:

- Medical devices such as diagnostic equipment, monitoring systems, and treatment devices. These require strict quality standards due to health impacts.

- Automotive electronics, including engine control units, fuel management systems, and advanced vehicle features. SMT supports safety and efficiency in modern vehicles.

- Consumer electronics like smartphones, laptops, and household appliances. SMT enables sleek designs and reliable performance in everyday technology.

- IoT devices and wearables, where space constraints and lightweight construction are critical.

SMT PCBA allows you to achieve double-sided mounting and precise component placement, making it ideal for high-volume production and printed circuit board designs with limited space.

Best Uses for THT Assembly

Through-hole technology remains essential for projects that require robust mechanical strength and long-term reliability. You should consider THT assembly for applications exposed to vibration, shock, or extreme temperatures. The following table highlights typical scenarios:

| Industry | Application Area |

|---|---|

| Automotive industry | Vehicle control systems, engine management, and infotainment systems |

| Aerospace industry | Avionics, navigation, and communication equipment |

| Industrial machinery | Automation devices, motor drives, and power supplies |

| Medical devices | Patient monitoring, diagnostic tools, and surgical instruments |

| Telecommunications | Infrastructure components, switches, routers, base stations |

| Consumer electronics | Audio amplifiers, power supplies, and connectors |

| Instrumentation | Oscilloscopes, multimeters, data loggers |

THT assembly suits your pcb assembly project when you need durable connections and easy repairability, especially in industrial and military electronics.

Mixed Technology PCB Assembly

Many modern printed circuit board designs combine SMT and THT to balance performance, reliability, and flexibility. Mixed technology PCB assembly offers several advantages:

- Enhanced reliability and performance by leveraging both SMT and THT strengths.

- Greater component selection for tailored solutions in complex applications.

- Increased design flexibility and lightweight construction.

- Improved production efficiency through integrated assembly processes.

You may encounter challenges such as design complexity, space constraints, and thermal management issues. Testing and quality assurance require different methods for SMT and THT components. When you need advanced capabilities for mixed technology pcb assembly, professional manufacturers with expertise in both SMT and THT processes can help you achieve optimal results.

Decision Guide for PCB Assembly Choice

Checklist for Selecting SMT or THT

You need a clear checklist to guide your decision between SMT and through-hole assembly. This checklist helps you evaluate your project requirements and select the most suitable pcb assembly process.

- Define Your Project Goals

- Identify the primary function and expected lifespan of your product.

- Determine if your project demands high-density board designs or robust mechanical strength.

- Assess Environmental Conditions

- Consider whether your project will operate in environments with heat, vibration, or moisture.

- For consumer gadgets, focus on heat resistance and compact layouts.

- For automotive or industrial equipment, prioritize durability against mechanical stress and harsh conditions.

- Evaluate Component Requirements

- Decide if your project uses small, lightweight components or larger, heavy-duty parts.

- Surface mount technology supports miniaturized components and double-sided mounting.

- Through-hole assembly provides stronger mechanical bonds for connectors and components exposed to stress.

- Review Production Volume and Timeline

- Estimate the number of boards needed for your project.

- SMT offers cost-efficiency and speed for high-volume production.

- Through-hole assembly suits prototypes and low-volume runs.

- Confirm Budget and Cost-Effective Solutions

- Define your project budget and compare pricing structures for each assembly method.

- SMT is more cost-effective for mass production.

- Through-hole assembly may incur higher labor costs but offers reliability for specialized applications.

- Check Compliance and Safety Standards

- Identify necessary certifications for your industry, such as IPC or RoHS.

- Ensure your chosen assembly process meets all safety and compliance requirements.

- Consider Supplementary Services

- Determine if your project requires wire harnesses, finishing services, or turnkey solutions.

- Manufacturers can tailor pcb services to match your project needs.

Tip: Consult with experienced manufacturers to clarify technical requirements and optimize your pcb assembly process.

Matching Project Needs to Assembly Type

You must align your project specifications with the strengths of each assembly method. The following table summarizes how key project factors influence your choice between SMT and through-hole assembly.

| Project Requirement | SMT (Surface Mount Technology) | Through-Hole Assembly |

|---|---|---|

| High-density board designs | Supports compact layouts and double-sided mounting | Limited by the hole space and component size |

| Mechanical strength | Adequate for most consumer electronics | Superior for connectors and stressed components |

| Environmental durability | Suitable for controlled environments | Ideal for harsh, industrial, or automotive settings |

| Production volume | Cost-efficient for large-scale projects | Suits low-volume, specialized runs |

| Repairability | Challenging due to the small components | Easier with accessible leads |

| Component size | Best for small, lightweight parts | Handles large, heavy-duty components |

| Compliance needs | Meets industry standards with proper design | Ensures reliability for critical applications |

- Designing for consumer gadgets requires attention to heat resistance and compactness.

- Automotive projects need durability against mechanical stress and vibration.

- Heavy-duty industrial equipment demands robust environmental protection and long-term reliability.

You should understand your project’s unique needs, including pcb technology requirements and board size. Confirm that manufacturers can accommodate your specifications and provide the necessary certifications. Define your budget and production volume, then decide if supplementary services are required. Manufacturers offer a range of turnkey solutions and pcb services, allowing you to select options that best fit your project.

Note: You improve your project’s outcome by matching assembly type to your technical, environmental, and budgetary requirements. Always consult with experts to ensure your pcb assembly process meets industry standards and delivers reliable performance.

You make the best choice between SMT PCBA and THT assembly by focusing on your project’s speed, reliability, cost, and design needs. Use the table below to compare key decision factors:

| Factor | SMT PCBA (Surface Mount) | THT Assembly (Through-Hole) |

|---|---|---|

| Speed | Very fast | Slower |

| Reliability | Good in stable settings | Superior under stress |

| Cost | Lower for high volume | Higher for large projects |

Consult experienced manufacturers early for mixed technology PCBA. Review your requirements, document objectives, and involve your team. Reach out for expert advice to ensure your PCB assembly process meets your goals.

FAQ

What is the main difference between through-hole technology and surface mount technology?

You see the main difference in how you mount components. Through-hole technology uses leads inserted into holes, while surface mount technology places parts directly on the board. When you compare THT vs. SMT, you notice through-hole provides stronger mechanical bonds.

When should you choose through-hole technology over SMT?

You should select through-hole technology when your project needs durability and reliability. Through-hole works best for connectors, large components, or products exposed to vibration. In THT vs. SMT comparisons, through-hole technology stands out for mechanical strength.

Does THT vs SMT affect repairability?

You find that through-hole technology makes repairs easier. You can remove and replace components with basic tools. In THT vs. SMT, through-hole offers straightforward maintenance, while SMT often requires specialized equipment for rework.

How does THT vs SMT impact production speed?

You achieve faster assembly with SMT. Through-hole technology involves manual insertion, which slows production. In THT vs SMT, you see SMT excels in high-volume runs, but through-hole remains valuable for prototypes and low-volume projects.

Why do some designs use both through-hole and SMT?

You combine through-hole technology and SMT to balance performance and reliability. In THT vs SMT, mixed designs let you use through-hole for strength and SMT for density. Through-hole technology supports robust connections, while SMT enables compact layouts.