For most OEMs, you will find that PCBA contract manufacturing delivers lower operational costs and mitigates major risks compared to in-house assembly. Key risk factors often cited by decision-makers include quality control, intellectual property security, and production scalability. You must evaluate ROI, flexibility, and your specific project needs to determine the best fit. The table below outlines how each approach manages critical risks:

| Risk Factor | In-House Assembly | Contract Manufacturing |

|---|---|---|

| Quality & Compliance | Direct control; depends on internal expertise. | Strict standards (ISO 9001, IPC-A-610, RoHS) ensure reliability. |

| Intellectual Property Security | Full organizational control. | Protected by NDAs; third-party data sharing required. |

| Production Integration | Seamless internal collaboration. | External collaboration; strong partners minimize gaps. |

| Internal Expertise | Builds technical knowledge. | Frees resources for innovation. |

| Brand Accountability | Full brand control. | Quality relies on partner selection. |

| Sustainability Control | Direct oversight. | Select partners with ESG commitments. |

PCBA Contract Manufacturing vs. In-House Assembly: A Strategic Guide to Cost, Risk, and Business Growth

- Contract manufacturing often reduces operational costs and risks compared to in-house assembly, making it a favorable choice for many OEMs.

- Choosing contract manufacturing allows you to focus on your core business while experts handle the technical aspects of production.

- In-house assembly provides full control over quality and processes but can lead to higher costs and resource demands.

- Evaluate your specific project needs and use a decision matrix to determine whether contract manufacturing or in-house assembly is best for your business.

- Partnering with a reliable contract manufacturer can enhance flexibility, scalability, and access to advanced technologies, helping you stay competitive.

Understanding PCBA Contract Manufacturing

What Is PCBA Contract Manufacturing?

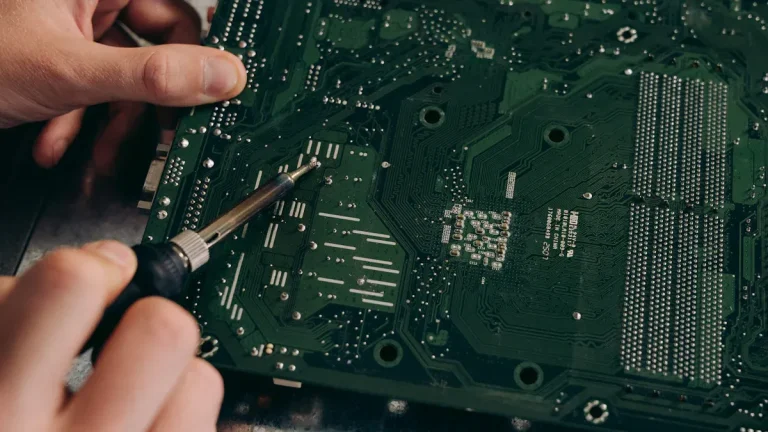

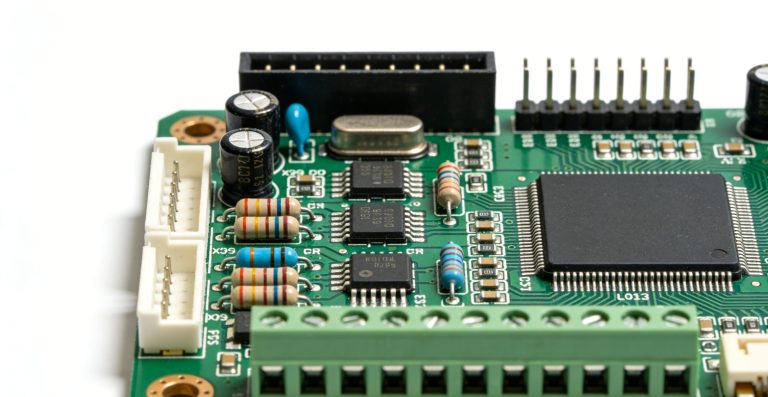

You rely on PCBA contract manufacturing to produce printed circuit board assemblies using external partners who specialize in electronics contract manufacturing. This approach allows you to delegate the entire assembly process, from sourcing components to final testing. You gain access to advanced technology and industry expertise without investing in expensive equipment or facilities. Electronics contract manufacturing partners use techniques like Surface Mount Technology (SMT), automation, and real-time data analytics to deliver high-quality results. You benefit from streamlined production and consistent quality standards.

Tip: Choosing electronics contract manufacturing helps you focus on your core business while experts handle the technical details.

Production lead times often differ between contract manufacturing and in-house assembly. The table below highlights key differences:

| Feature | Contract Manufacturing | In-house Manufacturing |

|---|---|---|

| Initial Build Time | Fast | Long |

| Overall Period | Depending on the order | Usually longer |

| Time Control | Strong external dependency | Strong internal control |

Key Benefits of Contract Manufacturing

You experience several advantages when you select PCBA contract manufacturing for your electronics production needs. The most significant benefits include:

- Economies of Scale: Electronics contract manufacturing providers operate large facilities, which lowers your cost per unit.

- Reduced Overhead Costs: You avoid the expense of maintaining your own production site.

- Expertise and Specialization: Electronics contract manufacturing partners optimize processes and improve quality, saving you money.

- Flexibility and Scalability: You can adjust production volume quickly to meet market demand.

- Risk Mitigation: Outsourcing to electronics contract manufacturing helps you manage production risks and maintain financial stability.

- Focus on Core Competencies: You concentrate on innovation and business growth while experts handle assembly.

Electronics contract manufacturing gives you access to advanced manufacturing techniques. SMT increases speed and precision. Automation boosts throughput and uses robotics for component placement. Industry 4.0 principles enable real-time analytics to optimize production. New technologies like additive manufacturing and MEMS further improve precision and reduce costs. You stay competitive by leveraging these innovations through your electronics contract manufacturing partner.

In-House Assembly Explained

What Is In-House Assembly?

You may choose in-house assembly when you want full control over your electronics manufacturing process. In-house assembly means you manage every step, from sourcing components to final testing, within your own facility. This approach is common for companies that produce high-margin, low-volume custom electronics or require strict intellectual property protection. In-house pcb assembly supports long-term investments in process innovation and enables close integration between research and development and manufacturing teams.

The table below highlights typical scenarios where in-house assembly is preferred:

| Scenario Description | Reason for In-House Assembly |

|---|---|

| High-margin, low-volume custom electronics | Allows for tailored production and higher profits. |

| Full IP protection for regulated products | Essential for compliance and safeguarding innovations. |

| Long-term investment in process innovation | Supports ongoing improvements and efficiency gains. |

| Close integration between R&D and manufacturing | Facilitates collaboration and faster product development. |

In-house production gives you the ability to adapt quickly to changing requirements. You can make rapid adjustments to meet deadlines and respond to market shifts without waiting for external partners.

Control and Customization Advantages

In-house assembly offers unmatched control over your manufacturing processes. You oversee quality, delivery, and performance directly. You manage every aspect of production, from incoming material inspection to end-of-line testing. This level of oversight reduces risks associated with relying on third-party providers.

You benefit from in-house production by having teams that are deeply invested in your products. They solve problems quickly and adapt processes to meet your needs. In-house pcb manufacturing allows you to change plans without the constraints of contract manufacturers. You can implement custom solutions and experiment with new techniques.

Key advantages of in-house assembly include:

- Direct management of quality and delivery.

- Full control over production schedules and output.

- Rapid response to issues and flexibility in operations.

- Ability to tailor processes for unique product requirements.

However, in-house assembly often leads to higher operational costs. You must invest in equipment, facilities, and skilled labor. In-house pcb assembly requires ongoing maintenance and process optimization. You may face challenges scaling up production or managing supply chain disruptions. In-house PCBA manufacturing is best suited for companies with specialized needs and resources to support continuous improvement.

Note: In-house production delivers superior customization and control, but you must weigh these benefits against increased costs and resource demands.

Cost Comparison

When you evaluate PCBA production strategies, you must consider both visible and hidden costs. The choice between pcba contract manufacturing and in-house assembly impacts your capital allocation, operational efficiency, and long-term profitability. A structured cost-benefit analysis helps you make informed decisions and optimize your return on investment.

CAPEX vs OPEX

You face two main categories of expenses in circuit board assembly: capital expenditure (CAPEX) and operational expenditure (OPEX). CAPEX covers the upfront investment in equipment, facilities, and infrastructure. OPEX includes ongoing costs such as labor, materials, utilities, and maintenance.

The following table summarizes the typical CAPEX and OPEX for in-house assembly compared to outsourced circuit board assembly:

| Category | In-House Assembly Costs | Outsourced Assembly Costs |

|---|---|---|

| Capital Expenditure | ||

| SMT line | pick-and-place machine ($50k–$500k) | N/A |

| reflow oven ($20k–$150k) | N/A | |

| wave soldering or selective soldering units | N/A | |

| inspection equipment (AOI, X-ray, functional test) | N/A | |

| facility costs (clean room, ESD flooring, storage) | N/A | |

| Operational Expenditure | ||

| Labor | technicians, engineers, QA staff | N/A |

| Consumables | solder paste, flux, stencils, solder wire, reels, packaging | N/A |

| Maintenance | machine calibration | N/A |

| Utilities | electricity, compressed air, HVAC | N/A |

You avoid high initial investments when you choose contract manufacturing. You leverage the provider’s infrastructure and only pay for the services you use. This approach improves cost control and preserves your cash flow.

A direct comparison of labor and equipment costs further clarifies the financial impact:

| Aspect | Contract Manufacturing | In-House Assembly |

|---|---|---|

| Initial Investment | Lower initial investment due to existing infrastructure | High capital expenditure for setup |

| Per-Unit Manufacturing Costs | Includes service fees, potentially higher per-unit costs | Lower per-unit costs if production volume is high |

| Skilled Workforce Requirement | Less need for in-house skilled labor due to outsourcing | Requires hiring and training skilled technicians |

Note: You benefit from contract manufacturing by reducing your exposure to equipment obsolescence and workforce turnover.

Hidden Costs in In-House Assembly

Many OEMs underestimate the hidden costs of in-house production. These expenses can erode your margins and complicate cost optimization efforts. You must account for the following factors when you consider in-house pcb assembly:

- Design-Related Costs: You incur additional expenses from design errors, multiple iterations, and incomplete documentation. These issues delay production and increase engineering hours.

- Fabrication Costs: Non-standard specifications, small batch penalties, and unnecessary layer counts drive up your costs. You may pay more for custom or low-volume runs.

- Assembly and Component Costs: Component shortages, excessive bill of materials (BOM) complexity, and last-minute substitutions add to your expenses. You also face inventory risks and potential write-offs.

- Equipment Maintenance: You must budget for regular calibration, repairs, and upgrades to keep your SMT line and inspection systems operational.

- SMT Engineer Labor: Recruiting, training, and retaining skilled engineers increases your ongoing costs. Labor shortages can disrupt your production schedule.

- Inventory Risks: You tie up capital in raw materials and finished goods. Obsolete inventory leads to financial losses and storage challenges.

Tip: You can reduce the hidden costs of in-house production by standardizing designs, optimizing your BOM, and improving supply chain management.

Contract manufacturers achieve cost optimization through bulk purchasing and established procurement channels. You benefit from lower material prices and streamlined logistics. In contrast, in-house assembly often struggles with efficient sourcing, which increases your costs and reduces your competitiveness.

ROI Analysis for PCB Production

You must evaluate the return on investment for each circuit board assembly strategy. ROI depends on cost reduction, process efficiency, and your ability to win new contracts. The following table highlights key ROI factors for pcb assembly:

| Factor | Impact on ROI |

|---|---|

| Cost Reduction | Average 10% reduction in operational expenses |

| New Contracts | Potential revenue increase of $50,000 from new contracts due to certification |

| Net Gain | $60,000 net gain in the first year from a $20,000 investment in certification |

| Improved First-Pass Yield | Higher FPY leads to lower costs and faster time-to-market |

You improve your ROI by reducing operational costs and increasing your first-pass yield. Certification and quality standards help you secure new business and enhance your reputation. Contract manufacturing partners often provide these advantages as part of their service offering.

The following comparison matrix summarizes the strategic differences between pcba contract manufacturing and in-house assembly:

| Dimension | PCBA Contract Manufacturing | In-House Assembly |

|---|---|---|

| Cost (CAPEX/OPEX) | Low CAPEX, predictable OPEX | High CAPEX, variable OPEX |

| Expertise | Access to specialized skills | Steep learning curve, internal training required |

| Risk | Minimal equipment obsolescence, high scalability | High risk of equipment obsolescence, limited scalability |

| Cost Control | Easier to forecast and manage | Challenging due to hidden costs |

| Cost-Benefit Analysis | Favorable for most OEMs | Justified only for niche, high-margin products |

| Cost Optimisation | Achieved through economies of scale | Difficult without high volume |

| Cost Optimization | Supported by supply chain management | Hindered by inventory and labor risks |

| Circuit Board Assembly | Outsourced, streamlined | Internal, resource-intensive |

You gain flexibility, scalability, and cost savings when you outsource circuit board assembly. In-house assembly may suit you if you require full control and have the resources to manage complex operations. For most OEMs, pcba contract manufacturing delivers superior cost-benefit analysis and supports long-term growth.

Risk Factors in Electronics Contract Manufacturing

When you evaluate electronics contract manufacturing, you must consider several risk factors that can impact your project’s success. These include quality control and consistency, intellectual property risks, supply chain flexibility, and scalability. Understanding these areas helps you make informed decisions and protect your business interests.

Quality Control and Consistency

You need to ensure that every assembly meets your standards for quality and reliability. In contract manufacturing, providers often implement rigorous automated processes to maintain high quality. These processes include Solder Paste Inspection (SPI), Automated Optical Inspection (AOI), and X-ray Inspection. Such systems help detect defects early and ensure consistent results, especially in high-volume production.

In contrast, in-house assembly may rely more on manual inspections. This approach can introduce variability and reduce the effectiveness of quality control. Contract manufacturers also adhere to strict regulatory requirements, such as ISO 9001 and IPC-A-610, because they serve diverse industries. Your in-house operations may focus on internal standards, which might not match the breadth of compliance seen in contract manufacturing.

Note: Automated inspection and regulatory compliance in contract manufacturing reduce the risk of defects and improve overall quality.

Intellectual Property Risks

Outsourcing production exposes your intellectual property to several risks. You may face threats such as theft, infringement, or unauthorized use of sensitive information. Some contract manufacturers lack robust security measures, which can lead to leaks or misuse of your designs and trade secrets.

You also risk disclosing core competencies during contract negotiations. Employees at external facilities can access and potentially steal valuable information if you do not enforce strict controls. Trade secrets play a crucial role in maintaining your competitive advantage. You must use confidentiality agreements to protect sensitive information during commercial discussions.

To mitigate these risks, you should:

- Establish joint IP ownership and confidentiality requirements before starting any engagement.

- Document and file intellectual property during and after outsourcing.

- Work with multiple providers to reduce knowledge transfer risk.

- Use contracts with business restrictions and incentives for exclusivity to prevent your partner from working with competitors.

Tip: Proactive IP management and legal safeguards are essential when you outsource assembly to protect your innovations.

Supply Chain and Flexibility

Supply chain flexibility determines how quickly you can respond to market changes. Contract manufacturers offer high flexibility because they have established infrastructure and can adapt to your changing needs. They can quickly slot in additional orders, which helps you meet customer demand and manage fluctuations.

The table below compares supply chain flexibility between in-house assembly and contract manufacturing:

| Aspect | In-house Assembly | PCBA Contract Manufacturing |

|---|---|---|

| Flexibility | Limited due to resource constraints | High, can adapt to changing needs easily |

| Infrastructure | Requires significant investment | Already established by the manufacturer |

| Time to Market | Slower due to setup and resource allocation | Faster, as manufacturers can quickly adapt |

| Customization Options | Limited by in-house capabilities | Extensive, with support for prototypes and changes |

| Focus on Core Competencies | Diverts attention from the core business | Allows focus on core areas, outsourcing production tasks |

You may encounter supply chain disruptions such as component shortages, production delays, increased costs, and unmet customer demands. Contract manufacturers help you manage these risks by leveraging their procurement networks and logistics expertise. They use digital tools to monitor supplier performance and respond quickly to market shifts.

Callout: Flexible supply chain management in contract manufacturing supports business growth and customer satisfaction.

Scalability and Market Response

Scalability is critical for responding to market fluctuations and capturing new opportunities. Contract manufacturers provide access to established production facilities and skilled teams. You can adjust production capacity without large upfront investments, which is essential for handling unexpected demand spikes.

Experienced contract manufacturers use digital tools for real-time monitoring. This capability shortens development timelines and enables faster product launches. You benefit from operational discipline and compliance, which are vital in industries with strict timelines and regulatory standards.

In-house assembly faces limitations in scalability. Internal resources are fixed, making it slow to scale operations up or down. Recruitment and training take time, which complicates quick responses to market changes. You may find yourself under-resourced during peak periods or carrying excess overhead during slow times.

Note: Contract manufacturing allows you to leverage economies of scale and respond rapidly to market changes, while in-house assembly may struggle with resource constraints and slower adaptation.

By understanding these risk factors, you can better evaluate the strategic fit of contract manufacturing for your business. You gain flexibility, reduce costs, and improve your ability to respond to market demands.

Strategic Decision: Contract Manufacturing vs In-House Assembly

When to Choose Contract Manufacturing

You should consider contract manufacturing when your business needs rapid time-to-market, high speed, and scalable capacity. This approach works best for high-volume production, projects requiring advanced technology, or when you want to minimize upfront costs. Startups and small to medium-sized OEMs often benefit from the flexibility and efficiency that contract manufacturing provides. You can transition smoothly from prototype to mass production, leveraging the partner’s established processes and supply chain. This model supports projects where speed and efficiency are critical, such as consumer electronics, medical devices, and complex box builds.

Key scenarios for contract manufacturing:

- High-mix, low-volume or high-volume production

- Projects needing advanced assembly techniques

- Fast time-to-market and rapid iteration cycles

- Limited internal capacity or resources

When In-House Assembly Makes Sense

You may prefer in-house assembly if your products require strict intellectual property control, life-critical quality standards, or if you produce ultra-high volumes that justify dedicated facilities. Large OEMs with significant resources can achieve long-term cost savings and maintain direct oversight of quality. In-house assembly suits projects where your process represents a competitive differentiator or when you need to tightly integrate R&D with manufacturing. You gain full control over speed, capacity, and quality, but must manage higher capital investment and operational complexity.

Typical in-house assembly use cases:

- Proprietary or regulated products

- Life-critical applications (e.g., aerospace, medical)

- Ultra-high daily production volumes

- Projects demanding unique process innovation

Decision Matrix for OEMs

You can use a decision matrix to evaluate your options. This tool helps you weigh factors such as scalability, speed, costs, quality, and internal workload. Scenario modeling and costing tools clarify trade-offs and align your choice with long-term goals.

| Decision Factor | In-House Assembly | Contract Manufacturing |

|---|---|---|

| Scalability | Limited by staff and equipment | Built to ramp production quickly |

| Cost at High Volume | Higher due to fixed overhead | Lower per unit with efficiency |

| Time-to-Market | Slower, more coordinated movement is needed | Faster, dedicated processes |

| Quality Systems | Varies, may lack formalization | Certified QA and traceability |

| Internal Workload | High, full management responsibility | Lower, partner handles production |

Tip: Use scenario modeling to compare costs, speed, and capacity for your specific project before making a final decision.

Which One is Right for Your Business?

You should choose contract manufacturing if you need speed, flexibility, and efficient capacity scaling for medium to high-volume or complex projects. In-house assembly fits best when you require maximum control, have the resources for large-scale investment, or must protect proprietary processes. Evaluate your priorities—time-to-market, costs, quality, and capacity—using a structured decision matrix to ensure your manufacturing strategy aligns with your business objectives.

The Sanshun Smart Advantage in PCBA

Cost Savings and Procurement Scale

You want to maximize cost savings for high-volume production. Sanshun Smart delivers this through strategic procurement and strong supplier relationships. You benefit from lower costs because Sanshun Smart leverages bulk purchasing power. This approach reduces your per-unit expenses and helps you avoid the high CAPEX associated with in-house assembly. You do not need to invest in expensive equipment or maintain a large inventory. Sanshun Smart’s supply chain management team negotiates the best prices and ensures reliable component sourcing. You gain a competitive edge in your market by controlling operational costs and improving your bottom line.

Tip: Partnering with Sanshun Smart means you can focus on your core business while experts handle procurement and logistics.

DFM Support and Engineering Expertise

You need more than just assembly. You require engineering expertise and robust DFM (Design for Manufacturability) support. Sanshun Smart’s engineering team works closely with you from the design phase through final production. You receive detailed feedback that helps you optimize your PCB layout for manufacturing efficiency and quality. This proactive approach reduces errors, shortens lead times, and increases your first-pass yield. You avoid costly design iterations and production delays. Sanshun Smart’s engineers have deep experience in SMT assembly outsourcing and advanced manufacturing processes. You can trust their guidance to deliver reliable, high-quality products.

Flexibility and Risk Reduction

You must adapt quickly to changing market demands. Sanshun Smart provides flexibility that supports both rapid prototyping and large-scale production. You can scale your orders up or down without the constraints of in-house resources. This flexibility reduces your exposure to market risks and supply chain disruptions. Sanshun Smart’s contract manufacturing model allows you to respond to customer needs faster than competitors who rely solely on internal capacity. You maintain control over your project timeline and quality standards while minimizing operational risks.

Note: Choosing Sanshun Smart as your PCBA partner positions you for growth, innovation, and long-term success.

You gain lower costs, reduced risks, and greater flexibility when you choose contract manufacturing for your PCBA needs. In-house assembly makes sense if you require strict control or have unique product demands. Use ROI analysis and a decision matrix to guide your decision. For expert support, consult with Sanshun Smart to optimize your electronics manufacturing strategy.

FAQ

What is the main difference between in-house assembly and contract manufacturing?

You manage all production steps with in-house assembly. Contract manufacturing lets you outsource assembly to a specialized partner. This approach reduces your need for equipment and skilled labor while improving scalability and access to advanced technology.

How does contract manufacturing help control operational costs?

You avoid large capital investments in equipment and facilities. You pay only for the services you use. This model streamlines your expenses and helps you maintain predictable operational costs.

When should you consider in-house assembly over outsourcing?

You should choose in-house assembly if you need strict control over intellectual property or if your products require unique processes. This approach works best for highly regulated industries or when you want to integrate R&D with production.

What are the risks of outsourcing PCB assembly?

You may face risks such as intellectual property exposure, quality issues, or supply chain disruptions. You can reduce these risks by selecting a reputable partner and using strong contracts and confidentiality agreements.

Can you scale production quickly with contract manufacturing?

You can scale production up or down rapidly. Contract manufacturing partners have established facilities and skilled teams. This flexibility helps you respond to market changes and customer demand without major delays.