In electronic manufacturing, SMT PCBA can be produced using different assembly processes depending on product requirements, performance expectations, and application environments. The three most common approaches—Surface Mount Technology (SMT), Through-Hole Technology (THT), and Mixed Assembly—each serve distinct functional purposes.

Understanding how and why an SMT PCBA adopts a specific assembly method helps engineers, designers, and procurement teams make informed decisions that balance reliability, cost, and manufacturability.

SMT PCBA Assembly Selection:

- SMT PCBA does not rely on a single assembly method.

SMT, THT, and mixed assembly each serve specific functional, mechanical, and reliability requirements within SMT PCBA designs.

- SMT assembly enables high-density and high-efficiency SMT PCBA production.

It is ideal for compact layouts, automated production, and high-volume applications where cost efficiency and electrical performance are priorities.

- THT remains essential for mechanically critical SMT PCBA applications.

Through-hole components offer superior mechanical strength and are essential for applications requiring high current, high stress, or exposure to vibration.

- Mixed assembly balances compact design with long-term SMT PCBA reliability.

By combining SMT and THT, SMT PCBA can meet both electrical performance and mechanical durability requirements.

- Assembly selection directly impacts SMT PCBA cost, reliability, and lifecycle performance.

Choosing the appropriate assembly method reduces failure rates, minimizes rework, and improves long-term product stability.

- Optimal SMT PCBA design aligns assembly technology with real-world application demands.

Functional requirements, component availability, environmental conditions, and production volume should guide assembly decisions.

Understanding the Three Main PCBA Assembly Technologies

Surface Mount Technology (SMT)

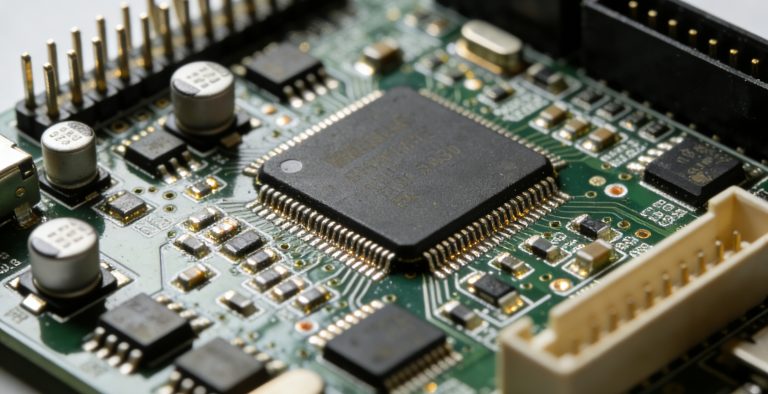

SMT is the most widely used process in modern SMT PCBA production. Components are mounted directly onto the surface of the PCB, allowing for compact layouts and high component density.

Key characteristics of SMT PCBA include:

- Smaller component size and reduced board footprint

- High assembly automation and repeatability

- Improved electrical performance due to shorter signal paths

- Suitability for high-volume and high-density designs

SMT PCBA is commonly used in consumer electronics, industrial control systems, communication devices, and automotive electronics.

Through-Hole Technology (THT)

In the THT assembly, component leads are inserted through drilled holes and soldered on the opposite side of the board. While less compact than SMT, THT offers superior mechanical strength.

THT-based PCBA is typically used when:

- Components must withstand mechanical stress or vibration

- High-current or high-voltage performance is required

- Connectors, transformers, or large capacitors are involved

Although THT is less common in modern compact designs, it remains essential in certain SMT PCBA applications requiring durability and structural integrity.

Mixed Assembly

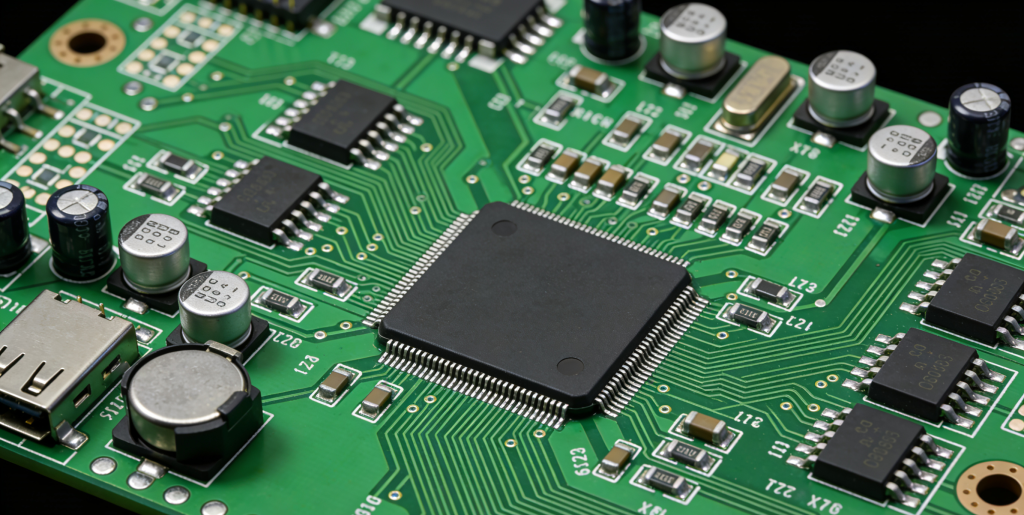

Mixed assembly combines SMT and THT on the same PCBA, leveraging the strengths of both technologies.

An SMT PCBA may adopt mixed assembly when:

- High-density surface-mounted components coexist with mechanically critical THT parts

- The design requires both a compact layout and strong mechanical anchoring

- Functional reliability outweighs pure assembly efficiency

Mixed assembly is widely used in industrial electronics, power modules, and automotive control systems.

Why SMT PCBA Uses Different Assembly Processes

Design and Functional Requirements

The choice of assembly method is primarily driven by the functional needs of the SMT PCBA:

- High-speed signal processing favors SMT

- Power handling and mechanical strength favor THT

- Complex, multi-functional boards often require mixed assembly

The assembly process must support the electrical, thermal, and mechanical requirements of the final product.

Component Availability and Compatibility

Not all electronic components are available in surface-mount packages. Some components—such as relays, power inductors, and certain connectors—are only suitable for THT.

In such cases, SMT PCBA naturally adopts mixed assembly to maintain compatibility without compromising performance.

Reliability and Environmental Conditions

Operating environments play a critical role in assembly selection:

- SMT PCBA performs well in controlled environments with minimal mechanical stress

- THT components provide better resistance to shock, vibration, and thermal cycling

- Mixed assembly balances compact design with long-term reliability

For harsh industrial or automotive environments, mixed assembly is often the preferred solution.

Cost and Production Efficiency Consideration

Assembly Efficiency

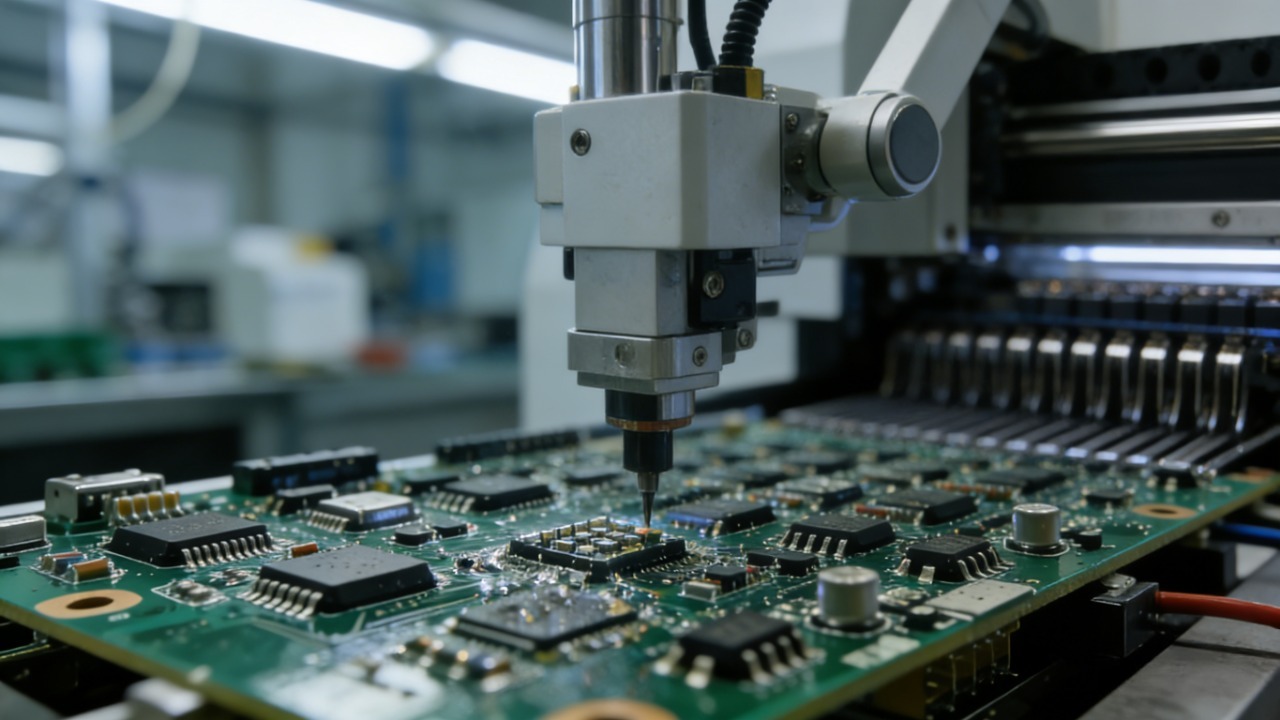

SMT PCBA offers the highest production efficiency due to automated placement and reflow soldering. This results in:

- Lower per-unit cost at scale

- Consistent solder quality

- Faster production cycles

THT assembly, often requiring manual or selective soldering, increases labor time and cost.

Long-Term Cost Perspective

While SMT PCBA is generally more cost-effective for high-volume production, long-term reliability considerations may justify the use of THT or mixed assembly in critical applications.

Choosing the right assembly method reduces failure rates, rework, and warranty costs over the product lifecycle.

Comparison of SMT, THT, and Mixed Assembly for PCBA

| Assembly Type | SMT PCBA | THT PCBA | Mixed Assembly |

| Component Density | High | Low | Medium–High |

| Mechanical Strength | Moderate | High | High |

| Automation Level | High | Low–Medium | Medium |

| Cost Efficiency | High (volume) | Lower | Moderate |

| Typical Applications | Consumer, Industrial | Power, Connectors | Automotive, Industrial |

How to Select the Right Assembly Method for SMT PCBA

When determining the optimal assembly approach, consider:

- Electrical and signal integrity requirements

- Mechanical stress and environmental exposure

- Component package availability

- Production volume and cost targets

- Long-term reliability expectations

An effective SMT PCBA design aligns assembly technology with real-world application demands rather than defaulting to a single method.

FAQ – SMT PCBA Assembly Processes

Q1: Is SMT always the best choice for SMT PCBA?

Not necessarily. While SMT is ideal for compact and high-density designs, some SMT PCBA applications require THT or mixed assembly for mechanical or power-related reasons.

Q2: Can SMT PCBA include through-hole components?

Yes. Many SMT PCBA designs use mixed assembly to integrate surface-mounted and through-hole components effectively.

Q3: Does mixed assembly increase SMT PCBA cost?

It can increase assembly complexity, but it often improves reliability, reducing long-term operational costs.

Q4: Are THT assemblies becoming obsolete in SMT PCBA?

No. THT remains essential for specific components and high-reliability applications.

Q5: How does assembly choice affect SMT PCBA reliability?

Assembly technology directly influences solder joint strength, thermal performance, and mechanical durability—key factors in SMT PCBA reliability.