Understanding SMT PCBA is critical for any electronics project. You need to assess not only the supplier but also the manufacturing process, technical capabilities, quality control, and supply chain management. Proper evaluation ensures reliable production, reduces risk, and avoids costly mistakes. Use the questions below as a framework to assess SMT PCBA processes and capabilities, and ensure your project’s success.

5 Key Questions to Evaluate SMT PCBA

- Experience and Technical Expertise: How mature is the SMT PCBA process? Does it support high-mix/low-volume and high-volume production?

- Certifications and Compliance: Are ISO 9001:2015, IPC-A-610, RoHS, and UL standards maintained?

- Facility Processes: Can you audit the processes or review the documentation for soldering, reflow, and AOI checks?

- Component Traceability: Is there a robust system for tracking parts and preventing counterfeit risks?

- After-Sales Support: Are warranty, RMA, and technical support processes clearly defined?

SMT PCBA Qualifications

Evaluating SMT PCBA begins with understanding process qualifications. Key areas include:

Experience and Expertise

- Years of SMT, through-hole, and mixed-technology assembly

- Ability to handle complex boards and diverse projects

- References or case studies demonstrating reliability

Tip: Choose a manufacturer or process that scales from prototypes to mass production. This ensures flexibility for future projects.

Certifications and Industry Compliance

- ISO 9001:2015, ISO 14001:2015

- IPC-A-610, RoHS, UL

- Regular audits, operator training, and corrective action documentation

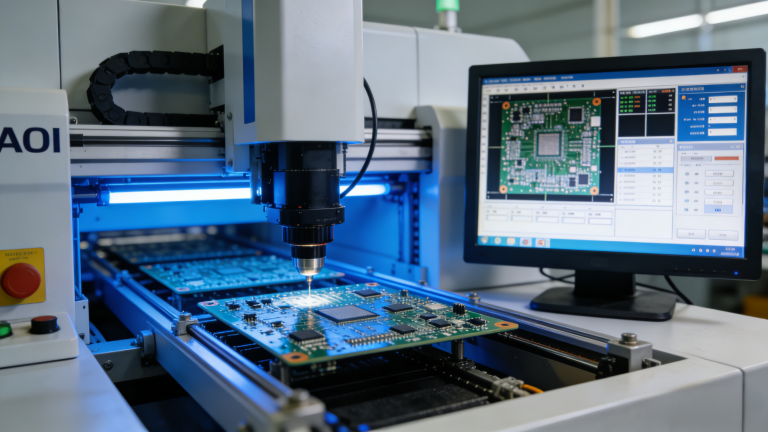

Facility Audit and Process Control

| Audit Checkpoint | Impact on Quality Outcomes |

| Solder Paste Printing | Ensures proper application and thickness, reducing defects |

| Pick-and-Place Machine | Accurate placement prevents misalignment of components |

| Reflow Oven | Correct temperature profiles ensure proper soldering |

| AOI | Detects visible defects early |

| BGA X-ray Inspection | Checks hidden joints, preventing latent failures |

Note: Virtual tours or third-party audits are acceptable if in-person visits aren’t possible.

Quality Assurance in SMT PCBA

Focus on quality throughout the manufacturing process:

| Aspect | Description |

| Key Process Parameters | Monitor solder paste thickness, volume, alignment via SPI |

| Inspection Methods | AOI, X-ray, ICT, FCT |

| Traceability Systems | Track components, lot numbers, and production records |

| Quality Documentation | Inspection reports, corrective actions, and non-conformance logs |

Solder paste inspection and AOI help catch over 95% of defects early, ensuring high First-Pass Yield. In-circuit and functional testing validate correct operation and reliability.

Supply Chain Transparency and Component Traceability

- Bill of Materials (BOM) clarity

- Sourcing strategies: direct manufacturer, distributor, or turnkey PCBA service

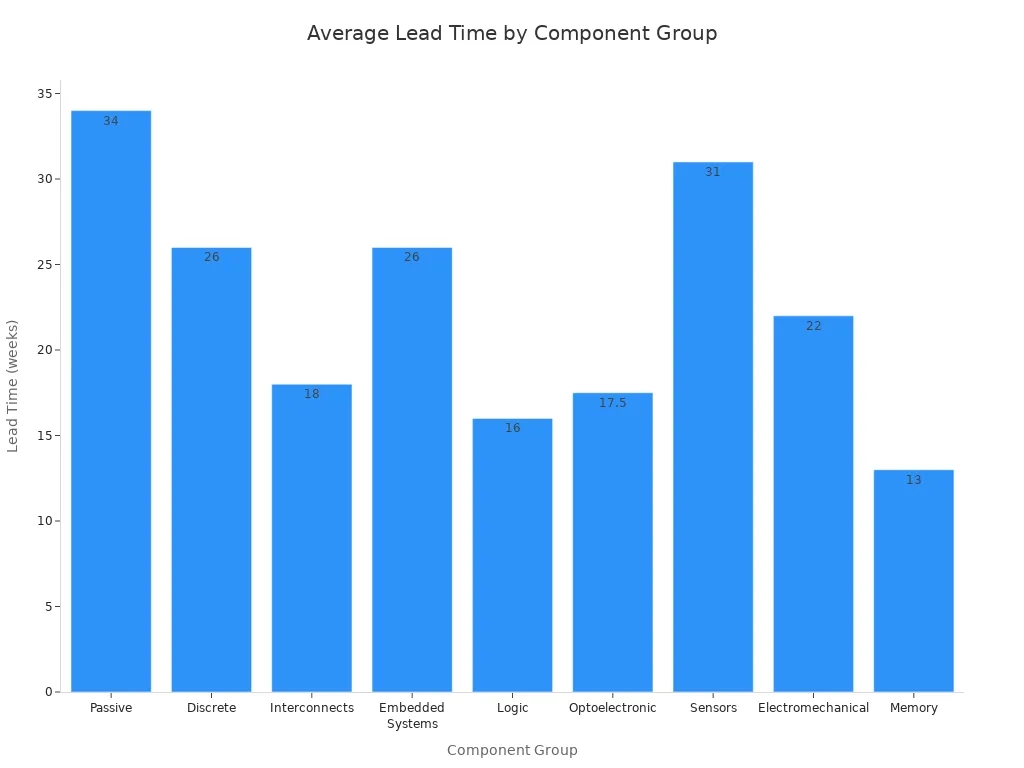

- Lead time monitoring for component groups:

| Component Group | Average Lead Time |

| Passive | 34 weeks |

| Discrete | 26 weeks |

| Interconnects | 18 weeks |

| Embedded Systems | 26 weeks |

| Logic | 16 weeks |

| Sensors | 31 weeks |

- MES, barcode/QR code tracking, and IPC-1782 standardization ensure anti-counterfeit and full traceability.

- Approved Vendor List (AVL) monitoring ensures component integrity.

Tip: Choose SMT PCBA providers like Sanshun Smart, which offer full traceability, anti-counterfeit controls, and MES-based data management.

Technical Capabilities and DFM Support

- Maximum board size and layer count verification

- Support for complex BGA, FAI, and X-ray inspection

- DFM analysis to reduce manufacturing defects and costs

Sanshun Smart provides detailed DFM reports and engineering support, helping clients optimize PCB layouts for SMT assembly, detect early issues, and ensure traceability.

Ordering Process, Lead Times, and Cost Transparency

- Confirm production capacity for your volume needs

- Check lead times for prototypes and mass production

- Request a detailed cost breakdown, including PCB, components, assembly, testing, and operational costs

| Cost Component | Description |

| PCB Manufacturing | Material and process fees |

| Component Procurement | Often 40%-60% of total cost |

| SMT Assembly | Based on component count |

| DIP Assembly | Manual or wave soldering cost |

| Testing/QC | All inspection steps |

| Auxiliary Materials | Equipment depreciation, operational costs |

After-Sales Support and Warranty

- Warranty coverage for defects and standard use

- Structured RMA process for returns

- Technical support throughout the project lifecycle

- Customer references and case studies

Sanshun Smart offers clear warranty policies, RMA workflows, and proactive project support, ensuring long-term reliability.

Quick Checklist for SMT PCBA Evaluation

Key Areas to Audit:

- Equipment Calibration: SPI, AOI, FCT, reflow ovens

- Process Control: Reflow profiles, solder paste monitoring

- Quality Systems: ISO 9001, IPC-A-610 compliance

- Material Traceability: Barcode scanning, lot tracking

- Anti-Counterfeit Measures: Authorized distributors, original packaging

Tip: Keep the checklist updated to reflect project changes. Sanshun Smart supports clients with all checklist items and transparent documentation.

FAQ

What certifications should SMT PCBA processes follow?

ISO 9001:2015, IPC-A-610, RoHS, and UL. These confirm adherence to quality and safety standards.

How is component traceability ensured?

Barcode, MES, AVL management, and IPC-1782 standardization allow full traceability and counterfeit prevention.

What technical capabilities are essential for complex PCBAs?

Advanced assembly, X-ray for BGAs, DFM analysis, and FAI inspection.

How does after-sales support add value?

Warranty coverage, technical assistance, and structured RMA processes protect your investment.

How to quickly evaluate SMT PCBA readiness?

Use a checklist covering quality systems, traceability, technical capability, and after-sales support. Sanshun Smart provides detailed audit checklists and guidance for clients.