Is investing in LED light for poultry farm really worth the cost?

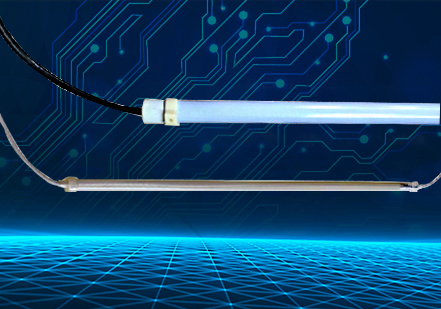

For modern poultry operations, lighting is no longer just an energy expense—it directly impacts bird welfare, feed conversion, egg production, and long-term ROI. High-quality poultry house LED lighting can reduce electricity consumption by up to 70% while improving production consistency across broiler and layer houses.

This article provides practical guidance for poultry farmers and decision-makers on evaluating LED poultry house lighting, including selection parameters, installation layouts, control system compatibility, and lighting recommendations for different poultry types and growth stages.

Key ROI Highlights for LED Light for Poultry Farm

- High-quality LED light for a poultry farm can reduce electricity consumption by 50–70%.

- Properly designed chicken house LED lights improve feed conversion, growth uniformity, and laying consistency.

- Long-life dimmable LED lighting for poultry lowers maintenance and labor costs.

- Strategic installation and integration with controllers maximize ROI and operational reliability.

Why LED Light for Poultry Farm Improves ROI and Productivity?

Lighting directly affects bird behavior, metabolism, and production cycles. Inconsistent light intensity, flickering, or poor spectrum can lead to uneven growth, stress, and lower productivity. Using low-flicker poultry lighting with appropriate spectrum control enhances welfare and stabilizes production.

A well-planned LED light for a poultry farm provides:

- Uniform illumination across broiler or layer houses

- Tunable spectrum and dimming for different growth stages

- Compatibility with modern controllers or automated dimmers

By treating lighting as a controllable production variable rather than a fixed cost, farms can optimize ROI over the lifespan of their lighting system.

How to Choose the Right LED Light for Poultry Farm?

When evaluating LED light for poultry farm, consider the following technical specifications:

| Parameter | Recommendation |

| Luminous Intensity | 10–30 lux for layers; 20–50 lux for broilers (adjust per growth stage) |

| Light Spectrum | Full-spectrum white light for general growth; red/blue spectrum for stress management or laying stimulation |

| Flicker | Low-flicker < 1% to reduce stress |

| IP Rating | IP65/IP66 for dust and moisture resistance |

| Lifespan | ≥50,000 hours |

| Dimmable | Ensure compatibility with dimmable LED lighting for poultry or controllers |

These parameters help ensure that the LED light for poultry farm meets both production needs and operational reliability requirements.

For farms planning to upgrade or expand, selecting a high-quality LED light for poultry farm should be based on the total cost of ownership rather than the upfront price. Factors such as lifespan, controller compatibility, flicker control, and supplier support play a critical role in long-term performance and ROI. Choosing reliable suppliers like Sanshun Smart can help ensure consistent quality, reduce maintenance issues, and maximize investment benefits.

LED Light for Poultry Farm Installation Layout Best Practices

Proper installation is critical to achieving consistent results. An LED light for poultry farm should be installed with:

- Even spacing along ceiling trusses or beams to avoid bright/dark zones

- Overlapping coverage to ensure light reaches all tiers or cages

- Reflective surfaces or diffusers to maximize uniformity

- Verification of light intensity with a lux meter after installation

Illustrative Layout Table

| House Type | Fixture Spacing | Recommended Height | Notes |

| Broiler house lighting | 1.5–2.0 m | 2.5–3.0 m | Even coverage for growth uniformity |

| Layer house lighting | 1.0–1.5 m | 2.0–2.5 m | Avoid flicker, ensure consistent egg production |

| Small poultry house | 1.0 m | 2.0 m | Use reflective panels if necessary |

Recommended Light Intensity and Duration

Lighting requirements vary by poultry type and growth stage. Using LED lights for poultry farms with dimming capability allows for gradual adjustments.

| Poultry Type | Growth Stage | Light Intensity (lux) | Daily Photoperiod |

| Broilers | Starter (0–3 wks) | 20–30 | 22 h light / 2 h dark |

| Broilers | Grower (3–6 wks) | 25–40 | 18 h light / 6 h dark |

| Layers | Pullets (0–16 wks) | 10–15 | 8–10 h light / 14–16 h dark |

| Layers | Laying (16 wks+) | 15–25 | 14–16 h light / 8–10 h dark |

Gradual dimming and light schedule adjustment help reduce stress and improve growth and production outcomes.

Controller and Dimming Compatibility

Modern LED poultry house lighting often integrates with control systems for:

- Automated dimming schedules

- Remote monitoring of light intensity

- Integration with ventilation or environmental control systems

Decision-makers should verify that the LED light for poultry farms is compatible with dimmable LED lighting controllers for poultry and supports programmable schedules for both broilers and layers.

Energy Savings and ROI of LED Light for Poultry Farm

| Lighting Type | Energy Consumption | Lifespan | Maintenance Frequency |

| Incandescent | Very High | Short | Very Frequent |

| Fluorescent | High | Medium | Medium |

| Generic LED | Medium | Medium | Medium |

| High-Quality | Low | Very Long | Minimal |

High-quality chicken house LED lights reduce electricity bills while minimizing labor for replacements and downtime.

ROI Calculation Example

| Factor | Impact |

| Energy Savings | 50–70% lower electricity bills |

| Maintenance Savings | Fewer replacements and labor over 5–7 years |

| Productivity Gains | Improved FCR or egg output |

| Payback Period | ~18–36 months |

This demonstrates why ROI evaluation should consider the total cost of ownership, not just the initial investment.

Key Takeaways for Poultry Lighting Decisions

- Evaluate technical specifications: luminous intensity, spectrum, flicker, IP rating, and dimmable capability.

- Plan fixture layout for uniform coverage in broiler house lighting/layer house lighting.

- Adjust light schedules and intensity according to poultry type and growth stage.

- Ensure the LED light for poultry farm is compatible with controllers or dimmers.

- Factor in long-term savings from energy efficiency, lower maintenance, and improved production.

A high-quality LED light for poultry farm is a long-term investment. Proper selection, layout, and integration with control systems enhance bird welfare, productivity, and ROI. Farms that prioritize these factors will see sustainable benefits from their lighting systems.

Frequently Asked Questions

How long does it take to see ROI from LED poultry lighting?

Most farms achieve ROI within 1.5–3 years, depending on farm size, energy costs, and operating hours.

Can LED poultry lighting be tailored for different poultry types?

Yes. Broiler house lighting and layer house lighting require different intensity and photoperiod schedules, which can be managed using dimmable LED lighting for poultry.

Is low-flicker poultry lighting important?

Yes. Low-flicker lighting reduces bird stress and promotes stable growth and laying patterns.

What IP rating should poultry barn LED lights have?

Fixtures with IP65 or IP66 ratings are recommended for dust, moisture, and high-humidity conditions in poultry barns.

Can LED poultry lights integrate with control systems?

High-quality LED poultry house lighting is typically compatible with automated controllers, enabling programmable light schedules and integration with ventilation or environmental controls.