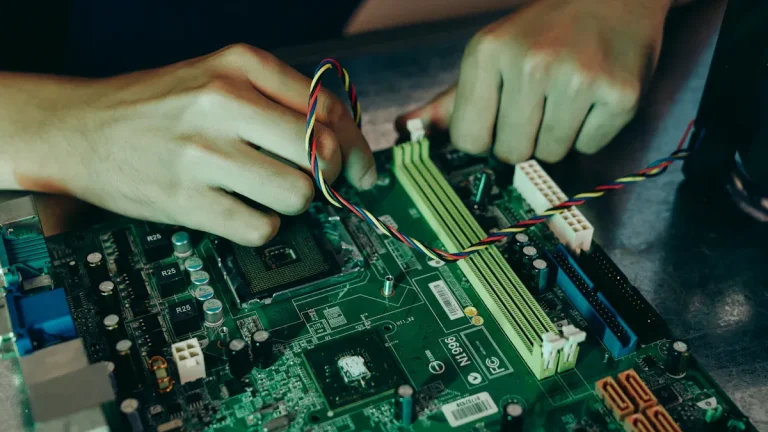

You’ve invested weeks refining your design and locking down your BOM—only to discover that 15% of your PCBA boards fail AOI inspection. At that moment, most manufacturers make the same decision: rework the boards and push the shipment out the door.

But here’s the uncomfortable truth—reworking defective PCBA boards is one of the fastest ways to bleed profit in electronics manufacturing.

In high-mix, high-reliability SMT production, the real cost of PCBA board rework isn’t the technician’s hourly rate. It’s hidden in lost throughput, compromised reliability, delayed deliveries, and long-term brand damage. In fact, a reworked PCBA board often becomes the most expensive unit in your entire production run.

Key Takeaways for Managing PCBA Board Quality Costs

To help you navigate the complexities of production recovery, here are the essential points covered in this guide:

- The 5X Rule: Reworking a PCBA board can cost up to 5 times the initial assembly price when factoring in re-testing and loss of throughput.

- Adherence to Standards: Professional rework processes must align with IPC-7711/7721 guidelines to maintain solder joint integrity.

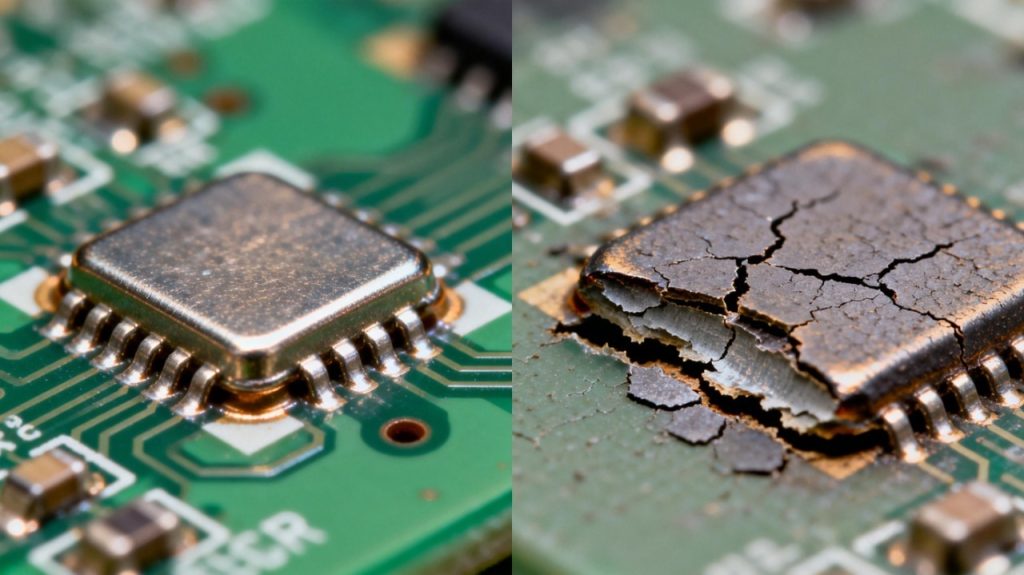

- Reliability Risks: Excessive “heat excursions” degrade the FR-4 substrate and the intermetallic layers of the copper traces.

- The Power of Prevention: Optimizing the Pick-and-Place and stencil process is the only way to achieve a high First Pass Yield (FPY).

1. Why Defective PCBA Boards Create Hidden Manufacturing Costs?

When calculating rework, many OEMs only account for “Direct Labour.” However, the financial impact of a defective PCBA board involves the entire contract manufacturing ecosystem:

- The Throughput Bottleneck: Every minute a technician spends desoldering a BGA (Ball Grid Array) is a minute they aren’t completing new orders on the SMT line. You aren’t just losing labour; you’re losing production capacity.

- Component Recovery Risk: During IC (Integrated Circuit) shortages, the risk of heat-damaging a specialised microprocessor during removal can lead to catastrophic project delays.

- The Re-Verification Tax: Reworked units require secondary X-ray Inspection (AXI) or In-Circuit Testing (ICT). This doubles the quality control overhead for a single unit compared to a first-pass product.

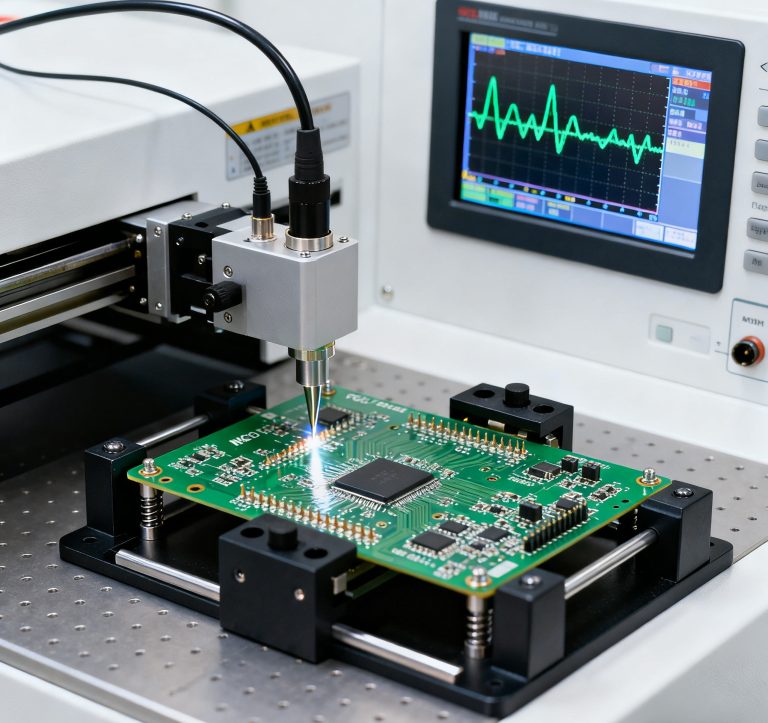

2. Why is Adhering to IPC-7711/7721 Critical for PCBA Board Integrity?

While rework is a common part of the Electronic Manufacturing Services (EMS) lifecycle, it must be performed without compromising the board’s lifespan. Professional facilities align their methods with IPC-7711/7721 (Rework, Modification, and Repair of Electronic Assemblies) to ensure structural stability.

Key Technical Requirements for Reliable Rework:

- Controlled Thermal Profiles: Rework should utilize localized heating that mimics the original reflow soldering ramp rates to prevent “thermal shock” to nearby passive components.

- Intermetallic Layer Integrity: Excessive heat duration can cause the solder bond to grow too thick, resulting in a brittle solder joint that may fail under mechanical stress or vibration in the field.

- MSD (Moisture Sensitive Device) Management: Proper protocols ensure that PCBA boards are pre-baked to remove trapped moisture, preventing pad delamination or the “popcorn effect” during rework heating.

3. Rework vs. Scrap: When Should You Give Up on a PCBA Board?

Deciding whether to repair or dispose of a board requires a cold, data-driven analysis of the Total Cost of Quality.

| Decision Factor | Favor Rework | Favor Scrap |

|---|---|---|

| Component Value | High-cost FPGAs or BGA chips | Low-cost SMT passives ($0.01) |

| Board Complexity | Simple 2-4 layer designs | Multi-layer HDI or Flex-Rigid |

| Standard Class | IPC Class 1 (Consumer) | IPC Class 3 (Medical/Defense) |

| Failure Nature | Surface Solder Bridges | Scorched Laminates or Internal Shorts |

If the estimated rework time exceeds 30% of the board’s value, or if it involves damaged micro-vias in a mission-critical environment, scrapping is often the safer financial and technical choice.

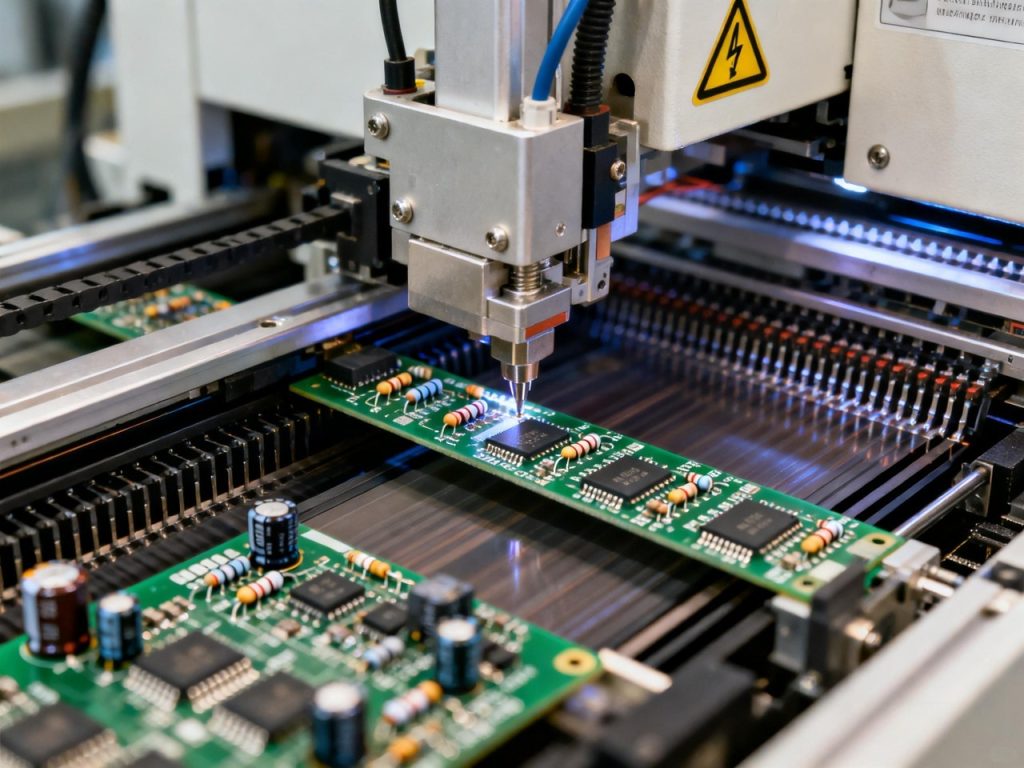

4. How to Prevent Defects in PCBA Board Assembly?

To maximise your First Pass Yield (FPY), your production strategy must shift from “detection and repair” to “prevention.” Use this checklist to audit your assembly line:

- DFM (Design for Manufacturing) Review: Ensure component footprints and solder pads are optimised to prevent common issues like “tombstoning.”

- 3D SPI (Solder Paste Inspection): Verify paste volume and alignment before the board enters the reflow oven.

- Stencil Aperture Optimisation: Ensure the laser-cut precision and stencil thickness are tailored to the specific solder alloy.

- Strict MSD Floor Life Tracking: Prevent internal board damage by strictly controlling the exposure time of moisture-sensitive ICs.

- Regular Thermal Profiling: Use data loggers to ensure even heat distribution across the entire PCBA board during mass production.

For OEMs and startups alike, most PCBA board failures are not caused by design errors—but by insufficient process control during assembly. This is why choosing the right PCBA manufacturing partner is often more important than choosing the lowest unit price.

5. Achieve Zero-Defect Goals with Sanshunsmart

Lowering the true cost of quality starts with choosing a partner who prioritises precision from the very first step. At Sanshunsmart, we focus on Turnkey PCBA solutions where quality is engineered into the process.

By integrating rigorous DFM analysis and advanced ICT/AOI testing into our production lines, we ensure that your PCBA board is handled with the highest level of care. We help our clients protect their margins and their reputations by delivering stable, high-yield production runs that minimise the need for costly rework.

Looking to reduce your assembly rework rates? [Contact Sanshunsmart today for a professional DFM evaluation of your next project.]

FAQ: Professional Insights on PCBA Board Rework

Q: Is a reworked PCBA board as reliable as a new one?

A: If performed under controlled conditions following industry best practices, a reworked board can meet functional requirements. However, a “first-pass” board always offers superior mechanical reliability and long-term thermal longevity.

Q: What is the most common cause of SMT rework?

A: Improper solder paste deposition is responsible for nearly 70% of defects. This is why Sanshunsmart emphasises 3D SPI as a critical preventative measure in every project.

Q: Can rework be performed on multi-layer HDI boards?

A: It is significantly more difficult. High-density interconnect (HDI) boards act as large heat sinks, and localised rework can lead to internal via cracking or pad lifting if not handled with professional-grade convection equipment.