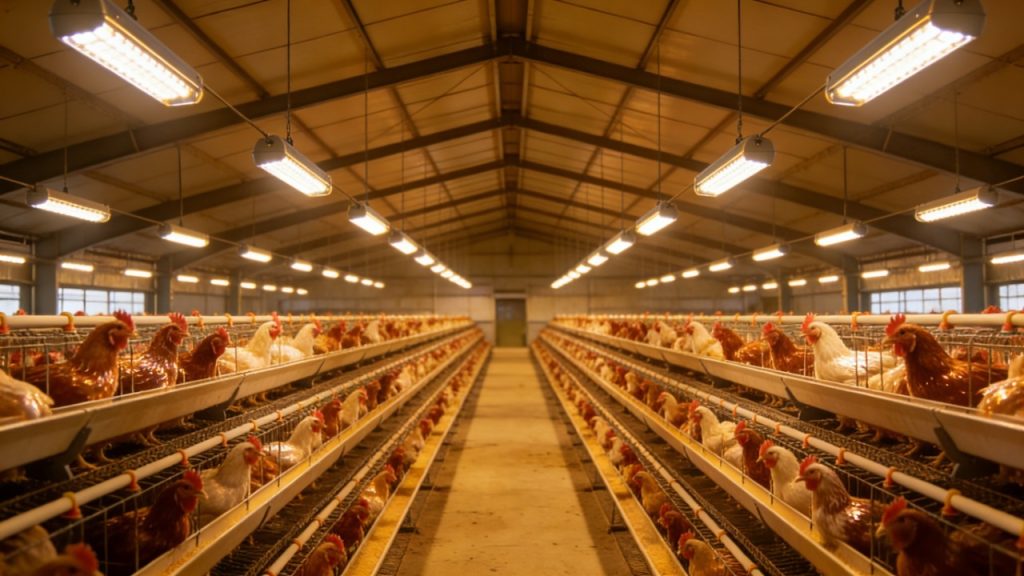

Let’s be honest: most poultry farms don’t lose money because electricity is expensive — they lose money because cheap barn lights fail at the worst time.

One flickering fixture can trigger stress and piling. One corroded driver can force emergency replacements mid-cycle. And every unexpected lighting issue steals what you can’t get back: uniform growth, stable egg output, and labor hours.

Choosing the right LED light for poultry farm isn’t “buying bulbs.” It’s buying predictable production: the right spectrum for your birds, IP69K durability against ammonia wash-downs, and true flicker-free dimming that keeps the house calm.

Before you sign a PO, use these 5 questions to separate high-performance poultry lighting systems from low-cost imitations — and protect your ROI from day one.

Executive Summary: The 5-Point Strategic Checklist for Poultry Lighting

To transform your LED light for poultry farm from a utility cost into a production asset, your lighting system must pass these five critical benchmarks. Use this checklist to filter out low-quality fixtures and secure your farm’s long-term ROI:

- Biological Spectrum Optimization: Does the light output match the specific biological needs of your flock (e.g., Red light for egg production or Blue/Green for Broiler calmness)?

- Ammonia & Moisture Defense: Is the fixture certified IP69K and constructed with PMMA materials to withstand high-pressure wash-downs and corrosive ammonia gas?

- Welfare-Centric Dimming: Does the driver provide smooth, flicker-free dimming (0-100%) to eliminate strobe effects that cause bird stress and piling?

- Total Uniformity: Is the optic engineering designed to eliminate “dark spots” and “shadows,” ensuring even bird distribution and dry litter across the entire floor?

- Installation & Maintenance ROI: Does the system feature daisy-chain connectivity and a 50,000+ hour lifespan to drastically reduce labor and replacement costs?

1. Why Is the Spectrum of Your LED Light for Poultry Farms Critical?

Birds don’t see the world the way we do. While a “standard” light might look bright enough to you, it could be leaving your birds in the dark biologically. The right LED light for poultry farm must be engineered for avian retinas.

- Layer Houses: You need a spectrum rich in Red light (600-700nm). This mimics the long days of spring, stimulating the hypothalamus to keep egg production at its peak.

- Broiler Houses: Here, you want a balance of Blue and Green light. This combination calms the birds, reduces unnecessary activity, and significantly improves your FCR (Feed Conversion Ratio).

2. How to Choose Ammonia-Resistant LED Light for Poultry Farm (IP69K, IK10, PMMA)?

The air inside a chicken house is brutal. The mixture of dust, moisture, and ammonia (NH3) will eat through a cheap light fixture in months. When shopping for an LED light for poultry farm, durability is non-negotiable.

- Hermetic Sealing: Look for an IP69K rating. This means you can hit the lights with a high-pressure power washer during disinfection without blowing a circuit.

- Chemical Resistance: Ensure the housing is made of Ammonia-resistant materials like PMMA. Standard plastics will yellow and crack, leading to rapid lumen depreciation and lost brightness.

- Impact Rating: Always ask for an IK10 rating—it’s the “armor” that protects your lights from being shattered by cleaning tools or equipment.

3. What Is True Flicker-Free Dimming for Poultry Lighting (0.1% / THD < 15%)?

To a chicken, a flickering light looks like a strobe light in a nightclub. This causes massive poultry stress, leading to feather pecking and higher mortality rates.

- Smooth Transitions: Your LED light for poultry farm must support smooth sunrise and sunset simulation. A sudden “snap” from dark to light can cause the birds to “fight or flight,” leading to pile-ups and broken bones.

- Clean Power: Demand a Total Harmonic Distortion (THD) < 15%. This ensures the lights don’t interfere with your sensitive environmental controllers or other farm tech.

4. Generic vs. Professional LED Light for Poultry Farm: TCO, Lifespan, Labor Cost

The purchase price is only 20% of the total cost. If you’re replacing “cheap” bulbs every six months, you’re losing money on labor and downtime.

| Performance Metric | Generic Industrial LED | High-Output LED Light for Poultry Farm |

|---|---|---|

| Luminous Efficacy | 100 lm/W | 140 – 160 lm/W |

| Labor Cost | High (Individual Wiring) | Low (Plug & Play Daisy-Chain) |

| Lifespan | 10,000 – 15,000 Hours | 50,000 – 100,000 Hours |

| Warranty | 1-2 Years | 5 Years (Heavy-Duty) |

5. Is the LED Light for Poultry Farm Designed for Maximum Uniformity?

Uniformity isn’t just a technical spec—it’s the difference between a calm flock and a chaotic one. If your barn has “dark spots,” birds will instinctively huddle in brighter zones, leading to overcrowding, wet litter, and increased mortality.

When selecting your LED light for poultry farm, focus on the engineering behind the lens rather than just the brightness:

- Precision Beam Angles: High-performance poultry lights are engineered with specific optics to eliminate shadows. Whether you operate multi-tier cages or floor-raised systems, look for fixtures designed to distribute light evenly across every square foot, ensuring birds on the bottom tier receive the same intensity as those at the top.

- Optimal Light Distribution: Instead of relying on third-party simulations, choose a lighting system that is pre-engineered for standard poultry house dimensions. Our lights are designed to achieve a uniformity ratio of >0.7 when installed at industry-standard spacing, ensuring no bird is left in the dark.

- Anti-Glare Optics: Professional-grade LEDs use specialized covers to soften the light source, preventing the harsh glare that can trigger aggression and pecking in sensitive flocks.

Boost Your Farm’s Productivity with Science-Backed Lighting

Upgrading to a specialized LED light for poultry farm is the most effective way to lower your operational costs while improving bird welfare. Don’t let poor lighting eat into your margins—switch to a system built for the biology of your birds.

Ready to optimize your barn’s performance? [Browse our 2026 Poultry Lighting Catalog] to find the perfect fit for your facility. Experience the power of professional illumination today.

FAQ: Expert Answers for Savvy Farm Owners

Q: How many LED lights does a poultry house need?

A: This depends on your target lux levels (e.g., 40-60 lux for broilers, up to 80+ lux for layers). Typically, one high-output LED fixture covers a 3-5 meter radius. We recommend checking our spacing guide in the product catalog for specific layouts.

Q: What’s the best mounting height and spacing for poultry LED lights?

A: For floor-raised birds, a mounting height of 2.5-3 meters is ideal. For cage systems, lights should be positioned to avoid “shading” from the tiers. Using a staggered layout often provides the best uniformity.

Q: What warranty should a professional LED light for a poultry farm include?

A: Given the harsh ammonia and moisture levels, you should settle for nothing less than a 5-year heavy-duty warranty. This ensures the internal driver and the ammonia-resistant housing are built to last multiple flock cycles.