Launching a new product shouldn’t feel like running an obstacle course.

Yet for many companies, fragmented suppliers, component shortages, and repeated handoffs turn PCBA assembly into a bottleneck that quietly kills time-to-market.

This is exactly why more OEMs are switching to one-stop PCBA assembly.

By consolidating PCBA fabrication, component sourcing, SMT/DIP assembly, testing, and final delivery under a single turnkey PCBA assembly partner, companies can eliminate delays, reduce risk, and cut product launch timelines by up to 50%. One-stop PCBA assembly isn’t just about convenience—it’s about speed, accountability, and predictable results.

Key Takeaways About One-stop PCBA Assembly Solutions

Here’s what you’ll learn in this article:

- One-stop PCBA assembly definition and workflow – end-to-end turnkey solution.

- Major benefits – speed, cost reduction, and risk mitigation.

- Comparison with traditional PCBA assembly – why a centralized workflow is faster.

- Partner selection tips – choosing a reliable PCBA assembly service provider.

- Industry applications – IoT, medical devices, automotive electronics.

- Technical capabilities – mini parts, multi-layer boards, testing methods.

- Next steps – how to leverage one-stop PCBA assembly with Sanshun Smart.

What Is One-stop PCBA Assembly? Turnkey Workflow Explained

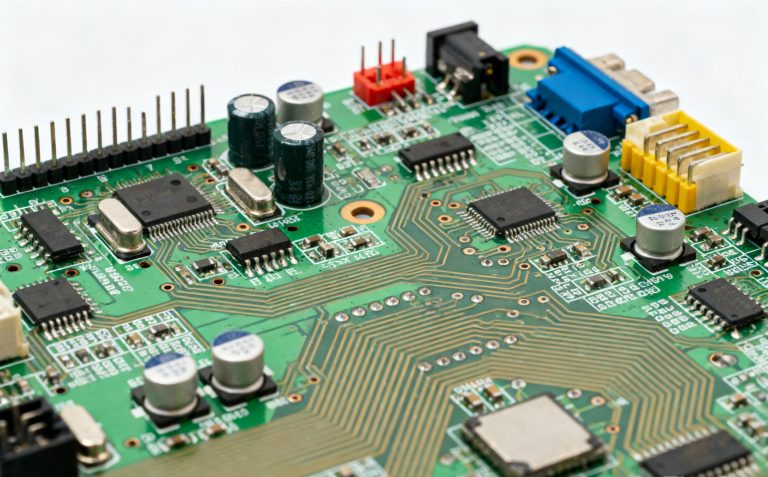

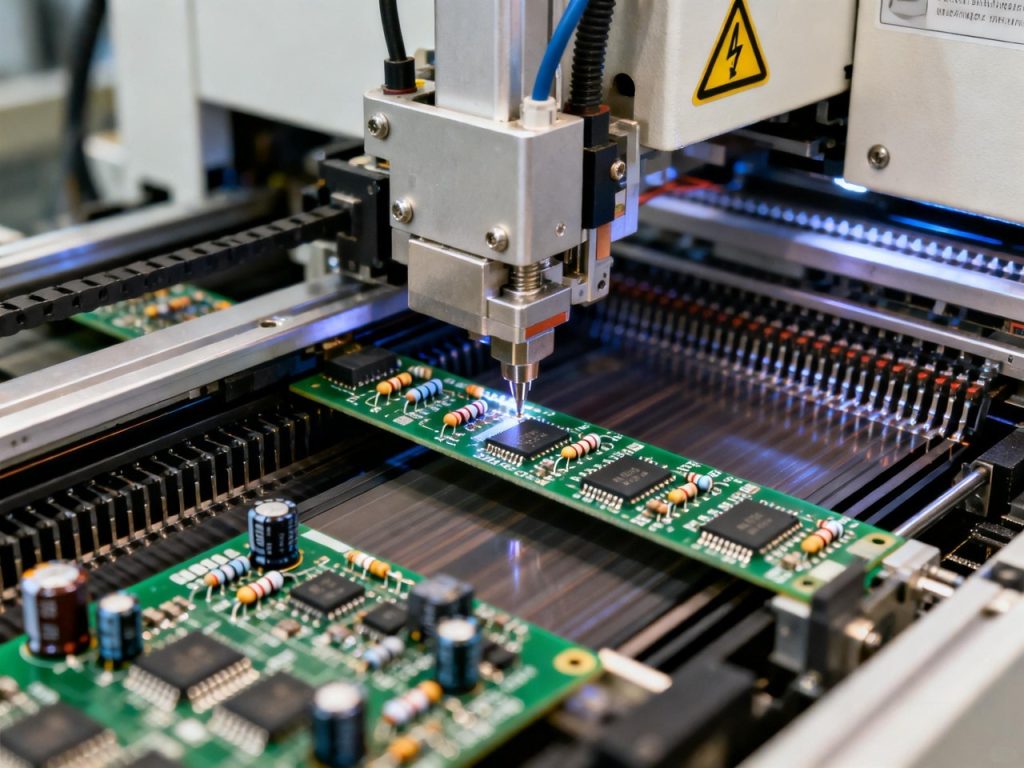

A one-stop PCBA assembly service, also known as turnkey PCBA assembly, handles every step of the PCBA manufacturing process under one roof. Instead of juggling multiple vendors for PCBA fabrication, SMT/DIP assembly, component sourcing, testing, and packaging, a turnkey provider manages it all.

Key Components of a One-stop PCBA Assembly Service

- PCBA prototyping and design review (DFM analysis) – Detect potential BOM errors or design flaws before production, saving thousands in rework.

- Component sourcing and supply chain management – Established supplier networks reduce lead times and ensure availability for high-mix products.

- SMT/DIP assembly – Precision placement and soldering for complex PCBAs, including ultra-fine pitch and mixed technology boards.

- Testing & quality assurance (ICT, FCT, AOI, X-ray) – Inline QA ensures defects are caught early, preventing costly delays.

- Final packaging and delivery – Ready-to-ship products with traceability and protective packaging.

Key Benefits of One-stop PCBA Assembly for Faster Product Launch

Accelerated Product Launch

The primary advantage of one-stop PCBA assembly is speed. Centralized operations allow:

- Faster communication between engineering and production teams

- Reduced component lead times with established procurement channels

- Inline testing and QA prevent weeks of rework

For industries like medical devices, where compliance testing can be lengthy, or automotive electronics, where safety certifications are critical, a turnkey provider can cut product launch cycles by 30–50%.

Cost Efficiency and Risk Reduction

Upfront costs may be slightly higher, but the total cost of ownership (TCO) decreases thanks to:

- Reduced logistics and shipping fees

- Fewer assembly errors and warranty claims

- Efficient bulk procurement and component management

Pre-production DFM analysis prevents BOM errors that could otherwise cost tens of thousands in scrap and rework—turning prevention into measurable ROI.

Scalability and Flexibility

Whether it’s a small prototype run or high-volume production, one-stop PCBA assembly providers like Sanshun Smart adapt seamlessly. High-mix, low-volume runs and large-scale production are managed with consistent quality, flexibility, and on-time delivery.

One-stop PCBA Assembly vs Traditional Multi-vendor Approach

| Feature | Traditional PCBA assembly | One-stop PCBA Assembly |

| Vendors | Multiple suppliers, fragmented workflow | Single turnkey provider |

| Lead time | Long, dependent on coordination | Short, optimized end-to-end workflow |

| Communication | Prone to errors | Centralized, seamless |

| Rework risk | High | Reduced via inline QA & DFM |

| Cost | Hidden fees from delays | Transparent TCO savings |

| Flexibility | Hard to scale | Scalable from prototype to mass production |

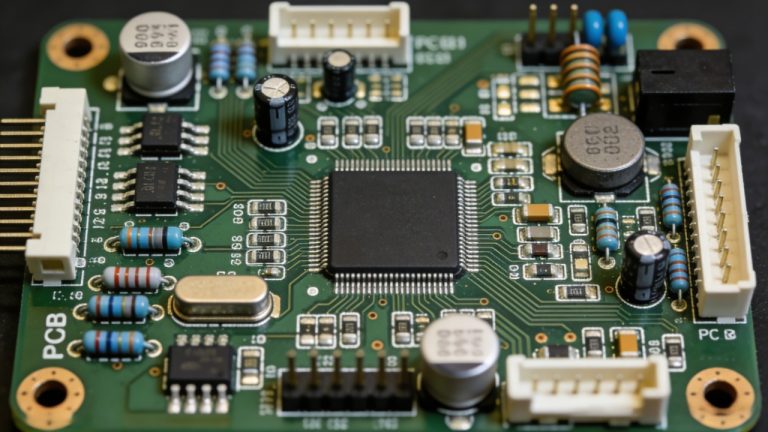

Technical Capabilities Snapshot

| Capability | Specification |

| Minimum component size | 01005 |

| PCBA layers | 1–36 layers |

| Testing methods | ICT, FCT, AOI, X-ray |

| Assembly type | SMT, DIP, mixed technology |

| Component sourcing | Global suppliers with buffer stock |

How to Choose the Right One-stop PCBA Assembly Partner?

Not all turnkey providers are equal. Key criteria:

- Certifications & Quality Standards – ISO 9001, IPC, UL compliance

- Experience & Capacity – Handling complex PCBAs with multi-layer boards

- Speed & Responsiveness – Rapid design changes and urgent order handling

- Transparency & Communication – Real-time project updates and reporting

- Proven Track Record – Case studies from IoT, medical, and automotive electronics

Example: Sanshun Smart has over a decade of experience in turnkey PCBA assembly, with advanced SMT/DIP lines, inline AOI/X-ray testing, and global client delivery. Their integrated workflow ensures your project moves quickly from concept to mass production.

Take the Next Step to Accelerate Your Product Launch

Ready to cut your product launch time in half? Partnering with a one-stop PCBA assembly provider like Sanshun Smart ensures your PCB prototyping, SMT/DIP assembly, testing, and delivery are handled seamlessly under one roof.

- Over 10 years of experience in PCBA manufacturing

- Advanced in-house testing (AOI, X-ray, ICT)

- Proven global client base

- Flexible for both prototype and mass production

Discover how Sanshun Smart’s one-stop PCBA assembly services can transform your project.

Request a free DFM review or a fast turnkey PCBA quote today.

FAQ: One-stop PCBA Assembly

Q1:Is one-stop PCBA assembly more expensive than traditional PCBA assembly?

A1: Upfront costs may be slightly higher, but total costs drop due to fewer errors, faster launch, and reduced logistics.

Q2: Can one-stop PCBA assembly handle complex, high-mix products?

A2: Yes. Experienced providers like Sanshun Smart manage high-volume, high-mix, and complex PCBAs efficiently.

Q3: How can I monitor my PCBA assembly project?

A3: Many turnkey providers offer dashboards to track procurement, assembly, and testing in real-time, ensuring transparency and accountability.

Q4: What industries benefit most from one-stop PCBA assembly?

A4: IoT, consumer electronics, medical devices, and automotive electronics benefit from accelerated time-to-market and risk reduction.

Q5: How quickly can I move from prototype to mass production?

A5: With a turnkey provider like Sanshun Smart, prototyping and production can overlap, significantly shortening overall timelines compared to fragmented vendor approaches.