Choosing the right Circuit Board PCBA Supplier is one of the most critical decisions in electronics manufacturing. A single mistake—poor DFM review, untraceable components, or inadequate inspection—can turn an entire production run into scrap and delay your product launch by months.

If you are sourcing a reliable Circuit Board PCBA Supplier for prototype, low-volume, or mass production, this guide will help you avoid the 7 most costly mistakes buyers make—and show you exactly how to evaluate a supplier before your Gerber files go into production.

Executive Summary: Circuit Board PCBA Key Evaluation Matrix

Before diving into the 7 mistakes, here’s a quick audit tool for evaluating potential suppliers. This Red Flags vs. Professional Standards matrix helps assess reliability for PCBA Assembly Services and Electronic Manufacturing Services (EMS):

| Critical Category | Red Flags (Avoid) | Professional Standards |

|---|---|---|

| Engineering Support | Blind manufacturing without feedback | Comprehensive DFM/DFA Audit before production (link to [DFM Checklist Download]) |

| Component Integrity | Sourcing from grey-market brokers | 100% Authorized & Traceable Components via distributors |

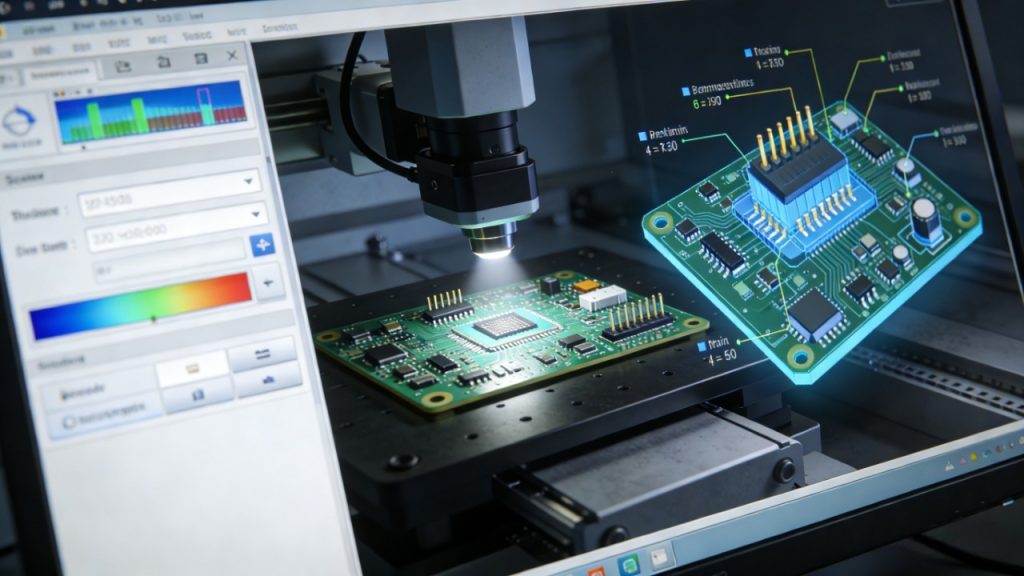

| Quality Control | Visual inspection only | 3D AOI, X-Ray, Functional Testing (FCT), Flying Probe Testing |

| Soldering Standards | Vague compliance claims | IPC-A-610 Class 2/3; ISO 13485 (Medical), IATF 16949 (Automotive) |

| Communication | 48-hour+ delays | Dedicated PM with real-time technical support |

Pro Tip Box: Always request documentation of equipment calibration.

1. DFM/DFA Audit: A Must-Have When Choosing a Circuit Board PCBA Supplier

Assuming CAD software checks are enough is a common mistake. Circuit Board PCBA suppliers must perform manual DFM (Design for Manufacturing) and DFA (Design for Assembly) reviews.

The Trap: Suppliers processing your files blindly may miss pad clearance issues or insufficient solder mask dams → tombstoning during SMT.

Pro Tip Box: Demand a DFM report highlighting yield issues before the first boards are produced. Include checks for Pick and Place alignment, Thermal Relief, and Stencil accuracy.

2. Low-Cost Circuit Board PCBA Suppliers: Hidden Quality Risks

A quote 30% below market rates is often a red flag.

The Risk: Using low-Tg FR4 boards, reducing inner layer copper weight, or skipping the proper soldering process.

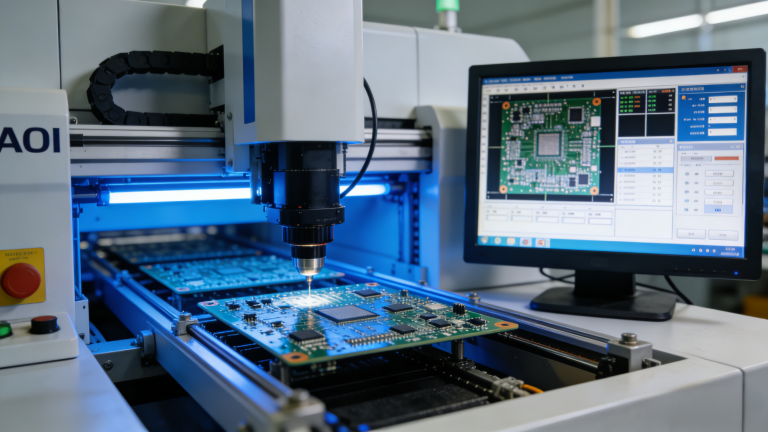

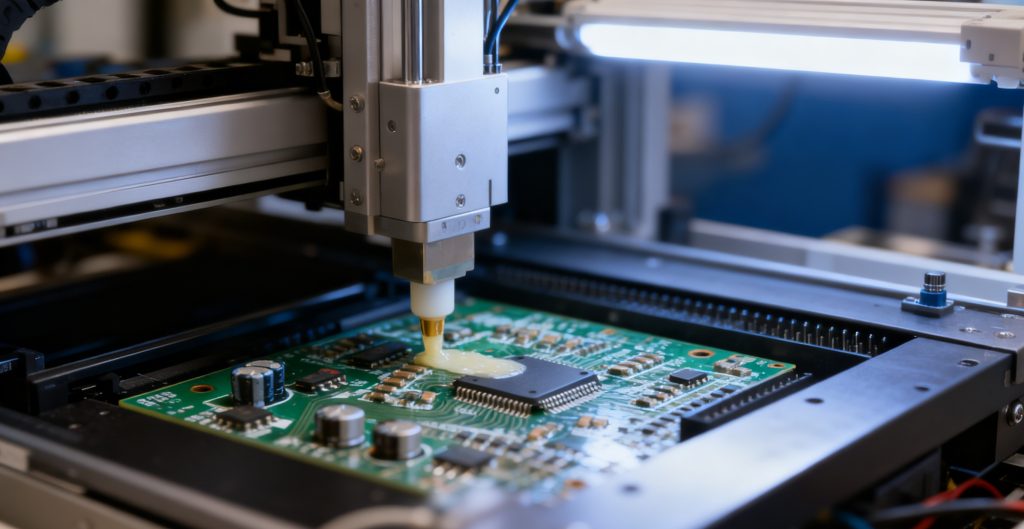

Reality: High-quality PCBA Assembly Services require calibrated Pick and Place machines, controlled reflow profiles, and verified thermal relief. Hidden technical debt manifests as field failures and warranty claims.

3. Component Traceability in PCBA Manufacturing

Global supply chains tempt some suppliers to use grey-market components.

- Mistake: Not demanding a Certificate of Conformance (CoC) or full traceability.

- Solution: Ensure “No Broker” sourcing policies. Full Component Traceability prevents intermittent failures and simplifies regulatory compliance (ISO 13485, IATF 16949).

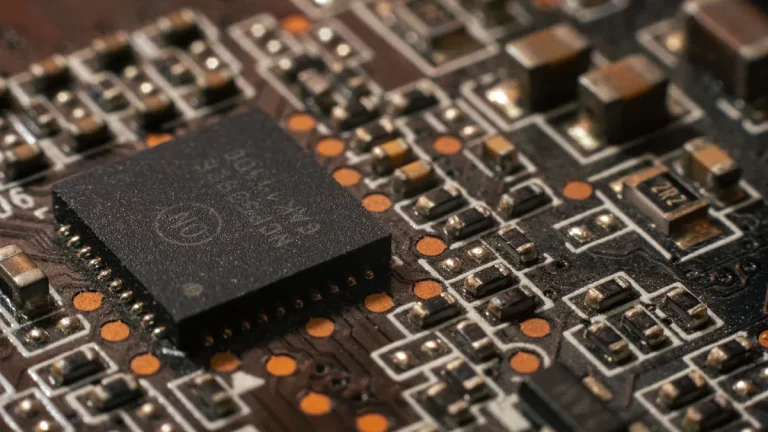

4. IPC Class 2 vs Class 3 for PCBA Assembly

Soldering quality matters. Buyers often fail to specify the IPC Class:

- Class 2: Consumer electronics

- Class 3: High-reliability sectors (Medical, Automotive, Aerospace)

Insight: Verify technicians are trained for Class 3 solder fillet and barrel fill. Include AOI inspection for mission-critical boards.

5. Why 3D X-Ray Inspection Matters in PCBA Assembly

BGA/QFN packages hide defects.

- Mistake: Relying solely on 2D AOI → hidden solder voids may cause thermal cycle failures.

- Solution: Use 3D X-Ray, AOI, FCT, and Flying Probe Testing to verify joint integrity.

6. Choosing a Scalable Circuit Board PCBA Supplier

Choosing a “prototype-only” supplier or ignoring small-batch needs of a “mega-factory” is risky.

Strategy: Look for suppliers that manage NPI (New Product Introduction) processes. Your first 10 boards should receive the same rigour as a 10,000-unit run. Conduct FAI (First Article Inspection) and prototype testing.

7. Communication Risks with PCBA Suppliers

Manufacturing is a conversation. Silent BOM substitutions or slow replies create errors.

Pro Tip Box: Ensure your supplier provides a dedicated PM with real-time feedback for transparent change management.

Supplier Risk vs. Trust Comparison

| Dimension | High-Risk Supplier | Reliable |

|---|---|---|

| Component Source | Grey-market | 100% Authorized & Traceable |

| DFM Checks | None | Free Pre-Production DFM/DFA Audit |

| Testing Coverage | Visual only | 3D AOI + X-Ray + FCT + Flying Probe |

| Communication | Slow | Dedicated PM, real-time updates |

| Traceability | Limited | Full Traceability & Documentation |

Achieve Zero-Defect Production with SanShun Smart

Struggling with complex designs? Don’t leave it to chance.SanShun Smart offers a Free DFM Audit to ensure your Circuit Board PCBA is optimised for mass production. We catch errors before SMT assembly, reducing rework, field failures, and hidden costs. ISO 9001 and IATF 16949 compliance ensure reliability across industries.

Looking for a trusted Circuit Board PCBA Supplier with proven DFM expertise and full component traceability?

👉 Upload your Gerber files today and get a Free DFM/DFA Audit within 24 hours — before costly SMT errors happen.

FAQ: Circuit Board PCBA Selection

Q1: How does SanShun Smart verify component authenticity?

A: Authorised-only sourcing, lot/date code traceability, CoC documentation.

Q2: What files are needed for a precise PCBA quote?

A: Gerber (RS-274X), complete BOM, Pick-and-Place (Centroid) data, FCT instructions.

Q3: Can you handle high-density 0201 components or fine-pitch BGAs?

A: Yes. Yamaha/Mycronic SMT lines + 3D AOI + X-Ray ensure 100% joint integrity.

Q4: Why do PCBA quotes differ among suppliers?

A: Component sourcing, substrate quality, and testing rigour. SanShun Smart optimises total cost by reducing rework and field failures.