Choosing the right Local PCBA Assembly partner can determine whether your product launches on time—or becomes an expensive delay buried in rework, logistics issues, and miscommunication.

If you’re selecting a PCBA manufacturer based solely on the lowest quote, you could be sacrificing up to 20% of your total ROI without realizing it. Offshore PCBA assembly may look cheaper on paper, but hidden costs such as long lead times, quality risks, and time zone barriers often turn “low-cost” builds into costly engineering setbacks.

In today’s volatile supply chain environment, Local PCBA Assembly services are no longer a premium option—they are a strategic advantage for companies that care about speed, quality, and long-term profitability.

Here is how a localized strategy transforms your production from a logistical headache into a high-yield asset:

Executive Overview: How Local PCBA Assembly Protects Your ROI

Before diving into technical and financial details, here’s a quick snapshot of why experienced teams increasingly prioritize local PCBA assembly over offshore options:

- Faster NPI & prototyping cycles by eliminating international shipping delays

- Lower Total Cost of Ownership (TCO) beyond unit price

- Real-time DFM feedback from engineers in your time zone

- More resilient, regional supply chains across the US, Canada, Italy, Sweden, Japan, Australia, Indonesia, Vietnam

- Stronger IP protection and compliance traceability

- Reduced financial risk through smaller, flexible production runs

These advantages compound over time—directly impacting cash flow, time-to-market, and customer satisfaction.

Is Local PCBA Assembly Faster for Prototyping and NPI Services?

If you’ve ever searched for “fast-turn PCB assembly near me” or quick-turn PCBA prototype, what you’re really looking for is iteration speed.

With local PCBA assembly:

- Prototypes aren’t stuck in transit for weeks

- Engineering changes can be implemented within days—not months

- SMT stencils, rework, and component swaps happen immediately

Imagine identifying a layout issue on Monday. With a local partner, corrected boards can be back in your lab by Thursday. That kind of agility supports modern product development models like fail-fast, iterate faster, which is essential in industries such as IoT, industrial automation, aerospace, automotive, and medical electronics.

Why Unit Price Is Misleading: The True Cost of PCBA Ownership

One of the most common procurement mistakes is optimizing for unit price instead of TCO. Local PCBA assembly shines when you look at the full financial picture.

When comparing Local PCBA Assembly services with offshore alternatives, the real difference becomes clear once total cost, risk, and operational efficiency are evaluated side by side.

Offshore vs. Local PCBA Assembly: Real Cost Comparison

| Cost Factor | Offshore Assembly | Local PCBA Assembly |

|---|---|---|

| Shipping & Logistics | High (air/sea freight) | Low (domestic ground, regional supply chains) |

| Import Duties & Tariffs | 10–25% (variable) | None |

| Lead Time Risk | High | Low |

| MOQ Flexibility | Rigid | Low-volume friendly |

| Quality Audits | Costly travel or third-party | Easy on-site visits |

| Rework & Scrap Risk | High | Significantly reduced |

| Carbon Footprint | High | Minimal |

When these hidden costs are factored in, local PCBA assembly often delivers higher ROI, especially for low-to-medium volume, high-mix production.

How Local Communication Reduces Costly Rework

Rework is one of the most expensive—and least visible—costs in electronics manufacturing.

With local PCBA assembly:

- BOM discrepancies are caught early through BOM scrubbing

- DFM issues are discussed directly with manufacturing engineers

- Component substitutions are vetted using authorized local distributors

- Engineering feedback loops shrink from weeks to hours

This eliminates common issues like incorrect component orientation, mismatched footprints, or voltage-rating mistakes that can otherwise destroy entire production runs.

Supply Chain Stability in an Unpredictable Market

Global component shortages have changed the rules of electronics manufacturing. Long lead times, allocation issues, and EOL components are now routine challenges.

Local PCBA assembly partners often maintain:

- Relationships with domestic distributors (Arrow, Avnet, Digi-Key)

- Real-time visibility into regional component inventories (US, Canada, Italy, Sweden, Japan, Australia, Indonesia, Vietnam)

- Faster approval cycles for pin-to-pin alternatives

This flexibility dramatically reduces production stoppages and keeps your build schedule aligned with market demand.

IP Protection, Compliance, and Traceability Advantages

If your product includes proprietary designs, firmware, or regulated components, manufacturing location matters.

Local PCBA assembly offers:

- Stronger IP protection under domestic legal frameworks

- Full traceability for RoHS, REACH, and adherence to IATF 16949 / ISO 9001 quality standards

- Reduced risk of counterfeit or gray-market components

For medical, industrial, automotive, and defense electronics, these safeguards are essential—not optional. Using a partner certified to IATF 16949 or ISO 9001 demonstrates compliance to B2B clients and regulators, while also boosting SEO relevance for industry-specific searches.

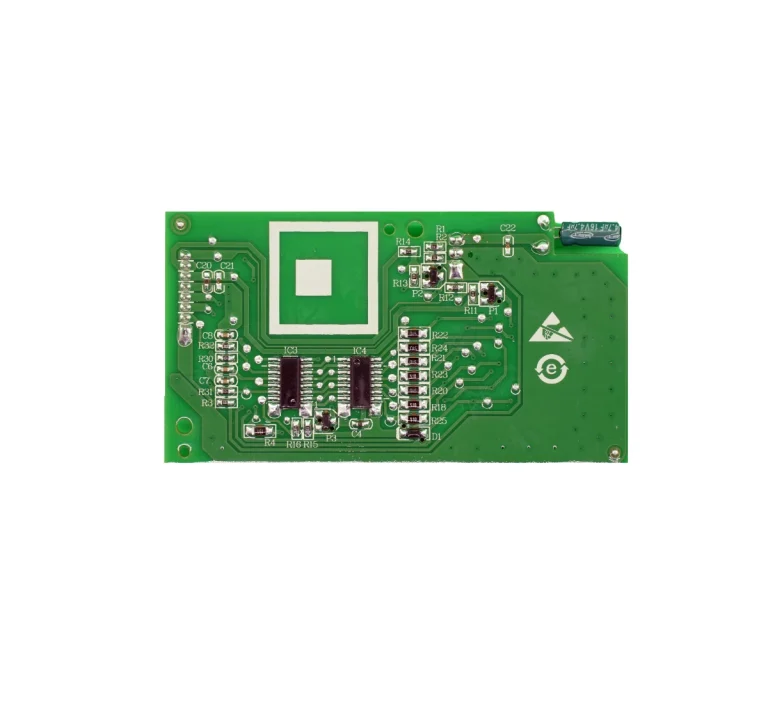

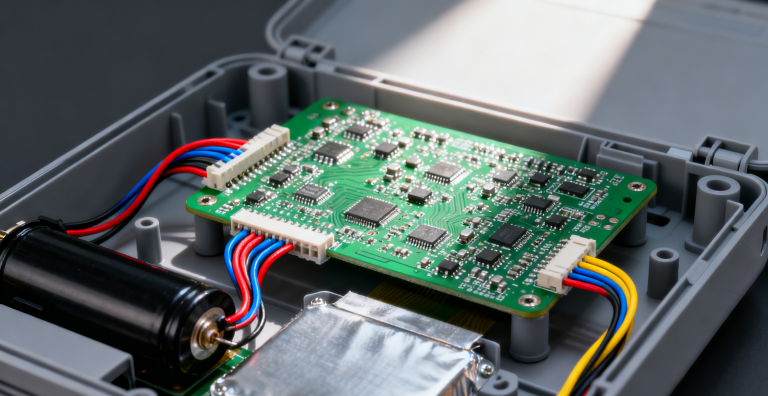

Scaling Smoothly from Prototype to Production with SanShun Smart

As projects move from early prototypes to stable production, consistency becomes critical.

SanShun Smart provides a seamless path from development to full-scale manufacturing by combining:

- High-speed SMT and THT assembly

- Turnkey PCB assembly and component sourcing

- AOI, 3D X-ray, and functional testing

- Box-build assembly and system integration

Unlike overseas mega-factories where small-batch customers are deprioritized, SanShun Smart focuses on engineering-driven, customer-centric manufacturing. Their local PCBA assembly approach ensures your product scales without sacrificing quality, communication, or schedule control. They maintain strong regional supply chains across the US, Canada, Italy, Sweden, Japan, Australia, Indonesia, and Vietnam, improving lead time reliability and supply flexibility for global clients.

Conclusion: Why Local PCBA Assembly Is a Long-Term Competitive Advantage

Maximizing ROI isn’t about finding the lowest quote—it’s about reducing uncertainty and risk at every stage of production.

Local PCBA assembly delivers:

- Faster time-to-market

- Lower hidden costs

- Better quality control

- Stronger IP security

- Greater operational flexibility

If your goal is to spend less time managing logistics problems and more time building great products, local PCBA assembly is the smarter long-term strategy.

👉 Ready to see how local PCBA assembly can improve your ROI? Contact SanShun Smart today for a transparent, engineer-led PCBA quote tailored to your project.

Frequently Asked Questions About Local PCBA Assembly

Q1: Is local PCBA assembly suitable for advanced inspection like X-ray or Flying Probe testing?

Yes. Professional local PCBA assembly providers use AOI, 3D X-ray, and functional testing to ensure solder joint integrity, especially for BGA and fine-pitch components.

Q2: Can local PCBA assembly help mitigate component shortages?

Absolutely. Local partners perform proactive BOM analysis and suggest approved alternatives early, minimizing delays caused by long lead-time components.

Q3: Is local PCBA assembly cost-effective for low-volume builds?

In most cases, yes. When shipping, MOQs, rework risk, and cash-flow impact are considered, local PCBA assembly often outperforms offshore options.

Q4: Do local PCBA assembly providers offer box-build services?

Many do. Full turnkey solutions often include enclosure assembly, cable harnessing, labeling, and final functional testing.

Q5: Are local PCBA assembly partners compliant with industry standards?

Yes. Reputable partners adhere to IATF 16949, ISO 9001, RoHS, and REACH, ensuring your production meets global quality and regulatory expectations.