Choosing the right PCBA assembly factory can directly determine whether your product launches smoothly—or becomes trapped in rework, delays, and unexpected costs.

If you are searching for a reliable PCBA assembly factory to support prototyping or high-volume production, selecting the wrong partner can cost thousands of dollars and delay your time-to-market. Issues like cold solder joints, missing components, or poor communication are not just inconveniences—they are signs of an unreliable factory.

In this guide, we break down exactly what defines a dependable PCBA assembly factory, from certifications and manufacturing capabilities to DFM support, testing standards, and total cost of ownership—so you can confidently choose a partner that scales with your business.

Key PCBA Assembly Factory Factors You Must Evaluate

Before diving into the technical details, here’s a high-level summary of what to look for in a reliable PCBA assembly factory. These benchmarks help you quickly screen potential partners and focus on those who can meet your standards.

| AOI, X-Ray (AXI), ICT, and FCT reduce defects and rework | Why It Matters |

|---|---|

| Certifications & Compliance | ISO 9001, IATF 16949, IPC-A-610 ensure consistent quality and workmanship for industrial, automotive, and medical boards |

| Manufacturing Capabilities | SMT, DIP, mixed technology, and turnkey services cover all assembly needs |

| Technical Expertise | Engineers provide DFM feedback and troubleshooting, catching errors early |

| Production Capacity | Ability to handle prototypes and scale to high-volume efficiently |

| Quality Control | AOI, X-Ray (AXI), ICT, FCT reduce defects and rework |

| Supply Chain Management | Verified authorized distributors prevent counterfeit components |

| Cost Transparency | Understand total cost of ownership (TCO), not just unit price |

| Lead Time & Communication | Timely updates and responsive project management reduce delays |

Tip for readers: Evaluating these factors first increases your chances of selecting a reliable factory and also helps Google recognize this table as structured content for featured snippets.

1. Certifications and Compliance

A top-tier PCBA assembly factory demonstrates credibility through recognized certifications:

| Certification | Purpose |

|---|---|

| ISO 9001 | Quality management and consistent processes |

| IATF 16949 | Automotive and high-reliability electronics |

| IPC-A-610 Class 2/3 | Industry-standard workmanship for industrial/automotive boards |

| RoHS / REACH | Environmental compliance for hazardous substances |

Without these certifications, you risk inconsistent quality, production errors, and non-compliance penalties.

2. Manufacturing Capabilities That Define a Reliable PCBA Assembly Factory

Not every PCBA assembly factory can handle complex designs. When evaluating manufacturing capabilities, focus on:

- SMT Lines: Capable of handling 01005 / 0201 components (±0.03 mm placement accuracy)

- BGA & QFN Expertise: Thermal profiling prevents voids in bottom-terminated components

- Multi-layer HDI Boards: Align and assemble 10+ layers with micro-vias

- Mixed Technology: SMT + DIP + through-hole as needed

- Turnkey Solutions: From PCB fabrication to full Box Build assembly

Technical Capability Benchmark:

| Metric | Standard Workshop | Leading PCBA Assembly Factory |

|---|---|---|

| Minimum Component Size | 0402 | 01005 / 0201 |

| BGA Pitch | >0.5 mm | ≤0.3 mm |

| Primary QA Testing | Manual Visual Inspection | AOI, 3D X-Ray (AXI), ICT, FCT |

| Solder Paste Inspection | Manual | Fully Automatic SPI |

| Cleanliness Standard | Basic ventilation | Class 10,000 / 100,000 Clean Room |

Choosing a factory with advanced capabilities ensures fewer defects, faster production, and scalability.

3. Why DFM Support Is Critical When Selecting a PCBA Assembly Factory

A proactive PCBA assembly factory reviews your BOM and Gerber files before production starts. Common issues caught at this stage include:

- Tombstoning: Unequal heat causing small components to stand on one end

- Solder Bridging: Pads too close together for solder mask insulation

- Component Obsolescence: EOL or long-lead-time parts flagged early

Early DFM intervention reduces scrap rates, rework costs, and time-to-market delays.

4. Component Sourcing & Counterfeit Prevention

Supply chain reliability is non-negotiable. Ask: Who are your authorized vendors?

- Reputable factories work with Arrow, Avnet, Digi-Key, and Mouser

- Gray-market sourcing requires internal verification (X-Ray, decapping)

- Transparency ensures authentic components and avoids costly counterfeits

Strong supply chain management is a hallmark of a reliable PCBA assembly factory.

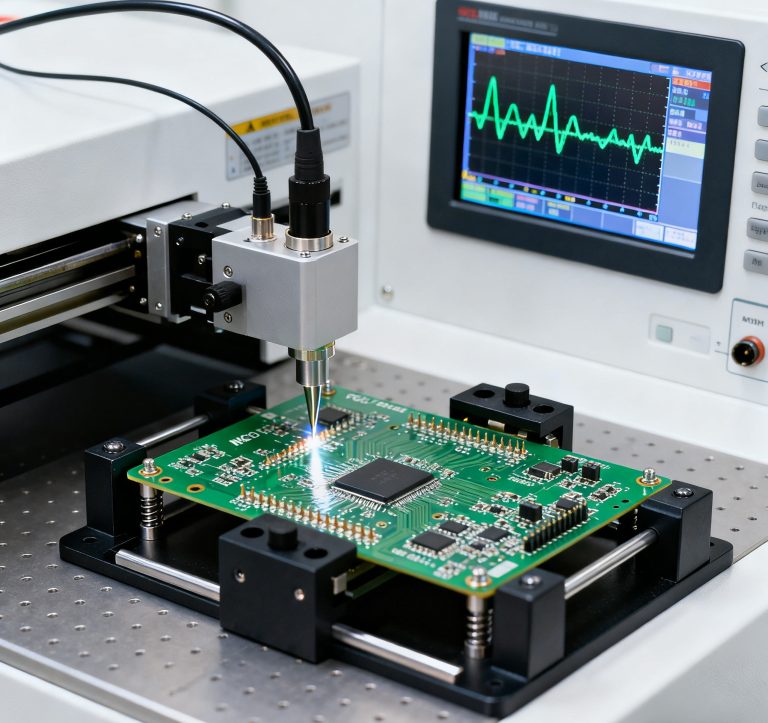

5. Testing Standards Used by Professional PCBA Assembly Factories

Top factories integrate QA at every stage:

- SPI (Solder Paste Inspection): Ensures correct paste volume and alignment

- AOI (Automated Optical Inspection): Checks for missing components, polarity, and solder joint quality

- 3D X-Ray (AXI): Critical for BGA and hidden joints

- ICT / Functional Circuit Testing (FCT): Simulates real-world conditions to verify board function

These protocols minimize risk of failures reaching your customers.

6. Production Capacity & Scalability

Your factory must scale with your needs:

| Project Type | Ideal Capability |

|---|---|

| Prototype / Low Volume | Flexible lines, fast turnaround |

| Medium Volume | Balanced speed and QA |

| High Volume | Large-scale automation, consistent output |

Reliable PCBA assembly factories communicate throughput and lead times clearly.

7. Domestic vs Overseas Factories

| Factor | Domestic | Overseas |

|---|---|---|

| Lead Time | Short | Longer, customs possible |

| Communication | Easy | Time zone/language challenges |

| Cost | Slightly higher | Lower unit cost, shipping adds |

| Quality Control | Easier audits | Remote QA or third-party audits |

Domestic factories suit prototypes; overseas factories reduce costs for high-volume production.

8. Turnkey vs Partial Assembly

| Model | Best For | Pros | Cons |

|---|---|---|---|

| Turnkey | Full-service | Saves time, single point of contact | Higher upfront cost |

| Partial | Client-supplied components | Flexible, cost-efficient | Requires coordination |

Choose a PCBA assembly factory offering both options for maximum flexibility.

9. Total Cost Considerations (TCO)

Lowest unit price isn’t always cheapest. Consider:

- FAI Accuracy: Speed of first article validation

- Rework & Scrap Rate: High defects increase cost per unit

- Communication Efficiency: Timely responses prevent delays

- Value Engineering: BOM and design optimization reduce SMT complexity

Evaluating TCO ensures your budget accounts for hidden costs, not just the unit price.

SanShun Smart: A Trusted PCBA Assembly Factory for Scalable Production

SanShun Smart (Qingdao SanShun Smart Technology Co., Ltd.) is a premier example of a PCBA assembly factory that balances scale and precision:

- Founded in 2013, a 30,000 sqm state-of-the-art facility

- ISO 9001 and IATF 16949 certified, fully integrated R&D, manufacturing, and sales

- Offers turnkey solutions from PCB fabrication to intelligent software development

- Specialized in smart displays, automotive electronics, and modular products

Choosing SanShun Smart ensures you get a reliable partner capable of scaling from prototypes to high-volume production.

Conclusion: How to Choose the Right PCBA Assembly Factory for Long-Term Success

Selecting the right PCBA assembly factory requires balancing technical capability, quality, reliability, and total cost. By evaluating certifications, manufacturing technology, DFM support, supply chain integrity, QA/testing, scalability, and TCO, you can confidently choose a partner that delivers success from prototype to high-volume production.

SanShun Smart exemplifies a factory that combines certified experience, technical precision, and turnkey solutions — the kind of partner you can trust with critical PCBA projects.

Frequently Asked Questions About PCBA Assembly Factories

Q1: How do I verify a PCBA assembly factory’s reliability?

A: Check certifications (ISO 9001, IATF 16949), review AOI/X-Ray/FCT logs, and evaluate responsiveness during RFQ.

Q2: Should I choose a domestic or overseas PCBA assembly factory?

A: Domestic factories suit prototypes or urgent projects; overseas factories reduce costs for high-volume runs. SanShun Smart combines both advantages.

Q3: What’s the difference between turnkey and partial assembly?

A: Turnkey handles everything, including component procurement. Partial assembly requires you to supply some or all components.

Q4: Can a PCBA assembly factory help reduce production costs?

A: Yes, via Value Engineering and BOM optimization.

Q5: What files are needed for a quote?

A: Gerber files (RS-274X), BOM (Excel), Pick-and-Place file (Centroid data).