When you consider working with an overseas PCBA supplier, you need to focus on several essential areas. Start by looking at supplier audit, quality control, manufacturing capability, cost transparency, and communication. A strong audit process helps you spot problems early, supports quality control, and reduces risks like fraud or late deliveries. Regular audits of suppliers can improve your chances of building a successful partnership. Keeping a robust quality control plan in place ensures your products meet your standards. Use the checklist and FAQs to help guide your decisions.

Essential Risk-Management Practices for Choosing a Reliable PCBA Supplier

- Conduct thorough background audits to verify the legitimacy and experience of your PCBA supplier. This step protects your business from fraud.

- Implement a strong quality control plan. Regular audits and documentation ensure your products meet high standards and reduce the risk of defects.

- Assess the manufacturing capabilities of your supplier. Understanding their production capacity and equipment helps avoid delays and ensures they can meet your needs.

- Establish clear communication channels. Address language barriers and set expectations for response times to foster a successful partnership.

- Protect your intellectual property with strong agreements and data security measures. This reduces the risk of theft and ensures your designs remain safe.

PCBA Supplier Background Audit

A thorough background audit helps you avoid costly mistakes during supplier selection. You need to confirm that your pcba supplier is credible, reliable, and experienced. This process protects your business from fraud and ensures you work with a trustworthy partner.

Verifying Legitimacy

Start by checking if your pcba supplier operates legally. Many Chinese manufacturers provide business licenses and registration documents. You should always verify these details through official channels. Use the 18-digit USCC or the full Chinese company name to access government databases. Third-party verification services can also help you confirm the legitimacy of a supplier.

- Check business licenses and quality certifications in government databases.

- Use the official company name or USCC for registration details.

- Consider third-party verification for extra assurance.

If a pcba supplier hesitates to share legal documents, treat this as a warning sign.

Checking Certifications

Certifications show that a supplier meets industry standards. Western companies often require specific certifications from their pcba supplier. These documents prove that the supplier follows strict quality, safety, and environmental rules. Here are some of the most important certifications:

| Certification | Description |

|---|---|

| IPC | Defines accepted industry practices for PCB assembly, widely adopted by OEMs and EMS providers. |

| ISO | Ensures quality management standards, improving communication and efficiency in PCB assembly. |

| RoHS | Restricts hazardous materials in electronic equipment, ensuring environmental compliance. |

| UL | Addresses safety requirements for PCB manufacturing, crucial for preventing fire and electrical shock risks. |

| ITAR | Protects sensitive technology, mitigating risks of counterfeiting and espionage. |

| MIL | Sets performance and environmental requirements for PCBs, often used as a quality benchmark by manufacturers. |

Ask your pcba supplier for copies of these certificates and check their validity.

Assessing Experience

Experience matters when choosing a PCBA supplier. Ask how long the supplier has worked with Western clients. Request references or case studies from other companies. Many Chinese manufacturers highlight their experience in international markets. You should look for a supplier with a proven track record in your industry. This step reduces risk and increases your confidence in the partnership.

Tip: A supplier with strong experience and valid certifications will help you avoid common pitfalls in overseas manufacturing.

Quality Control Audit

A strong quality control plan protects your business from costly mistakes. You need to maintain a quality management system and perform regular audits to ensure compliance. This process helps you catch problems early and keeps your products at a high standard.

Reviewing Management Systems

Start by asking your PCBA supplier about their quality management system. A reliable supplier uses a documented system to control every step of production. You should check if they follow standards like ISO 9001. Ask for details about their internal audits and how they handle non-conformities. A good quality management system tracks issues and prevents them from happening again. This system also supports continuous improvement and helps you avoid repeated defects.

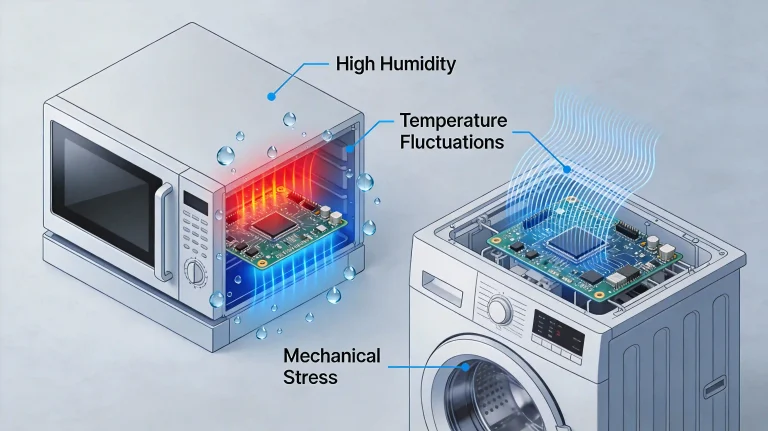

Inspecting Testing Procedures

You must review the supplier’s quality inspection process. A reputable supplier uses several industry-standard testing methods to control quality and reduce the risk of defects. Here are some common testing procedures you should expect:

| Testing Method | Description |

|---|---|

| Functional Testing | Checks the performance of the assembly by measuring electrical functionality, load capacity, and compliance with standards. |

| Automated X-Ray Inspection (AXI) | Uses X-rays to inspect hidden solder joints and complex components without damaging the board. |

| In-Circuit Testing (ICT) | Tests each component in isolation using a custom fixture and specific voltages to ensure accuracy. |

| Automated Optical Inspection (AOI) | Scans the board with cameras to find defects in component placement and solder joints by comparing to a standard database. |

You should ask for records of recent quality inspection results and review how the supplier handles failed tests.

Evaluating Documentation

Proper documentation is a key part of quality control. It allows you to track every detail of the manufacturing process. Good documentation supports traceability, which helps you find and fix defects quickly. It also ensures compliance with industry standards, especially in regulated fields like medical devices.

- Documentation records all details about circuit board creation, including component sources and manufacturing steps.

- Traceability helps you identify and resolve defects by tracing issues back to specific parts or processes.

- Good records are essential for meeting industry requirements and passing audits.

Tip: Always request sample documentation from your supplier to check for completeness and accuracy.

Manufacturing Audit & Production Capability

A manufacturing audit gives you a clear view of a supplier’s strengths and weaknesses. When you plan to start manufacturing overseas, you need to know if your partner can handle your current and future needs. Site audits help you see the real situation on the ground. Use an audit checklist to guide your review and make sure you do not miss any important steps.

Assessing Capacity

You should start your manufacturing audit by checking the supplier’s production capacity. This step helps you avoid delays and shortages. Use an audit checklist to review these key metrics:

- Check industry certifications like ISO 9001 or IATF 16949.

- Evaluate production volume and assembly operations.

- Inspect quality control procedures for incoming materials.

- Assess supply chain management and inventory systems.

- Confirm lead times and on-time delivery guarantees.

- Ask about communication and technical support.

- Compare prices and look for hidden fees.

- Verify references and experience.

A strong manufacturing audit will also look at contingency plans for natural disasters or supply chain disruptions. This process ensures your supplier can keep up with your needs as your business grows.

Reviewing Equipment

Your manufacturing audit should include a close look at the supplier’s equipment. Modern, well-maintained machines improve quality and reduce defects. Ask to see the equipment list and maintenance records. Use your audit checklist to check if the supplier has the right tools for your product. Reliable equipment supports consistent results, especially when manufacturing overseas.

| Metric | Importance |

|---|---|

| Manufacturing Capabilities | Assess production volume, assembly operations, and testing facilities. |

| Quality Control Procedures | Evaluate processes for incoming material inspection and testing. |

| Scalability | Determine if the supplier can handle increased production demands. |

Evaluating ODM PCBA Services

Many Western companies choose ODM PCBA services when manufacturing overseas. These services offer custom solutions and one-stop support. During your manufacturing audit, use your audit checklist to review the supplier’s ODM capabilities.

| Benefit | Description |

|---|---|

| Customized Solutions | ODM PCBA services provide tailored PCB assembly solutions. |

| One-stop Services | They offer comprehensive services, simplifying the process. |

| Industrial Control | Specialised solutions for various industrial applications. |

A thorough manufacturing audit with a detailed audit checklist gives you confidence in your supplier’s ability to deliver quality products. This process also improves transparency and helps you avoid surprises.

Communication & Responsiveness

Strong communication and quick responsiveness set the foundation for a successful partnership with an overseas PCBA supplier. You need to address several challenges that often arise when working across borders. These include language barriers, slow response times, and the use of project management tools.

Language Proficiency

You should assess your supplier’s English proficiency before starting any project. Many manufacturers in Asia have limited English skills, which can lead to misunderstandings about product specifications or requirements. Clear communication helps you avoid costly mistakes and delays. Ask for written samples, schedule video calls, and check if the supplier employs bilingual staff. You can also request technical documents in English to confirm their ability to handle complex instructions.

Tip: Use simple language and visual aids when sharing technical details. This reduces confusion and speeds up the approval process.

Response Times

Timely responses matter when you need to solve design issues or approve changes. Time zone differences often slow down collaboration, especially with suppliers in Asia. You should set expectations for response times at the start of your partnership. Ask your supplier about their working hours and preferred communication channels. Track how quickly they reply to emails or messages during your initial interactions. Fast responses show that your supplier values your business and can handle urgent requests.

| Challenge Type | Description |

|---|---|

| Less Collaboration | Time zone differences hinder timely discussions on design issues, especially with manufacturers in Asia. |

| Language Barriers | Limited English proficiency in manufacturing regions complicates communication and product specifications. |

| Risk of Theft | Greater distance increases vulnerability to fraud and intellectual property theft. |

| Shipping Problems | Issues with lost shipments and customs due to language and paperwork challenges. |

Project Management Tools

Modern project management tools help you track progress and share updates in real time. You should ask your supplier which platforms they use, such as email, instant messaging, or specialised software like Trello or Asana. These tools allow you to monitor milestones, review documents, and address problems quickly. Choose a supplier who uses reliable systems and can provide regular status reports. This keeps your project on schedule and improves transparency.

Note: Consistent use of project management tools builds trust and reduces the risk of miscommunication.

Intellectual Property & Data Security

Protecting your designs and sensitive information is critical when you work with an overseas PCBA supplier. You face risks such as intellectual property theft and data breaches. You must take steps to safeguard your business before sharing any technical details.

IP Protection Policies

You should establish clear policies to protect your intellectual property. Register your IP in the country where manufacturing takes place. This step prevents others from claiming your designs. Use NNN agreements, which restrict suppliers from using, disclosing, or sharing your information. These agreements offer stronger protection than standard NDAs. Limit the information you share with each supplier. By restricting access, you reduce the risk of intellectual property theft.

| Strategy | Description |

|---|---|

| Register IP Locally | Register your intellectual property in the manufacturing country to prevent unauthorised claims. |

| Use NNN Agreements | Protect your information with agreements that prevent use, disclosure, and sharing. |

| Limit Information Access | Share only necessary details with each supplier to minimise exposure. |

Tip: Always consult legal experts familiar with international IP law before finalizing agreements.

Data Security Measures

You must secure your data throughout the supplier relationship. Work closely with IT teams, engineers, and vendors to keep systems updated. Back up critical files such as PCB designs and supplier contacts. Create a disaster recovery plan to maintain operations during disruptions. Test and update this plan regularly. Segment your network to block unauthorised access. Conduct security audits and vulnerability checks. Enforce Multi-Factor Authentication and strict access controls. Build a culture of cybersecurity awareness. Evaluate the security practices of your suppliers and partners. Share best practices with industry peers to strengthen your defences.

- Collaborate with IT and production teams for smooth updates.

- Back up important data regularly.

- Develop and test disaster recovery plans.

- Use network segmentation to contain threats.

- Perform security audits and vulnerability assessments.

- Require Multi-Factor Authentication and strict access controls.

- Promote cybersecurity awareness among staff.

- Assess supplier and vendor cybersecurity standards.

- Share best practices with industry partners.

Contractual Safeguards

You should include strong contractual safeguards in your supplier agreements. Specify IP ownership, confidentiality requirements, and penalties for breaches. Define clear terms for data handling and storage. Require suppliers to follow your security protocols. Review contracts with legal professionals who understand international manufacturing. These steps help you enforce your rights and protect your business from costly disputes.

Note: Well-written contracts give you legal recourse if a supplier violates your intellectual property or data security policies.

Cost & Outsourcing PCB Manufacturing

When you start outsourcing pcba manufacturing, you need to understand the full cost structure. Clear and transparent pricing helps you avoid surprises and make better decisions. You should always ask for detailed quotations and compare them across multiple suppliers.

Quotation Transparency

You should request itemised quotations from each supplier. A transparent quote lists every cost, such as materials, assembly, testing, and shipping. This approach lets you compare offers and spot any inconsistencies. Ask suppliers to explain any unclear charges. If a supplier hesitates to provide details, you may want to reconsider working with them. Transparent pricing builds trust and helps you plan your budget more accurately when outsourcing pcba manufacturing.

Hidden Costs

Many Western companies encounter hidden costs when outsourcing pcba manufacturing. These costs can disrupt your budget and delay your project. You need to look beyond the initial quote and ask about possible extra charges. The table below highlights some common hidden costs:

| Hidden Cost | Description |

|---|---|

| Rework and Scrap | Poor quality control leads to additional labour and material costs, disrupting production schedules. |

| Expediting Fees | Premium charges incurred from expedited shipments due to supplier delays or production bottlenecks. |

| Warranty Claims and Field Failures | High costs are associated with product recalls and damage to brand reputation from field failures. |

| Time-to-Market Delays | Delays in product launch result in lost sales opportunities and market share. |

| Lost Innovation Momentum | Distraction from innovation due to ongoing quality issues and production delays. |

You should discuss these risks with your supplier before outsourcing pcba manufacturing. Ask for examples of how they handle unexpected costs and what steps they take to prevent them.

Value-Added Services

Leading suppliers set themselves apart by offering value-added services during outsourcing pcba manufacturing. You benefit from strong customer support, which includes experienced partners who help you solve production issues quickly. Many top suppliers support you from the prototype stage through to full production. Some suppliers use IoT and AI technologies to automate processes, improve quality, and reduce costs. Others use 3D printing to speed up prototyping and offer more customisation. These services help you bring innovative products to market faster and more efficiently.

Tip: When outsourcing pcb manufacturing, always compare the value-added services offered by each supplier. These extras can make a big difference in your project’s success.

Logistics & Lead Times

Efficient logistics and reliable lead times play a crucial role in your success when working with overseas PCBA suppliers. You need to understand how your supplier handles shipping, manages delivery schedules, and responds to supply chain challenges.

Shipping Capabilities

You should always ask your supplier about their shipping options. Most suppliers offer both air and sea freight. Air shipping delivers your PCBA products quickly, while sea shipping costs less but takes longer. The table below shows the average shipping times from major manufacturing regions to Western countries:

| Shipping Method | Average Shipping Time |

|---|---|

| Air | 1 to 3 days |

| Sea | 14 to 21 days |

Choose the shipping method that matches your project timeline and budget. Reliable suppliers provide tracking information and help you handle customs paperwork.

Lead Time Reliability

You cannot ignore the importance of accurate lead times. Many overseas PCBA suppliers now face unpredictable lead times. Geopolitical tensions and material shortages often disrupt schedules. The process for calculating lead times has changed. It now involves negotiation and flexibility. This uncertainty can create risks for your hardware projects. Missed deadlines may lead to lost market opportunities or extra costs from rush orders. You should always ask your supplier how they manage these risks and what steps they take to keep you informed.

Tip: Build extra time into your project schedule to account for possible delays.

Supply Chain Management

Strong supply chain management helps you avoid delays and disruptions. You can use several best practices to keep your projects on track:

- Diversify suppliers in different regions to reduce the risk of shortages.

- Amass inventory buffers for key materials to cushion against interruptions.

- Optimise logistics by working with reliable shipping partners for better tracking and planning.

You should review your supplier’s supply chain strategies before starting production. Good planning and communication help you respond quickly to unexpected problems. This approach keeps your products moving and your business competitive.

Cultural & Language Factors

Business Culture

You will notice that business culture shapes every interaction with your overseas PCBA supplier. Different cultures have unique ways of expressing agreement, disagreement, and intent. For example, you might misread a Japanese supplier’s phrase like “That’s difficult.” You may think it means you should keep negotiating, but it often means “no.” You may also see hiring practices that look like nepotism. In some cultures, this is a positive sign of trust and loyalty. Business deals often reflect local customs. For instance, McDonald’s increased sales in Thailand by adding local dishes to its menu. You should learn about your supplier’s business culture before negotiations begin.

- Misinterpreting indirect responses can lead to confusion.

- Local customs may influence hiring and partnership decisions.

- Adapting your approach to local preferences can improve business outcomes.

Tip: Research your supplier’s cultural norms before your first meeting. This helps you avoid misunderstandings and build respect.

Language Barriers

Language differences can create challenges in your partnership. You may find that your supplier’s team has limited English skills. This can confuse technical requirements or deadlines. You should use clear, simple language in all communications. Visual aids and diagrams help explain complex ideas. Written summaries after meetings ensure everyone understands the next steps. You can also ask if your supplier has bilingual staff or translators available.

Note: Patience and clarity in communication reduce the risk of costly mistakes.

Relationship Building

Building strong relationships with your overseas PCBA supplier leads to long-term success. Effective communication forms the foundation of trust. You may face challenges such as language barriers and time zone differences. These issues can slow down collaboration and affect quality control. When you address these challenges, you improve your supply chain’s resilience. Regular check-ins, honest feedback, and a willingness to understand your partner’s perspective help you create a reliable partnership. Over time, strong relationships make it easier to solve problems and achieve your business goals.

Site Audit & Third-Party Inspection

Site audits and third-party inspections play a critical role when you select an overseas PCBA supplier. These steps help you confirm that your supplier meets your standards before you commit to a partnership. You gain a clear view of the supplier’s operations, quality control, and compliance with industry requirements.

Planning Site Visits

You should plan your site visit carefully to get the most value. A well-structured audit helps you spot potential risks and ensures the supplier can meet your needs. Follow these steps for an effective site audit:

- Assess the supplier’s ability to meet your production standards and quality requirements.

- Review all necessary certifications and compliance documents.

- Conduct a First Article Inspection (FAI) to verify the first production run matches your specifications.

- Implement ongoing quality control to monitor production throughout the process.

Tip: Prepare a checklist before your visit. This helps you stay organized and ensures you do not miss any important details.

Engaging Auditors

You can hire third-party auditors to provide an unbiased view of the supplier’s capabilities. These professionals bring specialised knowledge and experience. They know what to look for and can spot issues you might miss. Third-party inspectors help you reduce risk and make better decisions. The table below shows the main advantages of using third-party inspection services:

| Advantage | Description |

|---|---|

| Objectivity | Third-party inspectors provide unbiased evaluations, free from supplier influence. |

| Expertise | They bring specialised knowledge and experience to accurately assess product quality. |

| Comprehensive Reports | Detailed inspection reports offer actionable insights and facilitate informed decision-making. |

Note: Choose auditors with experience in PCBA manufacturing for the best results.

Reviewing Audit Reports

After the site visit, you should review the audit reports carefully. Look for clear findings and actionable recommendations. These reports help you decide if the supplier meets your standards. Share the results with your team and discuss any concerns. If the report highlights problems, ask the supplier for a corrective action plan. Regular audits and follow-ups help you maintain high quality and reduce long-term risks.

Remember: A thorough site audit and third-party inspection give you confidence in your supplier and protect your business from costly mistakes.

You should audit every key area before choosing an overseas PCBA supplier. Regular management and audits help you avoid costly mistakes. Use this checklist for supplier evaluation:

- Verify business legitimacy and certifications

- Review quality control systems and documentation

- Assess manufacturing capacity and equipment

- Check communication and data security

- Analyse cost transparency and logistics

Tip: Start with a small pilot project or hire a third-party inspector. Build strong relationships and monitor performance for long-term success.

FAQ

What documents should you request from a PCBA supplier?

You should ask for business licenses, ISO certificates, and quality control records. These documents help you confirm the supplier’s legitimacy and quality standards.

How can you check if a supplier’s certifications are valid?

You can verify certifications by checking official databases or contacting the issuing organizations. Always ask for copies and confirm their authenticity before moving forward.

What is the best way to protect your intellectual property overseas?

- Register your IP in the supplier’s country.

- Use NNN agreements.

- Limit the information you share.

These steps help you reduce the risk of IP theft.

Why do you need a third-party inspection before production?

| Reason | Benefit |

|---|---|

| Unbiased review | Ensures supplier meets standards |

| Risk reduction | Identifies problems early |

| Quality control | Confirms product requirements |

A third-party inspection gives you confidence in your supplier’s capabilities.