Selecting the right PCBA contract manufacturing partner shapes your product’s quality, overall reliability, and speed to market. You need to define your pcb assembly requirements and understand how a poor provider choice can increase costs and delays. A strong manufacturing partner offers robust pcb assembly service, supports your electronic contract manufacturing needs, and protects your investment in manufacturing. Request proposals and samples to verify quality and ensure your PCBA meets industry standards.

5 Key Steps to Choosing a PCBA Contract Manufacturing Partner

- Define your project requirements clearly to find a PCBA partner that matches your needs for quality and delivery.

- Research potential partners thoroughly, focusing on their experience, certifications, and quality control processes to ensure reliability.

- Request proposals and samples to evaluate quality and turnaround times, helping you make informed decisions.

- Choose a partner with strong communication skills and after-sales support to ensure a smooth manufacturing process and address any issues quickly.

- Avoid common pitfalls like focusing solely on cost; prioritize long-term value, reliability, and the ability to scale with your project.

Define Project & PCBA Requirements

Before you begin searching for a PCBA partner, you need to clarify your project’s requirements. This step ensures that you select a manufacturer whose capabilities align with your goals for pcb assembly, cost, and delivery.

Technical Specs & Complexity

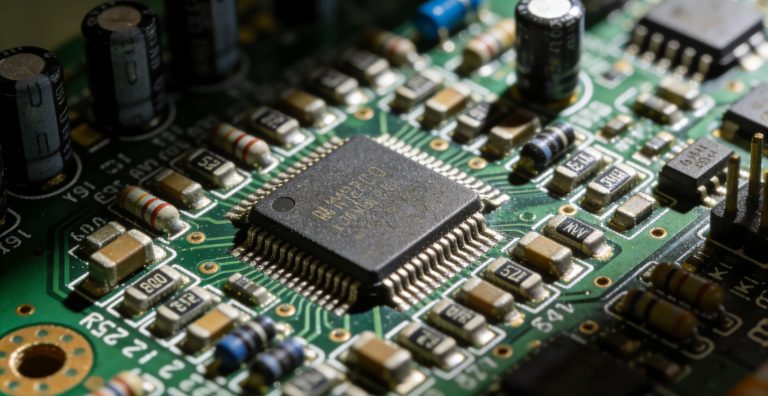

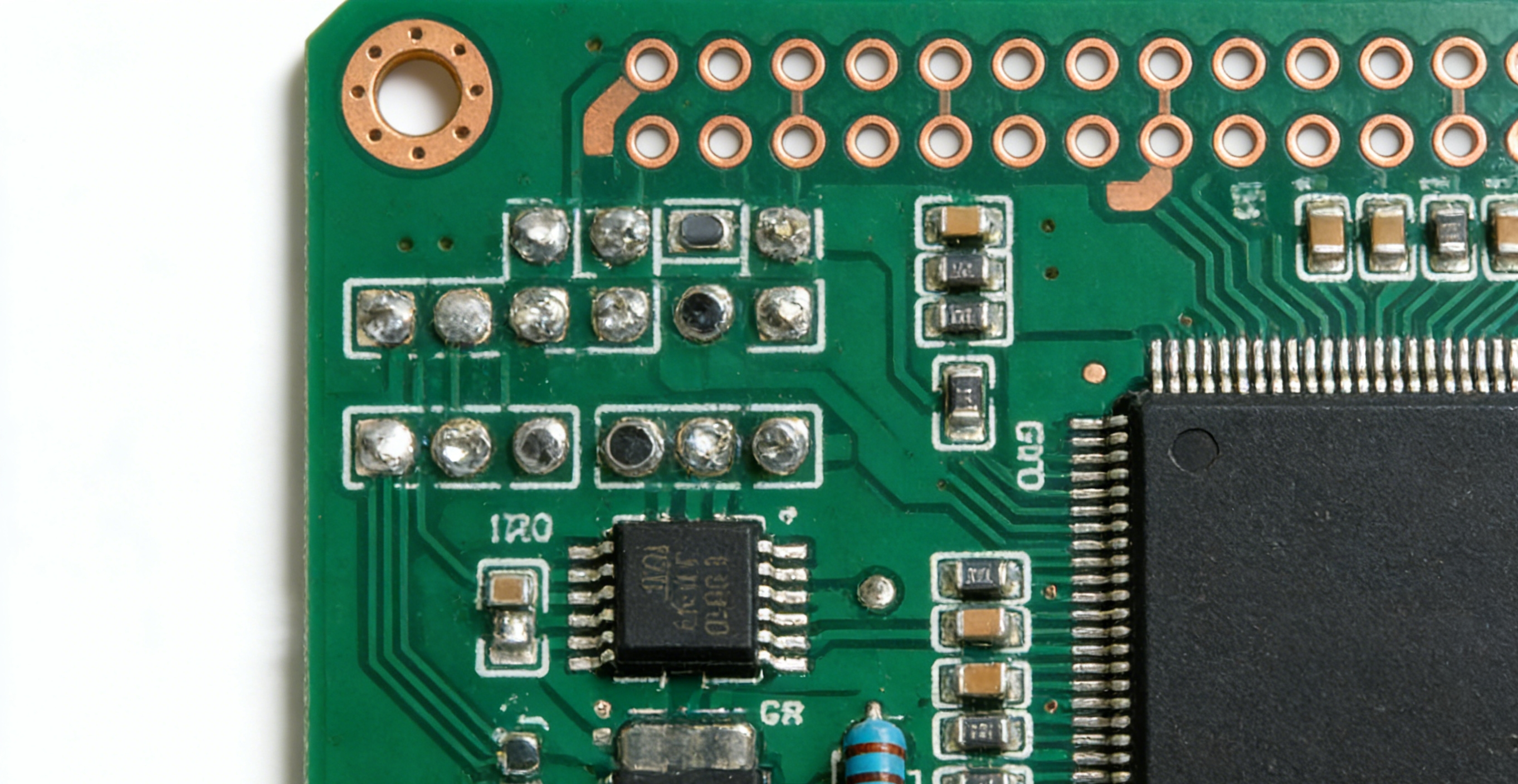

Start by listing the technical specifications for your printed circuit board assembly. Consider the complexity of your pcb, the types of components, and the manufacturing processes required. Most consumer electronics projects require several key steps:

- Solder paste application using SMT stencils for even coverage.

- Component placement with pick-and-place machines for accuracy.

- Reflow soldering with controlled temperature profiles.

- Through-hole assembly using wave or manual soldering.

- Testing and inspection, including functional and visual checks.

You should also evaluate the following specification types:

| Specification Type | Description |

|---|---|

| Thermal stability | Materials must withstand assembly and operational temperatures. |

| Mechanical strength | Supports heavy or high-density components. |

| Cost considerations | High-performance substrates are more expensive but necessary for advanced applications. |

| Passive components | Resistors, capacitors, and inductors that do not require power to operate. |

| Active components | ICs, transistors, diodes, and microcontrollers that require power and perform functions. |

| Solder and flux types | Essential for creating strong electrical and mechanical connections. |

| Design for Manufacturability | Focuses on creating PCB designs that are easy and cost-effective to manufacture. |

| Design for Testability | Ensures that boards can be easily tested and troubleshooted during production and maintenance. |

| Signal Integrity | High-frequency or high-speed boards require careful design to maintain signal integrity. |

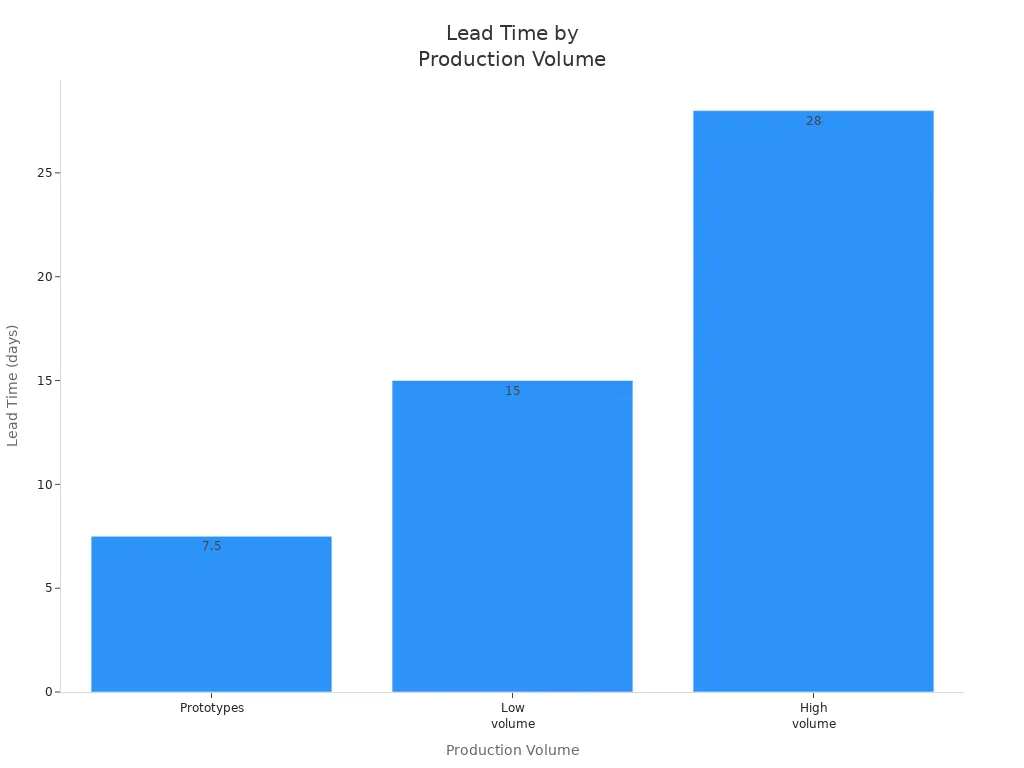

Volume, Timeline, Budget

Project volume and timeline play a major role in partner selection. You must communicate your production needs clearly. Manufacturers who offer flexibility and scalability can adapt to your requirements, whether you need prototypes or high-volume runs.

- Flexibility in accommodating different production volumes.

- Scalability to handle varying project demands.

- Improved overall experience when the partner can adapt to project needs.

Lead times vary by volume:

| Production Volume | Lead Time |

|---|---|

| Prototypes | 5–10 days |

| Low volume | 10–20 days |

| High volume | 4+ weeks |

You should choose a pcba assembly partner who is transparent about timing and can solve problems quickly. This helps you avoid delays and keeps your project on track.

Special Needs & Turnkey Solutions

If your project requires special features, such as turnkey PCB assembly, advanced testing, or unique packaging, you must specify these needs early. Some manufacturers offer complete solutions, handling everything from sourcing components to final testing. This approach streamlines the process and reduces risk. You should confirm that your partner can support your requirements for pcb assembly and printed circuit board assembly, including any customizations or compliance standards.

Tip: Align your requirements with your partner’s strengths to ensure a smooth manufacturing process and reliable results.

Research & Audit PCBA Manufacturing Partners

Choosing the right PCBA contract manufacturing partner requires a thorough evaluation process. You must research each provider’s background, audit their facilities, and request proposals and samples to confirm their capabilities. This step helps you avoid costly mistakes and ensures your printed circuit board assembly project meets your expectations for quality, reliability, and on-time delivery.

Company Background & Experience

Start your search by examining the company’s history and expertise. A strong provider demonstrates stability, technical capabilities, and a proven track record in electronic contract manufacturing. When you review a potential manufacturing partner, consider these key factors:

- Expertise in PCB assembly service, including DFM reviews to optimize your printed circuit board design for manufacturing.

- Certifications such as ISO 9001, IPC-A-610, and industry-specific standards guarantee quality and control.

- Rigorous quality control protocols and continuous improvement measures.

- Supply chain management strength, including an extensive supply network and the ability to source high-quality materials.

- Communication skills and project management support throughout the electronic assembly manufacturing process.

- Data-driven capacity to scale production based on your demand.

- Evidence of past project success and reliability in outsourcing.

- Financial stability of the partner to ensure long-term support.

Sanshun Smart stands out as a leading PCBA contract manufacturing provider. The company operates a 30,000 sqm facility, backed by more than 10 years of experience in contract electronics manufacturing. Its dedicated R&D center employs over 60 engineers who focus on innovation and process optimization. Sanshun Smart’s commitment to ‘Zero Defect’ quality ensures your printed circuit assembly project receives the closest attention to detail.

Facility Tour & Process Audit

A facility tour and process audit allow you to verify the provider’s capabilities firsthand. You should inspect the manufacturing environment, equipment, and staff qualifications. Use the following table to guide your audit:

| Criteria | Description |

|---|---|

| Stock Balance | Does the on-hand stock balance reflect the physical stock quantities for the two samples taken? |

| Maintenance Logs | Are Daily Maintenance logs kept at the machine, and are they up to date? |

| Preventative Maintenance | Is a Preventative Maintenance System used to flag when periodic Preventative Maintenance is required? |

| Operator Training | Is there evidence that the Operator has been trained and certified against the Standard Operating Procedure for the Machine? |

| Inspector Training | Does the Inspector have the IPC-610 standard available to them at all times? |

| Chemical Compatibility | Is there a master matrix that outlines the Chemical Compatibility for solder wire, fluxes, flux pens, cleaning solutions, etc? |

During your audit, verify certifications that demonstrate the provider’s commitment to quality, environmental compliance, and safety. The table below lists essential certifications for a PCBA manufacturing partner:

| Category | Certification | Primary Purpose | Requirements for a PCBA Manufacturer |

|---|---|---|---|

| Quality Management | ISO 9001 | Quality management system | Documented workflows, standardized production, and continuous improvement |

| ISO 13485 | Medical device quality system | Full traceability, risk control, process validation, and strict documentation | |

| Environmental Compliance | RoHS | Restriction of hazardous substances | Lead-free PCB assembly, RoHS components, material declarations |

| REACH | Chemical substance regulation | No SVHC, safe material handling, verified component sources | |

| ISO 14001 | Environmental management | Waste board recycling, reduced emissions, and energy efficiency | |

| Industry & Product Certs | UL | Fire and safety compliance | Flame-retardant materials, dielectric safety, and North America compliance |

| IPC-A-610 | Global workmanship standard | Class 1/2/3 workmanship requirements | |

| IPC-7711/7721 | Precision rework standard | BGA, fine-pitch IC, through-hole, and micro-jumper rework | |

| Manufacturing Process Certs | IATF 16949 | Automotive electronics quality system | Strict process control, full traceability, extremely low defect rates |

| ISO 45001 | Occupational health & safety | Machine safety, chemical handling, ESD protection, operator training | |

| Testing & Reliability | CE Support | EU regulatory readiness | EMC safety, compliant materials |

| FCC Support | RF emission compliance | EMC design rules, reduced EMI, compliant stackups | |

| ISO/IEC 17025 | Accredited testing competence | RF testing, thermal cycling, and reliability verification |

Sanshun Smart welcomes factory audits and provides full transparency during your visit. You can observe their advanced SMT assembly services, robust process control, and commitment to continuous improvement.

Request Proposals & Samples

Requesting proposals and samples is a critical step in evaluating a contract manufacturing partner. You should compare turnaround times, pricing, and sample quality to ensure the provider meets your project requirements. The table below outlines typical turnaround times for different PCB assembly services:

| Service Type | Typical Turnaround Time |

|---|---|

| Bare Board (fabs) | 24 hours (48 hours max for domestic) |

| PCB Assembly Quickturn | 48 hours (same day for labor only) |

| PCB Assembly Production | 1 week (2 weeks max) |

| Box Builds | 2–4 weeks (hard to predict) |

Sample evaluations play a vital role in confirming long-term quality and reliability. When you assess samples, you ensure the provider meets international standards such as ISO 9001 and IPC-A-600. Continuous monitoring of supplier performance helps maintain quality throughout your printed circuit board project.

| Evidence Type | Description |

|---|---|

| Supplier Evaluation | Sample evaluations ensure suppliers meet quality standards, impacting long-term manufacturing quality. |

| Continuous Monitoring | Ongoing assessment of supplier performance is essential for maintaining quality over time. |

| Quality Standards | Adherence to international standards like ISO 9001 and IPC-A-600 is crucial for reliability. |

Tip: Always request transparent quotes and detailed proposals. This approach helps you compare providers and select the best PCB assembly partner for your needs.

Sanshun Smart provides clear, competitive quotes and encourages you to request samples for your next PCBA project. Their team supports you from initial inquiry to final delivery, ensuring your outsourcing experience is seamless and successful.

Ready to take the next step? Contact Sanshun Smart today to schedule a factory audit or request a transparent quote for your PCBA contract manufacturing needs.

Evaluate Technical & Quality Strength

Selecting a PCBA contract manufacturing partner with strong technical and quality capabilities is essential for your project’s success. You must assess the provider’s equipment, quality control system, and inspection processes to ensure your printed circuit board meets industry standards and delivers long-term reliability.

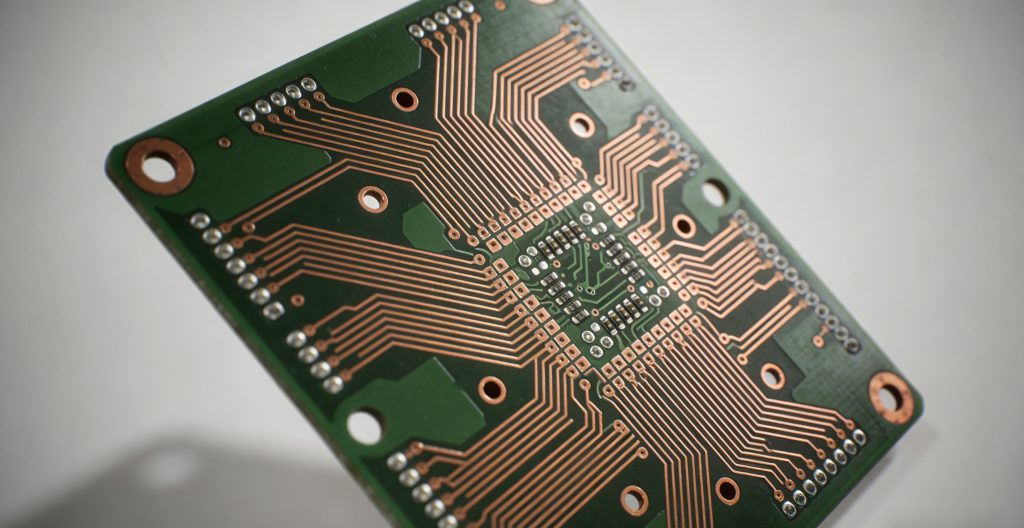

SMT Assembly & Equipment

Surface Mount Technology (SMT) precision directly impacts the quality of your pcb assembly. You should look for a provider that invests in advanced SMT assembly equipment and maintains strict control over every step. Modern SMT lines use specialized machines to optimize production and reduce defects. Key factors to consider include:

- Combo Loader: Automatically loads production lines, ideal for double-sided pcb projects.

- Inspection Systems: Perform pre-reflow and post-reflow checks on components and solder joints.

- Dry Cabinets: Protect sensitive materials by controlling moisture levels.

- Hot Bar Soldering: Creates permanent bonds between parts by melting solder.

- Dispensing Systems: Apply adhesives or solder paste with accuracy.

Advanced SMT technology, such as Solder Paste Inspection (SPI) machines, enhances quality control in electronic contract manufacturing. SPI machines detect solder paste printing defects in real time, allowing immediate corrections. This reduces defects in the final product and improves qualification rates. When your manufacturing partner uses these systems, you gain a competitive edge in outsourcing and project management.

Quality Systems & Certifications

A robust quality control system forms the backbone of a reliable pcb assembly service. You should verify that your provider holds industry-recognized certifications and follows strict quality standards. Leading PCBA manufacturing partners typically maintain:

- IPC: Recognized standards for PCB assembly practices.

- ISO: Certification that improves quality control and customer satisfaction.

- RoHS: Regulation limiting hazardous substances in electronic equipment.

- UL Listing: Ensures safety standards for pcb assembly.

- ITAR: Protects sensitive military technology in PCB assembly.

- MIL: Military standard for performance and environmental requirements.

IPC standards ensure uniformity in pcb manufacturing, leading to consistent high-quality products. They enhance product reliability and longevity, reducing malfunctions and failures. IPC guidelines cover board thickness, copper weight, and soldering quality. Implementing ISO 9001 and IPC standards streamlines processes and documentation. These standards help identify potential failure points and implement preventive actions. ISO 9001’s risk-based thinking and IPC’s defined quality levels reduce product recalls and customer complaints. Continuous improvement is a key aspect of these standards, helping reduce warranty claims and enhance overall product quality.

Testing & Inspection Processes

Effective testing and inspection processes are critical for maintaining quality and reliability in pcba contract manufacturing. You should confirm that your provider uses a comprehensive approach to detect and correct issues early. In-process testing allows manufacturers to identify potential problems before they affect the final product. This proactive strategy protects your investment and ensures consistent results.

| Inspection Method | Description |

|---|---|

| Visual or Microscope-based Inspection | Individuals check PCBAs visually or with a microscope to identify defects. |

| X-Ray Inspection | Finds defects like solder shorts that are not visible through standard visual inspection. |

| Automated Optical Inspection (AOI) | Uses images to compare PCBAs against ideal configurations to identify defects. |

| DRC Checks | Ensures schematics are viable for manufacturing, preventing unfeasible designs from progressing. |

You should also look for advanced inspection techniques, including:

- Solder Paste Inspection (SPI)

- Automated Optical Inspection (AOI)

- Automated X-Ray Inspection (AXI)

- Flying Probe Testing (FPT)

- In-Circuit Testing (ICT)

- Functional Testing (FCT)

These methods form a comprehensive quality control system, ensuring your PCBA meets strict quality standards. When your provider demonstrates expertise in these areas, you can trust their ability to deliver reliable pcb assembly service for complex boards and high-volume projects.

Tip: Always choose a manufacturing partner with proven experience in handling multi-layer, HDI, and complex printed circuit board designs. Their commitment to quality and advanced testing will safeguard your project from costly errors.

Supply Chain & Risk Management

A reliable supply chain forms the backbone of successful PCBAs contract manufacturing. You need a provider who can manage your bill of materials (BOM), prevent counterfeit components, and scale production efficiently. These capabilities ensure your pcb assembly project stays on schedule and meets quality standards.

BOM Handling & Sourcing

Effective BOM management supports both reliability and cost control in electronic contract manufacturing. You should expect your provider to:

- Source components only from reputable suppliers.

- Advise you about NRND (Not Recommended for New Designs), EOL (End of Life), and obsolete parts.

- Update CAD libraries and verify part numbers before production.

- Validate inventory quantities and recommend proper BOM formats.

- Integrate AVL, lifecycle, and pricing data into a central system.

- Keep procurement views synchronized with design intent.

- Require all changes to go through an Engineering Change Order (ECO) process.

- Maintain visible revision identifiers for every BOM.

- Push updates into the central system with ECOs.

- Ensure compliance and service visibility even after production ends.

- Build strong supplier relationships through regular communication.

- Evaluate the total cost of ownership, not just unit price.

- Implement quality control with supplier audits and incoming inspections.

Tip: Clear requirements and thorough supplier research help you avoid costly mistakes in pcb assembly service.

Counterfeit Prevention

Counterfeit components threaten the reliability of your electronic contract manufacturing project. Top providers use strict controls to verify authenticity. You should look for these practices:

| Evidence Type | Description |

|---|---|

| Component Certification Documents | Certify manufacturer, part number, and lot code. |

| Testing Reports | Document test methods and results for each batch. |

| Incoming Inspection Records | Track inspection steps for all incoming parts. |

| Counterfeit Mitigation Plan | Outline steps to prevent, detect, and address counterfeits. |

| Non-conformance Reports | Record failed inspections and corrective actions. |

| Training Records | Show staff are trained in counterfeit detection. |

| Independent Testing Laboratories | Provide third-party authentication for critical components. |

| Supply Chain Audits | Evaluate sourcing processes for vulnerabilities. |

| Escrow Services | Hold components until authenticity is confirmed. |

| Continuous Monitoring Services | Monitor the supply chain for new risks. |

You should always confirm that your provider follows these best practices to protect your investment in outsourcing.

Scalability & Flexibility

Your provider must support your growth from prototype to mass production. Leading electronic contract manufacturing partners use structured New Product Introduction (NPI) processes. These include DFM analysis, pilot builds, and engineering reviews. This approach minimizes risk and ensures a smooth transition to higher volumes.

Key strategies for scaling production include:

- Transitioning from flexible sourcing to structured supply management.

- Running pilot batches to validate processes.

- Conducting thorough DFM and DFT reviews.

- Adjusting shop floor and work cell configurations quickly.

- Offering rapid changeovers for different product types.

- Supporting small-batch rapid sampling with delivery times as fast as 24 hours.

- Operating multiple automatic SMT lines for efficient scaling.

A provider with these capabilities can adapt to changes in project scope or volume, reduce costs, and improve project management outcomes.

For seamless supply chain management and risk mitigation in your next pcb assembly project, contact Sanshun Smart. Schedule a factory audit or request a transparent quote to experience industry-leading reliability and support.

Communication & Support from Your Manufacturing Partner

Clear communication and ongoing support set the foundation for a successful PCBA contract manufacturing relationship. You need a provider who offers proactive feedback, transparent updates, and reliable after-sales service. These qualities help you avoid costly mistakes and ensure your PCBAs project stays on track.

DFM Feedback & Engineering Support

Design for Manufacturing (DFM) feedback plays a critical role in improving your product’s quality and manufacturability. When you involve your provider early, you gain several advantages:

- You identify potential issues before production begins.

- Your designs align with manufacturing capabilities and industry standards.

- You reduce production costs and improve overall quality.

You should incorporate DFM analysis at the start of your design process. Industry-standard tools, such as Valor NPI, help validate data and ensure your layout meets all requirements. Key DFM principles focus on manufacturability, assembly, reliability, testing, and serviceability. These principles optimize your design for both electrical performance and efficient assembly.

A strong technical team will cross-check your Gerber files, BOM, and assembly drawings. They validate line widths, spacing, and material availability. This proactive approach prevents design-related issues and supports smooth electronic contract manufacturing.

Tip: Early collaboration with your provider helps you avoid tolerance-related risks and costly rework.

Responsiveness & Transparency

Responsiveness and transparency are essential for effective project management. You should expect your provider to deliver timely updates, clear communication, and fast problem resolution. Leading providers achieve:

| Metric | High-Performing Provider | Industry Average |

|---|---|---|

| Lead Time Reduction | Up to 60% faster | 20–30% faster |

| First Pass Yield (FPY) | 95–98% | 85–90% |

| On-Time Delivery Rate | 97% | 85–90% |

| Defects Per Million (DPMO) | 500–1000 | 2000–3000 |

| Production Cycle Time | 12 hours | 24–48 hours |

| Scrap Rate | 2–5% | 8–12% |

| Customer Return Rate | <1% | 3–5% |

You should choose a provider who shares production schedules, inspection results, and any issues as they arise. This level of transparency builds trust and allows you to make informed decisions.

After-Sales Service

After-sales service ensures your project’s long-term success. You need a provider who stands behind their work and offers support after delivery. This includes:

- Technical assistance for troubleshooting and repairs.

- Warranty coverage for manufacturing defects.

- Fast response to quality concerns or returns.

A reliable provider will help you resolve issues quickly and maintain your product’s reputation in the market.

For a seamless experience in PCBA contract manufacturing, partner with a team that values communication, engineering support, and ongoing service. Contact Sanshun Smart to schedule a factory audit or request a transparent quote for your next project.

Compare Costs & Avoid Common Mistakes

Selecting the right provider for your PCBA project requires more than just comparing prices. You need to understand the full cost structure, review contract terms, and recognize common pitfalls that can impact your bottom line.

Cost Structure & Transparency

A transparent cost structure helps you avoid surprises and make informed decisions. You should ask your provider to break down all costs related to your pcb project. The table below outlines the key components you should review:

| Component Type | Description |

|---|---|

| BOM Optimization | Focus on optimizing the Bill of Materials to reduce costs. |

| Component Sourcing | Identify cost-effective suppliers and components. |

| Collaboration with SMEs | Engage experts to analyze and justify BOM choices for cost efficiency. |

| Resilient Supply Chain | Ensure a robust supply chain to mitigate risks and maintain cost-effectiveness. |

| Cost Drivers | Major cost drivers include BOM cost, PCB cost, assembly cost, and tooling costs. |

Tip: Request a detailed quote that includes all line items. This approach helps you compare providers fairly and avoid hidden charges.

Contract Terms & Hidden Fees

You must review contract terms carefully to avoid unexpected costs. Hidden fees often arise when quotes lack transparency or when issues occur during production. Common sources of hidden fees include:

- Lack of transparency in quotes

- Surprise markups that erode profit margins

- Quality concerns that result in unexpected costs

- Manufacturability issues that require costly rework

You may also face additional costs such as project delays, rework, and resource drain if the agreement is not clear. Always clarify payment terms, warranty coverage, and change order processes before signing.

Pitfalls in PCBA Partner Selection

Many companies make mistakes when choosing a manufacturing partner. The table below highlights common pitfalls and their impact:

| Pitfall | Description |

|---|---|

| Focusing Solely on Cost | Low prices may compromise quality or reliability, leading to higher long-term costs. |

| Ignoring IP Risks | Weak IP protections can jeopardize proprietary designs. |

| Overlooking Communication | Poor communication can cause delays and misunderstandings. |

| Neglecting Scalability | A provider unable to scale with your growth can limit your market potential. |

Clear communication and timely updates are essential for successful electronic contract manufacturing. You should prioritize providers who offer transparency, strong collaboration, and the ability to support your growth.

Note: Avoid selecting a partner based only on the lowest price. Consider long-term value, reliability, and support to ensure your project’s success.

You improve your chances of success when you choose a provider through careful evaluation and alignment with your project needs. Auditing and requesting samples deliver clear benefits:

| Benefit | Description |

|---|---|

| Lowering operational risk | Identifies issues early and reduces business risk. |

| Improving efficiency | Streamlines processes and cuts costs. |

| Isolating process issues | Highlights outdated or inadequate procedures. |

| Fostering communication | Encourages feedback for ongoing improvement. |

| Celebrating performance | Recognizes excellence in manufacturing. |

You confirm quality systems, measure compliance, and ensure capabilities match your requirements. Contact Sanshun Smart to schedule a factory audit or request a transparent quote for your next project.

FAQ

What is PCBA contract manufacturing?

You outsource your printed circuit board assembly to a specialized provider. This partner manages component sourcing, SMT assembly services, testing, and delivery. You gain access to advanced technology and quality control without investing in your own production line.

How do I evaluate a PCB manufacturer’s quality systems?

You should check for certifications like ISO 9001 and IPC-A-610. Ask about their inspection processes, such as AOI and X-ray. Request sample reports and audit their facility to confirm robust quality management.

Why choose turnkey PCB assembly?

You save time and reduce risk. The provider handles everything from sourcing components to final testing. You focus on design and market launch while your partner ensures reliable contract electronics manufacturing.

What are the common mistakes in PCB manufacturer selection?

You might focus only on price or overlook communication. You risk delays and quality issues if you ignore scalability or fail to review contract terms. Always prioritize experience, transparency, and technical support.

How can I start a project with Sanshun Smart?

You contact Sanshun Smart for a factory audit or request a transparent quote. Their team guides you through every step of your PCBA contract manufacturing project, ensuring quality and on-time delivery.