Choosing the right PCBA Contract Manufacturing approach can define your product’s reputation and your company’s long-term competitiveness. A single strategic misstep in PCBA contract manufacturing decisions may expose you to quality failures, communication breakdowns, supply chain disruptions, or even intellectual property risks.

PCBA contract manufacturing is not merely about “who builds your boards,” but about how manufacturing capability, engineering depth, quality systems, and collaboration models come together to support your product lifecycle. The stakes are high—poor decisions at this stage can lead to defective products, delayed launches, and lasting brand damage.

How to Evaluate PCBA Contract Manufacturing: A Strategic Decision Framework

To avoid costly mistakes in PCBA contract manufacturing, you must evaluate the manufacturing model as a whole—not just the quoted price or a single factory capability.

Key principles include:

Prioritize quality systems, not promises. Robust quality control must be embedded across the entire PCBA contract manufacturing process.

Assess real manufacturing experience. Proven execution across industries and product types matters more than marketing claims.

Look beyond unit price. Total cost of ownership (TCO) is the only meaningful cost metric in PCBA contract manufacturing.

Ensure engineering-driven communication. Effective collaboration between design, manufacturing, and testing teams is critical.

Use structured audits. A disciplined audit framework reveals whether PCBA contract manufacturing capabilities are sustainable.

Common Mistakes in PCBA Contract Manufacturing Decisions

Overlooking Quality Control Across the Manufacturing Process

One of the most common and costly mistakes in PCBA contract manufacturing is underestimating the role of quality systems. Many OEMs assume that basic inspection is sufficient, only to discover too late that inconsistent process control leads to field failures.

Don’t: Assume all PCBA contract manufacturing operations follow the same quality standards.

Do: Demand documented quality systems, process controls, and regular audits.

Ignoring quality risks leads to:

- Rework and yield losses that disrupt production schedules

- Escalating costs from returns, failures, and corrective actions

- Customer dissatisfaction and irreversible brand damage

In high-reliability industries such as automotive and aerospace, even minor wiring or assembly defects have triggered recalls and safety incidents. These examples highlight a core truth: PCBA contract manufacturing quality must be systemic, not reactive.

Underestimating Industry Experience and Technical Depth

Another critical mistake is treating PCBA contract manufacturing as a commodity service. Complex electronics require deep process knowledge, advanced equipment, and experienced engineering teams.

Don’t: Choose a PCBA contract manufacturing solution based solely on price or short-term capacity.

Do: Evaluate technical expertise, engineering resources, and project management maturity.

Strong PCBA contract manufacturing capabilities include:

- Experience with diverse technologies and component types

- Advanced SMT lines, precision placement, and automated inspection

- Continuous training aligned with IPC and industry standards

- Structured project management and risk control

Without sufficient experience, OEMs often face quality escapes, delays, and compliance risks that undermine product success.

Focusing on Cost Instead of Manufacturing Value

A narrow focus on cost is one of the most damaging PCBA contract manufacturing mistakes. Low quotes often hide higher downstream expenses.

Don’t: Select PCBA contract manufacturing purely on the lowest price.

Do: Evaluate value, performance, and total lifecycle impact.

Hidden costs may include:

- Excessive PCB layers or unsuitable surface finishes

- Component price inflation during shortages

- Rework caused by inadequate DFM consideration

- Testing fixtures, compliance validation, and redesigns

- Logistics, duties, and warranty-related expenses

Effective PCBA contract manufacturing balances cost efficiency with manufacturability, reliability, and long-term scalability.

Weak Communication and Poor Collaboration Models

PCBA contract manufacturing succeeds or fails based on communication quality. Misaligned expectations, unclear specifications, and delayed feedback frequently derail projects.

Don’t: Assume requirements are understood without continuous alignment.

Do: Establish clear communication channels, engineering access, and regular updates.

Signs of strong PCBA contract manufacturing collaboration include:

- Dedicated project management

- Direct engineering-to-engineering communication

- Transparent reporting on production and quality metrics

Collaboration-driven manufacturing reduces risk, improves yield, and accelerates time to market.

Core Evaluation Criteria in PCBA Contract Manufacturing

Capacity Planning and Scalability

Your PCBA contract manufacturing partner must support both current production and future growth. Insufficient scalability leads to bottlenecks, missed launches, and rising costs.

Key evaluation points:

- Prototype-to-volume production capability

- Secure component sourcing and substitution strategies

- SMT, through-hole, and mixed assembly support

- Comprehensive testing: ICT, FCT, X-ray

- Resilient supply chain management

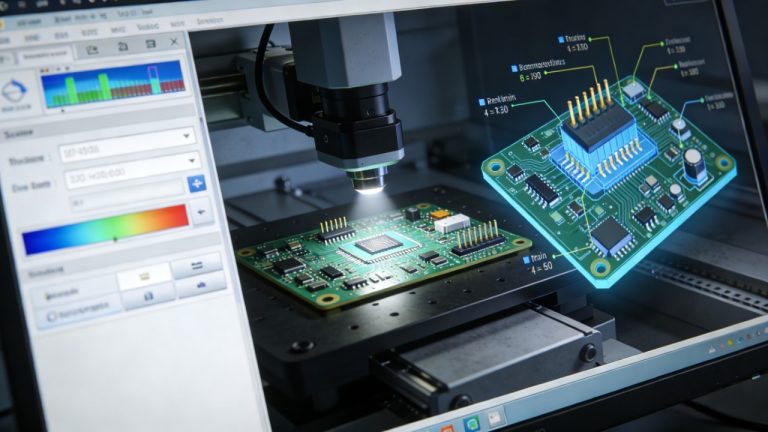

Facility Audits and Process Validation

Facility audits provide real insight into PCBA contract manufacturing maturity. Audits should assess:

- Training and quality governance

- Continuous improvement systems

- Factory layout, capacity, and environmental control

- ESD protection and process discipline

Document findings, implement corrective actions, and verify improvements through follow-up audits. This data-driven approach links process control directly to yield and reliability.

Financial Stability and Operational Continuity

Financial instability in PCBA contract manufacturing introduces severe supply chain risk. OEMs should review:

- Credit and liquidity indicators

- Profitability and leverage ratios

- Cash flow sustainability

Stable financial foundations ensure uninterrupted manufacturing and long-term partnership viability.

References and Proven Performance

Past performance remains one of the strongest predictors of future success in PCBA contract manufacturing. Validate:

- Historical project data

- Defect rates and delivery metrics

- Customer references and trend analysis

Reliable manufacturing partners demonstrate consistency across programs, not isolated successes.

The Role of DFM and Engineering Support in PCBA Contract Manufacturing

DFM as a Core Manufacturing Capability

Design for Manufacturability (DFM) is not optional—it is fundamental to effective PCBA contract manufacturing. Early DFM feedback reduces redesign cycles, improves first-pass yield, and lowers total cost.

Key benefits include:

- Early identification of assembly risks

- Simplified layouts and reduced defect potential

- Faster ramp-up and higher production stability

Ignoring DFM often results in hidden costs and compromised quality.

Engineering Collaboration and Continuous Improvement

Strong PCBA contract manufacturing integrates engineering collaboration throughout the product lifecycle. This enables:

- Real-time quality improvements

- Cost reduction through process optimization

- Shared innovation and problem-solving

Direct access to engineering support strengthens execution and builds long-term reliability.

Supply Chain Transparency in PCBA Contract Manufacturing

Component Traceability

Without traceability, PCBA contract manufacturing exposes OEMs to counterfeit risk and compliance failures.

Best practices include:

- Lot and date code tracking

- Production data linkage

- Regular audits and system reviews

Traceability empowers rapid root-cause analysis and protects product integrity.

Transparent Sourcing Practices

Effective PCBA contract manufacturing relies on sourcing transparency. Authorized distributors, documented procurement, and full visibility into component origin are essential to preventing counterfeit or substandard parts.

Testing, Inspection, and Quality Assurance

Robust PCBA contract manufacturing employs layered testing strategies, including:

- In-Circuit Testing (ICT)

- Functional Testing (FCT)

- Automated Optical Inspection (AOI)

Skipping or minimizing testing increases defect escape risk and downstream cost.

Supplier quality audits should verify:

- Incoming material control

- SMT and assembly discipline

- Testing coverage and documentation

- Traceability and corrective action systems

Avoiding Hidden Costs in PCBA Contract Manufacturing

Hidden costs frequently surface when OEMs fail to analyze the total cost of ownership. Beyond unit price, consider:

- Tooling and fixture investments

- Testing and certification expenses

- Logistics, warehousing, and duties

- Redesign and warranty exposure

A structured TCO analysis ensures informed decision-making and protects margins.

Building Long-Term Value Through PCBA Contract Manufacturing

Vendor Reliability and Partnership Longevity

Successful PCBA contract manufacturing is built on long-term reliability, not transactional pricing. Key indicators include:

- Consistent quality performance

- On-time delivery discipline

- Transparent communication

- Adaptability to demand changes

Reliable manufacturing partnerships reduce risk and strengthen supply chains.

Value-Added Services Beyond Assembly

Leading PCBA contract manufacturing partners offer more than assembly:

- DFM and DFT engineering support

- Component lifecycle management

- Process optimization and quality analytics

- Scalable production models

These capabilities differentiate sustainable manufacturing relationships from short-term outsourcing.

PCBA Contract Manufacturing Audit Checklist

A structured audit framework helps prevent costly mistakes. Key evaluation questions include:

- How is quality consistency ensured across programs?

- What KPIs govern manufacturing performance?

- Which certifications and standards are maintained?

- How is DFM feedback integrated into execution?

Red flags include a lack of certifications, poor communication, unrealistic pricing, and outdated equipment.

Conclusion

Avoiding mistakes in PCBA Contract Manufacturing requires a disciplined, system-level approach. By prioritizing quality, engineering collaboration, transparency, and structured audits, you protect your brand, control costs, and build a resilient supply chain.

FAQ

What are the most common mistakes in PCBA Contract Manufacturing?

Focusing only on price, ignoring quality systems, and underestimating engineering support are the most frequent errors.

How can OEMs avoid hidden costs in PCBA Contract Manufacturing?

By analyzing the total cost of ownership, demanding cost transparency, and integrating DFM early.

Why is DFM critical in PCBA Contract Manufacturing?

DFM reduces defects, improves yield, and prevents costly redesigns before production begins.

What should be included in a PCBA Contract Manufacturing audit?

Certifications, testing capability, traceability, past performance, and communication processes.

How does manufacturing reliability impact long-term success?

Reliable PCBA contract manufacturing ensures stable quality, on-time delivery, and sustainable growth.