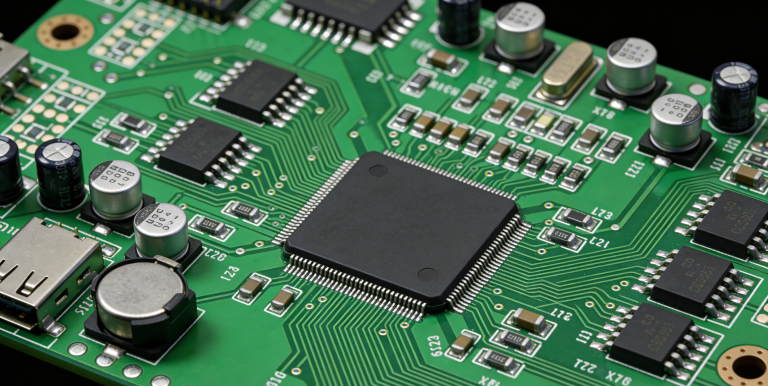

When you source China SMT PCBA, you often encounter challenges that can jeopardize your project if they are not properly managed. Many buyers focus only on price, underestimate lead times, or fail to verify suppliers thoroughly. Others overlook hidden costs, documentation accuracy, or quality control processes, which can lead to delays, defective products, and budget overruns.

Sourcing China SMT PCBA is not just about finding a low-cost supplier. It requires a clear understanding of manufacturing processes, supply chain risks, and communication practices. Whether you work directly with a China SMT PCBA factory or through an EMS partner, success depends on disciplined sourcing strategies, robust documentation, and transparent collaboration.

5 Best Practices When Sourcing China SMT PCBA

- Prioritize quality over price

Low cost without process control often results in high defect rates and rework. Balance pricing with quality assurance and manufacturing capability. - Confirm realistic lead times

Always align your project schedule with actual production capacity in China’s SMT PCBA manufacturing. - Account for NRE fees early

Non-recurring engineering costs can significantly affect low-volume SMT PCBA projects. - Maintain accurate documentation

Clear BOMs, Gerber files, and labeling are essential for consistent PCB assembly. - Verify suppliers thoroughly

Factory audits, certifications, and traceability systems reduce sourcing risks.

Common Supplier Mistakes in China SMT PCBA Sourcing

Prioritizing Price Over Process Control

One of the most frequent mistakes in China SMT PCBA sourcing is choosing suppliers based solely on price. Intense competition in the Chinese electronics manufacturing market can push some factories to cut corners on process control, inspection, or component sourcing.

Without proper quality management, low-cost SMT PCBA services often result in:

- Higher defect rates

- Inconsistent soldering quality

- Increased field failures

Tip: Always evaluate a China SMT PCBA factory’s process control systems—such as SPI, AOI, and MES traceability—before making cost-driven decisions.

Sanshun Smart mitigates these risks by investing in advanced inspection equipment and standardized quality control procedures, ensuring stable and repeatable SMT PCBA outcomes.

Underestimating Lead Times

Many buyers assume that sourcing from China SMT PCBA automatically guarantees ultra-fast turnaround. While Chinese assembly lines are efficient, lead times still depend on material availability, NRE preparation, and testing requirements.

Typical low-volume SMT PCBA lead times:

- Standard markets: 4–6 weeks

- China SMT PCBA factories: 1–2 weeks (excluding component procurement)

Failure to align expectations with realistic lead times often leads to missed product launches and rushed production.

Overlooking NRE Fees

NRE (Non-Recurring Engineering) fees are one-time setup costs required to prepare SMT lines for your specific PCB design. These fees do not scale with order quantity, making them especially impactful for prototypes and small batches.

Common NRE-related risks include:

- Inaccurate cost estimation

- Budget overruns

- Misleading supplier comparisons

A professional China SMT PCBA provider will clearly disclose NRE costs during quotation and help you plan production economically.

Poor Documentation and Labeling

Accurate documentation is the backbone of successful China SMT PCBA sourcing. Errors in BOMs, packing slips, or invoices can halt production or result in non-functional assemblies.

Missing or Incorrect BOMs

Incomplete or inaccurate BOMs often cause:

- Production stoppages

- Wrong component placement

- Defective PCB assemblies

Before submitting documents to a China SMT PCBA factory, every line item must be verified for part number, footprint, and revision control.

Improper Part Labeling

Poor labeling increases assembly errors and reduces traceability. Components must be clearly marked with model numbers, batch codes, and production dates. Proper labeling also supports regulatory compliance and quality audits.

Tip: Use anti-static packaging, moisture protection, and standardized labels with batch and quality identification.

Sanshun Smart supports clients with full BOM management, labeling standards, and end-to-end traceability to reduce documentation-related risks.

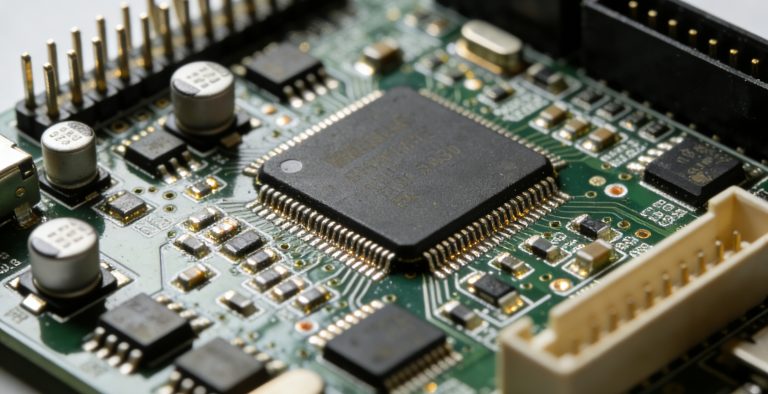

Component Substitution and Quality Risks

Unapproved Component Changes

Unauthorized component substitution remains a major risk in China SMT PCBA sourcing. Factories may replace specified parts due to shortages or cost pressure—sometimes without buyer approval.

These substitutions can:

- Degrade product performance

- Cause reliability failures

- Trigger warranty claims

A reliable China SMT PCBA factory follows approved vendor lists and requires written confirmation for any component change.

Counterfeit or Inferior Components

Counterfeit parts are a persistent threat in global electronics supply chains. Inferior components often imitate higher-grade parts but fail under real operating conditions.

To mitigate these risks:

- Enforce ISO and IPC compliance

- Require MES-based traceability

- Audit component sourcing channels

Working with Unverified Brokers

Lack of Factory Audits

Many buyers sourcing China SMT PCBA rely on intermediaries without verifying the actual manufacturing facility. This exposes projects to:

- Fraud and non-delivery

- Quality inconsistency

- Intellectual property leakage

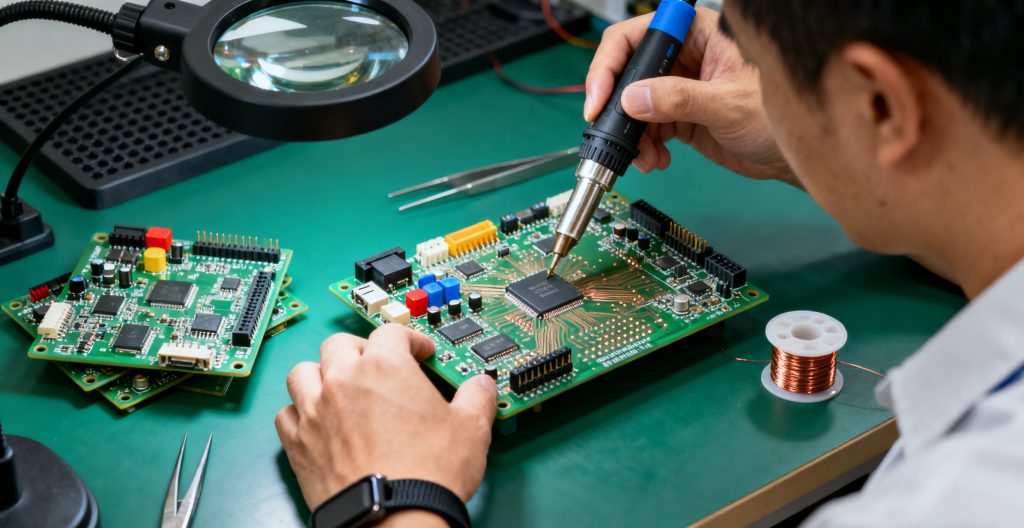

Direct audits—either onsite or virtual—are essential to verify SMT production lines, inspection systems, and material handling processes.

Traceability and Compliance Gaps

Unverified suppliers often lack consistent documentation, maintenance logs, or ESD controls. These gaps lead to non-compliance and unstable quality across production batches.

Red flags include:

- Poor communication

- Missing certifications

- Unrealistically low pricing

A transparent China SMT PCBA provider offers full traceability and compliance documentation.

Overlooking Communication During Prototype Handoff

Prototype handoff is a critical phase in China’s SMT PCBA projects. Poor communication during this stage often leads to delays, assembly errors, and failed validation builds.

Language and Time Zone Barriers

Differences in language and working hours can slow decision-making and obscure technical details. Informal communication increases the risk of misunderstandings.

Misinterpreted Specifications

Unclear or undocumented changes frequently result in assemblies that do not match design intent. Formal documentation, DFM reviews, and structured reporting are essential.

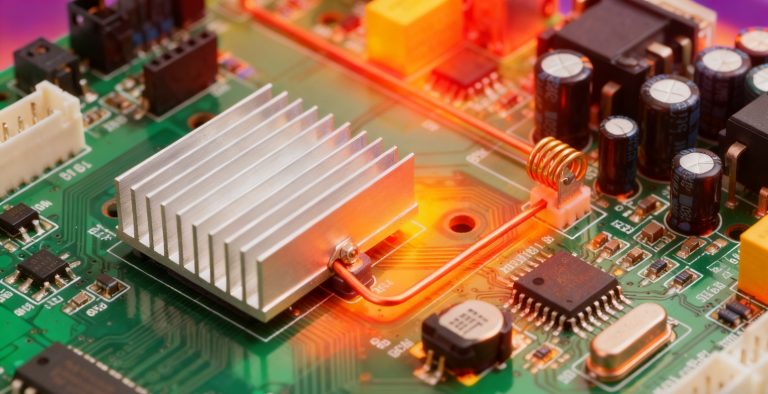

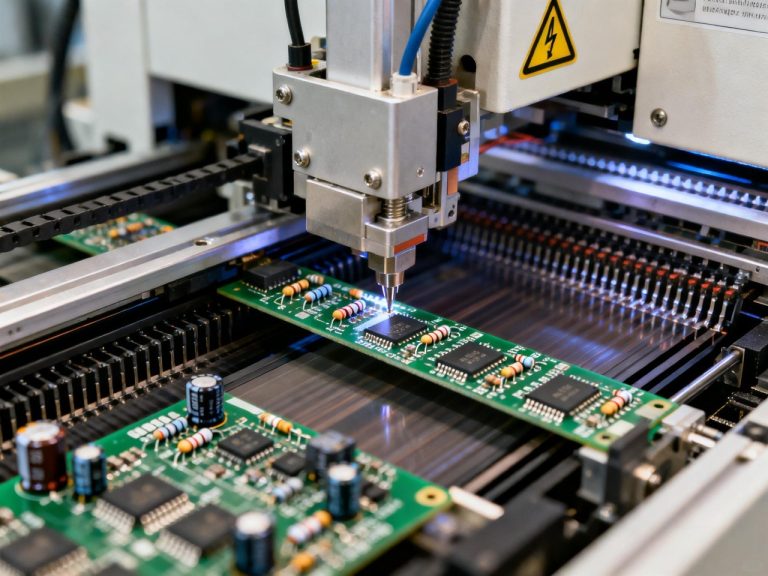

Process and Assembly Errors in China SMT PCBA

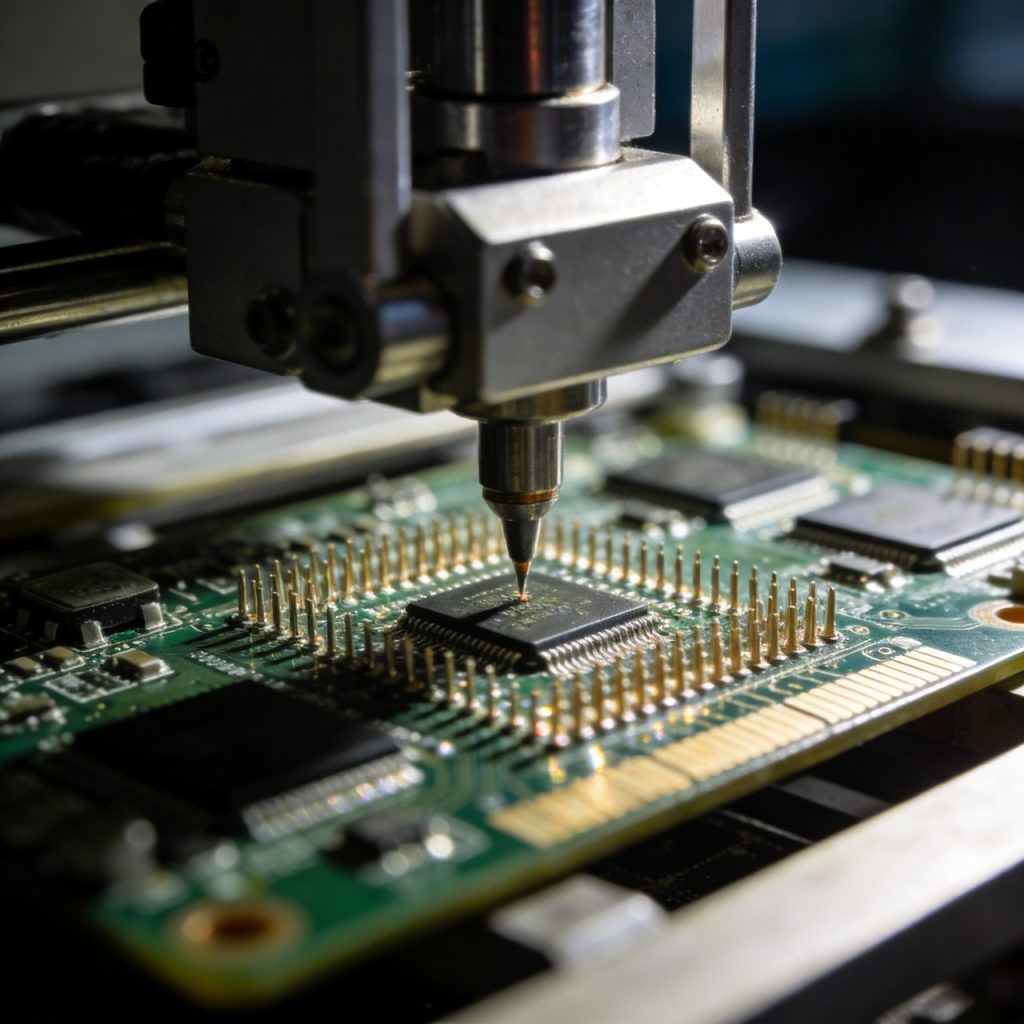

Pick-and-Place Accuracy Issues

Placement errors arise from calibration drift, feeder problems, or programming mistakes. Without early detection, these errors propagate across entire batches.

Preventive measures include:

- Regular machine calibration

- SPI and AOI inspections

- Verified fiducial recognition

- Soldering and Reflow Defects

Common soldering issues include cold joints, shorts, tombstoning, and solder balls. These defects often result from improper paste handling or reflow profiles.

Inspection methods such as SPI, AOI, X-ray, ICT, and FCT are essential to ensure SMT PCBA reliability.

Ignoring Intellectual Property Protection

IP protection is frequently underestimated when sourcing China SMT PCBA. Without legal safeguards, buyers risk design theft, unauthorized production, and counterfeit products.

Missing NDAs and Legal Controls

Essential protections include:

- Non-Disclosure Agreements

- IP ownership clauses

- Manufacturing agreements

Offshore Manufacturing Risks

To reduce IP exposure:

- Use encrypted file sharing

- Limit design access

- Work only with trusted China SMT PCBA partners

Sourcing China SMT PCBA involves more than comparing prices. Common mistakes—such as ignoring lead times, underestimating NRE fees, weak documentation, poor communication, and insufficient supplier verification—can quickly erode project success.

You can minimize risk by:

- Conducting factory audits

- Enforcing quality and traceability standards

- Maintaining clear communication and documentation

Partnering with a transparent and experienced China SMT PCBA provider like Sanshun Smart ensures reliable production, protected IP, and long-term sourcing success.

FAQ

What documents should I prepare before sourcing China SMT PCBA?

You should prepare a complete BOM, Gerber files, assembly drawings, and testing requirements to ensure accurate production.

How can I evaluate a China SMT PCBA provider’s quality?

Request ISO and IPC certifications, inspection reports, and sample test results. Factory audits are strongly recommended.

How should technical changes be handled during production?

All changes should be documented formally and confirmed in writing to avoid misunderstandings.

Why is working with verified China SMT PCBA suppliers important?

Verified suppliers reduce the risk of counterfeit parts, delays, and compliance failures, ensuring consistent product quality.