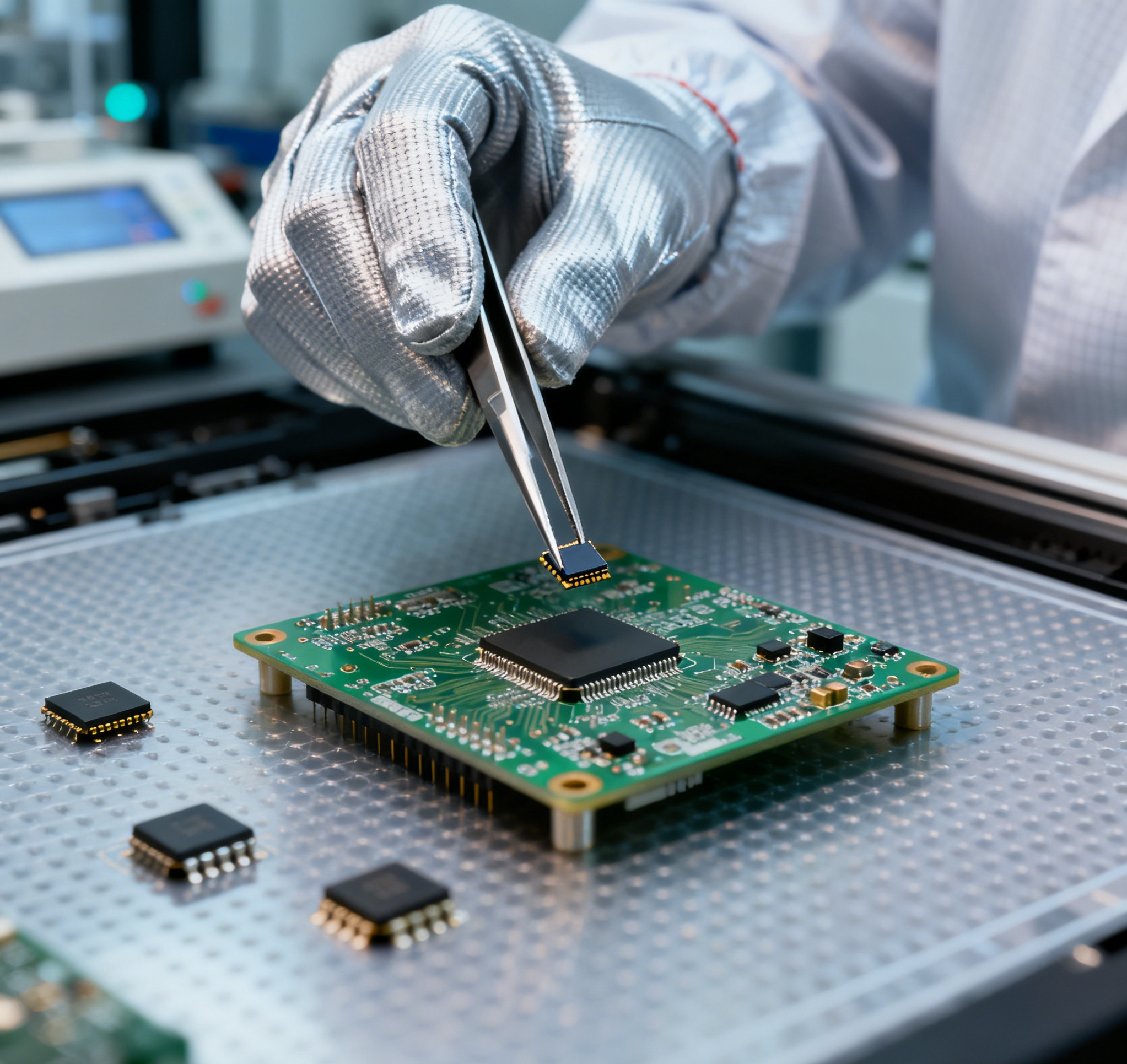

You face significant challenges when you pursue high-precision temperature control in PCBA design. Even a small temperature rise can accelerate material degradation, cause heat-induced failures, and compromise the performance of your PCBAs. Effective thermal management is vital because poor control can lead to reduced lifespan, unpredictable behavior, and even fire hazards. Addressing these issues in your PCBA and hardware design helps you prevent costly failures and ensure reliable operation in demanding environments.

- Poor thermal management can lead to component failure.

- A 10°C increase in temperature can halve a component’s lifespan.

- Overheating can create fire hazards or damage to nearby systems.

Thermal Design Principles Every Temperature Control PCBA Must Follow

- Effective thermal management is crucial. Poor control can lead to component failure and reduced lifespan.

- Select materials with high glass transition temperatures (Tg) to prevent thermal degradation in high-temperature environments.

- Optimize trace width and spacing to manage heat dissipation and maintain signal integrity in your PCBA design.

- Implement advanced thermal management strategies, such as heat sinks and thermal vias, to enhance reliability.

- Conduct thorough testing, including thermal shock and burn-in tests, to validate your high-precision temperature control PCBA.

Core Challenges in High-Temperature PCBA Design

Designing high-precision temperature control PCBA for high-temperature applications presents a unique set of technical and practical obstacles. You must address these challenges to ensure your hardware design delivers reliable performance, especially in demanding environments.

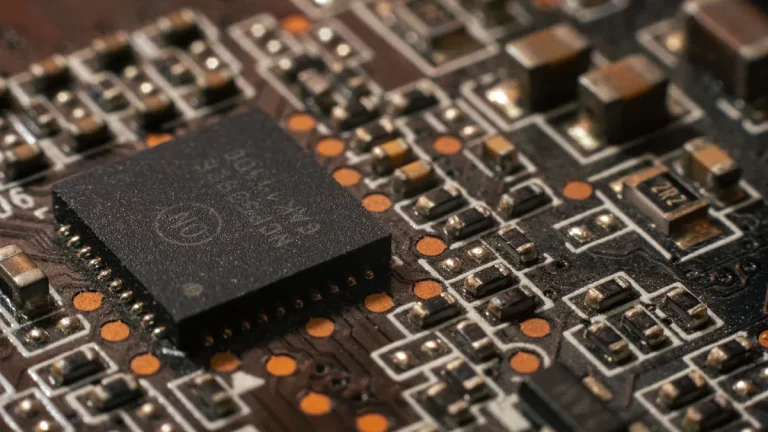

Material Degradation and Thermal Stress

You encounter material degradation as one of the most critical thermal challenges in high-temperature PCBA design. When circuit board operating temperatures exceed the glass transition temperature (Tg) of standard substrates like FR-4, you risk permanent damage and reduced reliability. Most FR-4 substrates have a Tg between 130°C and 170°C, but you should keep operating temperatures below 105°C to avoid thermal degradation of PCBA materials. Soldering processes often reach 200°C to 250°C, so you must select materials with higher Tg ratings for high-temperature designs.

Note: Prolonged exposure to temperatures above 125°C can cause irreversible changes in the substrate, leading to early failure.

Thermal cycling—repeated heating and cooling—introduces thermomechanical fatigue. This process degrades solder joints, creates micro-cracks, and increases failure rates in PCBA assemblies. You must consider mismatches in coefficients of thermal expansion (CTE) between materials, as these mismatches generate stress at solder joints and vias.

| Temperature Type | Value (°C) | Notes |

|---|---|---|

| Glass Transition Temperature (Tg) | 130–170 | Dictates the maximum safe temperature for FR-4 substrates. |

| Maximum Operating Temperature | 125 | Beyond this, materials begin to degrade, risking permanent damage. |

| Recommended Burn-In Temperature Range | 20–30 above max | Should exceed the PCBA’s maximum operating temperature to simulate long-term aging. |

Trace Delamination and Expansion

High-temperature environments can weaken the bond between copper traces and dielectric materials. You may see trace delamination, which leads to open circuits and unpredictable failures in high-temperature circuit boards. This risk increases with repeated thermal cycling and high-frequency vibration. Routing challenges become more pronounced as you must design wider traces for high current paths to prevent performance degradation due to heat.

- Prolonged exposure to heat causes trace delamination.

- Thermal cycling leads to solder joint fatigue and micro-cracks.

- High-frequency vibration accelerates delamination in high-temperature designs.

| Environmental Condition | Common PCBA Failure |

|---|---|

| High temperatures | Trace delamination |

You must address routing challenges by optimizing trace width and spacing, especially in high-temperature applications. This approach helps you manage heat dissipation and maintain signal integrity.

Substrate Leakage and Carrier Mobility Issues

In high-temperature designs, you face increased substrate leakage and reduced carrier mobility. As the temperature rises, leakage currents in the substrate increase, which can lead to dielectric failure and reduced insulation resistance. High voltage gradients, combined with elevated temperatures, may cause materials to fracture or puncture. These effects compromise the reliability of high-temperature circuit boards, especially in high-precision temperature control PCBA.

Thermal challenges also affect the electrical properties of semiconductors. You may observe a drop in carrier mobility, which impacts the speed and efficiency of your hardware design. This degradation becomes more severe in high-temperature environments, where even small temperature increases can accelerate failure mechanisms.

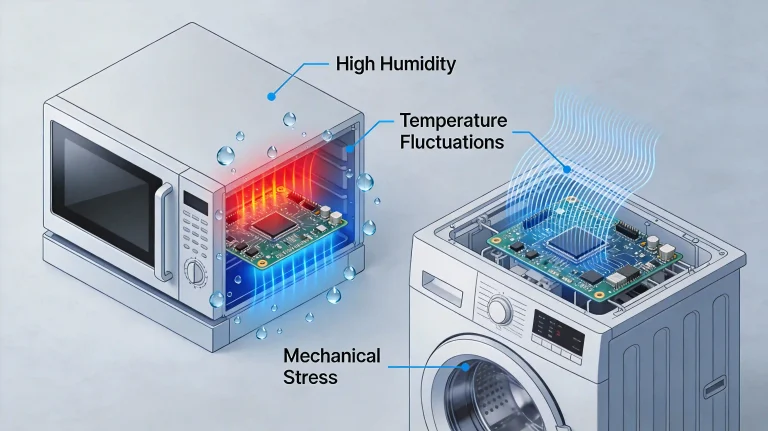

Environmental and Operational Factors

You must consider environmental and operational factors when designing for high-temperature applications. Mechanical loading, thermal loading, and electrical loading all influence the failure rates of PCBAs. High ambient temperatures and humidity can lead to dielectric breakdown and other failures. Duty cycles—how often and how long your PCBA operates—also affect reliability.

Reliability testing for high-temperature designs involves exposing PCBAs to extreme conditions, such as heat and thermal cycling. You should use electrical and mechanical stress testing to understand how your design will perform over time. These tests help you identify weaknesses in routing, material selection, and assembly processes.

| Technical Obstacle | Description |

|---|---|

| Material Selection | Use of materials with higher Tg ratings than standard FR-4 to withstand elevated temperatures. |

| Thermal Management | Strategies like heat sinks and thermal insulation are used to manage heat dissipation effectively. |

| Component Placement | Importance of spacing components to avoid creating high heat zones on the PCBA. |

| Routing Challenges | Need for wider traces for high current paths to prevent performance degradation due to heat. |

You must integrate advanced thermal management strategies, such as heat sinks and thermal insulation, to address these challenges. Careful component placement and routing help you avoid hot spots and ensure even heat distribution in high-temperature PCBA design.

Tip: Use reliability testing protocols that simulate real-world high-temperature environments to validate your high-precision temperature control PCBA and hardware design.

Impact of Temperature and Thermal Management on PCBA Performance

Reliability and Stability Concerns

You must prioritize reliability when you design high-precision temperature control PCBA systems. Inadequate thermal management remains the leading cause of failures in electrical devices. Over 55% of failures in pcbas stem from temperature issues, while vibration, humidity, and dust contribute to the rest. You often see the following reliability concerns in high-temperature environments:

- Solder joint cracking from thermal cycling

- Copper trace damage due to expansion differences

- PTH barrel cracking from hoop stresses

- Loss of mechanical strength from high-temperature degradation

- Solder joint fatigue caused by temperature fluctuations

- Warping from thermal expansion mismatch

You can address these challenges by integrating robust hardware design and advanced thermal solutions.

Electrical Performance and Aging

You will notice that temperature extremes accelerate the aging process of pcbas. Thermal aging describes how materials degrade when exposed to heat over time. Humidity can worsen this process, leading to insulation failure and reduced reliability over time. You should use aging tests that simulate real-world conditions to predict how your pcba will perform throughout their lifecycle. These tests reveal potential failures before they impact component reliability.

| Mechanism | Description |

|---|---|

| Material Degradation | Operating a pcba at or above its glass transition temperature weakens mechanical strength and increases delamination risk. Prolonged heat exposure accelerates resin decomposition. |

| Component Performance Drift | Electrical parameters of semiconductors drift with temperature, causing unpredictable behavior. High temperatures shorten the lifespan of capacitors and integrated circuits. |

| Mechanical Stresses from Expansion | Different materials expand at different rates, leading to solder joint fatigue, component cracking, and pcba warpage. |

Effects on Sensitive Components

You must pay special attention to sensitive components in your design. High temperatures can cause semiconductor instability, leading to unpredictable circuit behavior. Accelerated chemical reactions reduce component reliability and increase the risk of failure. Sensitive analog and digital circuits, such as those using a PID algorithm for control, require stable thermal conditions to maintain accuracy. Effective thermal management ensures your pcbas deliver consistent performance and reliability over time.

Tip: Always validate your high-precision temperature control PCBA with stress tests that include heat, humidity, and vibration to ensure long-term reliability.

Solutions and Best Practices for High-Temperature PCBA Design

Advanced Materials and PCBA Design Techniques

You can overcome high-temperature challenges by selecting advanced materials and optimizing your pcba design. High-Tg materials, such as specialized FR-4 variants and polyimide, withstand extreme heat and mechanical stress. For example, High-Tg FR-4 like IS410 offers a glass transition temperature of 180°C, while polyimide exceeds 250°C. These materials maintain structural integrity and electrical performance in demanding environments, which is essential for automotive, aerospace, and high-power electronics. When you design pcbas for high-precision temperature control PCBA, you must also consider high-reliability assembly techniques and thorough testing provisions.

| Technique | Description |

|---|---|

| Material Selection | Use materials with high thermal conductivity to move heat away from components. |

| Layer Management | Optimize stack architecture to improve heat dissipation through balanced power and ground planes. |

| Component Placement | Place heat-generating components strategically to reduce hotspots and ensure even heat dissipation. |

| Thermal Vias | Design thermal vias for effective heat transfer from surface layers to heat sinks. |

| Heat Sinks | Utilize heat sinks to expand surface area for passive heat dissipation. |

| Active Cooling Systems | Integrate fans or blowers to circulate air and maintain optimal temperatures. |

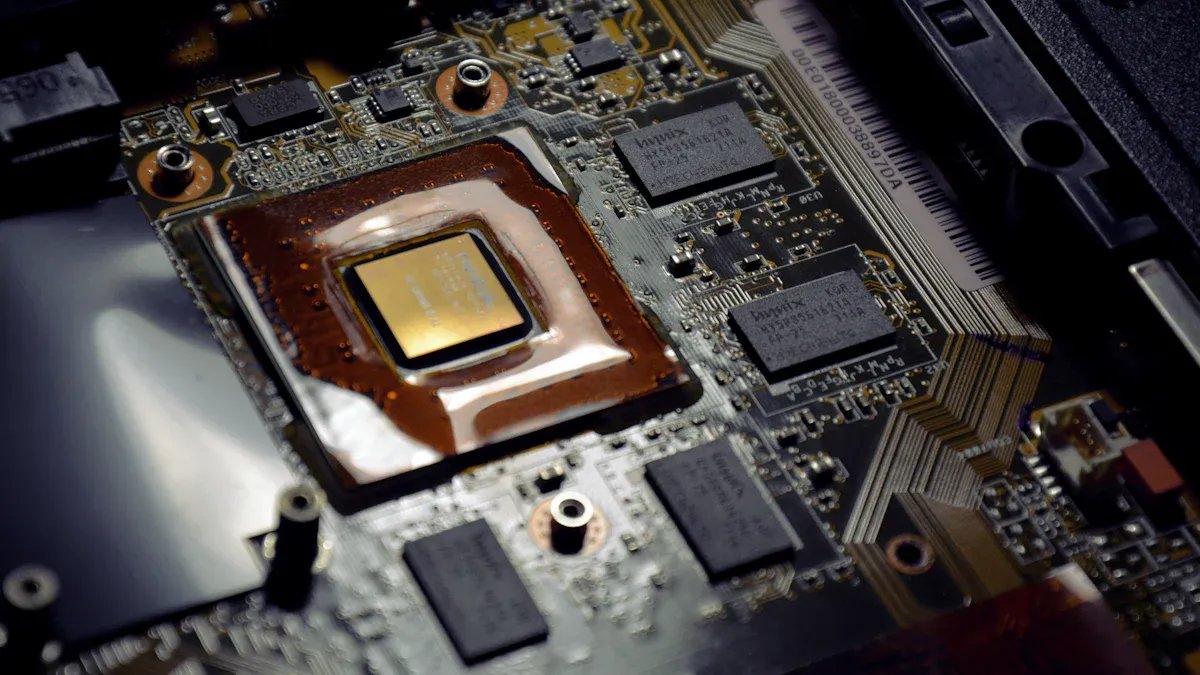

Thermal Management Strategies

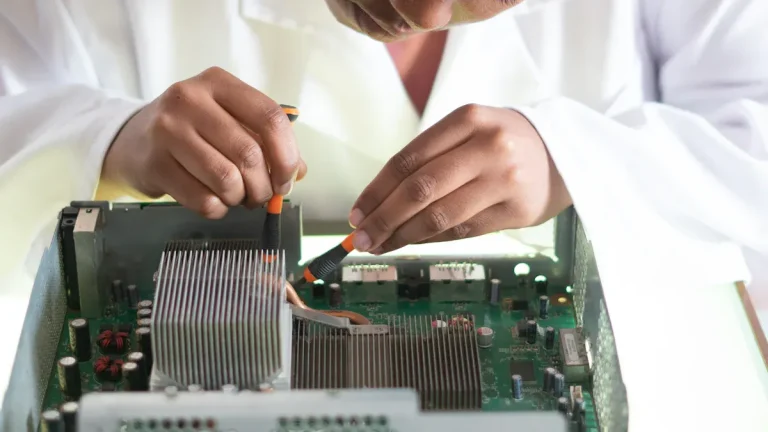

You must implement robust thermal management strategies to ensure reliable performance and longevity. Effective cooling methods include the design and location of heat sinks near hot components, thermal vias and planes for heat transfer, and selecting components with lower power dissipation. Forced air cooling with fans improves heat dissipation when passive methods are not enough. Advanced cooling techniques, such as liquid cooling systems or materials with high thermal conductivity, further enhance thermal management. The heat transfer coefficient plays a critical role; higher values indicate better cooling and lower trace temperatures. Introducing a plane in pcba design can reduce base temperatures from 56.7°C to 34.5°C, improving heat distribution and reliability. Optimizing trace widths also supports efficient heat dissipation and overall management.

- Design and location of heat sinks

- Thermal vias and planes for heat transfer

- Component selection for lower power dissipation

- Forced air cooling with fans

- Advanced cooling techniques, including liquid cooling

Testing and Calibration Protocols

You need thorough testing provisions to validate your hardware design and ensure long-term reliability. Testing methods such as thermal shock testing, highly accelerated life testing (HALT), and burn-in testing simulate real-world conditions and identify potential failures. Environmental testing assesses the impact of moisture, particle ingress, and vibration on pcbas. Matching the coefficient of thermal expansion (CTE) values of conductors, solder, and substrate materials prevents thermal shock failures. Using high-Tg substrate materials and high thermal conductivity substrates, such as metal-core or ceramic, helps dissipate heat quickly in hot environments. These protocols support the calibration of PID algorithm-based control systems and maintain consistent performance.

| Testing Method | Description |

|---|---|

| Thermal shock testing | Simulates temperature extremes to test durability. |

| Highly accelerated life testing | Evaluates longevity and estimates failure points. |

| Burn-in testing | Ensures components operate correctly during warmup. |

| Environmental testing | Assesses moisture, particle ingress, and vibration effects. |

| CTE matching | Prevents thermal shock failures by matching material expansion rates. |

| High-Tg substrate materials | Maintains low CTE over a broad temperature range. |

| High thermal conductivity substrates | Dissipates heat quickly in hot environments. |

Tip: Always align your thermal management techniques with industry standards such as IPC-2152 and IPC-2221 to ensure your pcba meets reliability and performance requirements.

You strengthen your pcba by addressing high-temperature design challenges early. When you use high Tg materials, you gain superior thermal reliability, dimensional stability, and improved electrical performance in your pcba. Effective temperature control keeps your pcbas within safe limits, which extends product life and ensures reliability. Recent innovations, such as polyimide laminates and metal-core technology, help you manage heat in demanding environments. Stay proactive and keep learning about new solutions to maintain the highest standards in your design process.

- Superior thermal reliability and mechanical strength

- Improved electrical performance at high temperatures

- Enhanced reliability in humid and harsh environments

Tip: Test your products in extreme conditions to verify long-term reliability.

FAQ

What materials work best for high-precision temperature control PCBA?

You should select high-Tg FR-4, polyimide, or ceramic substrates. These materials resist thermal degradation and maintain electrical performance.

Tip: Polyimide offers excellent stability for demanding hardware design environments.

How does the PID algorithm improve temperature control accuracy?

The PID algorithm adjusts heating or cooling in real time. You get precise temperature regulation by minimizing overshoot and steady-state error.

- Proportional: Reacts to error

- Integral: Eliminates offset

- Derivative: Predicts future trends

What testing methods validate high-temperature hardware design?

You should use thermal shock, burn-in, and HALT testing. These methods simulate extreme conditions and identify weaknesses in your high-precision temperature control PCBA.

| Test Type | Purpose |

|---|---|

| Burn-in | Reliability |

| HALT | Longevity |

| Thermal Shock | Durability |

How do you prevent trace delamination in high-temperature PCBA?

You must optimize trace width, use high-Tg substrates, and add thermal vias.

Note: Wider traces and matched CTE values reduce stress and prevent delamination in your hardware design.

Why is component placement critical for thermal management?

Strategic component placement avoids hot spots and improves heat dissipation. You should separate heat-generating parts and use thermal planes.

- Place power components near heat sinks

- Isolate sensitive circuits

- Use thermal vias for efficient cooling