Scaling production is exciting—but also nerve-wracking. When orders increase to tens of thousands or even millions of units, only a reliable high-volume PCBA partner can ensure your product consistently meets quality, cost, and delivery expectations. A misstep in your mass production process can delay shipments, increase rework costs, and affect your brand reputation.

This guide shows you exactly how to evaluate and select a high-volume PCBA manufacturer that acts not just as a vendor, but as a strategic partner supporting your business growth.

Executive Summary: Critical Factors for Successful High Volume PCBA

Before diving deeper, here’s what you need to evaluate in any high-volume PCBA manufacturer:

- Scalability & Capacity – Can they manage large, continuous production runs?

- Process Maturity – Do they use automated inspections like SPI, AOI, ICT, or AXI?

- Design for Manufacturability (DFM) – Will they identify potential production bottlenecks early?

- Supply Chain Reliability – Can they secure components to prevent delays?

- Cost Efficiency – Are setup and tooling costs optimized across large runs?

These are the core pillars that separate dependable mass production partners from risky choices.

Understanding High Volume PCBA

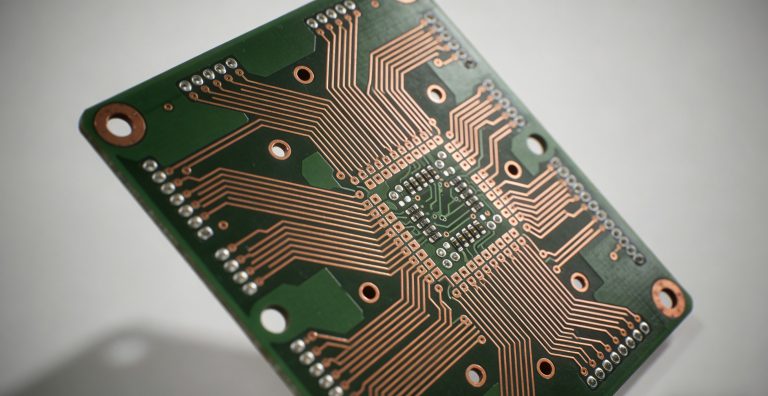

High-volume PCBA goes beyond prototypes and small batches. Key characteristics include:

- Annual production in the tens of thousands or higher

- Minimal design changes during production

- Extensive use of automated SMT assembly and advanced equipment

- Tight delivery schedules aligned with market demand

At this scale, your manufacturer must focus on volume manufacturing PCBA practices like process stability, takt time, and line balancing.

Evaluating Technical Capability and Production Capacity

Choosing the right manufacturer requires more than a facility tour. A true high-volume PCBA factory demonstrates:

| Capability | What to Check | Why It Matters |

|---|---|---|

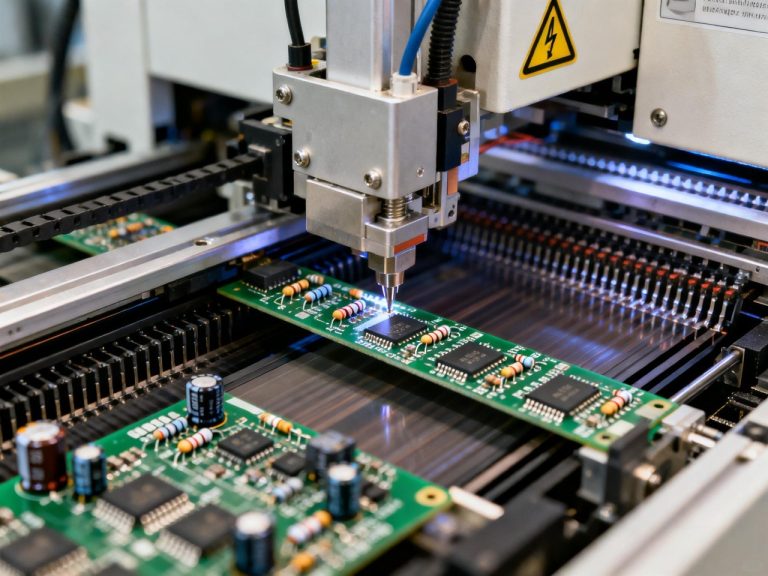

| SMT Line Capacity | Multiple high-speed lines | Supports continuous large-scale production |

| Automation & Inspection | SPI, AOI, ICT, AXI | Reduces errors and improves first-pass yield |

| Through-Hole & Mixed Technology | Automated wave/selective soldering | Handles complex or legacy components efficiently |

| DFM & DFA Review | Pre-production evaluation | Prevents bottlenecks and costly rework |

At high volumes, small inefficiencies become significant risks. Assessing these areas helps maintain smooth production.

Maintaining Quality at Scale

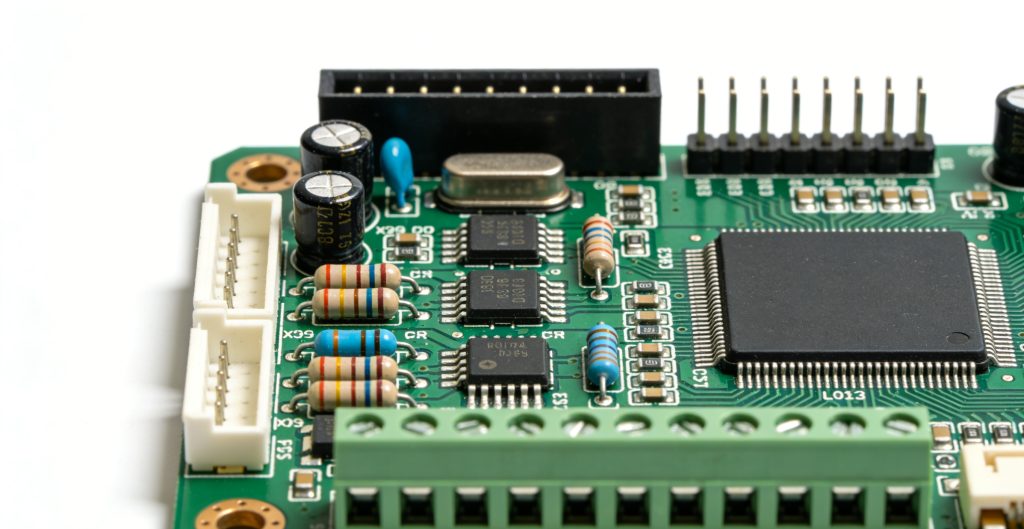

Quality challenges grow exponentially with volume. Reliable manufacturers implement:

- Automated inspection suites – SPI, AOI, ICT, AXI

- Full traceability & ERP integration – Track each component to its batch and supplier

- Statistical process control – Prevents drift across large runs

- Industry certifications – ISO 9001, IATF 16949 (Automotive), ISO 13485 (Medical)

Focusing on process repeatability and first-pass yield ensures consistent quality from the first board to the millionth.

Cost Optimization Strategies

High-volume PCBA projects require cost structures designed for scalability:

- Panelization – Optimize board layouts to reduce material waste

- Amortized Tooling – Spread fixture and stencil costs across thousands of units

- Turnkey Assembly – Leverage the manufacturer’s global sourcing power for cost efficiency

Efficient cost strategies protect your margins while maintaining product quality at scale.

Ensuring Supply Chain Reliability

Minor component shortages can halt entire production lines. Key factors to evaluate:

- Multi-source qualification for critical components

- Buffer stock and inventory management strategies

- Proven experience handling global supply volatility

- Realistic lead times and delivery commitments

Supply chain resilience is essential for smooth high-volume PCBA execution.

Low Volume vs High Volume PCBA: Risk Comparison

| Feature | Low Volume | High Volume PCBA |

|---|---|---|

| Focus | Rapid prototyping | Cost efficiency, yield, and consistency |

| Equipment | Flexible/manual lines | Automated high-speed SMT |

| Inspection | Visual/manual testing | SPI, AOI, ICT, X-ray |

| Unit Cost | High | Lower due to economies of scale |

| BOM Management | Local sourcing | Global procurement & buffer stock |

| Risk Impact | Minor | Major; requires mature processes |

This table highlights why scaling from low-volume to high-volume PCBA is not just a step up in quantity—it’s a shift in operational mindset.

High Volume PCBA Manufacturer Checklist

Before committing to a partner, ensure they meet these criteria:

- At least 3 high-speed SMT lines

- SPI integrated into production

- Pre-production DFM report provided

- Full traceability per batch

- Established relationships with global component distributors

A thorough audit ensures your manufacturer can deliver consistent quality at scale.

How SanShun Smart Supports Your High Volume PCBA Success

When scaling production, having a reliable partner can make all the difference. SanShun Smart is designed to support every stage of your high-volume PCBA journey, providing advanced SMT lines, comprehensive inspection suites, and turnkey assembly solutions. Their engineering-driven approach ensures consistent quality, process stability, and supply chain reliability—so you can focus on growing your business rather than managing production issues.

By choosing SanShun Smart as your strategic partner, you’re not just outsourcing assembly—you’re gaining a trusted ally dedicated to helping your products reach the market efficiently, reliably, and at the highest standard. Whether it’s managing complex designs, optimizing cost, or ensuring timely delivery, SanShun Smart’s solutions scale with your ambitions, making high-volume PCBA production predictable, manageable, and worry-free.

High Volume PCBA Related FAQs

Q1: How is “high volume” defined in PCBA?

A1: Generally, it refers to production runs exceeding 10,000 units per order, with continuous use of automated SMT lines and mature process control.

Q2: Why is SPI essential in high-volume PCBA?

A2: Automated Solder Paste Inspection identifies defects before components are placed, preventing costly rework and ensuring low scrap rates.

Q3: Can every manufacturer handle high-volume PCBA?

A3: No. Only manufacturers with strong automation, process maturity, and supply chain reliability can consistently meet high-volume requirements.

Q4: How does SanShun Smart support mass production?

A4: They offer high-speed SMT lines, comprehensive inspection suites, full traceability, and global sourcing, ensuring consistent quality and on-time delivery for large production runs.