Professional PCBA production forms the foundation of product reliability. You influence long-term durability at every stage, from sourcing components to final testing. If you overlook robust quality controls, you expose your products to early failures and costly repairs.

- Over 30% of early electronic product failures result from defects in the PCBAs process.

You reduce downtime and maintenance costs when you monitor manufacturing and analyse process improvements. High-quality standards in pcba production lead to lasting reliability.

How to Achieve Consistent and Reliable PCBA Production?

- High-quality components are essential for a reliable PCBA. Always source from trusted suppliers and ensure proper storage to avoid defects.

- Accurate placement and soldering techniques prevent common assembly issues. Use advanced machines and control solder paste volume for better results.

- Effective thermal management in PCB design extends component lifespan. Space high-power parts apart and use thermal vias for heat dissipation.

- Implement rigorous testing methods, such as in-circuit and functional testing. These methods help catch defects early and improve overall reliability.

- Choose a manufacturer with strong quality standards and certifications. This ensures consistent production quality and reduces the risk of failures.

Key Factors in PCBA Production Reliability

Component Quality and Traceability

You cannot achieve reliable pcb quality control without strict attention to component quality and traceability. In PCBA production, every component must meet high standards. If you use parts with mechanical damage, environmental degradation, or electrical stress, you risk early failures. The most common sources of component failures in PCBA circuit board assembly include:

- Mechanical damage, such as bent leads or cracked packages.

- Environmental degradation from moisture or dust.

- Electrical stress, such as electrostatic discharge or overvoltage.

- Solderability problems due to oxidised leads.

- Supply shortages that force last-minute redesigns.

You can mitigate these risks by sourcing from trusted suppliers, planning for lead times, and storing components properly. Including alternatives in your bill of materials also helps maintain supply chain stability. Certified quality management systems, such as ISO 9001 or AS9100, require you to document processes and conduct regular audits. These certifications reduce defects, ensure predictable quality, and provide traceable supply chains. When you implement traceability systems, you can quickly identify and resolve quality issues, which strengthens product integrity and performance.

Tip: Always partner with a manufacturer who demonstrates accountability and transparency through certifications and documented traceability.

Placement Accuracy and Soldering

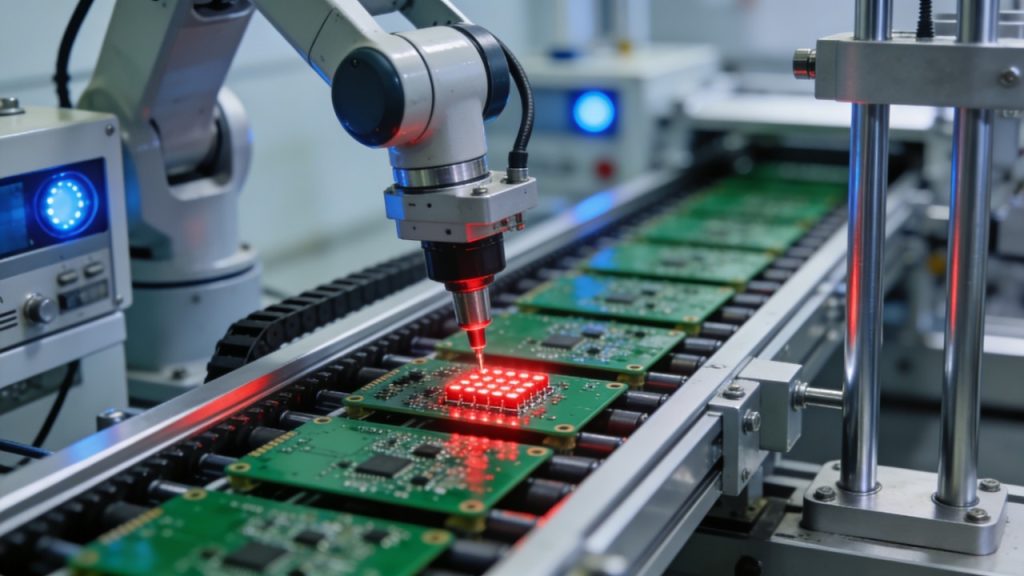

You must focus on placement accuracy and advanced soldering techniques to ensure assembly quality. Poor placement or soldering leads to defects like solder bridges, cold joints, and misaligned components. These issues cause open circuits, electrical shorts, and product failures. In professional PCBA production, you use precise machines for component placement and control the solder paste volume for each pad.

- Robust quality assurance programs reduce defects such as tombstoning.

- Custom temperature profiles during reflow optimise solder joint quality.

- Understanding and controlling void formation in solder joints improves reliability.

If you skip these steps or use low-cost assembly methods, you increase the risk of unstable solder joints and material contamination. Reliable pcb quality control at this stage lowers costs and enhances product performance by reducing rework and field failures.

PCB Layout and Thermal Management

You must design your pcb circuit board assembly with thermal management in mind. Poor layout leads to hot spots, excessive heating, and early component failure. To prevent thermal failures, you should:

- Place high-power components apart to distribute heat.

- Use thermal zones, copper pours, and thermal vias for heat dissipation.

- Ensure trace widths handle current without overheating.

- Select materials and layer stackups that support thermal performance.

Effective thermal management prevents costly redesigns and ensures your product meets performance expectations. Following standards like IPC-2152 for current carrying capacity is essential for reliable operation. When you manage heat well, you extend the lifespan of your components and increase overall reliability.

| Thermal Management Practice | Benefit for Product Performance |

|---|---|

| Component spacing | Reduces hot spots |

| Thermal vias and copper pours | Improves heat dissipation |

| Proper trace width | Prevents overheating |

| Material selection | Enhances durability and stability |

Environmental Controls and Coating

You must protect your PCBAs from moisture, dust, and contaminants to maintain long-term reliability. Professional assembly environments use humidity control, thorough drying procedures, and desiccants in packaging. These controls prevent moisture-related failures and preserve assembly integrity.

Applying conformal coating adds a protective barrier against moisture, dust, chemicals, and temperature changes. This coating prevents corrosion, short circuits, and other damage, making your PCBA suitable for harsh environments. Sealed enclosures that meet IP68+ standards offer additional protection for critical applications.

Note: Moisture protection systems, including drying, vacuum sealing, and desiccants, are essential for ensuring the stability and operational life of your product.

By prioritising environmental controls and coatings, you gain the benefits of reliable PCBA quality control: fewer failures, lower maintenance costs, and improved product performance. You ensure that your assembly withstands real-world conditions and delivers consistent results.

Reliable PCB Quality Control and Testing

Thorough testing and quality control in PCBAs production protect you from costly recalls and field failures. You must implement rigorous methods to verify the quality of components and assembly. Reliable pcb quality control ensures that your pcb circuit board assembly meets high standards for stability and product performance.

In-Circuit and Functional Testing

You rely on in-circuit testing (ICT) and functional testing (FCT) to detect assembly defects and confirm operational capability. ICT focuses on manufacturing anomalies such as shorts, open connections, and soldering issues. FCT evaluates the overall performance of the PCBA under simulated conditions, revealing design flaws and hidden problems. Both methods contribute to high fault coverage, reducing warranty claims and improving reliability.

| Testing Type | Strengths | Limitations |

|---|---|---|

| In-Circuit Testing | Detects manufacturing anomalies like shorts and open connections early. | May overlook design-related issues or system-level integration problems. |

| Functional Testing | Evaluates overall functionality under simulated conditions. | Less effective in identifying specific assembly defects compared to ICT. |

You benefit from early detection of defects, which lowers rework and scrap costs. ICT is essential in industries where reliability is critical, such as automotive and medical. FCT identifies issues under stress, leading to fewer field failures and reduced warranty claims.

Burn-in and Stress Simulation

Burn-in testing exposes your PCBAs to high temperatures and electrical stress for extended periods. This process identifies latent defects, such as weak components, cracked solder joints, and connector contact issues. You simulate real-world stress to ensure reliability and stability before shipping.

| Test Type | Purpose | Description |

|---|---|---|

| Operating Life (JEDEC JESD22-A108) | Accelerate thermally activated failure mechanisms | Intense stress test at 125°C with maximum voltage bias |

| High Temperature Operating Life (HTOL) | Determine resistance to prolonged operating stress | Simulates operating lifetime under specified conditions |

| Preconditioning (Precon) (JESD22-A113) | Simulate a real-life PC board assembly process | Dry bake, moisture soaking, and solder reflow simulation |

| Biased Highly Accelerated Stress Test (HAST) (JESD22-A110) | Simulate extreme operating conditions | Devices baked at high temperature and humidity with bias |

| Temperature Humidity Bias (THB) (JESD22-A101) | Determine resistance to prolonged temperature and humidity | Devices subjected to extreme conditions with electrical stress |

Burn-in and stress simulation reveal potential failure points that standard functional testing may miss. You reduce the risk of failures during customer use, which enhances product performance and reliability.

Quality Assurance Standards in PCBA

You must follow industry standards to achieve consistent quality in pcb quality control. ISO 9001, IPC-A-600, and IPC-A-610 are widely adopted by manufacturers. These standards reduce defect rates and ensure uniformity in assembly and pcb production.

| Quality Assurance Standard | Impact on Defect Rates |

|---|---|

| ISO 9001 | Significant reduction in defects |

| IPC-A-600 | Ensures high-quality PCBs |

| IPC-A-610 | Reduces defects in assembly |

| Domestic PCB Manufacturing | 40-55% lower defect rates compared to offshore alternatives |

By adhering to these standards, you benefit from reliable pcb quality control, improved product performance, and lower support costs. Advanced manufacturing capabilities, such as process consistency and effective supplier management, directly improve yield rates and delivery performance. You gain the benefits of reliable PCBA quality control: fewer defects, higher stability, and enhanced customer satisfaction.

Choosing a Reliable PCBA Partner

Technology and Certifications

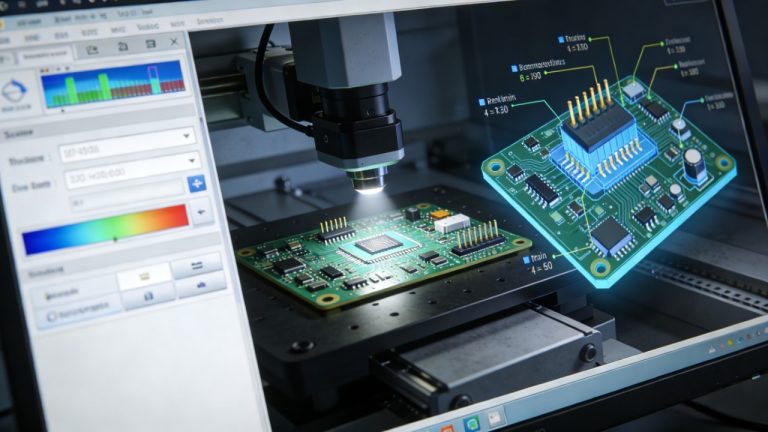

You need to evaluate a manufacturer’s investment in advanced technology and certifications. Modern PCBA production relies on automated optical inspection, X-ray inspection, and comprehensive functional testing. These measures verify component placement, detect hidden defects, and confirm product performance. Surface-mount technology and through-hole technology provide flexibility for different assembly needs. Mixed technology capabilities allow you to optimise stability and reliability in your pcb circuit board assembly.

| Certification | Description |

|---|---|

| ISO 9001 | Confirms a robust quality management system for consistent production. |

| IPC-A-610 | Sets standards for acceptable electronic assembly workmanship, critical for multi-layer boards. |

| RoHS Compliance | Ensures the use of environmentally safe materials, avoiding hazardous substances. |

| IATF 16949 | Specific to automotive applications, guaranteeing high reliability for safety-critical systems. |

| AS9100 | Relevant for aerospace and defence, focusing on stringent quality and safety requirements. |

Tip: Always request documentation for certifications and technology investments to ensure your assembly meets industry standards.

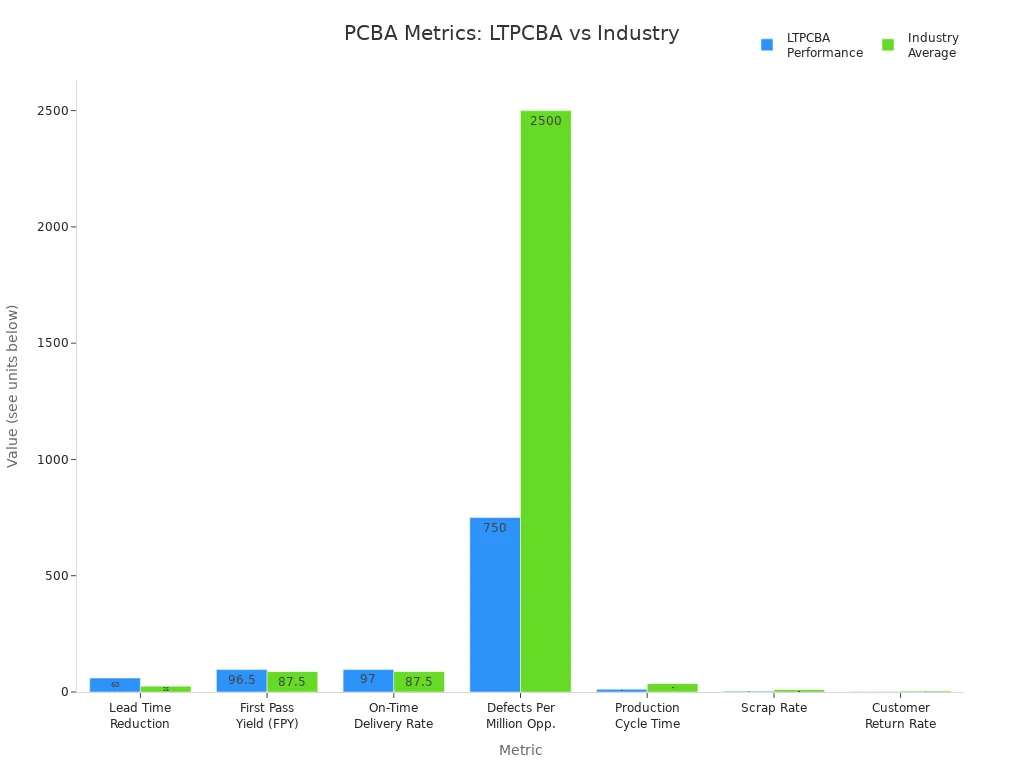

Track Record and Service

You should assess a manufacturer’s track record using clear metrics. Fast lead times, high first pass yield, and low defect rates indicate strong process control and quality. On-time delivery and low customer return rates reflect reliability and service commitment. Review the manufacturer’s ability to manage end-to-end processes, maintain supply chain strength, and provide responsive engineering support.

Sanshun Smart demonstrates excellence with a large facility, a dedicated R&D team, and a “Quality First” philosophy. Advanced testing equipment and flexible management allow rapid adaptation to your needs. You benefit from collaborative engineering, frequent product iteration, and strong supply chain partnerships.

PCB Circuit Board Assembly Checklist

You can use this checklist to evaluate potential PCBA partners and ensure reliable assembly:

| Essential Item | Description |

|---|---|

| Material Certification | Confirm compliance and traceability for all materials. |

| Incoming Material Inspection | Inspect raw materials and components before assembly. |

| Process Parameter Control | Maintain strict control over fabrication parameters. |

| In-Process Inspections | Conduct inspections at multiple stages of assembly. |

| Accurate Component Placement | Ensure correct placement to avoid functional failures. |

| Solder Joint Inspection | Check solder joints for reliability and open circuits. |

| Electrical Testing | Verify board function and product performance. |

| Environmental Testing | Simulate real-world conditions for stability. |

| Documentation and Traceability | Keep records of all production stages. |

Reliability Checklist:

- Confirm certifications (ISO 9001, IPC-A-610, RoHS, IATF 16949, AS9100)

- Review technology investments (AOI, X-ray, functional testing)

- Assess facility size, R&D capabilities, and quality philosophy

- Evaluate metrics: lead time, yield, defect rates, customer returns

- Inspect supply chain and engineering responsiveness

You strengthen your product’s reliability and impact by partnering with a manufacturer who prioritises quality, advanced assembly, and thorough testing. This approach ensures your PCBA delivers consistent product performance and long-term stability.

Pitfalls of Unprofessional PCBA Production

Counterfeit Components and Poor Soldering

You face serious risks when you choose a manufacturer that does not prioritise quality in assembly. Counterfeit components and poor soldering practices can quickly undermine product performance. Common issues include:

- Counterfeit parts often cause random failures and can deteriorate product performance parameters.

- Over 30% of product recalls result from counterfeit components.

- Poor soldering leads to open circuits, shorts, and unstable connections.

- Early field failures, overheating, and even fire hazards can occur due to unauthorised parts.

- Each year, electronic failures linked to counterfeit components cost the industry billions of dollars.

You risk customer dissatisfaction and loss of reputation when your assembly contains unreliable parts. Bad press and long-term negative impact on your brand can follow a single product recall.

Inadequate Testing and Controls

You cannot afford to skip thorough testing in your assembly process. Inadequate testing and weak controls often result in costly recalls, repairs, and replacements. These failures damage customer trust and your company’s reputation. When you neglect robust quality assurance, you increase production costs due to rework and defective pcb replacements. Consistent failures drive customers away and create long-term financial problems for your business.

Common pitfalls in unprofessional assembly include:

- Design errors such as misaligned components and unrouted signals.

- Incorrect component placement and inadequate spacing.

- Routing errors and shorted circuits.

- Power distribution mistakes that cause voltage drops and overheating.

- Poor thermal management leads to board warping and damage.

You must ensure your manufacturer uses strict testing and process controls to avoid these risks.

The Cost of Unreliability

Unreliable assembly impacts your bottom line and brand reputation. The hidden costs include RMAs, warranty claims, and lost business opportunities. You may face increased warranty costs and strained financial resources. Customers lose trust and may switch to competitors.

| Pitfall Description | Impact on Brand Reputation | Impact on Warranty Costs |

|---|---|---|

| Product failures due to counterfeit parts | High | Increased claims and recalls |

| Faulty products drive customers to competitors | High | Higher production and support costs |

| Counterfeit components cause financial losses | Medium | More resources needed for fixes |

You protect your product performance and reputation when you partner with a quality-focused manufacturer. Reliable assembly and strict quality controls help you avoid these costly pitfalls.

You secure product reliability and long-term success when you choose professional PCBA production and strict PCB quality control. Key factors include thorough inspection, stress testing, and robust process management. Use the checklist to evaluate suppliers and avoid risks such as delayed launches, poor board performance, and compliance violations.

| Testing Method | Purpose |

|---|---|

| Inspection Criteria | Limit defects with pass/fail standards |

| Stress Testing | Evaluate performance under demanding conditions |

| Quality Control | Ensure long-lasting service lives |

- Confirm trace width and spacing for safe current handling.

- Avoid crowded component placement to reduce errors.

- Standardise footprints for efficient assembly.

Partner with a manufacturer who prioritises quality to build trust and achieve reliable outcomes.

FAQ

What makes printed circuit board assembly reliable?

You achieve reliability in printed circuit board assembly by using certified processes, verified components, and thorough testing. A high-quality manufacturer ensures each step meets strict standards, reducing the risk of defects and improving product performance.

How does pcb manufacturing process affect product quality?

You control product quality by following a precise pcb manufacturing process. Accurate placement, controlled soldering, and environmental protection prevent failures. Consistent procedures and inspections help you maintain high standards and deliver dependable printed circuit boards.

Why is supply chain stability important for high-quality pcb manufacturing?

You depend on supply chain stability to avoid delays and shortages. Reliable sourcing ensures you receive genuine components, which supports high-quality pcb manufacturing. Stable supply chains reduce risks of counterfeit parts and last-minute design changes.

What should you look for in a high-quality manufacturer?

You should check certifications, advanced technology, and a strong track record. A high-quality manufacturer invests in automated inspection, maintains strict quality controls, and provides responsive support. These factors guarantee reliable pcb manufacturing and long-term product success.

How does testing improve reliability in pcb manufacturing?

You improve reliability by using in-circuit, functional, and stress testing. These methods detect defects early and confirm product performance. Rigorous testing in the pcb manufacturing process helps you avoid costly recalls and ensures your products meet industry standards.