Nobody responsible for sourcing PCBA EMS Manufacturing starts by asking, “How can I make this cheaper at all costs?” The real pressure usually sounds more like this: “Where can I reduce electronics manufacturing cost without creating quality issues I’ll be blamed for later?”

This is exactly why PCBA EMS Manufacturing cost optimization today is no longer about chasing the lowest quote—but about choosing an engineering-driven EMS partner that protects yield, reliability, and your professional reputation.

You are likely staring at two competing quotes right now. One is noticeably lower, but the price gap feels more like a warning sign than a saving. We’ve all seen the nightmare scenario: a “budget” contract electronics manufacturing deal that leads to a 15% scrap rate, late-night debugging of cold solder joints, and angry emails about field failures. In 2026, saving pennies on the unit price only to lose thousands on rework is a career-risking trade-off. This guide explains how to achieve true PCBA assembly cost reduction by focusing on the Total Cost of Ownership (TCO) and engineering-led optimization.

Quick Summary: Strategic Levers for PCBA EMS Manufacturing Efficiency

Before we dive into the technical details, here are the high-impact moves to optimize your budget:

- Early DFM (Design for Manufacturability): Fix layout errors in the prototype stage to avoid 70% of downstream production costs.

- Smart BOM Optimization: Swap high-cost brand-name passives for qualified, high-reliability alternatives.

- Turnkey EMS Integration: Consolidate PCBA fabrication and assembly to eliminate vendor hand-off errors and double NRE fees.

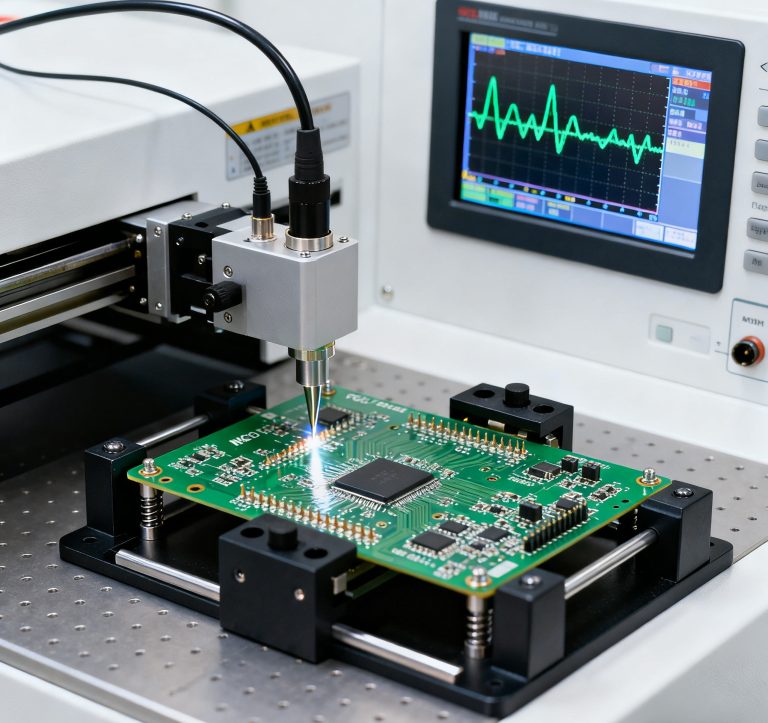

- Automated Quality Control: Prioritizing First Pass Yield (FPY) with AI-driven AOI and X-Ray inspection.

� Professional Tip: Want to know if your current BOM can be optimized for 10-20% savings? [Submit your design for a Free Cost-Benefit Analysis by SanShun Smart]

1. What Really Drives PCBA EMS Manufacturing Costs?

In the world of Electronics Manufacturing Services (EMS), cost is a reflection of process efficiency, not just labor rates.

Core Cost Drivers vs. The Price of Failure

| Cost Element | Optimized Strategy | The Risk of “Cheap” Quotes |

|---|---|---|

| PCBA Fabrication | Layer count & via-in-pad optimization | Poor registration & delamination |

| BOM Sourcing | Pre-qualified Equivalent Parts | Counterfeit risks & line stoppages |

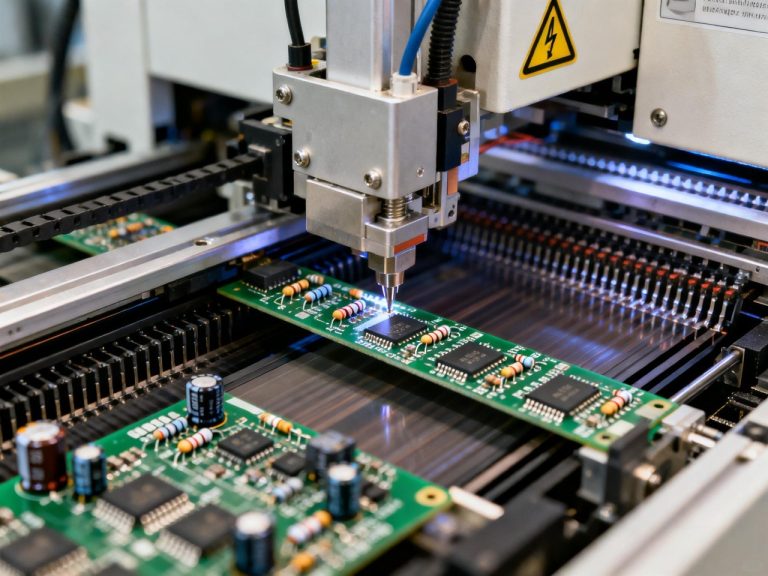

| SMT Assembly | Automated line balancing | Cold solder joints & manual rework |

| Testing & QC | IPC-A-610 Class 2/3 standards | Latent defects & field recalls |

2. The Hidden Cost of Low-Price PCBA EMS Manufacturing

Choosing an EMS partner based solely on the lowest headline price often triggers a chain reaction of “Ghost Costs”:

- The Rework Loop: A 5% drop in yield can double your labor costs as engineers spend days manually fixing SMT errors.

- Supply Chain Volatility: Without a partner providing Lifecycle Monitoring, a single EOL (End-of-Life) component can force a total product redesign mid-production.

- Compliance Gaps: Skipping X-Ray inspection on BGA components may save 500upfrontbutcost50,000 in batch recalls.

3. How Does DFM PCBA EMS Manufacturing Cost?

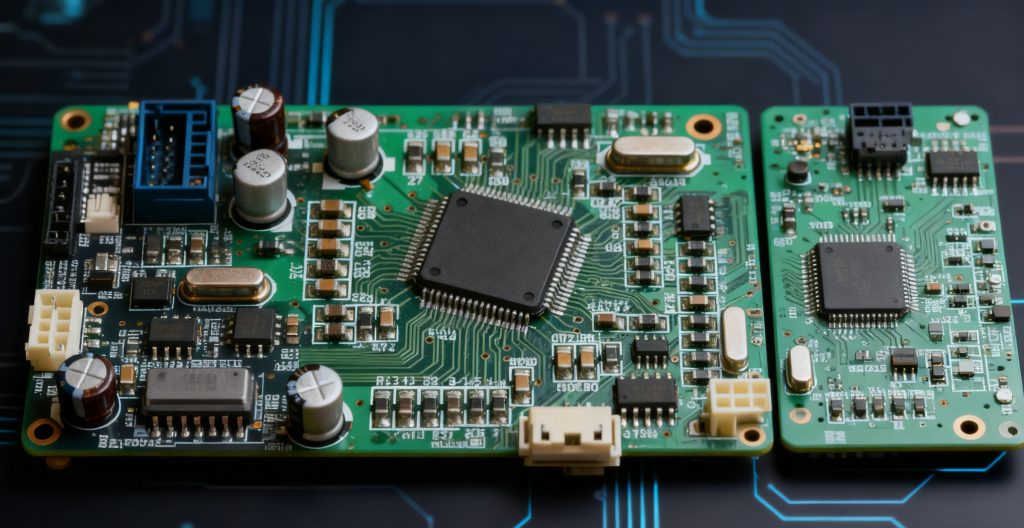

Design for Manufacturability (DFM) is the most powerful tool for PCBA assembly cost reduction. It ensures your project is “Born to be Built.”

- Standardization: Reducing the variety of resistor and capacitor values on your BOM allows your contract electronics manufacturing partner to buy in massive bulk, leveraging economies of scale.

- Panelization Efficiency: Increasing board density per panel reduces material waste and speeds up Pick-and-Place cycle times.

- Testability (DFT): Incorporating test points early allows for Automated ICT (In-Circuit Testing), which is significantly cheaper and more reliable than manual functional testing.

4. Why One-Stop PCBA EMS Manufacturing Reduces Cost & Risk?

Splitting your project between a PCBA shop and an assembly house creates a “blame game” when errors occur. A unified PCBA EMS Manufacturing partner like SanShun Smart provides:

- Zero Handoff Friction: We manage the synergy between PCBA tolerances and SMT requirements.

- Shortened Lead Times: Integrated supply chains respond 30% faster to market fluctuations.

- Accountability: We own the final yield. If it doesn’t work, it’s our responsibility to fix it before it ships.

5. Case Study: 18% Savings Through Engineering-Led Optimization

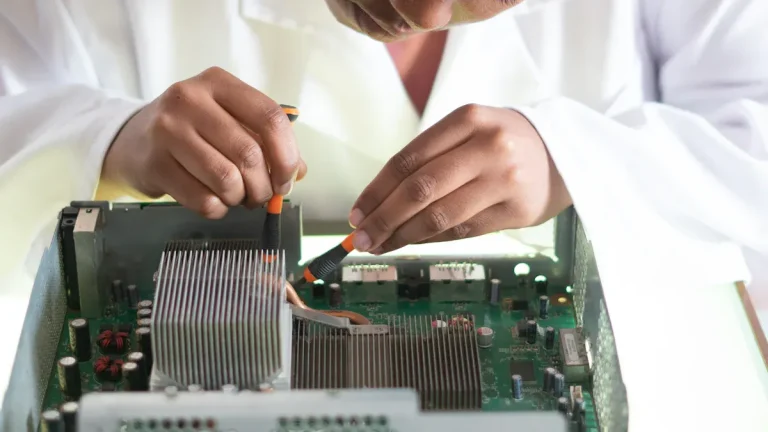

At SanShun Smart, we recently helped an Industrial IoT client whose legacy production was suffering from 12% scrap rates and rising component markups.

- The Solution: Our engineers performed a “BOM Scrubbing” and identified five qualified alternative passives. We also adjusted their 10-layer PCBA stack-up to an 8-layer high-density design.

- The Result: We achieved an 18% reduction in total manufacturing cost and stabilized their First Pass Yield (FPY) at 99.4%.

Our ISO 9001 and IATF 16949 certified facilities ensure that every board meets IPC-A-610 Class 3 standards, regardless of the budget.

Moving Forward with SanShun Smart

Whether you are navigating High-Mix Low-Volume (HMLV) challenges or scaling for mass production, you need a partner that treats your margins as its own. SanShun Smart combines 20+ years of manufacturing expertise with AI-driven inventory tracking to deliver high-quality, cost-optimized electronics.

Stop guessing your production costs. Let our experts provide a clear, risk-assessed roadmap for your next project.

[Get My Free DFM & BOM Risk Review Today]

Frequently Asked Questions (FAQ)

1. What is the biggest mistake in PCBA EMS Manufacturing cost reduction?

Optimizing for “Unit Price” instead of Total Cost of Ownership (TCO). A cheap board with a high failure rate in the field costs 10x more in the long run than a board built with proper Quality Control.

2. Can I reduce PCBA EMS Manufacturing costs without switching suppliers?

Yes, if your provider is proactive. By performing a DFM (Design for Manufacturability) review and standardizing your BOM, you can often remove 10-15% of the cost through material efficiency alone.

3. Is offshore PCBA EMS Manufacturing still the best option in 2026?

Only if the provider offers One-Stop Turnkey services and strong engineering support. Logistics and communication gaps can quickly erase any labor savings. A tech-forward partner like SanShun Smart bridges that gap with automated transparency.

4. What quality standards are non-negotiable for cost-effective production?

Always look for IPC-A-610 compliance and ISO 9001 certification. These ensure that the cost-saving measures taken don’t compromise the structural integrity or long-term reliability of your electronics.