You need ISO 9001 and IATF 16949 certifications when choosing a China PCBA manufacturer because these standards guarantee consistent quality and product reliability in PCBA assembly in China. Certified suppliers follow strict quality control systems that reduce defect rates by up to 20% and achieve over 95% defect detection. This commitment to quality and regulatory compliance boosts customer confidence in PCBA assembly in China. Certification also means your supplier meets industry standards, which lowers risk and raises reliability for every project.

The Essential Role of Certified PCBA Manufacturers

- Choose certified PCBA manufacturers to ensure consistent quality and reliability. ISO 9001 and IATF 16949 certifications guarantee adherence to strict quality control standards.

- Certified suppliers reduce defect rates significantly. Expect up to a 20% decrease in defects and over 95% defect detection, leading to fewer costly mistakes.

- Working with certified manufacturers builds customer confidence. They maintain high on-time delivery rates and low defect rates, ensuring your projects meet industry standards.

- Regular audits and inspections in certified factories minimize risks. This protects your business from issues like poor workmanship and inconsistent material quality.

- Verify supplier certifications before starting projects. Request documentation and check the validity to ensure you partner with reliable manufacturers.

Why Certification Matters for China PCBA Manufacturers

Quality and Reliability Assurance

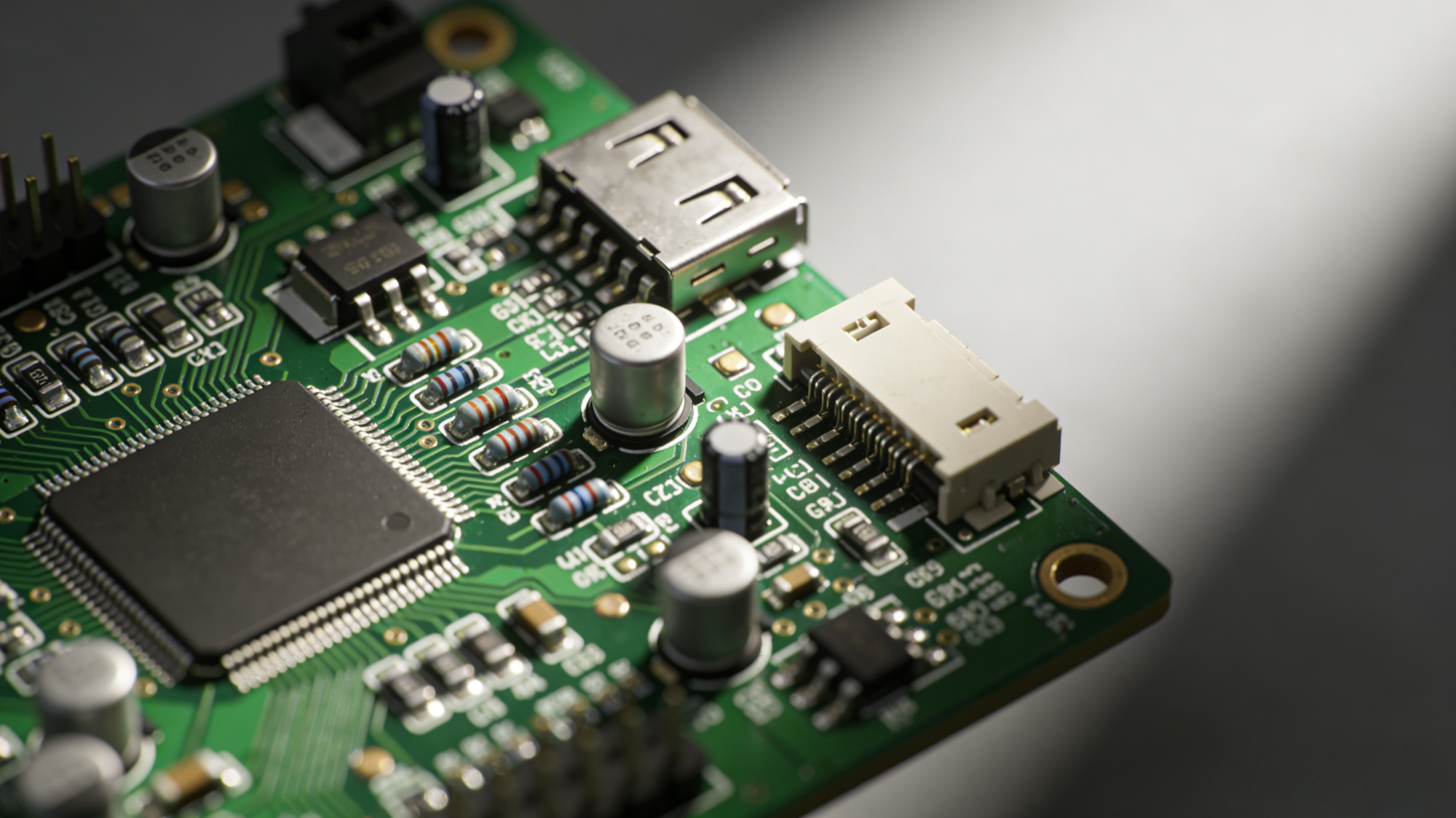

When you select a China PCBA manufacturer with ISO 9001 PCBA and IATF 16949 Automotive PCBA certifications, you gain access to proven quality management system practices. These certifications set strict standards for PCBA assembly in China, ensuring that every product meets high expectations for quality and reliability. Manufacturers with these credentials implement structured process controls and traceability, which reduce defect rates and improve production yields. For example, a global electronics company saw a 30% reduction in product defects after switching to a certified supplier. You benefit from streamlined operations, reduced wastage, and fewer costly mistakes such as product recalls. Certified PCBA assembly factories also achieve continuous improvements, aligning their processes with PCBA Quality Control Standards and business objectives.

Certified suppliers deliver products that fulfill your needs for longevity, security, usability, and efficiency. You can expect consistent quality, which leads to higher productivity, sustainability, and profitability.

Risk Reduction for Customers

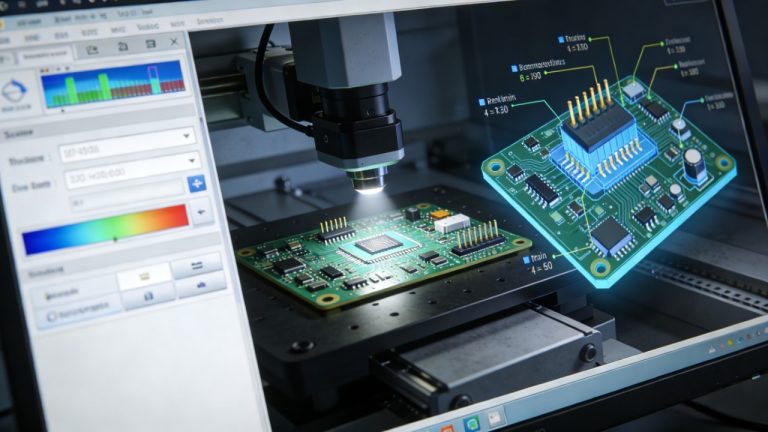

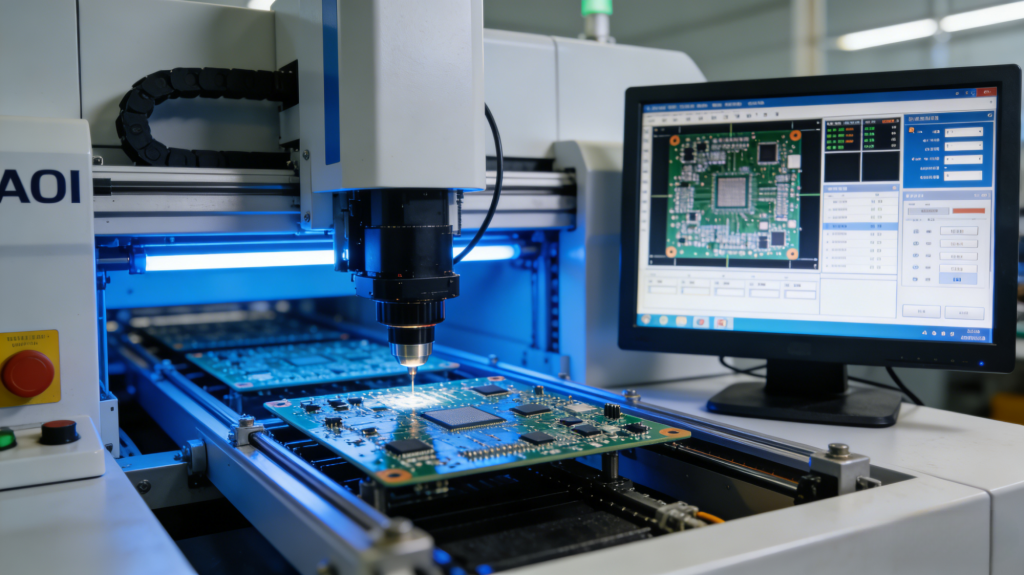

Choosing a certified China PCBA manufacturer helps you minimize risks throughout the supply chain. Certified pcba assembly factories use robust risk reduction strategies, including regular factory audits, third-party inspections, and automated optical inspection. These suppliers maintain safety stock, diversify their supplier base, and implement statistical process control. You avoid common issues found in non-certified PCBAs assembly in China, such as product defects from poor workmanship, inconsistent material quality, and defective soldering. Minimal quality checks in uncertified factories may skip essential inspections, allowing hidden defects like micro-cracks to go undetected. Certified suppliers use in-circuit testing and functional validation to ensure every product meets strict standards.

- Regular audits and continuous supplier vetting compliance protect your business from regulatory risks.

- Strategic inventory management and contingency planning safeguard your operations against disruptions.

- Certifications like ISO 9001 and IATF 16949 require strict quality control processes, minimizing risks of non-compliance and product failures.

Building Customer Confidence

Working with certified suppliers boosts your confidence in PCBA assembly in China. Top-tier manufacturers with ISO 9001 and IATF 16949 certifications report annual failure rates of 0.1% or less. Comprehensive inspections guarantee mechanical and electrical stability, while rigorous processes from planning to shipment ensure product reliability. You can rely on certified suppliers to deliver on time and meet your requirements for traceability and capabilities.

| Metric | Value |

|---|---|

| On-Time Delivery Rate | 99.59% |

| Defect Rate (DPPM) | ≤0.1% |

| Electrical Test Coverage | 100% |

You gain peace of mind knowing your supplier adheres to industry standards and maintains a well-documented quality management system. Certifications demonstrate a commitment to quality and reliability, making you more likely to choose certified pcba assembly factories for your projects. This trust translates into long-term business success and customer satisfaction.

ISO 9001 vs IATF 16949: Key Differences

ISO 9001 Scope in PCBA Manufacturing

You encounter ISO 9001 as the foundation for quality management system standards in PCBA assembly in China. This certification applies to all industries, including electronics, and sets clear expectations for process consistency, customer satisfaction, and continual improvement. When you work with PCBAs assembly factories certified to ISO 9001, you benefit from standardized production process standards that cover every stage, from design and material selection to assembly and testing. The framework helps you maintain consistent quality, minimize defects, and improve operational efficiency. You see cost savings and reduced rework, which are crucial for competitive advantage in PCBA assembly in China.

| Process Stage | Description |

|---|---|

| Design | Ensures adherence to quality standards and specifications. |

| Testing | Verifies that the PCBA meets required performance criteria. |

| Material Selection | Focuses on high-quality materials for reliability. |

| Assembly | Maintains consistency and quality across production batches. |

| Etching | Controls chemical concentrations for accurate trace widths. |

| Staff Training | Ensures personnel follow standardized protocols for quality. |

IATF 16949 for Automotive PCBA

You require IATF 16949 Automotive PCBA certification when your projects demand the highest reliability, especially in automotive applications. This standard builds on ISO 9001 PCBA but adds rigorous requirements like Advanced Product Quality Planning (APQP) and Process Failure Mode and Effects Analysis (P-FMEA). These processes help you identify and mitigate risks before mass production, ensuring defect prevention and supply chain traceability. Automotive PCBAs assembly in China must meet strict defect tolerance, often less than 10 parts per million (PPM), to guarantee safety and reliability. IATF 16949 also mandates Production Part Approval Process (PPAP) and Certificates of Conformance, which confirm that every batch meets automotive-grade standards.

| Requirement | Description |

|---|---|

| APQP | Organizes complex requirements and mitigates risks before production. |

| P-FMEA | Identifies potential failures in the manufacturing process, improving reliability. |

| PPAP Level 3 | Requires complete reports and samples for approval before mass production. |

| Certificate of Conformance (COC) | Certifies that automotive PCBAs meet customer and industry standards. |

Certification Impact on Supplier Selection

You strengthen your supplier vetting compliance by prioritizing certifications like ISO 9001 and IATF 16949. These standards demonstrate a supplier’s commitment to quality, reliability, and technical capabilities. When you select a China PCBA manufacturer with both certifications, you gain access to advanced PCBA Quality Control Standards and robust traceability systems. Suppliers with IATF 16949 certification deliver defect rates below industry benchmarks, supporting high-reliability applications. For example, automotive PCBAs assembly China suppliers often achieve PPM < 10, reflecting world-class quality and reliability. You ensure your projects meet regulatory requirements and customer expectations, reducing risk and enhancing your competitive position.

Tip: Always verify certifications and review a supplier’s capabilities in APQP, P-FMEA, and traceability to ensure they meet your project’s reliability needs.

Benefits of Certified Suppliers

Enhanced Quality Control Standards

You gain significant advantages when you choose PCBAs assembly China suppliers with recognized certifications. Certified suppliers follow strict quality management system protocols that set them apart from uncertified competitors. These suppliers use advanced tools such as DFM, automated optical inspection, and time domain reflectometer testing to ensure every board meets your requirements. Regular first article inspections confirm that each production run aligns with your expectations. The table below highlights how certified suppliers outperform non-certified ones:

| Aspect | Certified Suppliers | Non-Certified Suppliers |

|---|---|---|

| Standards | Follow international standards | Use inconsistent standards |

| Evaluations | Conduct regular audits and evaluations | Rarely perform audits |

| Compliance | Meet strict quality and safety requirements | May not comply with industry standards |

| Consistency | Deliver reliable and consistent products | Show frequent quality fluctuations |

You benefit from improved quality, optimized processes, and a clear competitive edge in the market.

Defect Prevention and Traceability

Certified PCBAs assembly China Suppliers focus on defect prevention and production traceability at every step. They qualify their suppliers, inspect incoming materials, and track each component by lot number. This approach allows you to quickly identify and isolate any issues, reducing the risk of widespread defects. Each circuit board links to its production records through unique identification codes, making it easy to trace problems and demonstrate compliance during audits. These practices are essential for meeting ISO 9001 PCBA and IATF 16949 Automotive PCBA requirements. You can trust that your products will meet the highest standards for reliability and safety.

Regulatory and Customer Requirements

You need a China PCBA manufacturer that can meet both regulatory and customer requirements. Certified PCBA assembly factories use compliance frameworks to define, measure, and repeat quality at every stage. They maintain approved vendor lists, test raw materials, and keep complete records from sourcing to final testing. This level of control ensures that every build is audit-ready and meets global standards. Certifications such as ISO 9001, IATF 16949, and others guarantee that your products will pass customer audits and regulatory inspections. You protect your brand reputation and reduce liability by working with suppliers who prioritize quality, reliability, and capabilities through robust certification and supplier vetting compliance.

How to Evaluate a Certified Supplier

Certification Verification Steps

You should always verify the authenticity of a supplier’s certifications before starting any project. Request copies of ISO 9001 and IATF 16949 certificates. Request additional documents, such as UL and RoHS certificates, to verify their validity. Review the scope and expiration dates on each certificate. Check that international accreditation organizations recognize the certifying body. Contact the issuing body directly or use their online database to confirm the certification status. This process ensures you work with a certified PCBA Supplier that meets global PCBA Supplier expectations for certification compliance and quality.

Supplier Vetting Checklist

A thorough vetting process helps you select high-quality pcba assembly partners. Use this checklist to evaluate PCBA assembly factories:

- Factory facilities and capacity

- Engineering and design support

- PCB fabrication capabilities

- Assembly capabilities

- Quality assurance systems

- Supply chain and inventory management

- Data and IP security

- Environmental, health, and safety (EHS)

You should also review the supplier’s manufacturing capabilities and PCBA Quality Control Standards. Assess their experience with ISO 9001 PCBA and IATF 16949 Automotive PCBA requirements. Confirm that they follow supplier vetting compliance protocols and maintain strong traceability systems.

Leveraging Certification for Competitive Advantage

You gain a significant advantage when you choose suppliers with dual certifications. Certification ensures adherence to strict standards, which enhances product reliability and quality. ISO 9001 certification demonstrates a commitment to continuous improvement. IATF 16949 certification shows expertise in automotive-grade requirements. Industry standards like IPC and ISO help suppliers stand out in the competitive PCB assembly China market.

Sanshun Smart serves as an example of a supplier with both ISO 9001 and IATF 16949 certifications. This dual certification gives you confidence in their ability to deliver consistent, high-quality products. You benefit from reduced risk, improved traceability, and reliable delivery from a trusted partner.

You strengthen risk mitigation and product quality when you require certifications like ISO 9001, PCBA, and IATF 16949 Automotive PCBA from PCBA assembly factories. These certifications help you achieve long-term success in PCB assembly in China.

- Enhanced credibility improves your reputation and contract opportunities.

- Increased customer satisfaction leads to repeat business.

- Improved process integration boosts efficiency.

Supplier vetting and certification verification ensure you select partners who meet PCBA Quality Control Standards and support supplier vetting compliance. These steps reduce procurement risks, improve operational efficiency, and foster lasting business relationships.

You gain a competitive edge by working with dual-certified suppliers. Ready to Partner with a Certified IATF 16949 PCBA Manufacturer? Contact Our Quality Team.

FAQ

What is the difference between ISO 9001 PCBA and IATF 16949 Automotive PCBA?

ISO 9001 PCBA covers general quality management for electronics. IATF 16949 Automotive PCBA adds stricter controls for automotive reliability, including advanced risk analysis and traceability. You need IATF 16949 for automotive or high-reliability applications.

How do PCBA Quality Control Standards benefit your project?

You receive consistent product quality, reduced defect rates, and improved reliability. These standards require regular inspections, process audits, and documentation. Your project meets industry benchmarks and passes customer audits with ease.

Why is Supplier Vetting Compliance important?

Supplier Vetting Compliance ensures you select manufacturers with proven quality systems. You avoid risks like late deliveries, poor workmanship, and regulatory issues. Verified suppliers meet certification requirements and maintain strong traceability.

How can you verify a supplier’s certifications?

Request copies of ISO 9001 PCBA and IATF 16949 Automotive PCBA certificates. Check the certifying body’s website for validity. Review expiration dates and scope. Reliable suppliers provide transparent documentation.

What makes PCBAs’ assembly in China suppliers with dual certifications stand out?

You gain access to advanced quality management, robust traceability, and lower defect rates. Dual-certified suppliers meet global standards and deliver reliable products for demanding industries.