You face high stakes in PCBA contract manufacturing. Even a single flaw can compromise an entire product line, risking costly recalls and damaged reputations. ISO 9001 stands as the gold standard for minimizing these risks. By adopting this quality management system, you benefit from:

- Rigorous testing that reduces defects

- Reliable processes that ensure product consistency

- Strong controls that support regulatory compliance

ISO certification gives you confidence in both product quality and manufacturing reliability.

Why ISO 9001 is Critical for Risk Mitigation in PCBA Contract Manufacturing

- ISO 9001 certification minimizes risks in PCBA manufacturing by enforcing rigorous quality management standards.

- Standardized workflows and thorough documentation reduce defects and ensure consistent product quality.

- Traceability of components enhances accountability and supports quick corrective actions in case of defects.

- Continuous improvement practices lead to operational efficiency, reducing waste and enhancing customer satisfaction.

- Choosing an ISO-certified manufacturer builds trust with stakeholders and opens new market opportunities.

ISO Certification in PCBA Contract Manufacturing

Quality Management System Overview

You rely on a robust quality management system to ensure every step in PCBA contract manufacturing meets strict standards. ISO 9001 provides a framework that guides you in establishing, maintaining, and improving these systems. This certification requires you to implement essential quality management principles tailored to your operations. The process involves a two-phase audit and demands continual improvement every three years. ISO 9001 standards help you focus on meeting requirements, adding value, and achieving business objectives. You benefit from a cyclical approach known as the PDCA method, which promotes ongoing risk management and process enhancement.

| Aspect of ISO 9001 | Description |

|---|---|

| PDCA Method | A cyclical process that promotes continuous improvement and risk management. |

| Quality Management Levels | Focuses on meeting requirements, adding value, achieving business objectives, and improving processes based on data. |

Standardized Workflows and Controls

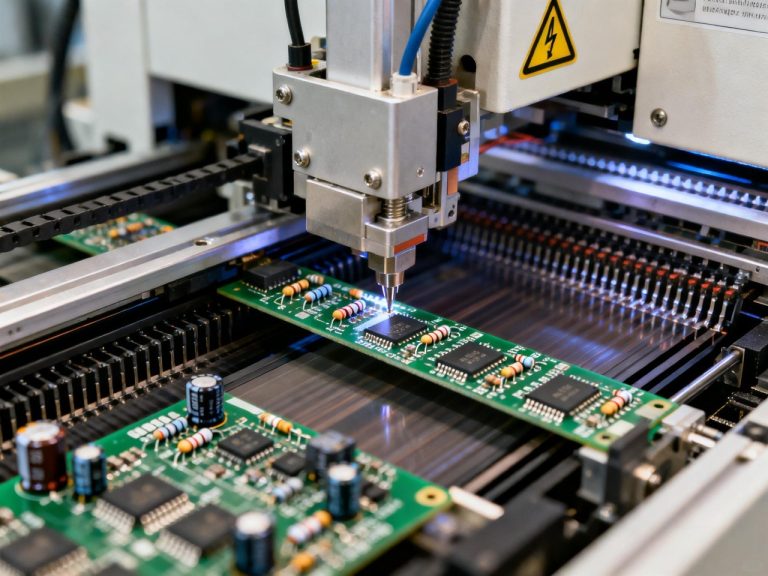

ISO certification enforces standardized workflows and process controls from component sourcing to final inspection. You document and standardize each process, reducing defects and ensuring consistency. The system mandates thorough planning, supplier quality management, in-process quality control, advanced testing techniques, continuous training, and regular audits. These controls minimize process variation and improve audit reliability.

| Aspect | Description |

|---|---|

| Quality Management System (QMS) | Establish, implement, maintain, and improve a QMS to ensure compliance and quality consistency. |

| Customer Focus | Engage with clients to understand and meet their requirements, minimizing misunderstandings. |

| Standardized Processes | Document and standardize processes to ensure consistency and reduce defects in production. |

| Risk-Based Management | Identify and assess risks to proactively address potential issues affecting quality and delivery. |

| Continuous Improvement | Systematically monitor and improve processes through audits, performance analysis, and feedback. |

| Documentation and Records | Maintain documented procedures and records for transparency and accountability in the manufacturing process. |

Companies with well-documented process criteria reduce audit errors by 22%. Organizations implementing measurable checkpoints see process variation drop by 18%. Businesses increasing audit frequency in critical processes experience a 20% reduction in defect-related losses. Firms using structured audit checklists report a 31% improvement in audit reliability.

Role in PCB Assembly and EMS Providers

ISO 9001 certification plays a vital role for PCBA assembly and EMS providers. You enforce rigorous process controls and quality assurance protocols, standardize manufacturing steps, and conduct comprehensive inspections. ISO ensures traceability of components from vendor to finished product. Regulatory bodies and industry associations recognize ISO as essential for establishing trust and reliability in manufacturing. You gain access to new markets and demonstrate a commitment to high quality, reliability, and compliance.

| Benefit | Description |

|---|---|

| High Product Quality | Ensures that products meet specifications and regulatory standards, leading to customer satisfaction. |

| Reduced Defects | Establishes quality control systems that minimize errors and variability in production. |

| Improved Operational Reliability | Streamlines operations, enhancing efficiency and reducing downtime and waste. |

| Enhanced Customer Confidence | Certification demonstrates accountability and transparency, assuring customers of product reliability. |

You ensure consistent product quality, enhance customer satisfaction, and provide a framework for continual improvement. ISO certification is not just a paper certificate; it is a comprehensive system that drives excellence in every aspect of PCBA contract manufacturing.

Benefits of an ISO-Certified Manufacturer

Traceability and Component Tracking

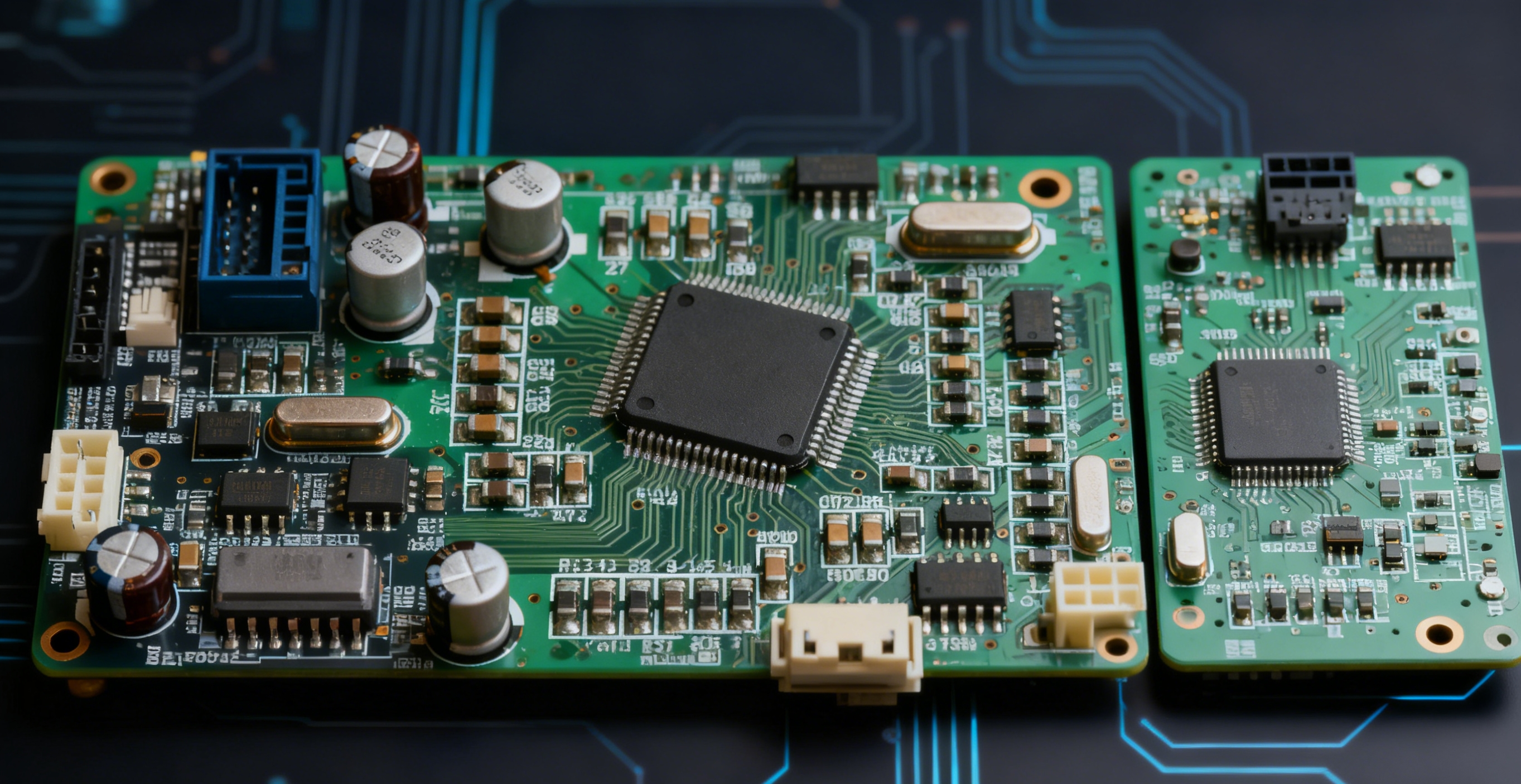

You gain a significant advantage when you choose PCBA contract manufacturing with an iso-certified manufacturer. Traceability stands as a cornerstone of quality control processes. Every component in your assembly receives a unique identifier, such as a serial number or barcode, at each stage of production. This system allows you to track electronic parts from supplier receipt through storage, assembly, and final dispatch. You can trace components both forwards and backwards, ensuring you know the exact origin and history of every part.

| Clause | Description |

|---|---|

| 8.5.2 | Outputs must be correctly identified and recorded at each stage. Documentation supports traceability throughout the lifecycle. |

| Clear Processes | ISO 9001:2015 requires systematic documentation from supplier receipt to dispatch. Electronic components must be traceable in both directions. |

| Root-Cause Analysis | Thorough traceability enables you to pinpoint the source of defects quickly, empowering rapid corrective actions and strengthening quality control processes. |

You benefit from industry best practices, including:

- Maintaining detailed records for every step in the PCB assembly process, including specifications, supplier details, and batch numbers.

- Documenting processes and focusing on continuous improvement.

- Using traceability to support root-cause analysis and corrective actions.

This level of transparency and accountability ensures you meet compliance requirements and maintain high product quality.

Consistent Product Quality

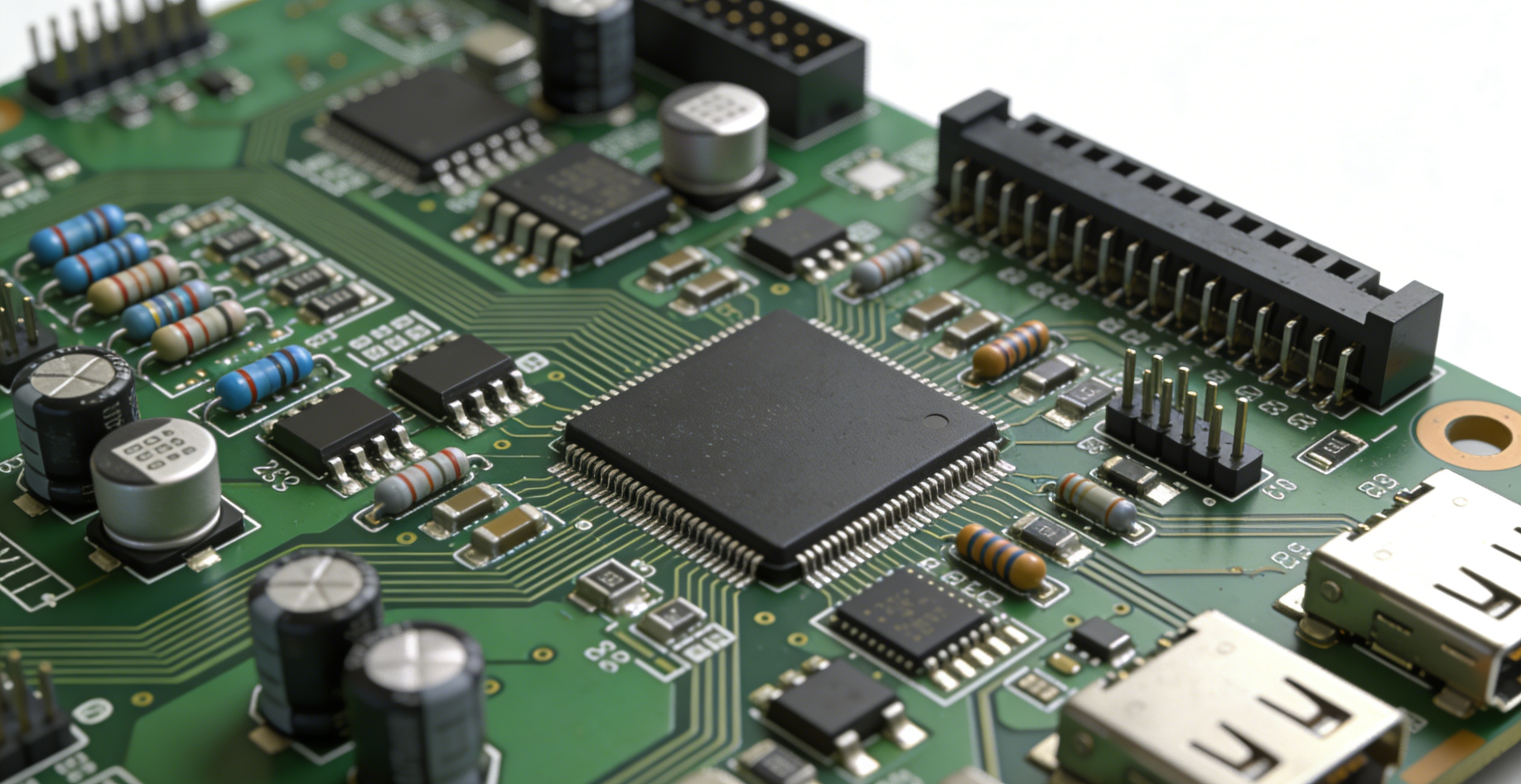

You expect every batch to meet the same high standards. Iso-certified manufacturing services deliver consistent product quality by implementing rigorous quality control processes. You see planning and project definition at the outset, followed by product and process design, validation, and ongoing feedback. Automated Optical Inspection (AOI) systems use high-resolution cameras to detect defects, while X-ray inspection examines hidden components and solder joints. These advanced tools ensure that every PCBA meets strict specifications.

You rely on a robust Quality Management System (QMS) that reduces defects and enhances customer satisfaction. The QMS covers:

- Planning and defining the project

- Product design and development

- Process design and development

- Product and process validation

- Feedback, assessment, and corrective action

You benefit from measurable results, efficient auditing, and clear processes that eliminate gaps in rules. The commitment to quality assurance and quality control processes ensures you receive reliable, high-performing products every time.

| Benefit | Description |

|---|---|

| Customer Satisfaction | Your manufacturing partner focuses on exceeding your needs, not just meeting basic requirements. |

| Consistent Compliance | You see proof that statutory, regulatory, and customer requirements are met every time. |

| Workforce Training | Employees receive complete training to understand and uphold company standards. |

| Measurable Results | You can easily identify inefficiencies and areas for improvement. |

| Efficient Auditing | Errors are resolved swiftly through quick and effective auditing processes. |

Risk Management and Defect Prevention

You minimize risks and prevent defects by partnering with iso-certified electronic manufacturing services. ISO 9001 requires you to identify and understand potential failure modes, assign risk priority numbers, and implement targeted strategies. You use process improvements, design changes, and material modifications to reduce risks proactively.

You follow best practices such as:

- Identifying and understanding failure modes

- Prioritizing failure modes based on impact

- Choosing strategies for process improvement, design changes, or material modifications

You benefit from design for manufacturing (DFM) reviews, high-quality material selection, and standardized process control. Comprehensive final inspection and testing verify functionality and catch defects before shipping. You track production metrics, such as defect rates and solder joint quality, and use automated inspection systems to detect issues early. Maintaining detailed records supports traceability and corrective actions.

You see measurable benefits, including:

- Consistent quality management systems

- Adherence to industry standards for safety, performance, and regulatory compliance

- Continuous improvement and process control

- Enhanced customer satisfaction and product quality

Choosing an iso-certified manufacturer demonstrates a commitment to quality control processes, quality assurance, and compliance with international standards. You receive reliable PCBA contract manufacturing, reduced risk, and consistent product quality.

Ready to experience the benefits of iso-certified manufacturing services? Visit Sanshun Smart’s website to request a quote or learn more about their quality control processes and commitment to excellence in PCBA contract manufacturing.

Efficiency and Trust in PCBA Contract Manufacturing

Streamlined Operations

You need efficient operations to stay competitive in PCBA contract manufacturing. ISO certification transforms your workflow by validating your quality management system and promoting a systematic approach to every process. You see improvements in repeatability, cost reduction, and product quality. The PDCA cycle encourages you to adopt best practices and identify areas for enhancement. You streamline your operations, reduce waste, and ensure every department communicates effectively.

| Aspect | Contribution to Streamlined Operations |

|---|---|

| Quality Management Systems | Validates the QMS of a manufacturing company |

| Consistent High Quality | Ensures products and services meet customer requirements |

| Customer Focus | Emphasizes strong customer focus for better satisfaction |

| Top Management Involvement | Encourages leadership engagement in quality processes |

| Process Approach | Promotes a systematic approach to operations |

| Continual Improvement | Drives ongoing enhancements in processes and efficiency |

You benefit from enhanced efficiency across the entire manufacturing process. Standardized procedures guarantee consistent outcomes, while improved employee performance tracking supports targeted training and development. You achieve compliance with industry standards and regulations, which protects your business and your customers.

Building Stakeholder Trust

You build trust with stakeholders by demonstrating your commitment to quality and operational excellence. ISO certification provides external validation that your company meets global standards. Major electronics brands prefer working with manufacturers who hold ISO certification because it assures them of reliability and innovation. You foster long-standing partnerships by consistently delivering high-quality products and maintaining compliance with safety and reliability standards.

- ISO certification enhances your credibility in the marketplace.

- Stakeholders recognize your dedication to quality and efficiency.

- You reduce risks and boost customer satisfaction through proven processes.

Sanshun Smart’s ISO Approach

You gain a strategic advantage when you choose Sanshun Smart for PCBA contract manufacturing. Sanshun Smart integrates ISO 9001:2015 standards into daily production, ensuring high-yield results and reliable service. You benefit from their commitment to continual improvement, robust quality management, and transparent communication. Their approach guarantees consistent product quality and operational efficiency.

Experience the difference with Sanshun Smart’s ISO-certified PCBA services. Visit their website to request a quote or learn more about their quality control process.

You gain strategic advantages when you choose an ISO-certified PCBA manufacturer. You see measurable improvements in product quality, compliance, and operational efficiency. The table below highlights key outcomes:

| Outcome Type | Description |

|---|---|

| Quality Improvement | Compliance with safety standards leads to enhanced product safety and reliability. |

| Compliance Advantage | Adhering to international standards opens new market opportunities and avoids penalties. |

| Brand Reputation | Meeting stringent standards enhances consumer trust and brand reputation. |

You benefit from proven quality management, risk reduction, and customer confidence. Request a quote from Sanshun Smart to experience reliable PCBA services and learn more about their quality control process.

FAQ

What is ISO 9001, and why does it matter in PCBA contract manufacturing?

ISO 9001 sets the standard for quality management systems. You gain confidence in your manufacturing partner’s ability to deliver consistent, reliable products that meet industry requirements.

How does ISO certification improve traceability in PCBA production?

You benefit from detailed tracking of every component. ISO certification requires you to document each step, making it easy to trace parts from suppliers to finished assemblies.

Can ISO-certified manufacturers help reduce defects?

Yes. You see fewer defects because ISO-certified manufacturers follow strict process controls and continuous improvement practices. This approach leads to higher product quality and fewer production errors.

Does ISO certification affect delivery times?

You experience more predictable delivery schedules. ISO-certified processes streamline operations, reduce delays, and help you receive products on time.

Why should I choose an ISO-certified PCBA partner?

You ensure compliance, quality, and reliability. ISO-certified partners demonstrate a commitment to best practices, giving you peace of mind and a competitive edge.