Certifications provide essential proof that an SMT PCBA meets internationally recognized standards for quality, safety, and regulatory compliance. When an SMT PCBA lacks proper certification, it introduces serious risks throughout the product lifecycle, including:

- Poor traceability of components and materials

- Increased likelihood of counterfeit or non-compliant parts

- Legal and regulatory exposure in global markets

- Higher failure rates, recalls, and production delays

Third-party certifications validate that an SMT PCBA conforms to strict requirements across design, assembly, testing, and environmental compliance—protecting both product performance and brand reputation.

SMT PCBA Certification Essentials: Key Takeaways for Quality, Safety, and Compliance

- Certifications demonstrate that an SMT PCBA complies with recognized industry standards, reducing quality and regulatory risks.

- Certified SMT PCBAs consistently achieve lower defect rates and longer service life.

- Compliance with RoHS and REACH protects products from legal barriers in global markets.

- Standards such as ISO 9001, IPC-A-610, and IATF 16949 establish measurable benchmarks for SMT PCBA quality and reliability.

- Certification verification is essential to prevent misleading or fraudulent claims.

Why SMT PCBA Certifications Matter

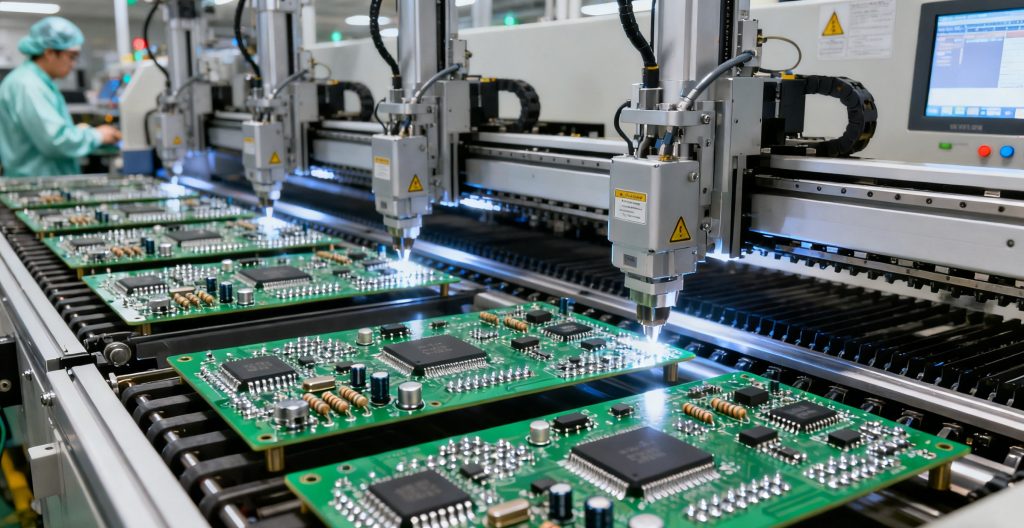

Ensuring Quality and Reliability

An SMT PCBA is the functional core of any electronic product. Even a single assembly defect can compromise system reliability, trigger recalls, or damage customer trust. Certifications ensure that SMT PCBAs are produced, inspected, and validated against well-defined criteria rather than subjective judgment.

Certified SMT PCBAs typically demonstrate:

- Verified electrical and mechanical performance under real-world conditions

- Stable solder joint quality and component placement accuracy

- Consistent process control supported by documented inspection data

- Continuous improvement driven by standardized quality systems

- By meeting recognized certification requirements, SMT PCBAs deliver predictable performance and reduced failure risk across applications.

Meeting Global Market Standards

Different regions impose different compliance requirements on electronic assemblies. Certified SMT PCBAs are designed and validated to meet these regional expectations, enabling smoother market entry and reduced regulatory risk.

| Region | Certification Requirements | Focus Areas |

| Europe | CE, RoHS, REACH | Environmental safety and product compliance |

| North America | UL, FCC | Electrical safety and EMC performance |

| Asia | JIS, KC | Product consistency and long-term reliability |

Essential Certifications for SMT PCBA

ISO 9001 – Quality Management Foundation

ISO 9001 establishes the baseline quality management framework that governs how SMT PCBAs are produced, inspected, and improved over time. It emphasizes process consistency, risk-based thinking, and data-driven decision-making.

Key benefits for SMT PCBA include:

- Reduced variability across production batches

- Documented process control from material input to final inspection

- Lower defect rates through preventive quality planning

- Continuous optimization of assembly and inspection processes

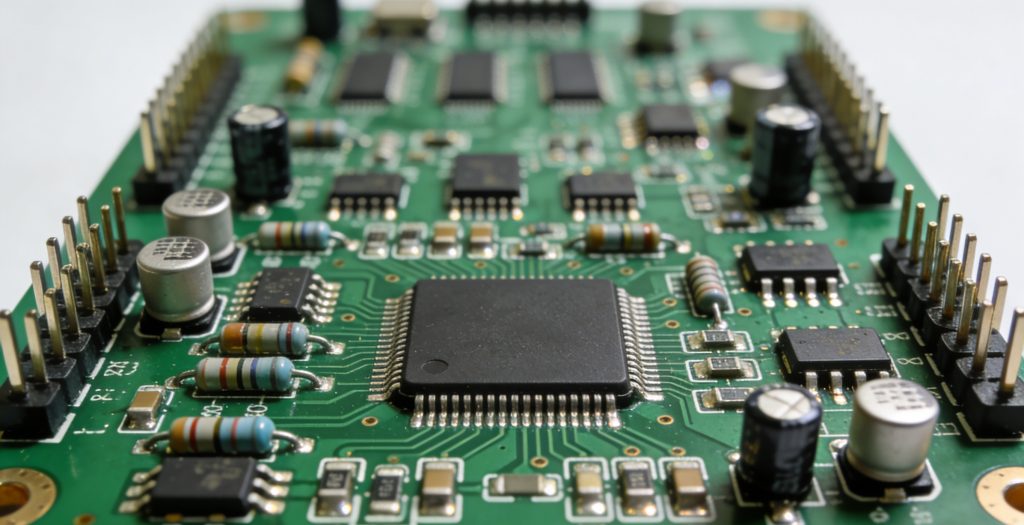

IPC-A-610 – Acceptability of Electronic Assemblies

IPC-A-610 defines workmanship standards for SMT PCBA soldering, assembly quality, cleanliness, and marking. It classifies assemblies into reliability levels based on application criticality.

Class 2: General electronics with stable functional requirements

Class 3: High-reliability electronics where failure is unacceptable

Compliance ensures that SMT PCBAs meet objective acceptance criteria rather than subjective visual inspection alone.

IATF 16949 – Automotive-Grade SMT PCBA

For automotive applications, SMT PCBAs must meet IATF 16949 requirements, which extend ISO 9001 with stricter controls for safety, traceability, and defect prevention.

This certification ensures:

- Robust risk analysis through FMEA

- Statistical process control for assembly consistency

- Lifecycle traceability from materials to finished PCBA

UL Certification – Electrical Safety

UL certification confirms that SMT PCBAs meet fire resistance, insulation, and electrical safety requirements, particularly for North American markets.

Certified SMT PCBAs undergo:

- Material flammability validation

- Thermal and environmental stress testing

- Documentation and marking verification

The UL mark enhances product safety credibility and market acceptance.

RoHS and REACH Compliance – Environmental Responsibility

RoHS and REACH ensure that SMT PCBAs do not contain restricted or hazardous substances beyond permitted thresholds.

- RoHS limits specific hazardous materials at the homogeneous level

- REACH mandates disclosure of Substances of Very High Concern (SVHCs)

Compliance supports legal market access while aligning products with sustainability expectations.

ISO 13485 – Medical-Grade SMT PCBA

For medical devices, ISO 13485 imposes strict documentation, traceability, and risk management requirements.

Certified medical SMT PCBAs demonstrate:

- Full process validation

- Detailed documentation and record control

- Strong risk management and traceability systems

These attributes are critical for regulatory approval and patient safety.

CE and FCC Compliance – Market Access

CE and FCC compliance confirm that SMT PCBAs meet electromagnetic compatibility and safety requirements for EU and US markets.

- CE addresses both emissions and immunity

- FCC focuses on emissions control

Compliance enables lawful distribution and reinforces product reliability.

How to Verify SMT PCBA Certifications

Checking Certificate Validity

Certification claims should always be verified through:

- Original certification documents

- Issuing body databases or third-party validation services

- Confirmation that certificates apply to the actual production site

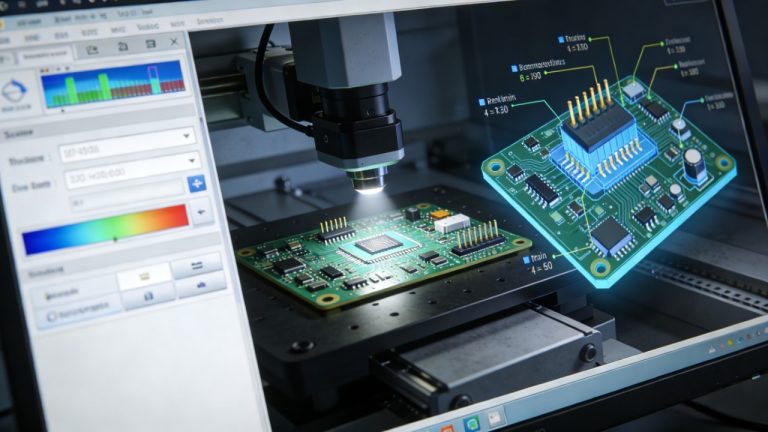

Inspection records such as AOI, X-ray, ICT, and functional testing further validate compliance.

Avoiding Fraudulent Claims

To protect product quality and compliance:

- Review documentation for consistency and traceability

- Inspect materials and labeling during incoming inspection

- Validate assemblies using electrical and functional testing

- Be cautious of unrealistic pricing or unsupported claims

Certified SMT PCBAs are supported by transparent documentation—not marketing statements.

Certification Impact on SMT PCBA Quality and ROI

Reducing Failures and Returns

Certified SMT PCBAs consistently show:

- Lower failure rates

- Reduced RMAs and warranty costs

- Predictable quality performance

These outcomes directly improve the total cost of ownership.

Enhancing Product Reputation

Certification signals reliability to procurement teams, engineers, and regulators. Products built on certified SMT PCBAs gain stronger market acceptance, reduced compliance risk, and improved long-term brand value.

Commitment to Quality: Sanshun Smart

Our PCBA Certifications

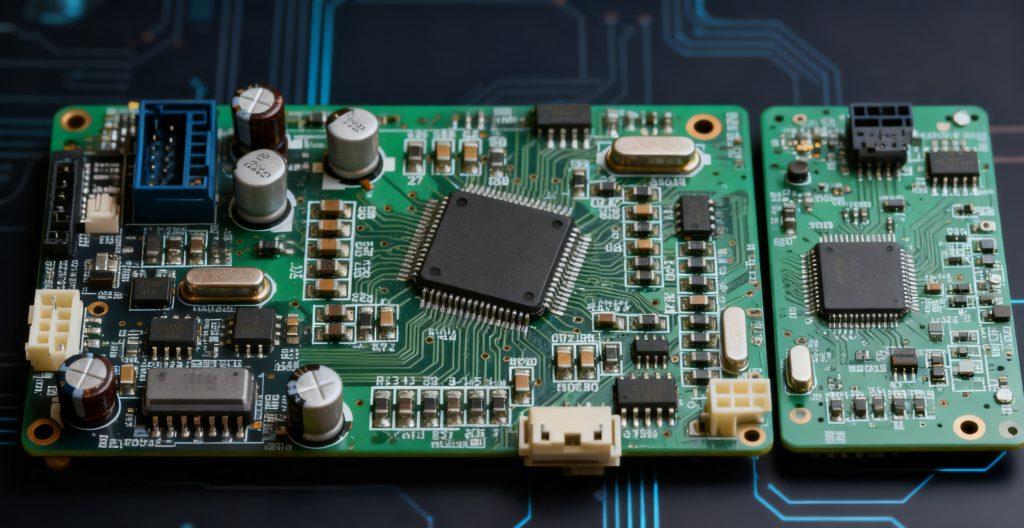

You want to work with an SMT PCBA manufacturer that meets global standards. Sanshun Smart holds all essential certifications that prove its commitment to quality and compliance. You can trust Sanshun Smart to deliver ISO 9001-certified PCBA, IATF 16949 automotive electronics, UL certification for PCB, and full RoHS and REACH compliance. These certifications ensure every assembly meets strict requirements for safety, reliability, and environmental protection.

FAQ – SMT PCBA Certifications

Q1: Why are certifications important for SMT PCBA?

They provide objective proof that the SMT PCBA meets recognized quality, safety, and regulatory standards.

Q2: Does IPC-A-610 apply to all SMT PCBA types?

Yes, but the required class (Class 2 or Class 3) depends on application reliability needs.

Q3: Is RoHS compliance mandatory worldwide?

It is mandatory in many regions and increasingly expected even where not legally required.

Q4: Can SMT PCBA be certified without ISO 9001?

Some standards may still apply, but ISO 9001 forms the foundation for consistent quality control.

Q5: How can certification authenticity be verified?

Through original documents, issuing bodies, and independent validation services.