You’re staring at a malfunctioning refrigerator control board worth $15,000. Production halted. Holiday shipments slipping. That knot in your stomach? We know it well. But here’s the truth: professional PCBA rework services aren’t just a repair option—they’re your strategic lifeline to slash replacement costs, eliminate weeks of downtime, and protect your brand’s reputation. For appliance manufacturers, automotive electronics teams, and industrial equipment builders, expert BGA recovery transforms crisis into continuity. Keep reading—because choosing the wrong path could cost far more than the board itself.

Why Professional PCBA Rework Services Are Essential for High-Value Boards?

This guide delivers actionable insights for engineers and operations leaders facing critical board failures across home appliances, automotive electronics, industrial automation, and smart consumer devices. We expose DIY pitfalls, reveal the 7 critical requirements of elite appliance PCBA repair services, share verified recovery cases (including automotive and industrial examples), and provide design strategies to prevent repeat failures—all grounded in real-world manufacturing experience.

Understanding BGA Rework: Precision Repair for Appliance, Automotive & Industrial Control Boards

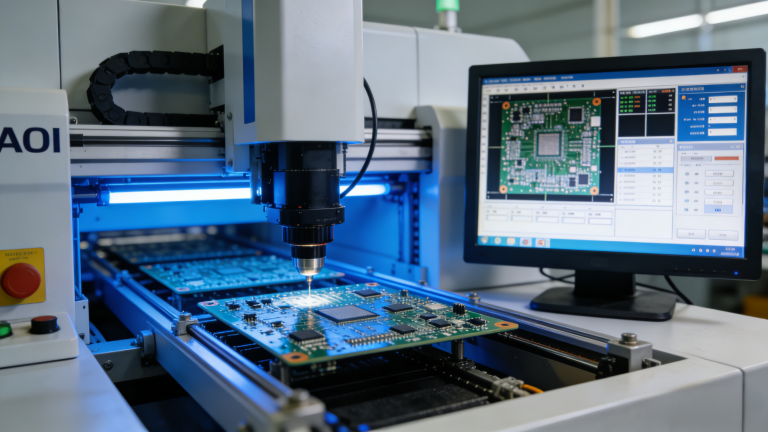

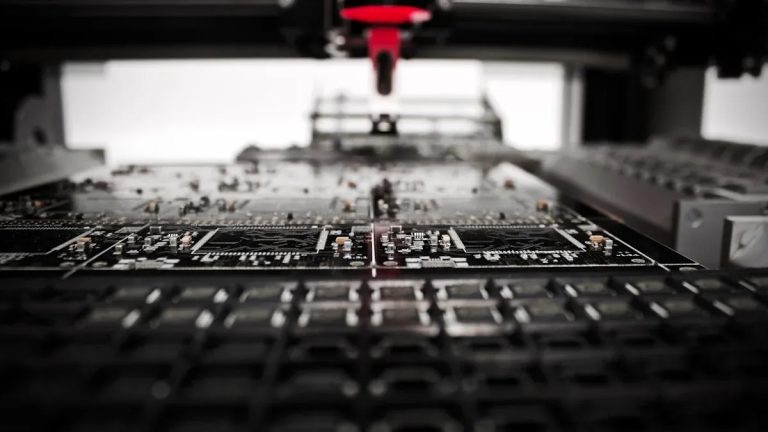

BGA rework demands surgical precision, especially for high-density boards in modern refrigerators, washing machines, EV battery management systems, and industrial PLCs. Today’s appliance control boards pack BGAs with pitches under 0.4mm—requiring specialized precision soldering techniques and nitrogen-controlled reflow environments. Amateur attempts using basic hot-air stations cause thermal shock, lifted pads, or hidden solder voids. Without rigorous thermal profiling and AXI validation, even a “successful” visual repair fails under real-world thermal cycling. That’s why IPC-certified PCBA repair protocols form the non-negotiable foundation of reliable recovery.

Why DIY BGA Repair Fails Without Professional PCBA Rework Services?

Attempting DIY BGA repair on critical appliances or automotive PCBAs often triggers cascading failures. Generic reflow profiles ignore component-specific thermal curves. Missing AXI validation leaves micro-cracks undetected. Without thorough board failure analysis, the same defect recurs. Here’s what truly separates risk from recovery:

| DIY Attempt Risk | Expert PCBA Rework Solution | Real Impact |

|---|---|---|

| Uncontrolled heating damages nearby sensors/LEDs | Localized nitrogen reflow with real-time thermal profiling | Prevents collateral damage to sensitive components |

| No pre/post AXI imaging | Full 2D/3D X-ray documentation per IPC standards | Catches hidden voids or bridging before deployment |

| Guesswork on failure origin | Detailed board failure analysis report with design feedback | Reduces repeat failures by 40%+ through actionable insights |

A major white goods manufacturer learned this the hard way: an internal rework attempt on a premium refrigerator control module caused substrate delamination. Replacement cost: 14,000.Downtime:6weeks.Expertrecoverywouldhavecostunder2,500 with full functional validation.

7 Non-Negotiables for IPC-Certified PCBA Rework Services

Demand these essentials when sourcing urgent automotive PCBA recovery service or industrial board repair:

- IPC-A-610/7711 certified technicians performing every reballing task

- Pre- and post-rework AXI validation to verify solder joint integrity

- Component-specific thermal profiling using nitrogen reflow systems

- Authentic component sourcing with full traceability documentation

- Functional testing under real operating conditions (compressor cycling, motor load tests)

- Clear chain-of-custody records for quality audits

- Actionable root-cause reports to improve future board designs

Missing even one—like skipping thermal profiling—risks pad cratering or latent defects that surface after shipment. In appliance manufacturing, that means field failures, warranty claims, and brand damage.

PCBA Rework Services Case Study: 0.4mm Pitch BGA Repair for Refrigerator Control Boards

Challenge: Failed BGA on a 14,000smartrefrigeratorcontrolmodule(0.4mmpitch).OEMleadtime:6weeks.Productionloss:5,000/day.

Solution:

- 3D AXI scan pinpointed micro-cracks in BGA solder joints

- Precision reballing with 0.15mm pitch tools under a nitrogen atmosphere

- Thermal profile matched original design specifications

- Full functional validation, including compressor cycling tests

Result:

✅ $12,000 saved vs. replacement

✅ Board returned in 5 days—not 6 weeks

✅ Zero field failures post-deployment

✅ Report used to refine future thermal design

Automotive PCBA Recovery: Urgent BGA Repair for EV Systems

Challenge: Failed BGA on an EV battery management board ($8,500 value). Standard shops refused due to complexity and automotive-grade requirements.

Solution: SanShun Smart executed an urgent automotive PCBA recovery service with automotive-specific validation protocols, including vibration testing and thermal cycling per automotive standards.

Result: $7,200 saved, board returned in 4 days, zero field issues.

Industrial Control Board Emergency Repair: Minimizing Downtime

Challenge: Critical PLC control board ($11,000) failed during peak production.

Solution: High-value PCBA emergency recovery initiated within 2 hours. Precision rework with industrial-grade validation under 24/7 operational stress simulation.

Result: Operations restored in 72 hours. Full documentation provided for audit compliance.

Choosing the Right IPC-Certified PCBA Repair Service: A Vetting Guide

Ask these questions before sharing your board for industrial board repair:

- “Can you share IPC certification numbers for your rework technicians?”

- “Do you provide AXI reports before and after rework per IPC-7711?”

- “What’s your first-pass yield on 0.4mm pitch BGAs for appliance or automotive boards?”

- “How do you validate functionality for refrigeration, motor-control, or automotive circuits?”

Red flags: Vague answers, no sample reports, and reluctance to discuss board failure analysis. Trust is built on transparency—not promises.

Why SanShun Smart Delivers Precision PCBA Rework Services for Real-World Applications

When your refrigerator, EV component, industrial controller, or smart home device board fails, you need a partner who speaks your language. SanShun Smart operates a 30,000㎡ Qingdao facility with 60+ in-house engineers and deep expertise across home appliances, automotive electronics, industrial automation, and consumer IoT. Our integrated workflow—from SMT assembly to precision rework—ensures seamless recovery:

- Powered Haier’s Casarte refrigerator series with reliable control board solutions

- Supported automotive Tier-1 suppliers with EV battery management board recovery

- Maintain strict component traceability and IPC-certified PCBA repair protocols

- Provide actionable design feedback to prevent repeat failures

Your 4-Step Recovery Action Plan

- Diagnose: Capture AXI images immediately—don’t power-cycle repeatedly

- Document: Note operating conditions when failure occurred (temperature, load)

- Partner: Engage a specialist like SanShun Smart with industry-specific experience

- Prevent: Apply root-cause insights to future board designs

Time is costly. Every hour of downtime compounds losses.

Smart Design Practices to Minimize Future BGA Failures

Prevention starts at the drawing board with design-for-rework principles:

- Specify 0.5mm+ BGA pitches where space allows for easier rework access

- Integrate thermal relief pads around high-stress components

- Document exact thermal profiles used during initial assembly

- Select components with MSL ratings under 3

- Collaborate early with your rework partner on design feedback

SanShun Smart’s engineering team helped a leading refrigerator brand reduce field BGA failures by 55% through these collaborative refinements—proving that recovery expertise strengthens future production.

Frequently Asked Questions About PCBA Rework Services

Q: What is the cost of the urgent automotive PCBA recovery service?

A: Typically 15–30% of board value. For an 8,500EVcontrolboard,expect1,275–$2,550—saving over 85% versus replacement through professional PCBA rework services.

Q: Can BGA rework be performed on obsolete industrial boards with legacy components?

A: Absolutely. Our industrial board repair process specializes in obsolete components. We source authentic replacements and validate functionality per original specs—even for boards 10+ years old.

Q: How does thermal profiling prevent damage during high-value PCBA emergency recovery?

A: Component-specific thermal profiling ensures heating stays within safe limits for the BGA and surrounding components, preventing pad cratering, substrate delamination, or collateral damage to sensors and LEDs.

Q: What distinguishes IPC-certified industrial board repair from standard repair shops?

A: True IPC-certified PCBA repair follows IPC-7711/7721 procedures with documented thermal profiles, AXI validation, and certified technicians. Standard shops often lack equipment, training, or validation protocols—increasing failure risk.

Q: What is the turnaround time for high-value PCBA emergency recovery?

A: SanShun Smart offers a 2-hour triage for critical failures. Most boards return in 3–10 business days with full validation documentation.

Stop letting failed boards derail your production schedule.

When every hour counts and brand reputation is on the line, trust SanShun Smart—your precision partner for appliance, automotive, industrial, and consumer electronics recovery. With IPC-certified workflows, full AXI validation, and deep industry experience, we turn high-stakes failures into proven recoveries.

👉 Download Your Free High-Value PCBA Recovery Checklist

👉 Request Urgent Assessment – Get a recovery plan within 2 hours

SanShun Smart: Where engineering excellence meets real-world reliability. Trusted by global appliance leaders and automotive innovators for precision pcba rework services that protect your products, timeline, and reputation.