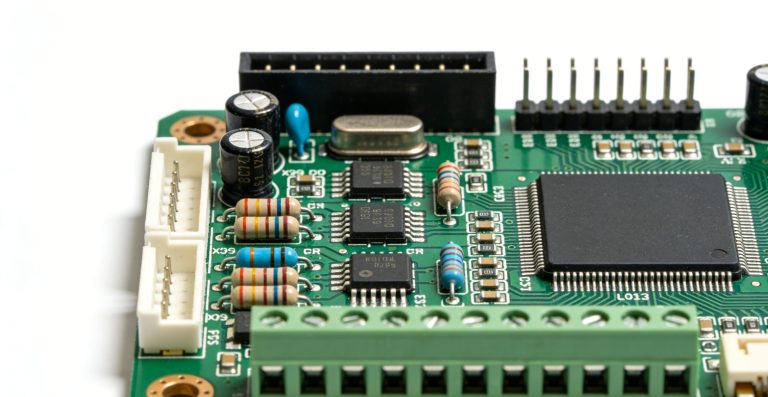

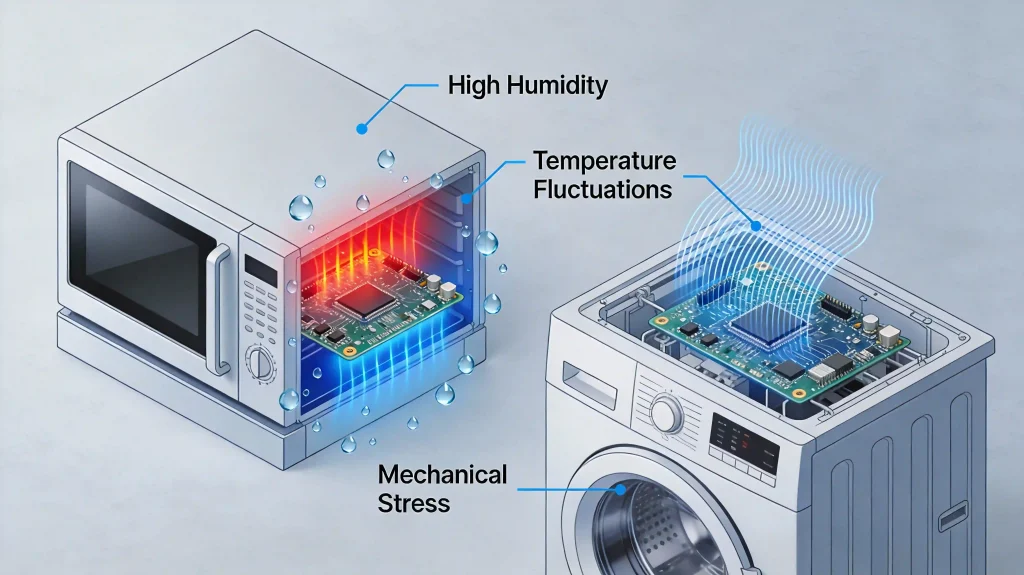

In today’s competitive home appliances market, PCBA services play a critical role in determining the reliability and performance of kitchen and laundry appliances. These appliances operate in harsh environments with high humidity, temperature fluctuations, and mechanical stress, demanding PCBA solutions that can withstand these challenges while maintaining consistent performance.

Market Trends and Demand for High-Reliability PCBA Services

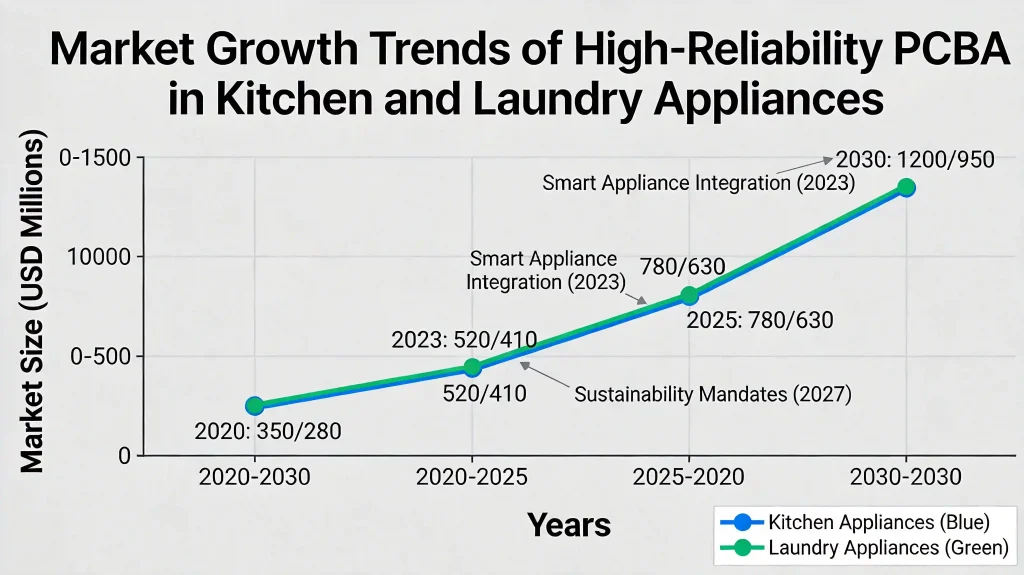

The global kitchen and laundry appliances market is projected to reach $325 billion by 2030, growing at a CAGR of 5.2%. With consumers increasingly seeking durable and long-lasting appliances, the demand for high-reliability PCBA services has surged. According to a 2025 report by the National Association of Home Builders, 78% of consumers prioritize appliance longevity when making purchase decisions, directly driving the need for robust PCBA solutions.

Figure 1: Professional business chart showing market growth trends in high-reliability PCBA for kitchen and laundry appliances

The rising adoption of smart features in kitchen and laundry appliances has further increased the complexity of PCBA design services. Smart refrigerators, dishwashers, and washing machines require PCBA that can support advanced connectivity, sensor integration, and real-time data processing, all while maintaining reliability in challenging environments.

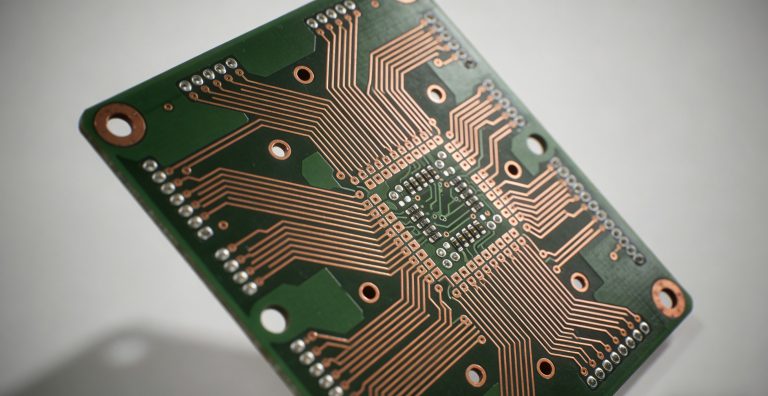

Key Challenges in PCBA Design for Kitchen and Laundry Appliances

Kitchen and laundry appliances present unique challenges for PCBA services due to their operating environments. High humidity in dishwashers and washing machines can cause corrosion and short circuits, while temperature fluctuations in ovens and refrigerators can affect component performance. Mechanical stress from vibration during spin cycles can also lead to solder joint fatigue and component failure.

Figure 2: Business scene showing challenges faced by PCBA in kitchen and laundry appliances including high humidity, temperature fluctuations, and mechanical stress

Warranty claims due to PCBA failures cost the home appliances industry an estimated $8.7 billion annually. A 2025 study by JD Power found that 32% of appliance warranty claims were related to electronic component failures, highlighting the critical need for high-reliability PCBA services.

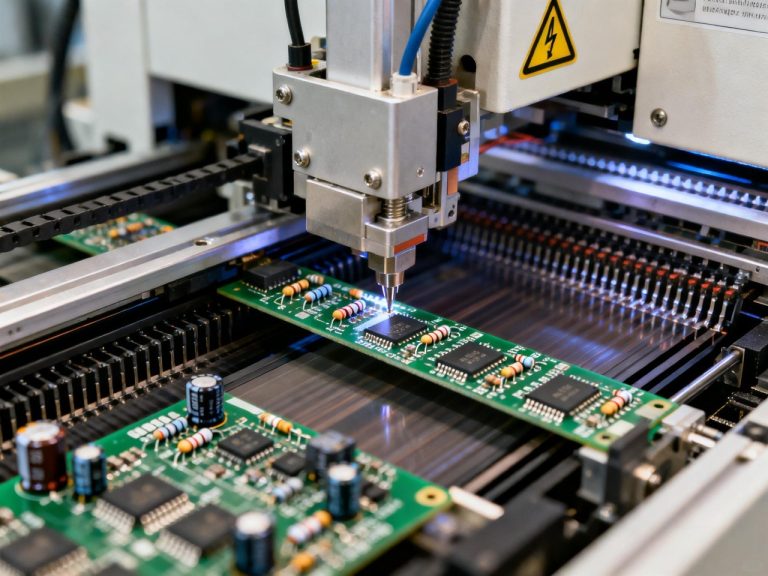

Solutions for High-Reliability PCBA in Home Appliances

To address these challenges, PCBA services providers must implement specialized design and manufacturing practices tailored for kitchen and laundry appliances. Key solutions include:

- Conformal Coating: Applying a protective coating to PCBA to prevent moisture ingress and corrosion, which is particularly critical for dishwashers and washing machines operating in high-humidity environments.

- Thermal Management: Using high-temperature resistant materials and optimized heat dissipation design to ensure PCBA performance in extreme temperature conditions, such as in ovens and refrigerators.

- Vibration Resistant Design: Implementing reinforced solder joints and mechanical stabilization features to withstand the vibration and shock forces during appliance operation.

- Component Selection: Choosing components with high reliability ratings and extended temperature ranges to ensure long-term performance in harsh environments.

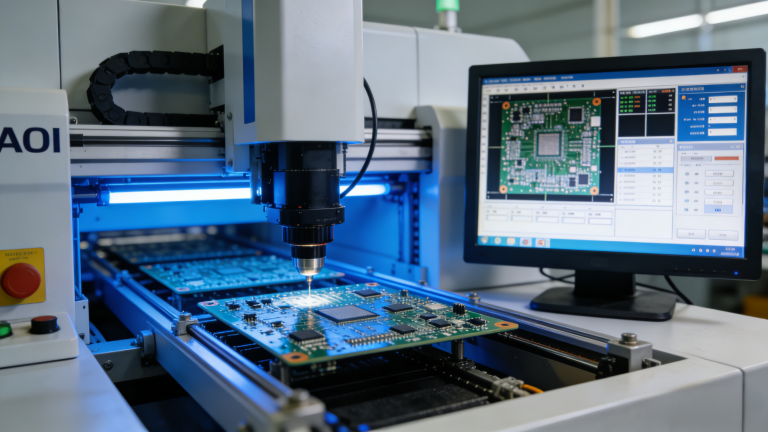

Figure 3: Professional business scene showing implementation of high-reliability PCBA solutions for kitchen and laundry appliances including conformal coating and vibration testing

Case Study: SanShun Smart Reduces Warranty Claims by 40% with High-Reliability PCBA Services

Partnered with a specialized PCBA services provider to improve the reliability of their dishwasher control boards. By implementing conformal coating, vibration-resistant design, and high-temperature components, the company reduced warranty claims related to PCBA failures by 40% within 12 months. The improved reliability also enhanced customer satisfaction, with SanShun Smart receiving a 15% increase in positive customer reviews related to product durability.

Conclusion

High-reliability PCBA services are essential for ensuring the long-term performance and durability of kitchen and laundry appliances. As consumer demand for durable appliances continues to grow, home appliance manufacturers must partner with specialized PCBA providers that can deliver robust solutions tailored to the unique challenges of these environments.

By implementing advanced design and manufacturing practices, PCBA services providers can help home appliance manufacturers reduce warranty costs, improve customer satisfaction, and gain a competitive edge in the market.

Frequently Asked Questions About PCBA Services for Kitchen and Laundry Appliances

Q: What is the role of PCBA services in appliance reliability?

A: PCBA services ensure that the design and manufacturing of control boards are optimized for the challenging environments of kitchen and laundry appliances. These services help prevent failures related to moisture, temperature, and mechanical stress.

Q: How can thermal management be optimized for appliances?

A: Using high-temperature resistant materials and optimizing heat dissipation designs ensures that PCBA can function effectively in extreme conditions, such as ovens and refrigerators.

Q: What challenges do appliance manufacturers face with PCBA in humid environments?

A: High humidity can lead to corrosion and short circuits in PCBA. Conformal coating and moisture-resistant materials are essential to ensure long-term performance in such environments.

Q: How can vibration affect the reliability of PCBA in appliances?

A: Vibration, especially during spin cycles in washing machines or dishwashers, can lead to solder joint fatigue. Vibration-resistant designs and reinforced solder joints are crucial to preventing these failures.

Q: What benefits does conformal coating provide in PCBA services?

A: Conformal coating protects PCBA from moisture, dust, and chemical exposure, which is particularly important in high-humidity environments like dishwashers and washing machines.