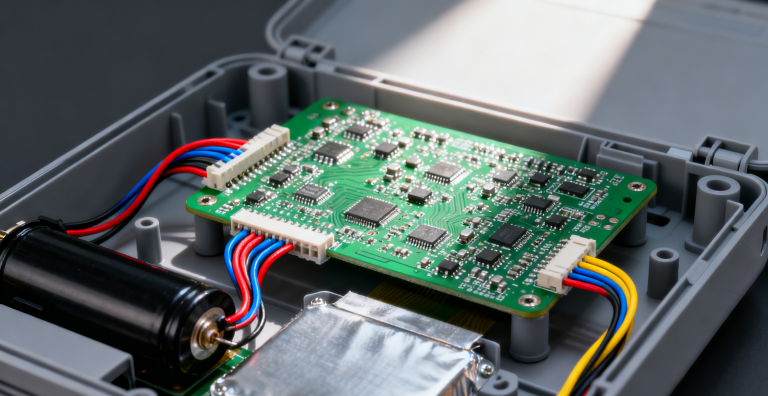

You face seven hidden cost factors that can affect China PCBA pricing: component sourcing risks, counterfeit parts, PCB design complexity, material choices, testing and quality control, logistics, and supplier selection. Identifying these hidden costs helps you avoid inflated expenses, project delays, and compromised product quality. Consider total costs, not just the initial quote, to optimize your budget and select the cheapest PCB manufacturer with confidence.

- Hidden costs can raise overall expenses.

- Delays often result from overlooked assembly issues.

- Quality suffers when you miss critical factors.

How to Master China PCBA Procurement: A Strategic Guide to Eliminating Hidden Costs and Manufacturing Risks

- Identify hidden costs in China PCBA to avoid budget overruns and project delays.

- Request detailed quotes from suppliers to uncover all potential fees, including testing and shipping.

- Select reliable components to prevent counterfeit issues that can result in costly recalls.

- Optimize your PCB design for manufacturing to reduce errors and improve assembly efficiency.

- Plan logistics carefully to manage shipping costs and avoid unexpected tariffs and delays.

Hidden Costs in China PCBA

Component Sourcing Risks

You face significant risks when sourcing components for a China PCBA. These risks often lead to hidden costs that can disrupt your budget and project timeline. Price volatility is common in the electronics market. Tariffs on imports, supply chain disruptions, and trade tensions can cause sudden increases in component costs. If you choose unusually low-priced parts, you may encounter long-term failures or delays in the assembly process.

| Factor | Description |

|---|---|

| Increased Costs | Tariffs and import fees raise the cost of raw materials and finished goods. |

| Supply Chain Uncertainty | Volatility complicates procurement and can delay manufacturing. |

| Production Delays | Disruptions lead to longer lead times and downtime in assembly. |

| Component Sourcing Risks | Quality and availability directly impact assembly and delivery schedules. |

| Supply Chain Disruptions | Natural disasters or global events can cause shortages and increase costs. |

| Component Obsolescence | Outdated parts require design changes, raising costs and causing delays. |

Tip: Always request a detailed bill of materials from your budget PCB supplier. Verify the source and authenticity of each component before finalizing your order.

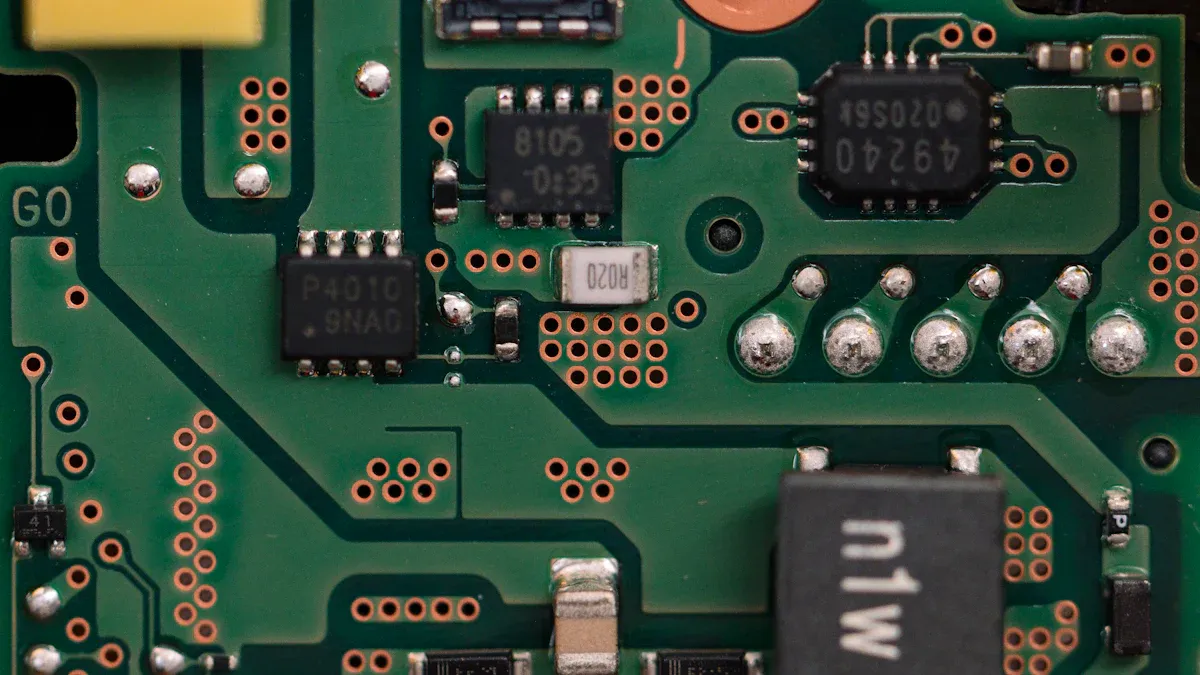

Counterfeit Parts and Quality

Counterfeit components remain a major concern in China’s PCBA assembly. The market for fake electronics is huge, and the risk has grown since 2022 due to shortages and rapid technology changes. Counterfeit parts can cause performance issues, safety hazards, and costly recalls. These hidden costs often outweigh any initial savings from cheap PCB assembly services.

| Evidence Type | Description |

|---|---|

| Prevalence | Counterfeit PCBA components pose a significant risk in 2025. |

| Market Size | The market for counterfeit electronics is worth hundreds of billions of dollars. |

| Trend | Counterfeit parts declined during the pandemic but have increased since 2022. |

| Factors Contributing | Shortages, long lead times, and fast tech advancements drive the issue. |

To protect your assembly and ensure affordability, you should:

- Inspect for incorrect labeling, mismatched part codes, and inferior logos or fonts.

- Check for incomplete packaging, missing dry packs, or signs of oxidation and wear.

- Compare markings to trusted manufacturer samples.

- Work only with the best cheap PCB manufacturer that offers transparent sourcing and quality guarantees.

Note: Reliable manufacturers help you avoid hidden costs by providing traceable components and thorough quality checks. This approach supports low-cost PCB fabrication without sacrificing reliability.

PCBA Design Complexity and Cost

Impact of Multi-Layer Boards

You encounter higher costs when your PCB design includes multi-layer boards. Multi-layer PCBs demand advanced manufacturing techniques and premium materials. You need intricate routing and thorough testing, which increases both assembly costs and overall project expenses. The complexity of these boards means you pay more for engineering support and quality assurance. If you want to maintain affordability, you must balance performance needs with your budget. Multi-layer designs often deliver better functionality, but they introduce hidden costs that can surprise you if you do not plan carefully.

Tip: Work with a budget PCBA supplier who can advise you on the optimal number of layers for your application. This approach helps you avoid unnecessary design-related costs and keeps your project on track.

Design for Manufacturing Errors

DFM errors create hidden costs that affect your China PCBA project. You face delays, increased assembly costs, and unexpected engineering questions when your design files contain mistakes. The most frequent DFM errors include:

| DFM Error | Description | Consequences |

|---|---|---|

| Over-specification and tight tolerances | Specifying dimensions beyond standard capabilities. | Increased costs and lead times due to advanced tooling and process control requirements. |

| Incomplete or unclear fabrication documentation | Missing or contradictory information in fabrication files. | Delays in production as manufacturers wait for clarifications, adding 2-4 days to production. |

| Poor component placement and orientation | Components are placed for convenience rather than assembly efficiency. | Slower placement speeds, higher likelihood of defects, and potential rework. |

You reduce hidden costs by providing clear documentation and realistic tolerances. You should optimize component placement for efficient assembly. If you want low-cost PCB fabrication, you must avoid these common mistakes. The cheapest PCB manufacturer will help you review your design and suggest improvements, but you need to communicate your requirements clearly.

- Review your PCB files before submitting them to the manufacturer.

- Ask for a DFM check from your supplier to catch errors early.

- Choose a manufacturer with experience in electronics manufacturing in China for reliable results.

You control your assembly costs and improve affordability by focusing on design quality. Careful planning and supplier collaboration help you avoid hidden delays and keep your China PCBA project within budget.

Material and Surface Finish Choices

Substrate Selection

You make a critical decision when choosing the substrate for your PCB. The substrate type directly affects both the upfront cost and the hidden costs in China PCBA. Many manufacturers offer FR-4 as the standard option because it is cost-effective and suitable for most assembly needs. However, advanced substrates like Rogers or ceramic provide superior performance for high-frequency or thermal applications. These options come with much higher costs and can introduce hidden fees if your design requires specialized materials.

| Substrate Type | Cost per Square Inch (USD) | Notes |

|---|---|---|

| FR-4 | 0.10 – 0.50 | Cost-effective, suitable for standard applications |

| Rogers | 20.00 – 75.00 | High-performance, used for specialized applications |

| Ceramic | 2.00 – 10.00 | Superior thermal and electrical properties |

You must balance performance and affordability. If you select a substrate that does not match your assembly requirements, you risk yield issues and increased costs. A budget pcb supplier can help you evaluate the best option for your project.

Tip: Always consult your manufacturer about substrate compatibility with your design. This step helps you avoid hidden costs and ensures reliable manufacturing.

When Standard Materials Aren’t Cheapest

You may assume that standard materials like FR-4 always offer the lowest cost, but this is not true for every project. If your PCB design pushes the limits of FR-4, you can face hidden costs from poor yields, frequent defects, and extra rework. These issues increase your total costs and reduce affordability. Advanced materials may seem expensive, but they can lower your overall assembly costs by improving reliability and reducing failures.

Surface finish choices also impact long-term costs and reliability. The finish you select affects solderability, corrosion resistance, and durability. Some finishes, such as HASL, offer lower costs but may compromise quality. Others, like ENIG, provide better performance but increase your initial cost.

- Cost: The finish type changes your total expenditure. HASL is affordable, but ENIG offers higher reliability.

- Volume: Small production runs may require finishes that resist tarnishing.

- Reliability: The finish must withstand environmental stress to meet your standards.

You improve your low-cost pcb fabrication strategy by considering both substrate and surface finish. The cheapest PCBA manufacturer will guide you through these choices, helping you avoid hidden costs and optimize your budget for China PCBA assembly.

Testing and Quality Control Costs

Skipping Testing Risks

You face high hidden costs when you skip essential testing during China PCBA assembly. Inadequate testing exposes your project to risks that can undermine reliability, increase warranty claims, and damage your reputation. Many budget manufacturers cut corners on quality control to offer lower prices, but these shortcuts often result in expensive problems later.

| Hidden Cost Category | Description |

|---|---|

| Defective Soldering | Inaccurate SMT placement and reflow processes cause cold joints and misaligned components. |

| Limited Testing and Inspection | Skipping quality checks allows hidden defects to pass, reducing reliability in harsh environments. |

| Supply Chain and Lead Time Risks | Budget manufacturers may create longer shipping times and unpredictable production capacity. |

| Intellectual Property Concerns | Weak confidentiality controls can lead to design copying and data security issues. |

| Regulatory and Compliance Risks | Non-compliance with safety standards increases warranty liabilities and complicates dispute resolution. |

You risk higher costs from rework, returns, and lost business if you ignore these hidden factors. The cheapest pcb manufacturer may seem attractive, but you must evaluate their testing protocols to protect your investment and maintain affordability.

Integrating Testing in the Budget

You improve your cost control and assembly reliability by integrating essential testing steps into your budget. A budget PCBA supplier should offer a comprehensive testing plan that covers all critical aspects of PCBA manufacturing. You should include the following steps to minimize hidden costs and ensure high-quality results:

- Functional Testing: Simulates real-world conditions to verify that your pcb operates as designed.

- In-Circuit Testing (ICT): Uses fixtures to check for shorts, opens, and correct component values, complementing functional testing.

- Burn-in Testing: Subjects boards to extreme conditions to identify early-life failures, which is vital for high-reliability applications.

- Solderability Testing: Assesses the wettability of component leads and pcb pads, preventing downstream soldering defects.

- Ionic Contamination Testing: Confirms cleaning effectiveness, reducing risks like dendrite growth and improving long-term reliability.

You should discuss these steps with your manufacturer before starting assembly. This proactive approach helps you avoid hidden costs and supports low-cost pcb fabrication. You protect your project’s affordability and performance by prioritizing thorough testing and quality control.

Tip: Always request a detailed testing plan from your manufacturer. This step ensures transparency and helps you compare the true costs of different suppliers in China PCBA.

Logistics, Shipping, and Lead Times

Logistics and shipping play a major role in the total cost of China’s PCBA assembly. You often overlook these hidden costs when comparing quotes, but they can quickly add up and impact your project’s affordability. International shipping fees, customs duties, and delays all contribute to the final price you pay for your pcb products.

International Shipping Fees

Shipping costs vary depending on your destination and the speed of delivery. You must consider not only the base shipping rate but also import duties, taxes, and processing fees. These expenses can make a significant difference in your overall budget for pcb assembly.

| Destination | Average Shipping Cost (USD/kg) | Lead Time |

|---|---|---|

| North America | $4.50 – $6.00 | 5–7 days |

| Europe | $5.00 – $7.50 | 7–10 days |

| Southeast Asia | $3.50 – $4.50 | 3–5 days |

- Import duty usually ranges from 0-5% for PCBs in most countries.

- Value-added tax or sales tax varies by country, such as 20% in the UK or 19% in Germany.

- Customs authorities may charge processing fees.

You should also factor in the cost of specialized packaging, such as ESD-safe materials, which protect sensitive electronics during transit. These packaging choices add to your hidden costs but help maintain product quality.

Tip: Optimize packaging by coordinating with your manufacturer to use appropriately sized cartons. This strategy reduces wasted space and lowers shipping costs.

Tariffs and Delays

Tariffs and customs delays can create unexpected costs and disrupt your delivery schedule. You may face unit cost increases of 15% or more due to tariffs, especially for shipments to the US under Section 301 regulations. Surprise customs fees can arise after delivery if audits or classification changes occur. Enhanced inspection protocols often lead to longer lead times.

- Current US duty rates range from 30% to 73%, with some exemptions available.

- Refunds may be issued if the final duty rate is lower than the initial rate.

- Longer lead times result from customs inspections and paperwork.

To minimize these hidden costs, you should:

| Strategy | Description |

|---|---|

| Negotiate with Freight Forwarders | Build relationships for volume discounts and cost-effective shipping routes. |

| Optimize Packaging | Use efficient packaging to maximize container space and reduce shipping expenses. |

| Compare Quotes | Request multiple shipping quotes to secure competitive rates. |

| Select the Right Shipping Method | Choose sea freight for large shipments to lower costs, or air/courier for urgent deliveries. |

| Choose the Right Incoterm | Clarify cost responsibilities with terms like FOB or EXW to manage expenses effectively. |

You improve affordability and control your budget by proactively managing logistics and shipping. The cheapest PCBA manufacturer will help you navigate these challenges, but you must stay informed to avoid hidden costs in China’s PCBA manufacturing.

Production Quantity and Setup Fees

MOQ and Per-Unit Cost

You must understand how the minimum order quantity (MOQ) shapes the hidden costs in China PCBA. When you order small quantities, the setup fee spreads across fewer units, raising the per-unit cost. This hidden fee can surprise you if you focus only on the initial quote. You see a significant price drop when your order reaches 50 to 100 units, as the setup fee is distributed over more boards. Higher order volumes lower your per-unit costs and improve your budget planning for pcb assembly.

- Ordering small quantities increases per-unit costs because setup fees are not spread out.

- Price drops sharply at higher volumes, especially above 50 units.

- Low MOQ options help startups test products and reduce risk, supporting faster iteration.

- Economies of scale play a key role in controlling costs for pcb manufacturing.

You should ask your manufacturer for a clear breakdown of costs. This step helps you spot hidden costs and compare offers from different suppliers. The cheapest pcb manufacturer often provides flexible MOQ terms, which can boost your affordability and help you manage your budget.

Set up Charges for Prototypes

Prototype runs in Chin, a PCBA often comes with setup charges that influence your total project cost. These fees cover machine calibration, tooling, and process adjustments. For low-volume prototypes, setup charges can create hidden costs that raise your per-unit price. You can reduce these costs by planning and avoiding rush orders, which often carry premium fees.

Consider these strategies to negotiate better terms with your manufacturer:

- Request quotes from multiple vendors to find the best deal.

- Scrutinize cost breakdowns for materials, testing, and shipping.

- Ask for all-inclusive quotes to avoid unexpected fees.

- Consolidate multiple designs into one order to share setup costs.

- Build long-term partnerships for better pricing and waived setup fees.

- Optimize your pcb design for cost-effectiveness with expert advice.

You improve affordability and control hidden costs by understanding how production quantity and setup fees affect your China PCBA assembly. Proactive negotiation and clear communication with your manufacturer help you achieve the best value for your project.

Supplier Selection and the Cheapest PCBA Manufacturer

Transparent Quoting

You need to compare apparent and hidden costs when selecting a supplier for China PCBA. Apparent costs include the unit price for pcb assembly, which may look attractive at first glance. Hidden costs often remain unnoticed until you face issues during manufacturing or delivery. These hidden costs can undermine your budget and affect your project’s affordability.

- Apparent costs show the basic price per pcb unit.

- Hidden costs include quality problems that require rework, inventory challenges from large minimum order quantities, and delays that impact your time-to-market.

- You may also encounter supply chain risks and intellectual property concerns that add to your total costs.

A transparent quote from a manufacturer should break down all expenses, including testing, shipping, and fixture development. You improve your cost control by requesting detailed quotes and clarifying every line item. The cheapest pcba manufacturer may not always offer the best value if hidden costs outweigh the initial savings.

Avoiding Hidden Fees

You must watch for hidden fees that suppliers often leave out of initial quotes. These fees can quickly increase your total costs and disrupt your budget planning for pcb assembly. Common hidden fees include charges for expedited orders, testing, and fixture development.

| Hidden Fee Type | Description |

|---|---|

| Expedited Orders | Extra fees (15%-25%) for urgent production requests. |

| Testing and Quality Control Costs | Charges for AOI and functional testing, which can add significant expenses. |

| Test Fixture Development Fees | Costs from 1500–8000 RMB for test fixtures, often not included in quotes. |

| Functional Test Development Fees | Additional costs between 2000 and 10000 RMB for functional test development are usually overlooked. |

You reduce hidden costs by choosing a manufacturer who provides clear, itemized quotes and explains all potential fees. Reliable suppliers help you avoid budget surprises and maintain affordability throughout your pcb project.

When selecting a partner for China PCBA, you should:

- Request certifications and audit records to verify quality standards.

- Ensure traceability by confirming the manufacturer links board serials to component lot IDs.

- Ask for recent DFM reports to assess engineering capabilities.

- Compare test strategies to your risk profile to avoid hidden costs.

- Check for supply chain resilience, such as dual-source options and local stocking.

- Review quality metrics like FPY and DPM to evaluate stability.

- Confirm transparent pricing for prototypes and small batches.

- Verify box-build competencies for sub-assemblies and firmware programming.

- Clarify communication channels and project management structure.

You improve your cost management and assembly reliability by following these steps. The cheapest pcb manufacturer should offer transparency, strong engineering support, and clear communication. These qualities help you avoid hidden costs and achieve successful pcb manufacturing in China.

Apparent vs. Hidden Costs Table

You often compare quotes from different manufacturers when planning your pcb assembly project. You see the apparent costs listed in the initial quote, but you may overlook the hidden costs that affect your final budget. Understanding both types of costs helps you make better decisions and avoid surprises during China PCBA assembly.

The table below summarizes the main differences between apparent and hidden costs in pcb assembly. You can use this comparison to evaluate offers from the cheapest pcb manufacturer and identify areas where hidden costs may arise.

| Apparent Costs | Hidden Costs |

|---|---|

| Unit price per pcb | Component sourcing risks |

| Setup fees | Counterfeit parts and quality issues |

| Material charges | DFM errors and design changes |

| Testing fees (if listed) | Unlisted testing and inspection steps |

| Shipping charges | Tariffs, customs, and delays |

| Packaging fees | Specialized packaging requirements |

| Prototype charges | Minimum order quantity impact |

| Assembly labor | Rework, returns, and warranty claims |

You should review each line item in your quote and ask your manufacturer for clarification. Many hidden costs come from quality problems, logistics, and unexpected changes during assembly. You can reduce these costs by working with a reliable manufacturer who provides transparent quotes and supports your budget goals.

Tip: Always request a detailed breakdown of costs from your manufacturer. This step helps you spot hidden costs and compare offers more effectively.

You improve your cost control and project reliability by understanding the full range of costs in China PCBA. Careful planning and supplier communication help you avoid budget overruns and achieve successful pcb assembly.

How to Minimize Hidden Costs

Proactive Planning

You can reduce hidden costs in China PCBA projects by planning and optimizing every stage of your PCBA assembly. Start by consolidating and standardizing components. This step simplifies your bill of materials and streamlines procurement. Optimize component placement and layout to improve assembly efficiency and lower labor costs. Request detailed quotes from your manufacturer that include all potential fees, such as engineering, setup, testing, and shipping. These fees can inflate costs by 20-40% if you overlook them.

The following table highlights strategies that help you control costs and avoid hidden expenses:

| Strategy | Impact on Costs |

|---|---|

| Design Optimization | Reduces errors and rework costs |

| Cost-effective Component Selection | Lowers material costs |

| Efficient Manufacturing Processes | Minimizes delays and associated costs |

| DFM Principles | Standardizes components, reducing complexity |

| Optimized Testing Procedures | Cuts down on inspection labor costs |

Tip: Upload your BOM and Gerber files to your manufacturer for a quick, accurate cost estimate. This step gives you clear visibility into material and assembly costs and shortens your design-to-production cycle.

Leveraging Supplier Expertise

You gain a competitive edge by working with a manufacturer who understands the China PCBA supply chain. Established relationships with component OEMs and distributors allow for efficient sourcing and streamlined production. This integration can reduce lead times by up to 70%, making costs more predictable and transparent. PCBA contract manufacturing helps you minimize engineering mistakes and avoid production delays, so you can focus on product improvement and market growth.

The cheapest PCBA manufacturer often provides valuable guidance on optimizing your PCBA design for budget and performance. You should leverage their expertise to select cost-effective materials and processes. A reliable manufacturer will help you identify hidden costs and suggest ways to improve assembly efficiency.

- Optimize the supply chain for better pricing and availability.

- Streamline assembly processes to reduce labor and overhead costs.

- Leverage technology for accurate quoting and efficient production.

- Choose the right manufacturing partners to ensure quality and cost control.

Note: When you upload BOM and Gerber files, you enable your manufacturer to provide transparent quotes. This approach reduces back-and-forth communication and accommodates both small-batch and large-volume orders.

You control your budget and avoid hidden costs by combining proactive planning with supplier expertise. These strategies help you achieve successful pcb assembly and maintain affordability in China PCBA projects.

You improve your PCBA assembly results by understanding and managing hidden costs in China PCBA. Proactive planning and clear communication with your manufacturer help you control costs and avoid budget surprises. The integrated supply network and digital management systems in China support efficient pcb production and rapid responses. Use the tips in this guide to optimize your budget and minimize hidden costs. Sanshun Smart offers over 10 years of experience, a dedicated R&D center with 60+ engineers, and a 30,000 sqm facility. Upload your BOM or Gerber files for a transparent, no-hidden-fee quote.

FAQ

What are the most common hidden costs in China PCBA Assembly?

You often encounter hidden costs from component sourcing risks, counterfeit parts, design errors, and logistics. These factors can increase your turnkey PCB assembly cost and delay your project. Always review quotes for unlisted fees and clarify every detail with your supplier.

How can you verify the quality of components in electronics manufacturing in China?

You should request traceability documentation and supplier certifications. Reliable manufacturers provide detailed records for each component. Ask for sample reports and inspect labeling. This approach helps you avoid counterfeit parts and ensures consistent quality in your China PCBA Assembly.

Why do PCBA pricing factors vary between suppliers?

Suppliers use different sourcing channels, testing standards, and production processes. Some include hidden costs in PCBA, such as extra testing or expedited shipping. You need to compare detailed quotes and ask about all potential fees to understand the true turnkey PCB assembly cost.

How does order quantity affect hidden costs in China PCBA Assembly?

Small orders often carry higher per-unit costs due to setup fees. Larger volumes spread these fees out, lowering your overall cost. You should discuss minimum order quantities and setup charges with your supplier to optimize your budget and reduce hidden costs in PCBA.

What steps help you minimize hidden costs in turnkey PCB assembly?

You can upload your BOM and Gerber files for a transparent quote. Work with experienced suppliers who offer clear pricing and strong engineering support. Proactive planning and supplier collaboration help you control PCBA pricing factors and avoid budget surprises.