You need a reliable PCBA Contract Manufacturing partner who consistently delivers high-quality results, protects your intellectual property, and responds to your requirements with precision. Experience and stability matter—an experienced supplier can reduce your risk of defects and delays. For example, suppliers with a proven track record show a defect rate of just 0.8%, compared to 5% from less experienced providers:

| Supplier Name | Defect Rate | On-time Delivery Rate | Total Defective Units (50,000 run) |

|---|---|---|---|

| Cheaper Supplier (Inexperienced) | 5% | 84.4% | 2,500 |

| Premium Supplier (Experienced) | 0.8% | 92.7% | ~400 |

Careful evaluation of quality, supply chain, cost, flexibility, technology, responsibility, and communication ensures you make the right choice. A supplier audit checklist will help you ask the right questions.

How to Evaluate Your Partner for PCBA Contract Manufacturing

- Choose a PCBA partner with proven experience. A reliable manufacturer reduces defects and delays, ensuring high-quality results.

- Verify certifications like ISO 9001 and IATF 16949. These credentials show a commitment to quality and industry standards.

- Protect your intellectual property with NDAs and secure data handling. This step safeguards your designs and sensitive information.

- Look for transparent pricing and value-added services. Clear quotes help you avoid hidden costs and enhance product quality.

- Assess supply chain strength and flexibility. A strong network ensures quality components and reliable delivery, supporting your production needs.

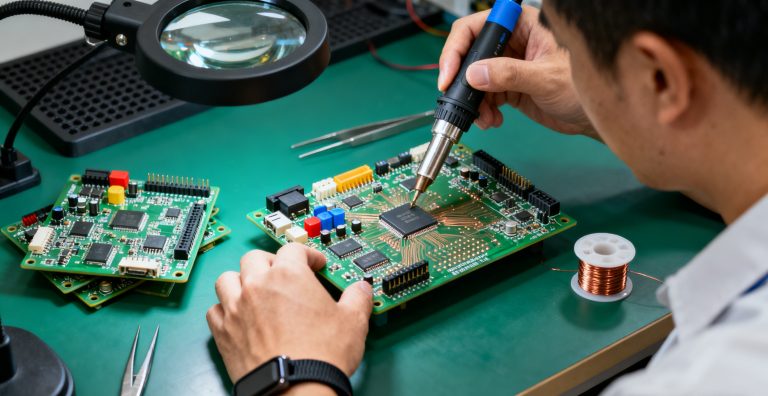

Experience and Stability

Years in PCBA Contract Manufacturing

When you evaluate a PCBA Contract Manufacturing partner, you should always check how many years they have operated in the industry. A company with a long history in PCBA Contract Manufacturing has likely faced and solved many technical and logistical challenges. This experience means you can expect fewer surprises during your project. You gain confidence that the manufacturer understands the latest industry standards and adapts quickly to new technologies. For example, Sanshun Smart has over a decade of experience, which shows their ability to deliver consistent results and handle complex requirements.

Tip: Ask for the company’s founding year and request examples of projects completed over time. This helps you verify their claims and understand their growth.

Proven Track Record

A reliable manufacturer does not just talk about quality—they prove it with data. You should request references, case studies, and performance metrics. Look for evidence of high on-time delivery rates, low defect rates, and successful partnerships with well-known brands. A strong track record shows that the manufacturer can meet deadlines and maintain quality, even under pressure. Sanshun Smart, for instance, provides detailed case studies and customer testimonials that demonstrate their commitment to excellence.

- Ask for:

- Customer references from your industry

- Data on past project outcomes

- Awards or recognitions received

You should always choose a partner who can show real results, not just promises.

Quality Assurance

Certifications (ISO9001, IATF 16949)

You should always verify the certifications held by your PCBA Contract Manufacturing partner. Top-performing companies invest in internationally recognized quality management systems. These certifications show a commitment to consistent processes and continuous improvement. The most respected certifications include:

| Certification | Description |

|---|---|

| ISO 9001 | International standard for quality management. |

| IATF 16949 | Quality management standard for the automotive sector. |

| ISO 13485 | Quality management for medical devices. |

| AS9100 | Quality management standard for aerospace. |

| IPC-A-610 | Acceptability of electronic assemblies. |

Sanshun Smart holds both ISO 9001 and IATF 16949 certifications. These credentials demonstrate their ability to meet strict industry requirements and deliver reliable results for diverse applications.

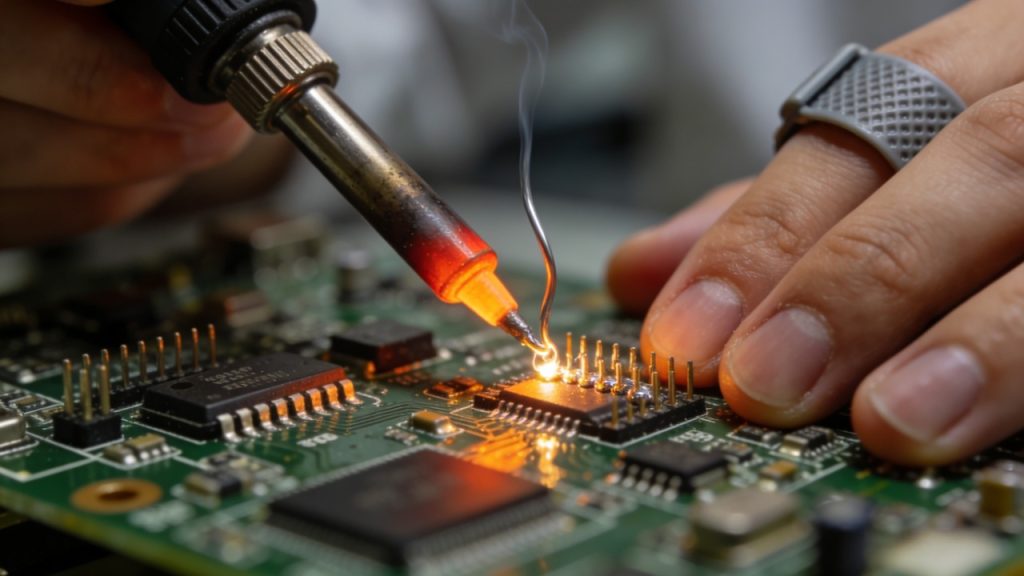

Quality Control Methods

You need a manufacturer who uses robust quality control methods at every stage. Leading companies implement incoming material inspections, in-process checks, and final product testing. These steps help catch defects early and prevent costly rework. Sanshun Smart uses a closed-loop quality management system. Their team tracks every batch and documents each inspection. This approach ensures you receive consistent, high-quality assemblies.

Tip: Ask your supplier to describe their quality control process and provide sample inspection reports.

Advanced Inspection (AOI, X-ray)

Modern PCBA production relies on advanced inspection tools. Automated Optical Inspection (AOI) systems quickly detect soldering issues and component placement errors. X-ray inspection reveals hidden defects, such as solder voids or misaligned ball grid arrays. Sanshun Smart invests in both AOI and X-ray equipment. Their engineers use these tools to verify every assembly meets your specifications before shipment.

You gain peace of mind when your partner combines certified processes, strict quality control, and advanced inspection technology.

Intellectual Property Protection

NDA and Legal Safeguards

You must protect your designs and sensitive information when you choose a PCBA Contract Manufacturing partner. The best manufacturers take intellectual property protection seriously from the start. You should always require a Non-Disclosure Agreement (NDA) before sharing any technical details. An NDA legally binds your partner to confidentiality and prevents unauthorized use of your data. Involving legal experts in contract drafting ensures your IP rights receive proper protection and that you have remedies if a breach occurs. Registering your IP with the relevant authorities strengthens your legal position and creates a clear record of ownership. You can also ask for confidentiality agreements from all parties involved in discussions to safeguard your trade secrets.

Tip: Request to review sample NDAs and ask how the manufacturer handles breaches of confidentiality.

Secure Data Handling

You need to know how your partner manages and protects your sensitive files. Leading companies adopt secure practices for sharing design files, such as file encryption and password protection. They maintain trusted relationships and conduct regular security audits to reduce the risk of IP theft. You should establish NDAs with every partner who handles your confidential files. Design obfuscation techniques can make it harder for unauthorized parties to access critical information. Top manufacturers implement monitoring systems to track who accesses your files and manufacture in locations with strong IP laws. Employee training on IP protection and cybersecurity awareness further reduces risks.

- Control how you transmit sensitive information by using advanced security tools.

- Ensure employees receive training on data protection to prevent accidental leaks.

- Consider removing unnecessary sensitive data from shared designs.

Cost and Value

Transparent Pricing

You need clear and predictable pricing when you select a PCBA Contract Manufacturing partner. Transparent pricing helps you avoid hidden costs and plan your budget with confidence. Leading manufacturers, such as Sanshun Smart, provide detailed quotes that break down every cost component. This approach allows you to compare suppliers and understand where your money goes.

Here is a typical cost breakdown for PCBA contract manufacturing services:

| Cost Component | Description |

|---|---|

| Component Cost | Cost of individual parts like resistors, chips, and connectors. |

| Labor Costs | Money is paid for assembly work, which depends on time and complexity. |

| Overhead Costs | Expenses for factory rent, utilities, and equipment upkeep. |

| Materials | Cost of the PCB itself, solder paste, and special materials. |

| Testing and Inspection | Money spent on checking boards for errors and making sure they work. |

| Quality Assurance | Costs for meeting industry standards and getting certifications. |

| Volume | How the number of boards you order affects the price per board. |

Tip: Ask your supplier for a detailed quote and clarification on each cost item. This step helps you avoid surprises and ensures you get the best value.

Value-Added Services

You gain more than just assembly when you choose a manufacturer that offers value-added services. Design for Excellence (DfX) services help you optimize your product design and production process. These services identify potential challenges early, which reduces risks and improves product quality. When you use DFM (Design for Manufacturability) and DFT (Design for Testing), you ensure your boards are easy to produce and test. This approach lowers costs and speeds up your time to market.

Partnering with an experienced manufacturer like Sanshun Smart gives you access to engineering support, early design reviews, and advanced testing. You can focus on your core business while your manufacturing partner handles technical details. This collaboration leads to efficient production, fewer errors, and a competitive edge in your industry.

- Look for:

- Early design support

- Prototyping and testing services

- Ongoing engineering consultation

You maximize cost-effectiveness and product quality when you select a partner who invests in value-added services.

Supply Chain Strength

A strong supply chain forms the backbone of reliable PCBA Contract Manufacturing. You need a partner who can source quality components, prevent counterfeit risks, and provide full transparency throughout the process. When you choose a manufacturer with robust supply chain management, you reduce delays, avoid costly errors, and ensure consistent product quality.

Supplier Network and Sourcing

You should always ask about your manufacturer’s supplier network. A reliable PCBA Contract Manufacturing partner builds relationships with authorized distributors and original component manufacturers. This approach ensures you receive genuine parts and stable lead times. Sanshun Smart works only with vetted suppliers and maintains long-term partnerships. This strategy helps you avoid shortages and last-minute substitutions that can compromise your product.

Tip: Request a list of primary suppliers and ask how your partner manages sourcing during shortages.

Anti-Counterfeit Measures

Counterfeit components pose a serious risk in PCBA Contract Manufacturing. You need a partner who takes proactive steps to prevent fake parts from entering your assemblies. Leading manufacturers use a multi-layered approach:

- Independent testing laboratories authenticate component samples.

- Professional auditors assess the sourcing process.

- Escrow services hold components until authenticity is confirmed.

- Continuous monitoring services track supply chain risks.

- Clear requirements for counterfeit avoidance appear in supplier agreements.

- Components come from authorized sources or directly from manufacturers.

- Rigorous inspection protocols combine several testing methods.

- Complete documentation ensures traceability from source to assembly.

- Teams stay informed about industry alerts on counterfeit parts.

- Strategies address component obsolescence.

- Ongoing monitoring and periodic audits verify prevention practices.

Supply Chain Transparency

Transparency in the supply chain builds trust and supports compliance. You should expect your PCBA Contract Manufacturing partner to provide:

- Traceability for every component, supporting regulations like RoHS and REACH.

- Ethical sourcing, especially for conflict minerals and sensitive materials.

- Full visibility into each production stage, enabling quick responses to disruptions.

Sanshun Smart offers transparent sourcing channels and detailed traceability reports. You always know where your components come from and how your assemblies are built. This level of openness protects your brand and ensures regulatory compliance.

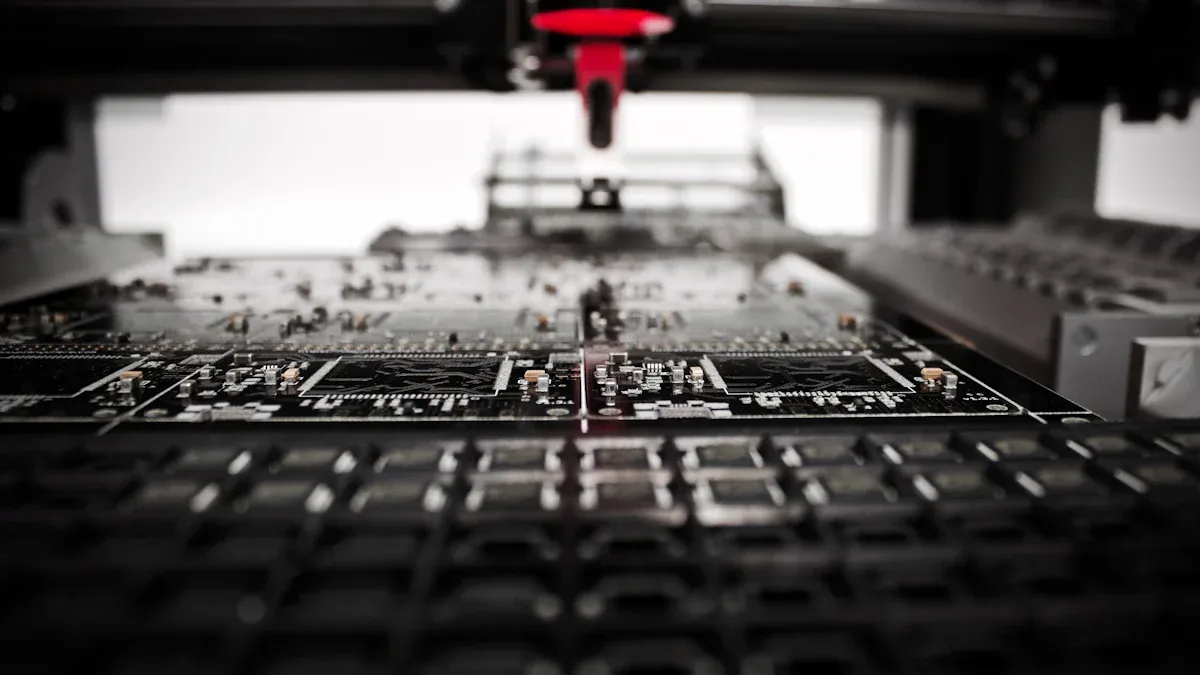

Production Flexibility

Prototyping to Mass Production

You need a PCBA Contract Manufacturing partner who can support your project from the earliest prototype to full-scale production. Flexibility in manufacturing ensures you can iterate quickly during development and scale efficiently when demand increases. Leading manufacturers, such as Sanshun Smart, offer seamless transitions between prototyping, small-batch runs, and mass production. This capability reduces risk and accelerates your time to market.

Here is how a reliable PCBA Contract Manufacturing provider supports every stage:

| Service Type | Description |

|---|---|

| Prototype PCBA service | Early evaluation, concept verification, and quick engineering builds. Short lead times and high flexibility. |

| Small-batch production | Ideal for pilot runs and small orders. Validates performance before mass production. |

| Mass production | Scales up to support stable, high-volume output with consistent quality. Automated lines maintain uniformity. |

| Full Production Scale Coverage | Supports all stages from prototyping to million-unit mass production, enabling rapid iteration and stable supply. |

Sanshun Smart specializes in New Product Introduction (NPI) and manages smooth transitions to mass production. You benefit from their experience in handling complex ramp-ups and maintaining quality at every phase.

Tip: Ask your manufacturer how they manage engineering changes and scale production without delays.

Lead Times and Delivery

You must consider lead times and delivery performance when selecting a PCBA Contract Manufacturing partner. Industry benchmarks show that top manufacturers achieve on-time delivery rates between 92% and 96%. Reliable partners provide clear timelines for each board type, helping you plan your project with confidence.

Typical lead times include:

- Double-sided board: 3–5 working days

- 4–6 layer board: 5–8 working days

- High-layer, HDI, or special material boards: More than 10 working days

| Metric | Benchmark Range |

|---|---|

| On-Time Delivery (OTD) Rate | 92–96% |

Note: Always request a detailed production schedule and track delivery performance to avoid unexpected delays.

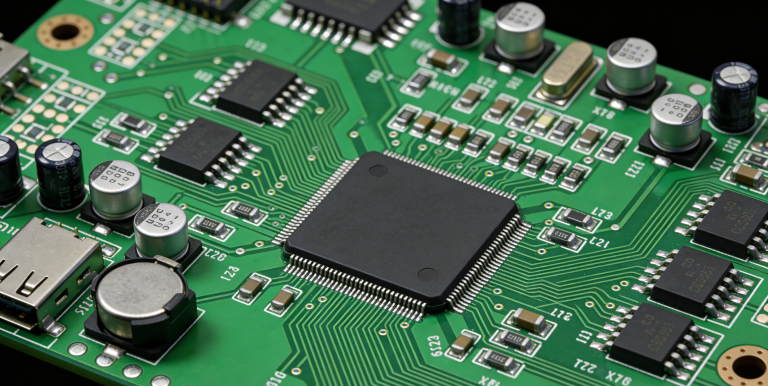

Technology and Engineering

SMT Production Lines

You need advanced SMT production lines to achieve consistent quality in PCBA Contract Manufacturing. Leading manufacturers invest in specialized assembly lines to handle a wide range of components and board complexities. The most common SMT assembly types include:

| Type of SMT Assembly | Description |

|---|---|

| Passive SMT Assembly | Handles resistors, capacitors, and similar parts. |

| Active SMT Assembly | Installs ICs, transistors, and complex components. |

| Mixed Technology | Combines SMT and through-hole for hybrid assemblies. |

Sanshun Smart operates high-speed SMT lines equipped with precision placement systems. These lines support advanced inspection tools, such as AOI (Automated Optical Inspection), SPI (Solder Paste Inspection), and X-ray. You benefit from their ability to assemble challenging components, including 01005 chip sizes and BGA (Ball Grid Array) packages. This technical expertise ensures your assemblies meet the highest industry standards.

Tip: Ask your manufacturer if they can handle both mixed-technology boards and ultra-fine pitch components.

Engineering Support

You gain a significant advantage when your PCBA Contract Manufacturing partner provides strong engineering support. Early collaboration with manufacturing experts helps you set clear test criteria and identify potential issues before production starts. This approach leads to consistent quality throughout your product’s lifecycle.

- You align quality standards with your contract manufacturer for effective teamwork.

- You develop test plans early to catch problems before they escalate.

- You adjust designs with engineering input to avoid costly rework and delays.

When you involve engineers from the start, you address tolerance risks and assembly challenges proactively. Sanshun Smart’s engineering team works closely with you during every project phase. Their support covers DFM (Design for Manufacturing) reviews, rapid prototyping, and process optimization. You can trust their expertise to deliver reliable results, even for complex or high-mix assemblies.

Note: Strong engineering support reduces project risks and accelerates your time to market in PCBA Contract Manufacturing.

Environmental and Social Responsibility

Environmental Compliance

You must ensure your PCBA Contract Manufacturing partner meets strict environmental standards. Leading companies follow regulations that protect air, water, and soil from industrial pollution. You should expect your manufacturer to comply with global standards such as RoHS and REACH, which restrict hazardous substances and regulate chemical safety in PCB production. Sanshun Smart demonstrates a strong commitment to environmental compliance by maintaining ISO 9001 and ISO 13485 certifications. These standards guarantee consistent regulatory practices and safe production environments.

| Compliance Area | Relevant Regulations |

|---|---|

| Stormwater & Wastewater Compliance | Clean Water Act (CWA), NPDES permits, Stormwater Pollution Prevention Plans (SWPPPs) |

| Chemical Storage & Reporting | EPCRA, Tier II reporting, Toxic Release Inventory (TRI) |

| Spill Prevention & Oil Storage Compliance | SPCC Rule |

| Hazardous & Non-Hazardous Waste Management | Resource Conservation and Recovery Act (RCRA) |

| Air Quality & Emissions Compliance | Clean Air Act (CAA) |

| Environmental Audits & Compliance Reviews | Regular environmental audits, internal and third-party assessments |

| Best Practices for Environmental Compliance | Regular training, pollution prevention strategies, and monitoring regulatory updates |

Tip: Ask your supplier about their pollution prevention strategies and request recent audit reports. This step helps you verify their commitment to environmental responsibility.

Social Accountability

You need a PCBA Contract Manufacturing partner who values social responsibility. Companies that prioritize ethical practices build trust and credibility for your brand. Sanshun Smart invests in responsible manufacturing and meets global sustainability standards. Their commitment attracts eco-conscious customers, investors, and business partners. You benefit from their reputation as an environmentally responsible entity.

- Responsible manufacturing builds trust and credibility for your products.

- Meeting sustainability standards secures a market advantage.

- Attracting environmentally conscious customers enhances your reputation.

- Building trust and loyalty among stakeholders supports long-term growth.

You should choose a partner who demonstrates social accountability through transparent labor practices, fair wages, and safe working conditions. Sanshun Smart’s dedication to social responsibility ensures your products meet the expectations of modern consumers and regulatory bodies.

Note: Responsible PCBA Contract Manufacturing supports your brand’s reputation and helps you meet the growing demand for sustainable products.

Communication and Location

Project Communication

Effective project communication forms the backbone of successful PCBA Contract Manufacturing. You need a partner who understands your requirements and keeps you informed at every stage. Clear communication reduces misunderstandings and ensures your project stays on track. The best practices for project communication include:

- Collaborate with your PCBA Contract Manufacturing partner before detailed design begins. Early discussions clarify your functionality requirements and set clear expectations.

- Use design for manufacturability and assembly (DFMA) assessments. These reviews help you and your partner identify production issues early, leading to cost-effective solutions and higher quality.

- Choose a proven PCBA assembler with a reliable supply chain and robust quality control. This choice ensures you receive timely updates and accurate information.

Sanshun Smart excels in project communication. Their team provides prompt responses and clear documentation. You benefit from their proficiency in English, which eliminates language barriers and streamlines collaboration for overseas clients. Their project managers keep you updated with regular progress reports and proactive problem-solving.

Tip: Request a dedicated project manager and establish preferred communication channels, such as email, video calls, or instant messaging.

Location and Logistics

The geographic location of your PCBA Contract Manufacturing partner directly affects logistics, shipping costs, and lead times. You must weigh the benefits and challenges of working with suppliers in different regions. Consider the following factors:

| Factor | Impact on Costs |

|---|---|

| Minimum Order Quantities | Larger quantities are required offshore |

| Lead Times | Extended (8-12 weeks vs. 2-4 weeks) |

| Safety Stock Levels | Higher levels are needed for delays |

| Working Capital | More capital tied up in inventory |

Labor costs may be lower in certain countries, but increased shipping costs and communication delays can offset these savings. Logistics and quality control issues sometimes negate the perceived benefits of offshore manufacturing. Sanshun Smart addresses these challenges with efficient logistics support and transparent shipping processes. Their global project management experience ensures smooth delivery and reliable timelines, no matter where you operate.

You gain peace of mind when you choose a PCBA Contract Manufacturing partner who combines strong communication with strategic location advantages.

Comprehensive Services

End-to-End PCBA Contract Manufacturing

You need a partner who can manage every stage of your project, from sourcing components to final assembly and testing. End-to-end PCBA Contract Manufacturing services streamline your workflow and reduce the risk of miscommunication. You benefit from a single point of contact who oversees the entire process, ensuring consistency and accountability.

Here is a summary of the key elements you should expect from a comprehensive provider:

| Key Element | Description |

|---|---|

| Manufacturing Process | Covers component sourcing, PCB assembly, and testing based on your specifications. |

| Quality Certifications | Includes ISO 9001, IATF 16949, UL Certification, RoHS, and REACH compliance for assurance. |

| Additional Services | Offers box build assembly, integration with enclosures, wiring, and user interface assembly. |

You also gain access to multi-stage testing, such as AOI, X-ray, ICT, and functional testing. These steps help you catch defects early and guarantee that your assemblies meet strict industry standards. Providers like Sanshun Smart deliver these services with a focus on quality and efficiency.

Tip: Choose a manufacturer who can handle both assembly and integration tasks. This approach saves you time and reduces project complexity.

Post-Production Support

Your relationship with a contract manufacturer should not end at delivery. Post-production support plays a critical role in your long-term success. You need a partner who stands behind their work and provides ongoing assistance.

- A comprehensive warranty covers defects in materials or workmanship. This protection boosts your confidence in the reliability of your products.

- You receive timely help for repairs or replacements. Quick response times build trust and keep your operations running smoothly.

- Your feedback matters. Leading manufacturers actively collect and use customer feedback to improve their products and services.

Sanshun Smart offers robust post-production support, including warranty management and responsive repair services. You can rely on their team to address issues promptly and help you maintain high customer satisfaction.

Note: Strong post-production support ensures your products perform well in the field and strengthens your reputation with end users.

Supplier Audit Checklist

A thorough supplier audit helps you select the right partner for PCBA Contract Manufacturing. Use this checklist to guide your evaluation and ensure you choose a manufacturer who meets your standards.

Key Audit Questions

Ask these essential questions during your supplier audit:

- What are your manufacturing capabilities?

- How do you ensure quality control?

- Can you share examples of similar projects?

- What are your typical turnaround and lead times?

- What kind of after-sales support do you offer?

These questions reveal the supplier’s technical expertise, reliability, and commitment to customer service. Sanshun Smart provides clear answers and detailed documentation for each area, helping you make informed decisions.

On-Site Visit Essentials

During an on-site visit, focus on these critical aspects:

| Aspect | Description |

|---|---|

| People and Culture | Assess team expertise and stability of the organizational structure for efficiency and error reduction. |

| Capability and Quality Control | Evaluate quality control systems, material traceability, and production workflows to ensure reliability. |

| Testing and Lifecycle Management | Review DFM and DFT support, along with repair programs, to minimize costs and extend product lifespan. |

A strong manufacturer like Sanshun Smart demonstrates robust quality control and a skilled workforce during facility tours.

Red Flags

Watch for these warning signs when auditing a PCBA contract manufacturer:

| Red Flag | Description | How to Avoid |

|---|---|---|

| Inconsistent Financial Records | Discrepancies between financial statements and supporting documents. | Maintain accurate bookkeeping and reconcile accounts monthly. |

| High Volume of Manual Journal Entries | Numerous manual adjustments may indicate manipulation or error. | Automate transactions and document manual entries with internal controls. |

| Unusual Related Party Transactions | Transactions lacking proper documentation or fair value assessment. | Disclose related party relationships and ensure proper agreements are in place. |

| Frequent Cash Transactions | Significant cash dealings may suggest potential tax evasion or fraud. | Minimize cash transactions and maintain proper logs and receipts. |

| Rapid Revenue Growth Without Supporting Evidence | Sudden sales increases not backed by market conditions or expenses. | Ensure sales growth is supported by market analysis and corresponding expense increases. |

If you notice any of these issues, proceed with caution. Reliable partners like Sanshun Smart maintain transparent records and strong internal controls.

Tip: Use this checklist to compare suppliers and identify the best fit for your PCBA Contract Manufacturing needs.

Selecting a reliable PCBA contract manufacturing company requires you to focus on key criteria:

| Criteria | Description |

|---|---|

| Location | Choose a manufacturer close to your base to reduce tariffs and shipping times. |

| Intellectual Property Safety | Ensure your designs are protected with secure NDAs and reliable manufacturing processes. |

| Engineering and Sourcing Experience | Look for manufacturers with deep knowledge in design and sourcing to ensure product quality. |

| Flexible Resources | Assess the manufacturer’s ability to adapt to demand changes and maintain production quality. |

| Quality Initiatives | Verify the presence of quality systems like ISO certifications to ensure safety and reliability. |

You should use the supplier audit checklist to verify capabilities, assess risks, and build long-term confidence. Balancing quality, cost, supply chain strength, flexibility, and communication helps you reduce risk and focus on your core business. For tailored support, prepare your project files and reach out to a trusted PCBA contract manufacturer for a detailed consultation or quote.

FAQ

What is PCBA Contract Manufacturing?

PCBA Contract Manufacturing means you outsource the assembly of printed circuit boards to a specialized company. You provide your design and requirements. The manufacturer handles sourcing, assembly, and testing. This process lets you focus on your core business.

How do you choose a reliable PCBA Contract Manufacturing partner?

You should check experience, certifications, supply chain strength, and quality control. Ask for references and visit the facility. Sanshun Smart offers transparent processes and strong engineering support, making your selection easier.

What certifications should a PCBA Contract Manufacturer have?

Look for ISO 9001, IATF 16949, and IPC-A-610. These certifications show the manufacturer meets industry standards for quality and reliability. Sanshun Smart holds multiple certifications to ensure consistent results.

How does Sanshun Smart protect your intellectual property?

Sanshun Smart uses NDAs, encrypted file transfers, and strict access controls. You can trust their team to keep your designs and data secure throughout the PCBA Contract Manufacturing process.

What support do you receive after production?

You get warranty coverage, repair services, and responsive customer support. Sanshun Smart values long-term partnerships and provides ongoing assistance to help you maintain high product quality.