Choosing the right OEM TFT display supplier shapes your product’s quality, cost, and innovation. You must evaluate manufacturing capabilities, quality control, customization, and supplier reliability. Suppliers directly influence your business success and product competitiveness. According to industry reports, up to 50% of product recalls stem from supplier-related issues, so a strong focus on quality and process is essential. The table below highlights how supplier selection impacts your long-term advantage:

| Benefit | Impact on Competitiveness |

|---|---|

| Customization Capabilities | Tailored solutions enhance user experience and product differentiation. |

| Quality Assurance | Ensures consistent product quality, crucial for brand reputation. |

| Access to Latest Technology | Keeps products innovative and relevant in a fast-paced market. |

| Cost-effective Scalability | Reduces unit costs and accelerates time to market, enhancing competitive positioning. |

Your choice determines the performance of each screen, the clarity of every image, and the reliability of your supply chain.

Top Considerations When Evaluating an OEM TFT Display Partner for Your Product Development

- Evaluate manufacturing capabilities to ensure your supplier can meet your technical requirements and support your business goals.

- Prioritize quality control and certifications to guarantee consistent product quality and protect your brand’s reputation.

- Look for customization options that allow you to tailor displays to your specific application needs, enhancing user experience.

- Confirm the supplier’s ability to provide reliable after-sales support and technical assistance throughout your project lifecycle.

- Assess lead times and minimum order quantities to ensure flexibility and timely delivery for your product launches.

OEM TFT Display Manufacturing Capabilities

When you evaluate an OEM TFT display supplier, you must look for comprehensive manufacturing capabilities. A strong supplier can manage every step, from panel fabrication to final module assembly. This ensures you receive LCD-TFT displays that meet your technical requirements and support your business goals.

Panel and Backlight Integration

You want your LCD-TFT displays to deliver sharp image quality and consistent brightness. Suppliers with advanced panel and backlight integration can offer a wide range of LCD sizes and resolutions. They use micro-LED backlighting to boost contrast ratios and improve energy efficiency. This technology also creates thinner screen profiles, which is important for modern product designs.

Tip: Ask your supplier about local dimming and direct-lit backlight options. These features enhance image clarity and reduce power consumption.

A supplier with in-house engineering can quickly produce custom FPC solutions and bond touch panels to LCD-TFT displays. This flexibility supports rapid prototyping and helps you bring new products to market faster.

Touchscreen Dashboard Displays Options

Touchscreen dashboard displays have become standard in many industries. You should look for suppliers who offer the latest trends in LCD-TFT displays, such as flexible screens and ultra-high-definition formats. These features improve user experience and set your products apart.

| Trend | Description |

|---|---|

| Flexible Displays | Foldable screens for enhanced portability and new form factors. |

| Increased Durability | In-Cell Touch Technology and advanced glass protection for better resistance to damage. |

| Improved Viewing Angles | IPS and Super PLS technologies for consistent color and contrast from any angle. |

| Higher Resolution | Support for 4K, 8K, and 16K formats for exceptional image clarity. |

| Integration of Smart Features | Smart connectivity (Wi-Fi, Bluetooth) and voice control for modern applications. |

| Mini-LED/Micro-LED Backlighting | Brighter lighting control and improved contrast for superior LCD-TFT display performance. |

You benefit from suppliers who provide technical support from prototype to mass production. This ensures your LCD-TFT displays meet your specifications at every stage.

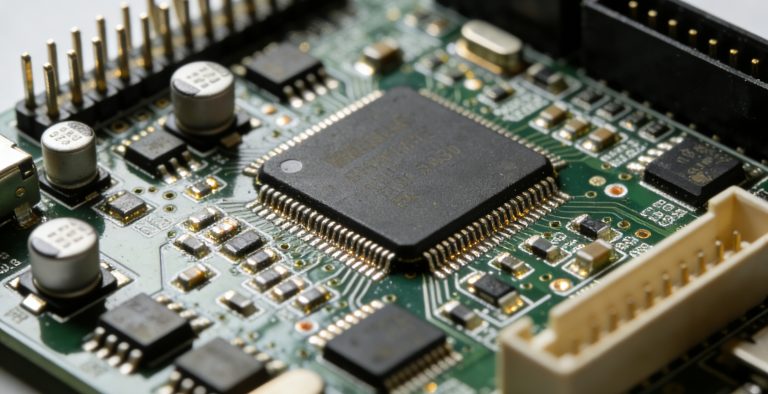

Driver Electronics and Module Assembly

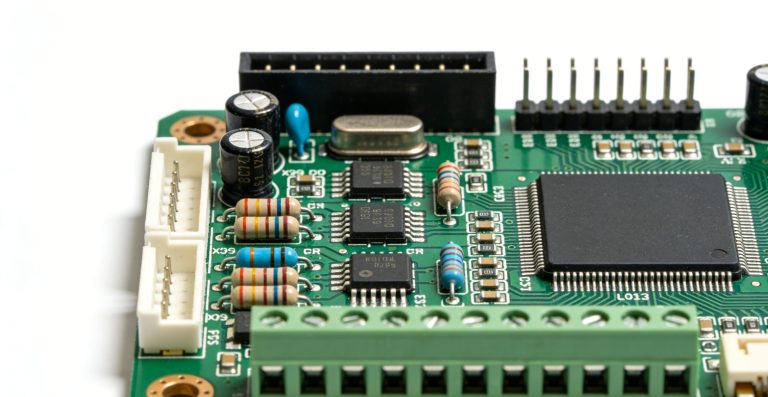

The quality of driver electronics and module assembly determines how well your LCD-TFT displays perform. Reliable suppliers integrate source driver chips, gate driver chips, and power management chips into their modules. These components control brightness, color, and refresh rates, which are critical for clear image reproduction.

| Component | Function |

|---|---|

| Source Driver Chip | Converts digital video signals for precise brightness and color control. |

| Gate Driver Chip | Activates transistors row by row for smooth screen refresh. |

| Control Circuit Board | Processes input signals and generates timing instructions. |

| Power Management Chip | Maintains stable power for consistent LCD-TFT display quality. |

| Timing Precision Matching | Synchronizes the driver chip and TCON to prevent screen tearing. |

| Energy Efficiency Balance | Adjusts backlight voltage for optimal performance and low-light modes. |

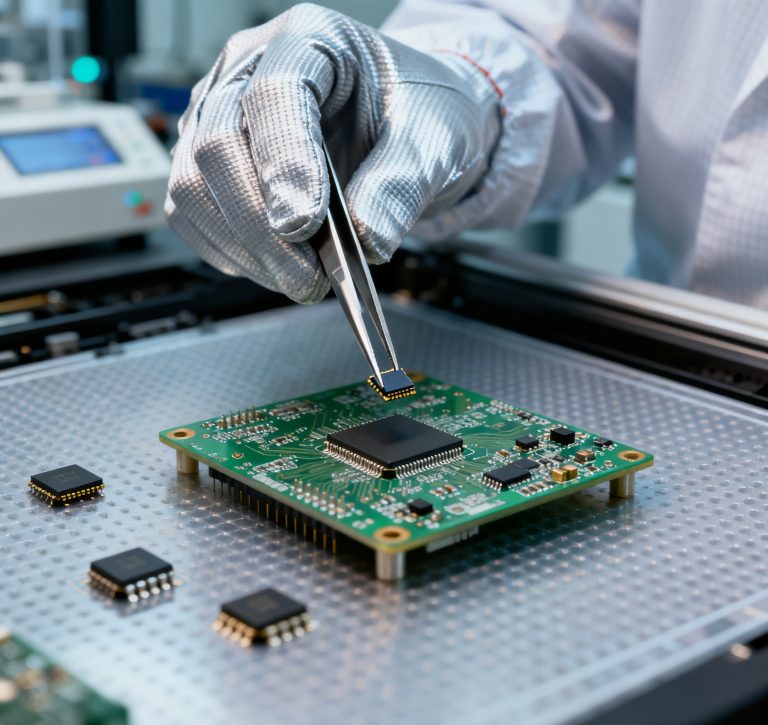

You should confirm that your supplier uses cleanroom assembly for high-quality production. This reduces contamination and ensures long-term reliability for your LCD-TFT displays.

Optical Bonding Methods

Optical bonding is a key factor in LCD-TFT display performance. It improves image clarity, enhances durability, and reduces glare. Suppliers with expertise in advanced optical bonding methods can offer you the best solution for your application.

| Bonding Method | Advantages |

|---|---|

| Wet Bonding | Provides strong adhesion and excellent optical clarity, but requires careful preparation. |

| Dry Bonding | Offers fast processing, reworkability, and high resistance to shock and vibration. |

| Air-Gap Bonding | Lightweight and cost-effective, suitable for less demanding environments. |

You should ask about the supplier’s experience with both wet and dry bonding. Dry bonding, in particular, offers increased shock resistance and eliminates the risk of yellowing, making it ideal for demanding environments.

Note: Advanced optical bonding not only improves the visual quality of lcd-tft displays but also extends their lifespan. This is especially important for products that require high durability and long-term availability.

A supplier with end-to-end TFT services, including concept design and turnkey module delivery, can support your OEM/ODM projects efficiently. Look for value-added services like touch integration and the ability to handle small-to-medium volume production. These capabilities ensure you get the right LCD-TFT displays for your needs, with short lead times and flexible minimum order quantities.

Quality Control and Certifications

Selecting an OEM TFT display supplier with robust quality control and recognized certifications is essential for your product’s reliability and market reputation. You must ensure that your supplier implements comprehensive inspection and testing processes at every stage of manufacturing. These measures guarantee consistent performance, defect-free screens, and long-term durability.

In-House Testing and Inspection

You should look for suppliers who invest in in-house testing and inspection capabilities. This approach allows for immediate detection of defects and ensures that every display meets strict standards before shipment. Suppliers with automatic LCD production lines and microscopic appearance inspection can identify even the smallest flaws. Electrical testing validates the functionality of each unit, while environmental reliability tests simulate extreme conditions, such as cycling from –30°C to +85°C. A 100% QC workflow covers every step, from initial appearance checks to final shipment.

| Feature | Description |

|---|---|

| Automatic LCD Production Lines | High throughput production |

| Microscopic Appearance Inspection | Ensures quality at a microscopic level |

| Electrical Testing | Tests the electrical functionality |

| Environmental Reliability Tests | Cycling from –30°C to +85°C |

| 100% QC Workflow | Comprehensive quality control from appearance to shipment |

You benefit from suppliers who use automated optical inspection, environmental stress testing, and spectral analysis. These processes confirm uniform brightness, color accuracy, and defect-free pixels. Consistent quality control reduces the risk of recalls and supports your brand’s reputation.

Tip: Always request details about your supplier’s inspection protocols and ask for sample test reports. This transparency helps you verify their commitment to quality.

Industry Certifications and Compliance

Certifications play a vital role in establishing supplier credibility. You should prioritize suppliers who hold internationally recognized certifications. These certifications demonstrate a commitment to rigorous quality management and environmental responsibility. ISO 9001 ensures that your supplier maintains strict quality management systems. ISO 14001 highlights their dedication to sustainable practices. IATF 16949 indicates automotive-grade reliability, which is crucial for demanding applications.

| Certification Type | Impact on Supplier Credibility |

|---|---|

| ISO 9001 | Ensures rigorous quality management |

| ISO 14001 | Demonstrates environmental responsibility |

| IATF 16949 | Indicates automotive-grade reliability |

Suppliers with ISO certifications deliver consistent quality and fast lead times. These credentials also support your compliance with international regulations, making it easier to enter new markets.

Note: Certified suppliers often have established processes for optical bonding, OEM/ODM customization, and flexible MOQ, which further enhance your project’s success.

Traceability and Documentation

Traceability and documentation are critical for long-term reliability. You need suppliers who maintain detailed records for every batch and component. This practice allows you to track the origin of materials, monitor production conditions, and verify compliance with international standards. Reliable documentation supports warranty claims and simplifies troubleshooting if issues arise.

| Quality Standard | Description |

|---|---|

| Reliability Testing | Ensures production parts meet operational requirements over temperature, humidity, and vibration. |

| Glass Cleanliness | Glass is protected and maintained to be free of contaminants and fingerprints. |

| Bezel Appearance | Bezels are uniformly painted and free of blemishes. |

| PCB Appearance | PCBs are delivered with reliability in mind, free of contaminants and meeting UL fire requirements. |

| Soldering | Consistent soldering provides mechanical security and electrical connectivity. |

| Consistency | Manufacturing processes ensure product consistency across lots. |

| Product Integrity | Ensures tight assembly and environmental compliance. |

| Glass Color | Maintains compliance with internal color charts despite manufacturing tolerances. |

| ESD Protection & Safety | Devices are designed with ESD protection in mind, including safe packaging. |

You should confirm that your supplier provides comprehensive documentation for every shipment. This includes test reports, compliance certificates, and traceability logs. These records protect your business and ensure that your products meet the highest standards of quality.

Callout: Strong traceability and documentation practices not only support long-term reliability but also streamline your supply chain management.

By focusing on quality control, certifications, and traceability, you position your products for success in competitive markets. These factors, combined with optical bonding expertise, OEM/ODM capabilities, short lead times, and flexible MOQ, help you select the right OEM TFT display supplier for your needs.

Customization and OEM/ODM Services

When you select a supplier for your OEM TFT display project, you gain a competitive edge by leveraging their customization and OEM/ODM service capabilities. These services allow you to create unique products that match your application requirements and market demands.

Custom Display Solutions

You can request a wide range of customization options to ensure your display fits your product perfectly. Suppliers often provide tailored solutions that address technical, environmental, and aesthetic needs. The table below highlights the most frequently requested customization features:

| Customization Option | Description |

|---|---|

| Resolution | Choose the optimal resolution for your content and cost targets. |

| Custom Icons | Add unique icons for improved contrast and brand identity. |

| Sunlight Readability | Enhance usability in outdoor or high-brightness environments. |

| Backlight Brightness | Adjust brightness for different lighting conditions. |

| Anti-Glare Treatments | Improve visibility and reduce fingerprints. |

| ESD Protection | Increase durability with higher electrostatic discharge thresholds. |

| Custom Interfaces | Integrate with your hardware using tailored electrical and mechanical interfaces. |

| Touch Panel Options | Select from capacitive or resistive touch technologies. |

| Drop Testing | Ensure ruggedness through design iterations and stress testing. |

| Environmental Considerations | Engineer for wide temperature ranges and harsh conditions. |

Tip: Customization not only improves product performance but also supports faster lead times and flexible minimum order quantities.

Design Collaboration

You benefit from close collaboration with your supplier’s engineering team. This partnership enables you to develop innovative solutions that meet your exact specifications. Key advantages of design collaboration include:

- Customized solutions that address your unique needs.

- Advanced manufacturing processes that improve efficiency and quality.

- Tailored display technologies that drive product innovation and adaptability.

You can expect your supplier to provide technical guidance from concept to mass production, ensuring that every detail aligns with your vision.

After-Sales and Technical Support

Strong after-sales and technical support are essential for long-term success. Leading suppliers structure their support teams to deliver fast, reliable assistance throughout your project lifecycle. The table below outlines the types of support you should expect:

| Type of Support | Description |

|---|---|

| Professional Service | Consistent quality and comprehensive after-sales care build trust. |

| Technical Support | Direct access to engineers for quick resolution of technical issues. |

| Complete Project Support | Fast, professional help from pre-sales consulting to mass production. |

You receive ongoing technical support, professional after-sales service, and rapid responses to inquiries—often within 24 hours. A dedicated technical team ensures your displays perform reliably, even as your needs evolve.

Note: Comprehensive support, combined with robust quality control and advanced optical bonding, ensures your project stays on schedule and meets all performance targets.

Performance and Long-Term Availability

Display Resolution and Color Depth

You must evaluate the resolution and color depth of TFT panels when selecting LCD-TFT displays for your products. High screen resolution ensures sharp image quality and precise detail, which is essential for medical, industrial, and consumer applications. You can choose from a wide range of LCD-TFT displays, each offering different resolution levels to match your requirements. Enhanced color depth allows your screen to reproduce vibrant images and accurate contrast, improving the overall user experience. Suppliers who offer custom resolution options help you achieve the ideal balance between cost and performance.

Tip: Ask your supplier about their ability to deliver lcd-tft displays with advanced contrast ratios and high brightness. These features boost visibility in challenging environments and support your product’s competitive edge.

Viewing Angles and Refresh Rates

Viewing angles and refresh rates play a critical role in the suitability of TFT displays for various applications. Wide viewing angles ensure that your LCD-TFT displays maintain consistent color and contrast, even when viewed from the side. Basic TN-based LCD panels may show color shift and washed-out visuals off-center, but modern TFT technology provides superior performance.

| Display Type | Viewing Angle Quality |

|---|---|

| tft | Wider |

| Traditional lcd | Narrower |

Fast refresh rates deliver smooth image transitions and reduce motion blur, which is important for interactive screens and dynamic content. You can compare response times to select the best option for your application.

| Display Type | Response Time (ms) |

|---|---|

| tft | 1-5 |

| Traditional lcd | 8-12 |

You should prioritize suppliers who use advanced optical bonding methods to enhance viewing angles and contrast. This ensures your LCD-TFT displays perform reliably in demanding environments.

Product Lifecycle Support

Long-term availability is essential for product sustainability. You need suppliers who guarantee supply continuity for 3–5 years and offer backward compatibility. This minimizes production disruptions and supports regulated product lines with lengthy certification processes. Industrial LCD-TFT displays require consistent quality and a clear End-of-Life management strategy to maintain system continuity.

- Collaborate with suppliers who prioritize supply continuity and backward compatibility.

- Choose LCD-TFT displays designed for long-term component availability and robust lifecycle support.

Note: Reliable product lifecycle support, combined with strong quality control, short lead times, and flexible MOQ, ensures your tft solutions remain competitive and sustainable.

Cost, Lead Time, and MOQ

When you select an OEM TFT display supplier, you must balance cost, lead time, and minimum order quantity (MOQ) to keep your project on track. These factors shape your budget, production schedule, and ability to respond to market changes. You need to evaluate how each supplier manages these elements to ensure your LCD-TFT displays meet your requirements.

Price-Performance Balance

You want to maximize value without sacrificing quality. The price-performance ratio of LCD-TFT displays directly influences your purchasing decisions. High-performance displays deliver superior image quality, faster response times, and better durability. However, these features often come with higher costs. Standard LCD modules may fit basic applications, but advanced LCD-TFT displays offer greater benefits for demanding projects.

| Display Type | Cost | Performance | Influence on Purchasing Decisions |

|---|---|---|---|

| TFT | High | Superior image quality, faster response times, better durability | Higher production costs lead to careful consideration by manufacturers and consumers |

| LCD | Low | Adequate for basic applications | More affordable, suitable for cost-sensitive markets |

Customized LCD-TFT displays range from $500 to $2000+, while standard options start as low as $5. You should match your screen choice to your application and budget.

Lead Time and Delivery Reliability

Lead time affects your ability to launch products on schedule. You must consider how suppliers manage component sourcing, production, and delivery. Reliable suppliers communicate clearly about lead times and adapt to unforeseen events. Factors such as local holidays or global disruptions can impact delivery schedules.

| Factor | Description |

|---|---|

| Component Lead Times | The primary driver for the overall schedule, often determined by a few long lead time items. |

| Price vs. Availability | Choices between lower prices from manufacturers and shorter lead times from distributors. |

| Local Holidays | Events like the Chinese New Year can significantly impact lead times. |

| Unforeseen Events | Global pandemics and other unexpected occurrences can disrupt supply chains. |

You should ask about the supplier’s quality control, optical bonding expertise, and OEM/ODM capabilities, as these can affect both lead time and delivery reliability.

Tip: Negotiate clear delivery terms and request regular updates to avoid delays.

Minimum Order Quantity Flexibility

MOQ flexibility determines whether you can start with small batches or prototypes. Many suppliers now offer flexible MOQs for LCD-TFT displays, making it easier to test new designs or enter niche markets. You can negotiate terms to reduce upfront costs and request paid samples to evaluate image quality before committing to larger orders.

| Evidence Type | Description |

|---|---|

| MOQ Flexibility | Many suppliers offer flexible minimum order quantities for prototypes, enhancing project feasibility. |

| Negotiation Potential | Businesses can negotiate terms directly with suppliers, reducing upfront costs. |

| Sample Testing | The ability to obtain paid samples allows assessment of product quality before larger commitments. |

You should prioritize suppliers who support small-batch production and provide technical support throughout the process. This approach gives you greater control over your LCD-TFT displays and helps you manage costs effectively.

Note: Always discuss MOQ, lead time, and price-performance balance early in negotiations to secure the best terms for your project.

Supplier Track Record and Sample Evaluation

Industry Experience and Reputation

You should always check the track record of any OEM TFT display supplier before making a decision. A strong reputation in industrial applications signals reliability and expertise. Suppliers with years of experience understand the demands of digital dashboard displays, human-machine interface systems, and custom user interface projects. They know how to deliver high image quality and consistent performance.

The table below outlines the main factors that contribute to a supplier’s reputation in the global market:

| Factor | Description |

|---|---|

| Technical expertise | Deep understanding of industry requirements and guidance on technology selection. |

| Customization capabilities | Ability to tailor products for industrial applications without exceeding budget constraints. |

| Quality assurance processes | Implementation of reliability, consistency, and compliance testing to meet standards. |

| Supply chain reliability | Effective management of lead times, availability, and communication about potential risks. |

| Engineering support | Collaboration during design, prototyping, and manufacturing phases. |

| Ongoing customer service | Support for adapting to changes during production and after delivery. |

You gain confidence when you see a supplier with positive reviews, repeat customers, and a history of supporting complex industrial applications. This background ensures they can handle your requirements for quality control, optical bonding, and flexible MOQ.

Requesting and Testing Samples

You should always request samples before committing to a large order. Testing samples allows you to evaluate display quality, touch responsiveness, and overall user experience under real-world conditions. For industrial applications, you need to check brightness, contrast, and viewing angles to ensure the displays meet your standards.

Here are proven methods for evaluating supplier quality and performance:

| Method | Description |

|---|---|

| Sample Testing | Request physical samples to assess brightness, contrast, viewing angles, and touch response. |

| Third-Party Audits | Use firms like SGS or TÜV to audit factory equipment, process documentation, and controls. |

| Data-Driven Insights | Analyze data, such as on-time delivery rates and average response times for supplier reliability. |

You should also consider third-party audits for a deeper look at quality control and optical bonding processes. Reviewing data on lead time and delivery reliability helps you select a supplier who can support your OEM/ODM projects and meet your minimum order quantity needs.

Tip: Always test samples in the actual environment where your product will operate. This step ensures the display performs as expected in your specific industrial applications.

When you select an OEM TFT display supplier, you must weigh several critical factors that shape your project’s success:

| Critical Factors | Description |

|---|---|

| Product Quality | High reliability using A-standard materials and strict processes. |

| Price | Moderate to high pricing based on quality. |

| After-sales Service | Long-term warranty and maintenance options. |

| Delivery Cycle | Timely delivery, with some suppliers offering faster options. |

| Supply Stability | Consistent product availability over time. |

| Technical Support | Comprehensive support from R&D teams. |

A structured evaluation process helps you achieve the best results:

- Review technical proposals and quotations.

- Test engineering samples on your device.

- Confirm design and validate pilot production.

- Move to mass production with ongoing improvements.

By focusing on these steps, you ensure your displays deliver outstanding quality, cost efficiency, and innovation.

FAQ

What is the most important factor when choosing an OEM TFT display supplier?

You should prioritize quality control. Strong quality systems ensure every display meets your standards. Reliable suppliers use in-house testing and hold industry certifications. This focus protects your brand and reduces the risk of defects.

How does optical bonding improve my product?

Optical bonding enhances display clarity and durability. You get reduced glare, better contrast, and improved touch accuracy. This method also increases resistance to shock and moisture, making your product more reliable in harsh environments.

Why should I consider OEM/ODM capabilities?

You gain flexibility and innovation. OEM/ODM services allow you to customize displays for unique applications. You can collaborate with engineers to create tailored solutions that fit your technical and design requirements.

How do lead time and MOQ affect my project?

Short lead times help you launch products faster. Flexible MOQ lets you order small batches for prototypes or niche markets. You should discuss these terms early to avoid delays and manage costs effectively.

Can I request samples before placing a large order?

Yes, you should always request samples. Testing samples lets you check display quality, touch response, and overall performance. This step ensures the supplier meets your expectations before you commit to a full order.