You face unique supply chain risks when sourcing TFT displays for industrial or commercial applications. The complexity of thin-film transistor technology creates vulnerabilities that can disrupt your production schedule or impact product quality. Common risks include:

- Geopolitical tensions

- Economic instability

- Procurement inefficiencies

- Impact of AI and emerging technologies

- Extreme weather events

- ESG compliance pressures

- Cyber-attacks

- Data integrity issues

- Challenges from generalist procurement teams

Understanding the intricacies of TFT display components and supply channels helps you address these challenges with confidence.

TFT Display Supply Chain Risk Management Strategies for Stable Production

- Monitor raw material markets to anticipate shortages and price fluctuations for TFT displays.

- Diversify your supplier base to reduce risks from geopolitical tensions and material shortages.

- Implement effective inventory management to respond quickly to supply disruptions and maintain production efficiency.

- Consider local sourcing to minimize delays and improve quality control in your TFT display supply chain.

- Leverage technology for real-time risk monitoring to stay ahead of potential supply chain disruptions.

Key Supply Chain Risks for TFT Displays

Thin-film transistor technology forms the backbone of modern TFT displays. You depend on a complex network of suppliers for raw materials, components, and advanced manufacturing processes. This reliance exposes your TFT display supply chain to several critical risks.

Material Shortages

You face significant challenges when sourcing materials for TFT displays. The intricate supply chain for TFT LCD manufacturing depends on specific raw materials like indium and gallium. When shortages occur, production slows down, and costs rise. In 2022, over 60% of manufacturers reported raw material shortages, which delayed TFT LCD production by up to 30%. These shortages make TFT displays more vulnerable compared to other display technologies. Fluctuations in material costs create price volatility, complicating your procurement cycles and budget planning. The growing demand for AI hardware has also caused a critical shortage of high-end printed circuit board materials, leading to unprecedented price increases and longer lead times across the electronics sector.

Tip: Monitor raw material markets closely to anticipate price swings and supply constraints for tft displays.

Geopolitical Factors

Geopolitical tensions directly impact your ability to source critical materials for TFT displays. China’s export controls on rare earth elements, including gallium and germanium, have raised international concerns about supply chain stability. The U.S. has responded with increased scrutiny over technology exports and tariffs on Chinese goods. Duties on TFT LCDs can range from 7.5% to 25%, affecting both cost and supply chain reliability. Many manufacturers now shift production to countries like Vietnam and Mexico to reduce exposure to these risks.

Logistics Disruptions

Logistics disruptions can halt your TFT display production unexpectedly. Common causes include:

- Natural disasters

- Geopolitical issues and trade policies

- Supplier financial difficulties

- Cyberattacks

- Technology failures

- Pandemics and health crises

- Transportation disruptions

- Quality control issues

- Demand fluctuation

- Regulatory changes

- Labor shortages

- Currency fluctuation

- Raw material shortages

Each of these factors can delay shipments, increase costs, and disrupt your production schedule for TFT displays.

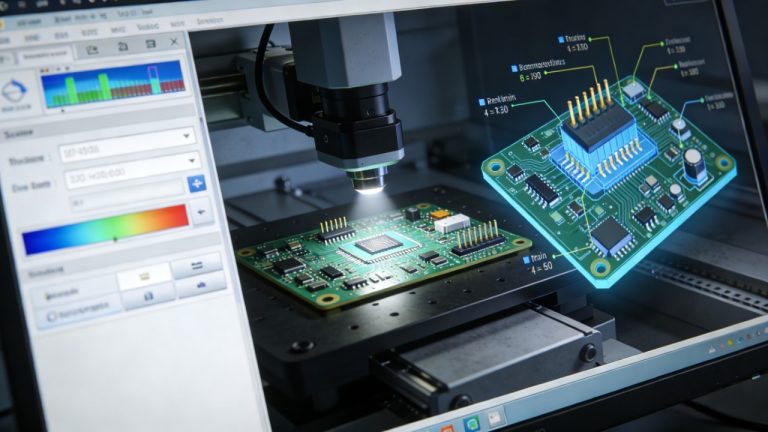

Quality and Supplier Issues

Quality problems with suppliers can reduce yield rates and impact your TFT display output. Automation and AI have improved yield rates by enabling early defect detection and optimizing operational efficiency. However, you must still implement strict quality control measures and manage suppliers closely to minimize defects. The table below summarizes the impact of automation on yield rates in TFT display production:

| Impact on Yield Rates | Description |

|---|---|

| Improved Yield Rates | Automation enhances yield rates in TFT display production lines. |

| Reduced Defect Rates | AI helps detect defects early, minimizing supplier-related quality issues. |

| Optimized Efficiencies | Advanced technologies support high-quality, efficient TFT display production. |

You can further reduce risks by calibrating manufacturing equipment and enforcing supplier management strategies.

Impact on TFT Display Production

Production Delays

You experience production delays when supply chain risks disrupt the flow of critical components for TFT displays. Lead times for key materials can stretch your project timelines. For example, the average lead time for LCD glass is 6 weeks, manufacturing takes 2 weeks, and shipping adds another 4 weeks. The total lead time reaches 12 weeks, which can slow your response to market demands.

| Component | Lead Time |

|---|---|

| LCD Glass | 6 weeks |

| Manufacturing | 2 weeks |

| Shipping | 4 weeks |

| Total Lead Time | 12 weeks |

Delays in the TFT supply chain increase your costs and reduce your market share. You may need to reevaluate your supply chain strategies and invest in local manufacturing or strategic partnerships to stay competitive. The global semiconductor shortage has also limited the availability of TFT display components, making it harder for you to meet customer demand.

Cost Increases

You face higher costs when disruptions affect the TFT supply chain. Rising prices for raw materials and tariffs on imported components often force you to pass these costs to your customers. As a result, TFT displays become more expensive in the market. Manufacturers of budget-friendly educational tools struggle to maintain pricing structures while managing increased production costs. These challenges can compress your margins and make it difficult to offer competitive prices.

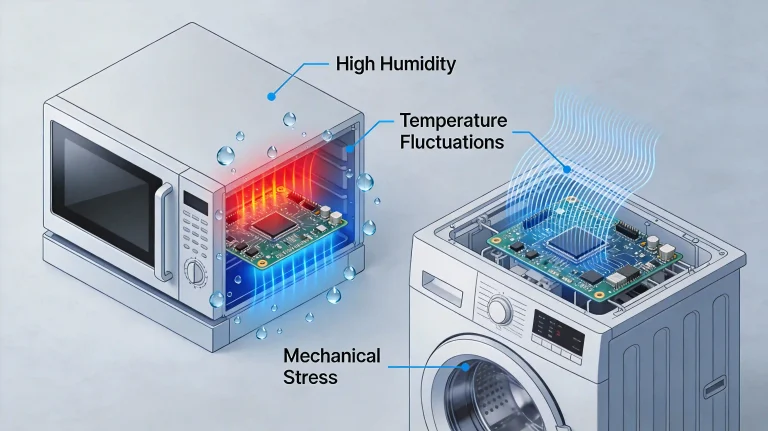

Quality Control Challenges

Supply chain risks create significant quality control challenges for your TFT display production. You rely on specialized materials and complex manufacturing processes. Limited suppliers for high-quality substrates can cause bottlenecks. The integration of protective layers requires close collaboration with material suppliers. Regional concentration in East Asia exposes your TFT supply chain to disruptions, prompting you to diversify sourcing.

| Challenge Type | Description |

|---|---|

| Reliance on Specialized Materials | Limited suppliers for high-quality flexible substrates create bottlenecks in the supply chain. |

| Complexity of Manufacturing | Integration of protective layers adds complexity and requires collaboration with material suppliers. |

| Regional Supply Chain Vulnerability | Concentration in East Asia introduces risks from regional disruptions, prompting diversification. |

You address these challenges by implementing rigorous raw material inspections, automated process controls, and advanced testing systems. Quality management frameworks and customer feedback help you maintain high standards for TFT displays.

Customer and Market Effects

Supply chain risks for TFT displays impact your customers and market position. Disruptions can delay manufacturing timelines and reduce product availability. When you cannot meet demand, customers may turn to competitors with more reliable supply chains. Recurring disruptions increase your costs and compress margins. You may need to realign your manufacturing to regions with favorable trade agreements or adopt dual-sourcing models to improve resilience.

| Impact Area | Description |

|---|---|

| Manufacturing Timelines | Disruptions can lead to delays in production, affecting product availability. |

| Product Availability | Shortages can result in unmet consumer demand, leading to dissatisfaction. |

| Market Share | Companies unable to deliver may lose customers to competitors. |

Note: You can protect your market share by investing in supply chain resilience and maintaining strong relationships with reliable suppliers.

Mitigation Strategies for TFT Display Supply Chain

You can strengthen your supply chain for TFT displays by adopting a proactive, multi-layered approach. The following strategies help you reduce risk, control costs, and maintain consistent quality in your TFT display production.

Supplier Diversification

You reduce your exposure to disruptions by diversifying your supplier base for TFT displays. Building long-term collaborative relationships with experienced display suppliers ensures you have reliable partners who understand your quality standards. You create contingency plans that allow you to respond quickly when disruptions occur. Designing your products with flexibility enables you to pivot to alternative components if certain TFT parts become scarce.

- Build long-term partnerships with experienced TFT display suppliers.

- Develop contingency plans for critical components.

- Design TFT displays with modularity for quick design changes.

For example, leading electronics manufacturers now maintain a network of secondary suppliers for key TFT display components. This approach allows you to switch sources rapidly during shortages or geopolitical events, minimizing downtime and protecting your production schedule.

Tip: Regularly review your supplier portfolio and assess their risk profiles to ensure you can adapt to changing market conditions.

Inventory Management

Effective inventory management gives you greater control over your TFT display supply chain. Lean supply chain practices help you reduce excess inventory while improving your responsiveness to market changes. Keeping spare TFT display parts onsite allows you to respond quickly to unforeseen events. Working closely with suppliers to maintain a stock of standard TFT display parts further enhances your resilience.

| Inventory Management Technique | Benefit |

|---|---|

| Lean supply chain management | Reduces excess inventory and improves market responsiveness |

| On-site spare LCD/TFT display parts | Enables quick response to supply disruptions |

| Supplier-maintained standard TFT display parts | Enhances supply chain resilience and availability |

You can use digital inventory tracking systems to monitor stock levels in real time. This visibility helps you avoid both shortages and overstock situations, keeping your TFT display production efficient and cost-effective.

Local and Regional Sourcing

You mitigate risk by sourcing TFT displays and components from local or regional suppliers. This strategy reduces your dependence on long international supply chains, which often face delays from geopolitical tensions or transportation disruptions. Local sourcing also allows you to respond faster to market demand and regulatory changes.

Many TFT display manufacturers now invest in regional production hubs. For example, shifting some TFT display assembly to facilities in North America or Southeast Asia helps you avoid tariffs and shipping delays. You also gain better oversight of quality control processes when you work with nearby suppliers.

Note: Evaluate the total cost of ownership, including logistics and compliance, when considering local or regional sourcing for tft displays.

Technology and Risk Monitoring

You can leverage advanced technology to monitor and manage risks in your TFT display supply chain. Real-time risk monitoring platforms provide customized alerts on over 60 risk events, including natural disasters, supply chain disruptions, and geopolitical conflicts. Multi-tier supplier analysis helps you identify critical dependencies and vulnerabilities across your TFT display network.

| Feature | Description |

|---|---|

| Customized Alerts | Receive notifications on over 60 risk events, from natural disasters to commodity shortages. |

| Multi-Tier Supplier Analysis | Identify critical dependencies and vulnerabilities in your TFT display supply chain. |

| Comprehensive Coverage | Monitor global supply chain risks on a single platform. |

You stay aware of risks and anticipate disruptions by mapping risks to key assets such as shipments and suppliers. Predictive analytics can alert you to potential machinery failures, allowing for timely interventions. Cloud-based risk management software connects your distributed teams and suppliers, providing real-time updates on compliance and supplier documentation.

| Risk Type | Management Strategy |

|---|---|

| Operational Risk | Maintain inventory buffers, diversify TFT display suppliers |

| Financial Risk | Use hedging strategies and insurance |

| Cybersecurity Risk | Implement stringent protocols and regular audits |

| Natural Disaster | Develop contingency plans and alternate sourcing |

Alert: Regularly update your risk monitoring tools to ensure you capture emerging threats to your tft display supply chain.

Do you want to secure your supply of high-quality industrial TFT displays? Contact Sanshun Smart’s engineering team for a stable procurement strategy and solution.

You strengthen your TFT display supply chain by managing risks early and choosing the right partners. Smart engineering selection, cross-match planning, and supplier alignment drive long-term reliability and profitability.

| Mitigation Strategy | Impact on Stability |

|---|---|

| Diversification | Reduces overdependence and boosts resilience |

| Proactive Management | Addresses threats and ensures steady operations |

| Technological Integration | Improves transparency and real-time oversight |

Consider expert resources, such as technical consultation, prototyping support, and guidance on long-term partnerships. Take action now to secure your supply and protect your market position.

FAQ

What is the most common supply chain risk for TFT displays?

Material shortages pose the most frequent risk. You often face delays and cost increases when sourcing rare elements like indium or gallium. Monitoring global supply trends helps you anticipate and manage these disruptions.

How can you quickly respond to a sudden supplier disruption?

You should maintain a list of pre-qualified secondary suppliers. This approach allows you to switch sources rapidly. Regular supplier audits and contingency planning further strengthen your response.

Why does local sourcing improve supply chain resilience?

Local sourcing reduces your exposure to international shipping delays and geopolitical risks. You gain faster lead times and better quality oversight by working with nearby suppliers.

What technology helps you monitor supply chain risks?

Real-time risk-monitoring platforms provide alerts for disruptions, natural disasters, and supplier issues. You can use these tools to map vulnerabilities and take proactive action.

How do you ensure consistent quality in TFT display procurement?

You implement strict quality control protocols and collaborate closely with suppliers. Automated testing and regular inspections help you maintain high standards for every batch.