Let’s be real—picking the wrong TFT LCD Touch Panel Manufacturer can ruin your product launch. You’ve poured time, budget, and heart into your design, only to discover the touch response is sluggish, the display washes out in sunlight, or worse—batches start failing after three months in the field. If you’ve ever stared at a stack of defective units, wondering, “Where did we go wrong?” then this guide is for you.

Choosing the right TFT LCD Touch Panel Manufacturer isn’t just about price or specs—it’s about finding a true engineering partner who gets your vision and delivers reliability, innovation, and scalability. Whether you’re building medical devices, industrial HMIs, or smart retail kiosks, this checklist will help you cut through the noise and pick a manufacturer that actually earns your trust. Think of it as your due diligence playbook for avoiding costly mistakes.

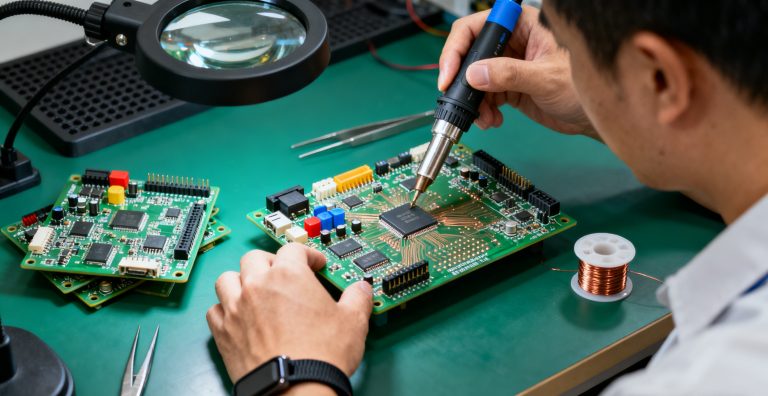

Quick Decision Checklist: What to Demand from Your TFT LCD Touch Panel Manufacturer. Not sure where to start? Use this visual anchor to evaluate vendors fast. Ideal for procurement managers, project leads, and engineering teams.

| Evaluation Factor | Must-Have Criteria |

|---|---|

| Technical Expertise | Experience with PCAP touch panel manufacturer workflows, display integration partner for complex systems |

| Customization Ability | Offers OEM/ODM services, supports EMI shielding, glove/wet touch, high-brightness LCDs |

| Quality Assurance | ISO 9001, ISO 13485, IEC 62368-1 certified; in-house reliability testing (thermal, humidity, touch durability) |

| Optical Bonding | In-house OCR/OCA bonding capability for sunlight-readable, ruggedized displays |

| Lead Time & Pricing | Transparent MOQs, no hidden tooling fees, sample → NPI → mass production in 8–12 weeks |

| Support & Communication | Pre-sales engineering, multilingual team, EMI debugging support, 24h response time |

| Sustainability | RoHS, REACH compliant, recyclable materials, energy-efficient production line |

| Scalability | Proven capacity to scale from 1K to 100K+ units/month without quality drop |

Pro Tip: Print this table and bring it to your next vendor meeting.

What Should I Look for in a Reliable TFT LCD Touch Panel Manufacturer for Industrial or Medical Applications?

When you’re sourcing a TFT LCD Touch Panel Manufacturer, especially for mission-critical industries like medical or industrial automation, you need more than just a component supplier—you need a display integration partner. Here’s what separates the pros from the pretenders:

- Industry-Specific Experience: Have they built touch panels for ventilators, infusion pumps, or factory HMIs? Look for case studies.

- Customization Depth: Can they modify border size, aspect ratio, or add anti-reflective coatings?

- EMI/RFI Shielding: Critical in medical environments. Ask if they do in-house shielding design and testing.

- Touch Technology: Resistive (for glove use) vs. PCAP (multi-touch, durability). A good PCAP touch panel manufacturer should support both.

- Environmental Resilience: Operating temp (-20°C to 70°C), IP65 sealing, anti-vibration mounting.

Don’t just buy a screen—partner with a TFT LCD Touch Panel Manufacturer who understands your end-use environment.

Quality Verification Checklist for TFT LCD Touch Panel Manufacturers

You can’t trust a TFT LCD Touch Panel Manufacturer until you’ve verified their quality backbone. Here’s how to audit them like a pro:

- Certifications Matter:

- ISO 9001: Standard for quality management.

- ISO 13485: A must for medical-grade displays.

- IEC 62368-1: Safety standard for AV and IT equipment.

- In-House Testing Labs? Non-Negotiable.

- Thermal cycling (−40°C to 85°C)

- Humidity testing (85% RH, 1,000 hours)

- Touch durability (5 million+ taps)

- EMI/EMC pre-compliance testing

- Traceability & Documentation:

- Full batch traceability (lot numbers, component origins)

- Reliability reports (MTBF, lifespan predictions)

- Defect Rate & RMA Process:

- Ask for their DPPM (Defective Parts Per Million).

- How fast do they replace faulty units?

📌 A certified, transparent TFT LCD Touch Panel Manufacturer with in-house testing is your best defense against field failures.*

Why Optical Bonding Matters When Choosing a TFT LCD Touch Panel Manufacturer?

If your device will be used in direct sunlight—think kiosks, outdoor HMIs, or agricultural machinery—optical bonding is not optional.

Air Gap vs. OCR/OCA Bonding (Imagine this as a side-by-side diagram)

- Air Gap (Standard): Air between touch panel and LCD → high reflectivity → poor readability in sunlight.

- OCR/OCA Bonding: Optical Clear Resin or Adhesive fills the gap → reduces reflection by 90% → sharp, readable display even at noon.

Key Benefits of OCR/OCA Bonding:

- 400%+ improvement in sunlight readability

- Eliminates condensation inside the display

- Increases mechanical durability (resists shock/vibration)

- Improves touch accuracy (no parallax error)

📌 Ensure your TFT LCD Touch Panel Manufacturer offers in-house OCR/OCA bonding for outdoor or high-brightness applications.

Cost, Lead Time & Scalability: The Real B2B Decision Trifecta

Let’s talk money—and time. Because no matter how good the tech is, if you can’t scale or the timeline slips, the project fails.

| Factor | Red Flags | Green Flags |

|---|---|---|

| Pricing | Vague quotes, hidden tooling fees | Transparent pricing, no MOQ for prototypes |

| Lead Time | “We’ll get back to you” | 2–3 weeks for samples, 8–10 for NPI |

| Scalability | No capacity planning data | Proven 50K+/month output with consistent yield |

| Communication | One-timezone support, slow replies | 24/7 multilingual engineering support |

A reliable TFT LCD Touch Panel Manufacturer balances cost, speed, and scalability—without sacrificing quality.*

👉 SanShun Smart offers fixed-fee NPI packages and scalable production—get a quote today.

Cross-Industry Comparison: What Your TFT LCD Touch Panel Manufacturer Should Know

| Industry | Key Requirements | Recommended Tech |

|---|---|---|

| Medical | ISO 13485, EMI shielding, glove touch | PCAP, OCR bonding, anti-microbial coating |

| Industrial | Rugged, wide temp, IP65 | Resistive/PCAP, metal bezel, EMI shield |

| Outdoor | >1000 nits, sunlight readable | OCA bonding, anti-reflective coating |

| Automotive | AEC-Q100, vibration resistance | Fully laminated, wide viewing angle |

Use this table to test your manufacturer’s versatility.

SanShun Smart: A Trusted TFT LCD Touch Panel Manufacturer and Display Integration Partner

After reviewing dozens of vendors, why do engineering teams at Fortune 500s and fast-growing medtech startups choose SanShun Smart?

✅ Proven Technical Edge:

- Full in-house R&D: optical bonding, EMI shielding, high-brightness BLU design

- Supports PCAP, resistive, and hybrid touch technologies

✅ Certified & Compliant:

- ISO 9001, ISO 13485, IEC 62368-1 certified

- RoHS, REACH, and medical-grade material compliance

✅ End-to-End Support:

- Pre-sales: Free feasibility analysis, mechanical/electrical integration

- Post-sales: 24h troubleshooting, EMI debugging, field failure analysis

✅ Real-World Applications:

- Medical: 10.1” PCAP touch panel for anesthesia machines (OCR-bonded, glove-touch)

- Industrial: 15.6” HMI display for CNC machines (1200 nits, IP65, metal frame)

- Retail: 21.5” touch kiosk with anti-reflective coating (OCA-bonded, EMI-shielded)

We don’t just make displays—we solve display problems. From concept to mass production, we’re your silent engineering partner.

👉 Contact SanShun Smart today for a free technical consultation, sample kit, or factory audit access.

Top Questions About TFT LCD Touch Panel Manufacturers

Q: Which TFT LCD Touch Panel Manufacturer is best for outdoor high-brightness applications?

A: Look for manufacturers offering 1000+ nits brightness, OCA/OCR optical bonding, and anti-reflective coatings. SanShun Smart specializes in sunlight-readable displays with full lamination and EMI shielding—ideal for kiosks, construction equipment, and smart city installations.

Q: How to evaluate the long-term reliability of a TFT LCD Touch Panel Manufacturer?

A: Check for ISO certifications, in-house reliability testing (thermal, humidity, touch cycles), and real-world case studies. Ask for MTBF data and DPPM rates. A reliable TFT LCD Touch Panel Manufacturer will provide full traceability and failure analysis reports.

Q: Can I get a custom TFT LCD touch panel with glove and wet touch support?

A: Yes—choose a PCAP touch panel manufacturer that supports projective capacitance with enhanced firmware. SanShun Smart offers glove/wet touch tuning as a standard service for industrial and medical clients.

Q: What certifications should a medical-grade TFT LCD Touch Panel Manufacturer have?

A: Essential certifications include ISO 13485 (quality management), IEC 62368-1 (safety), and biocompatibility (if used in patient contact). Also, confirm RoHS/REACH compliance for global market access.

Q: How long does it take to go from prototype to mass production?

A: A streamlined TFT LCD Touch Panel Manufacturer can deliver samples in 2–3 weeks, NPI in 8–10 weeks, and scale to 50K+ units/month. SanShun Smart offers fixed-timeline NPI programs with no hidden fees.