PCBA

PCBA

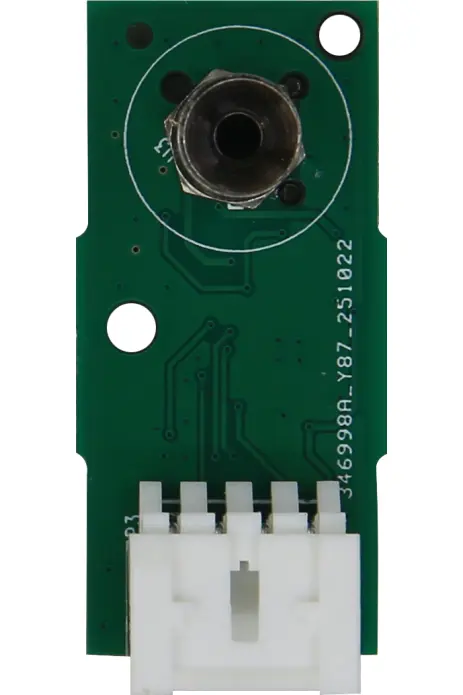

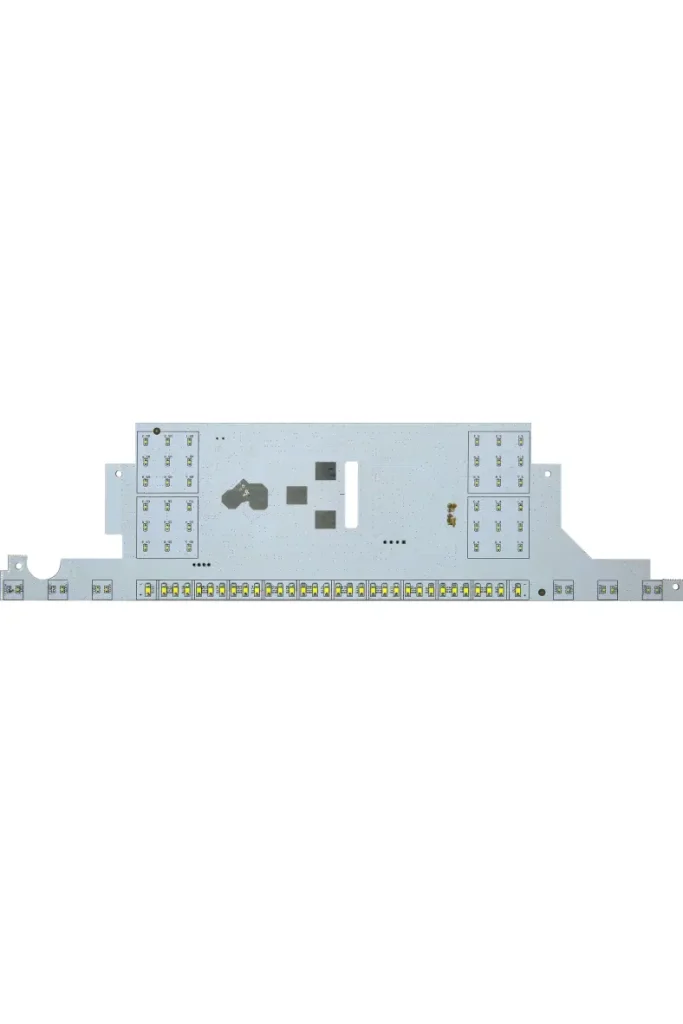

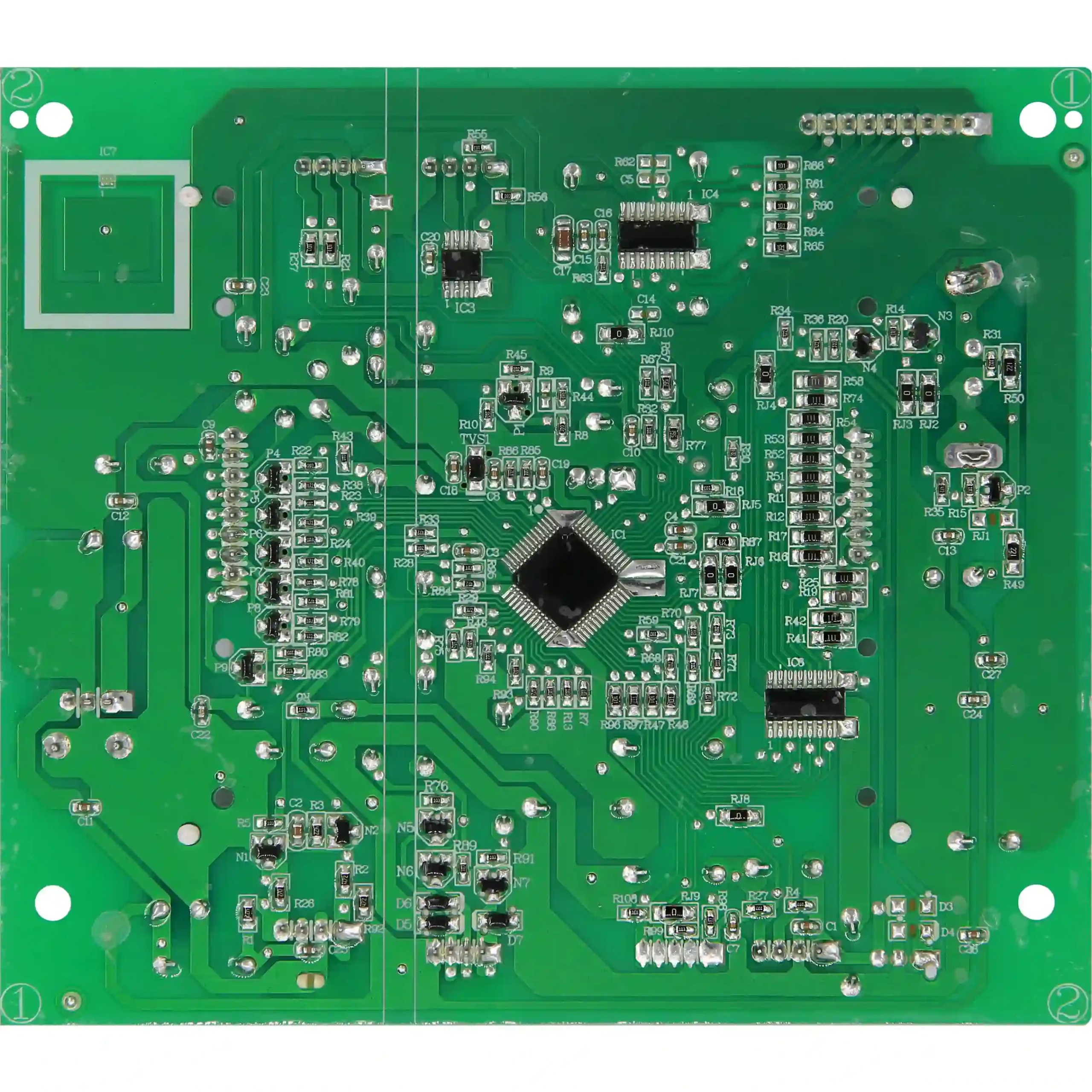

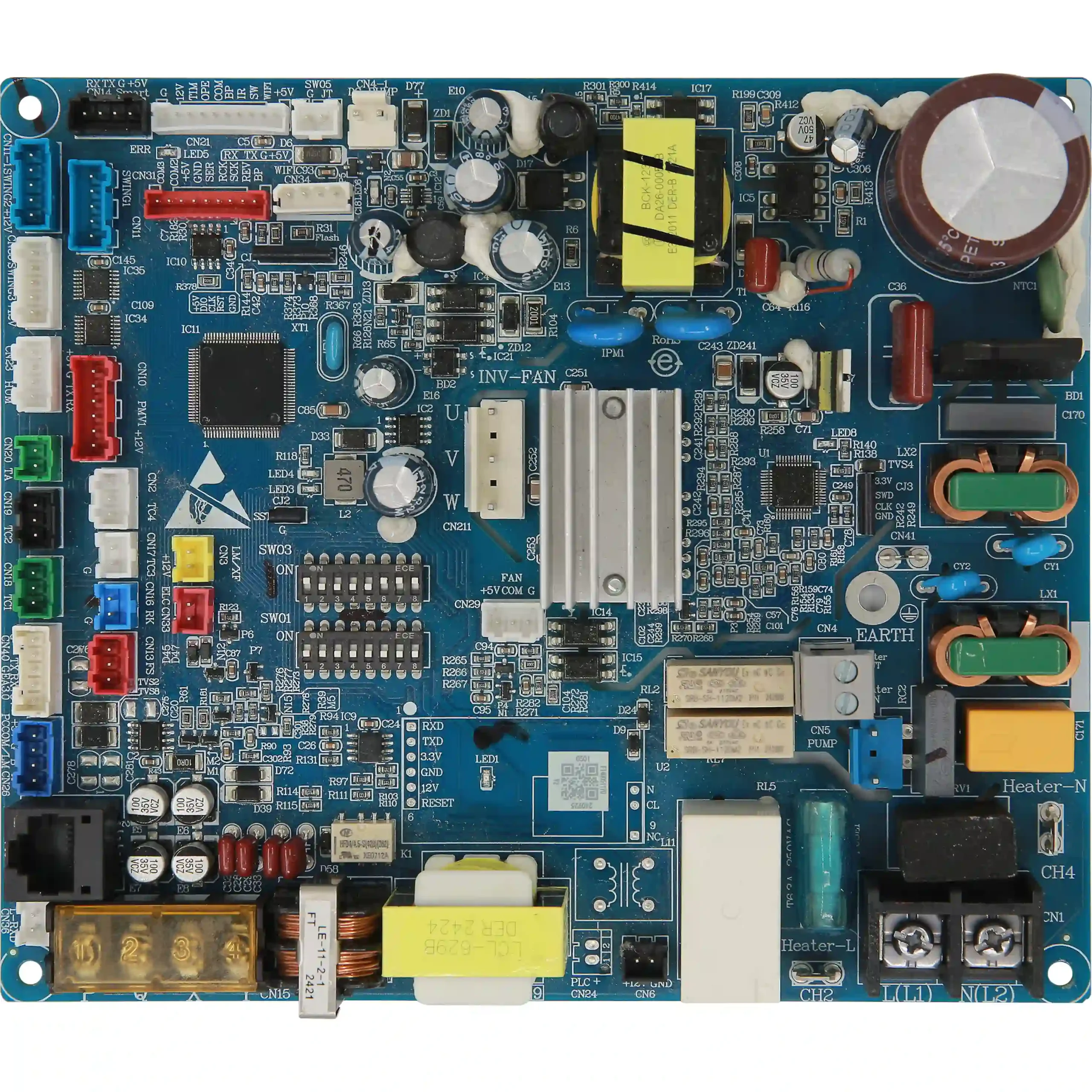

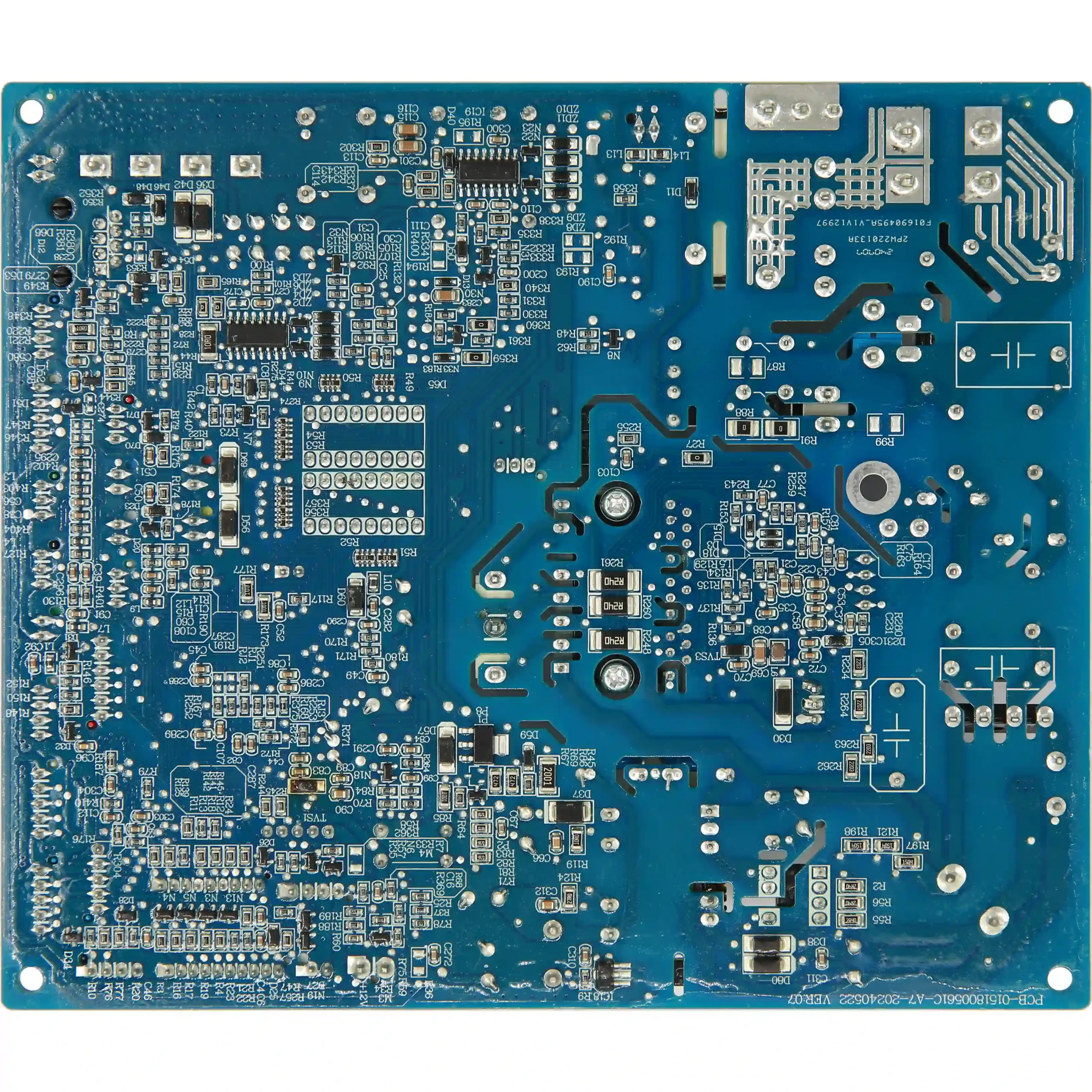

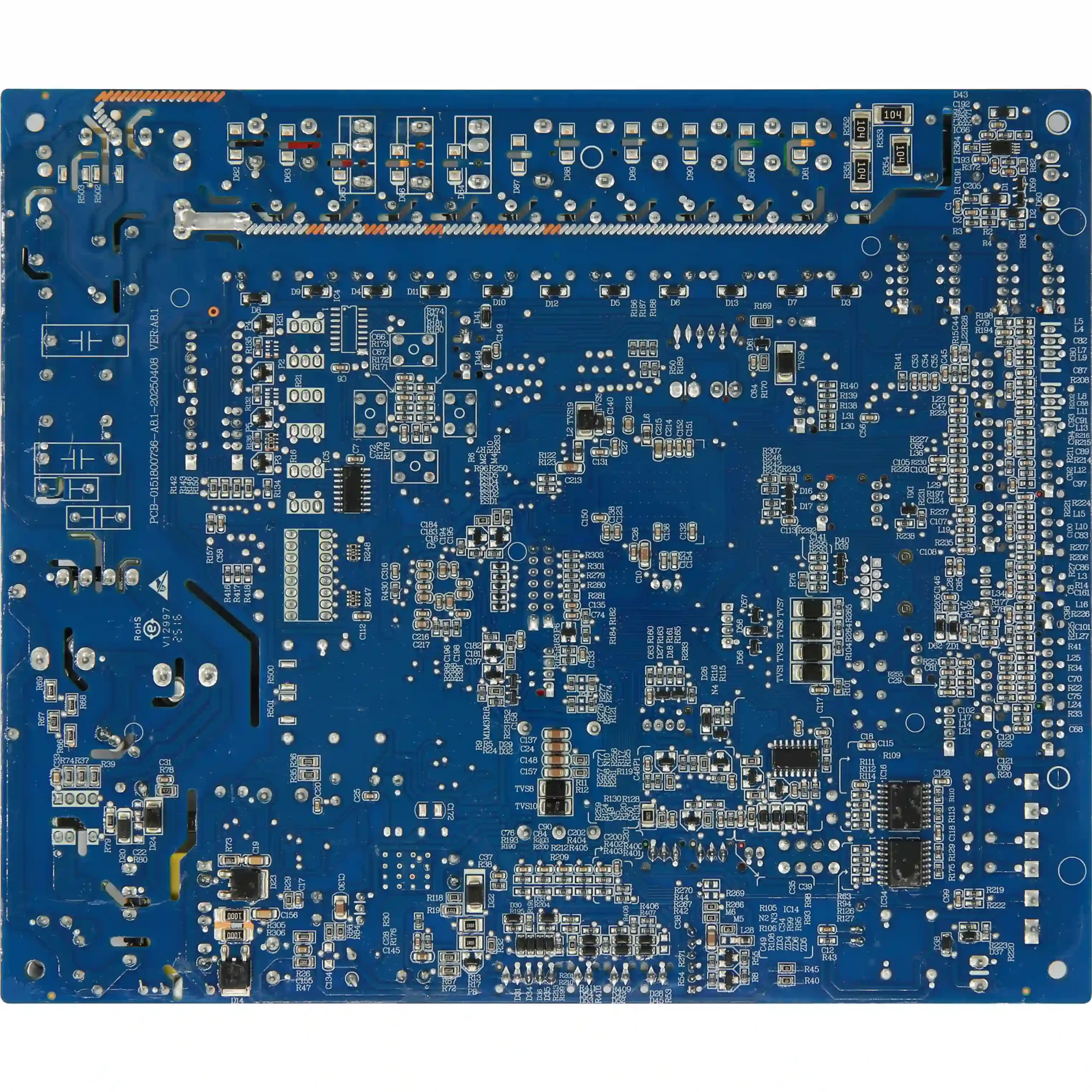

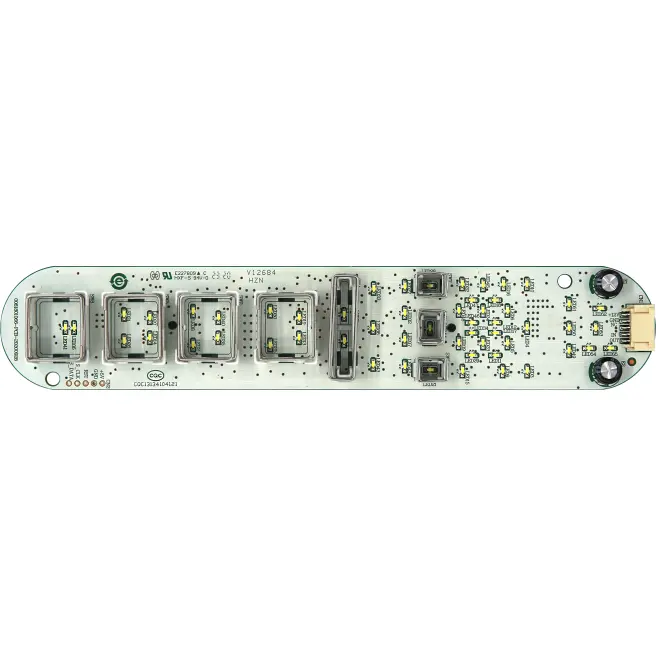

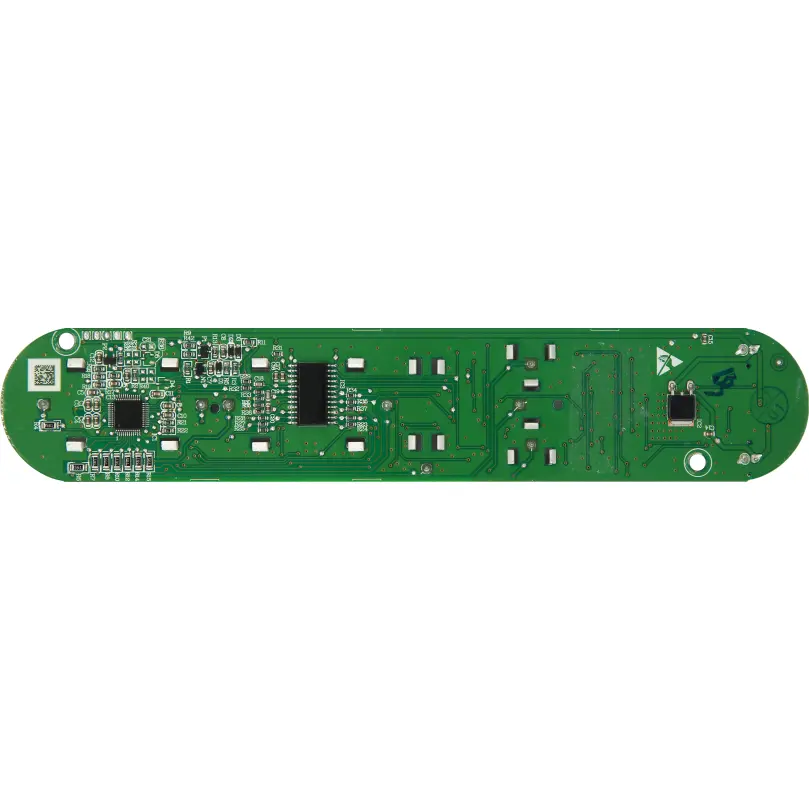

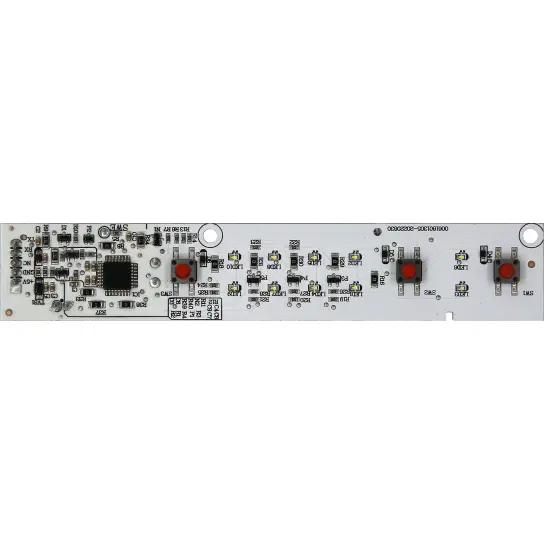

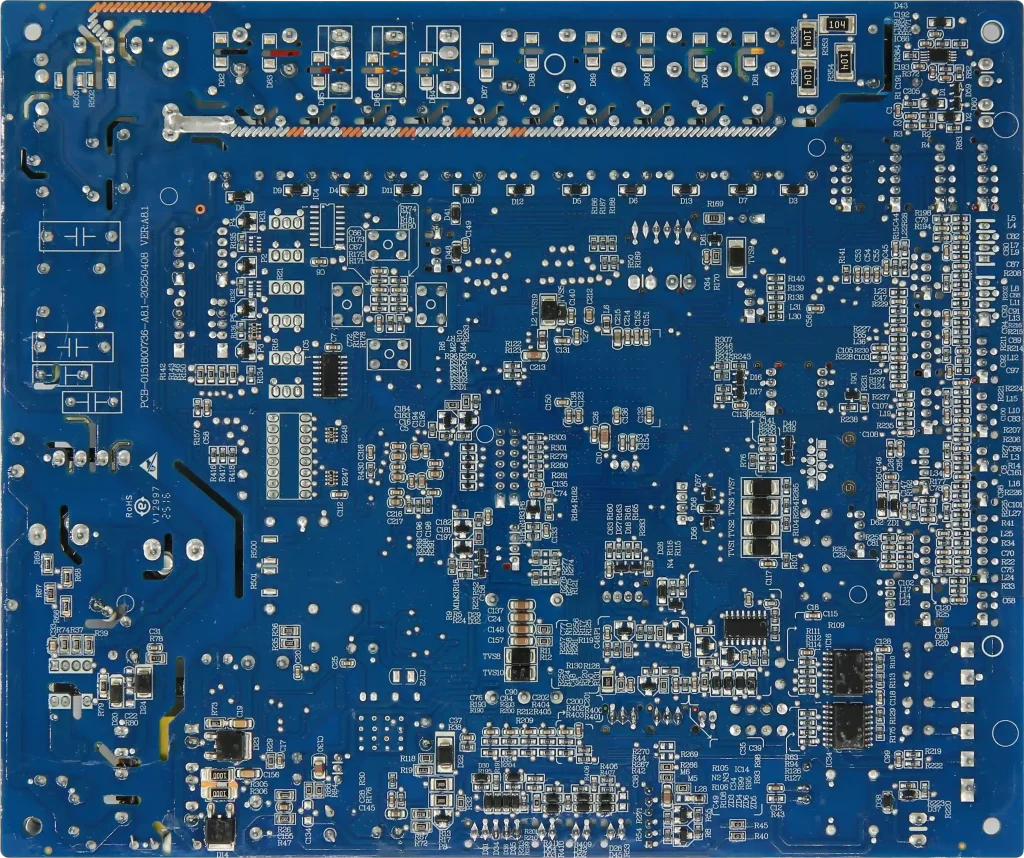

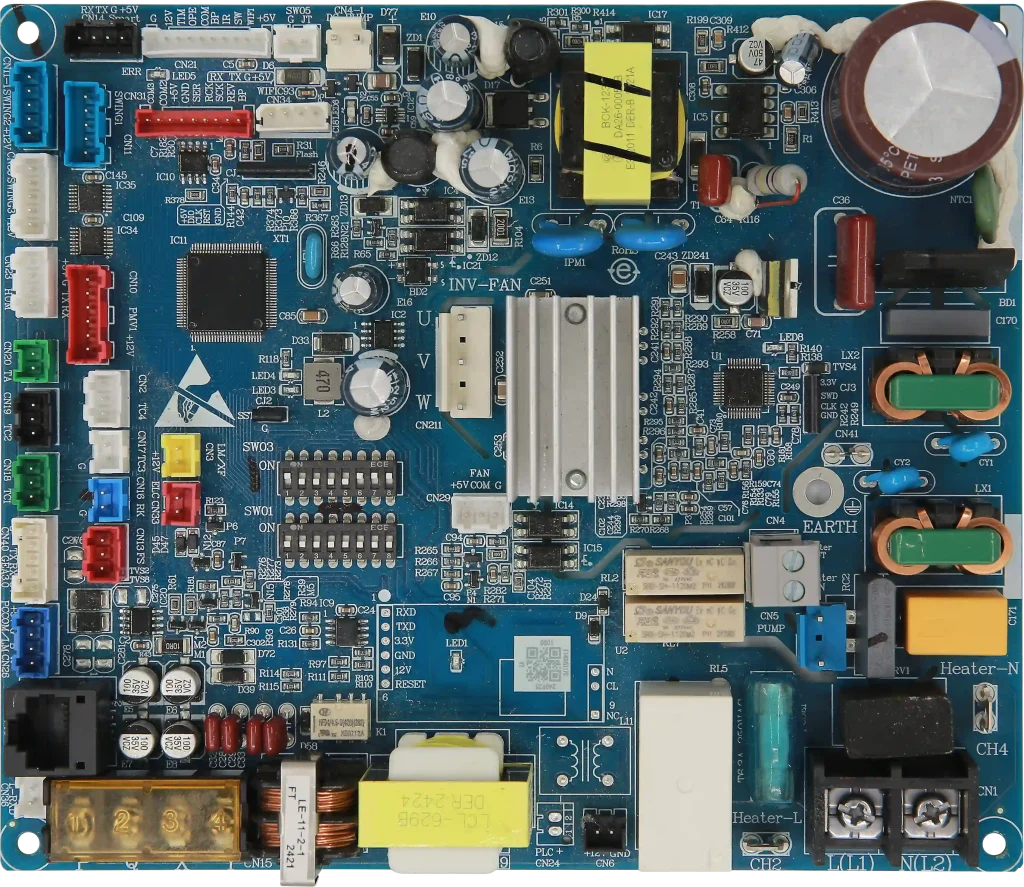

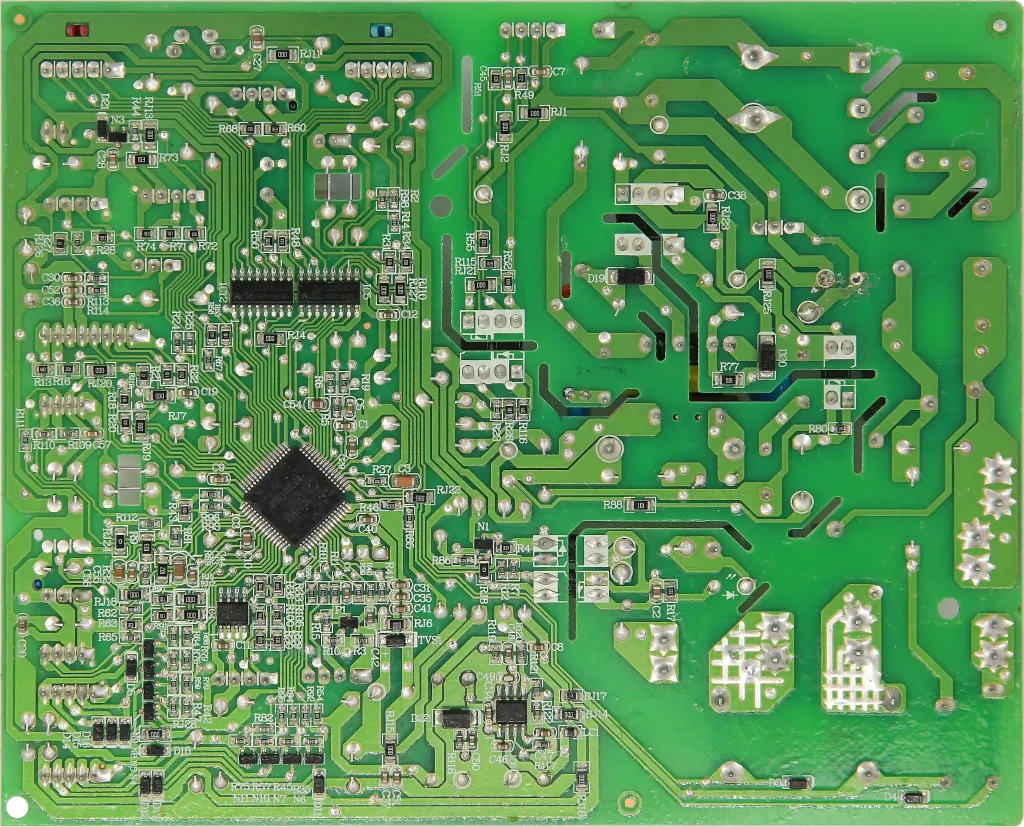

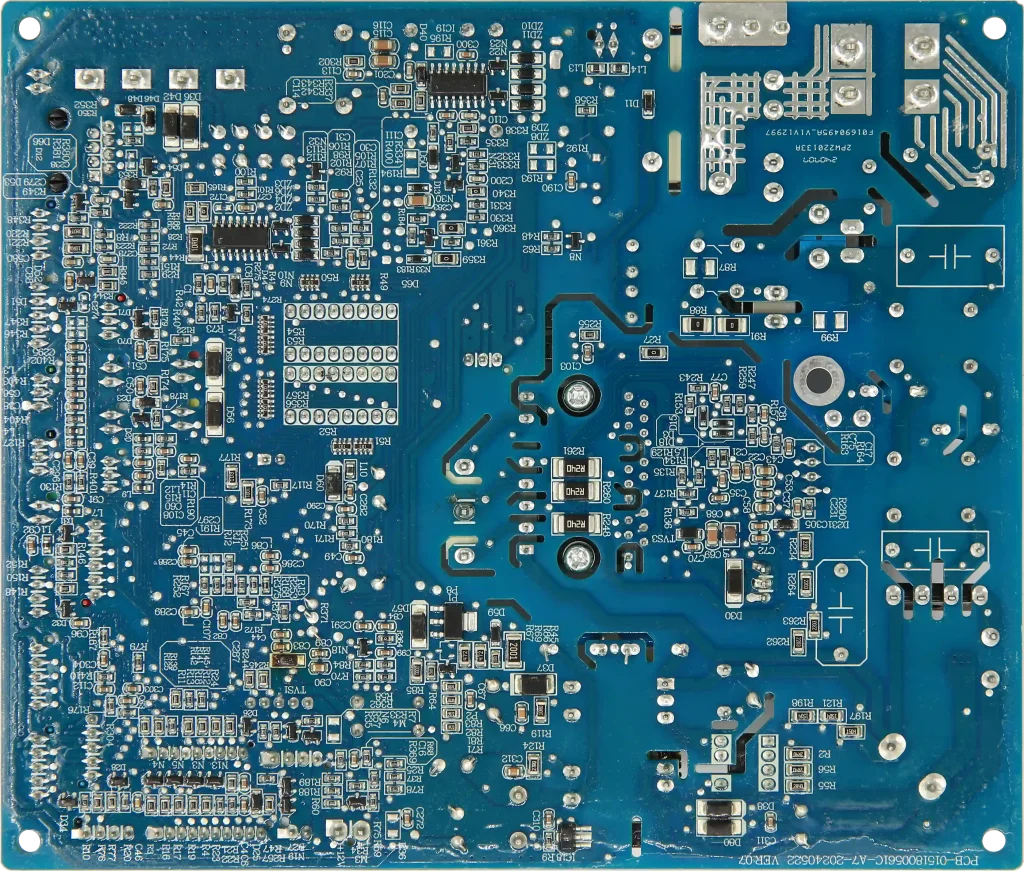

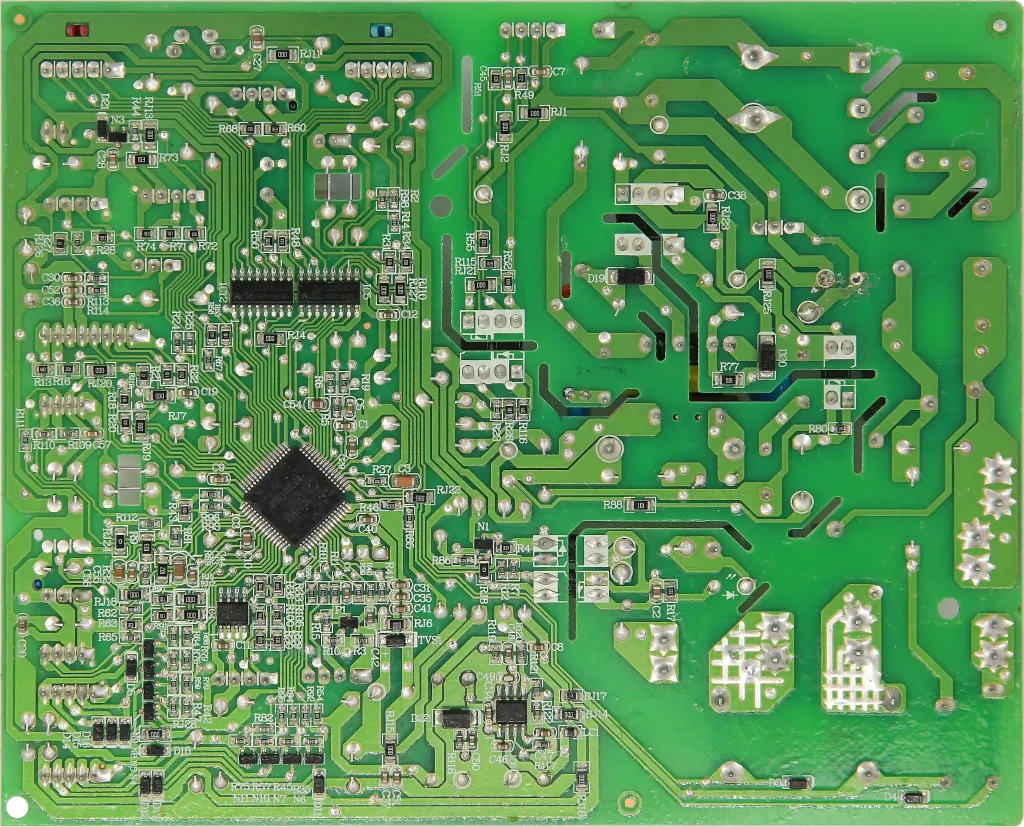

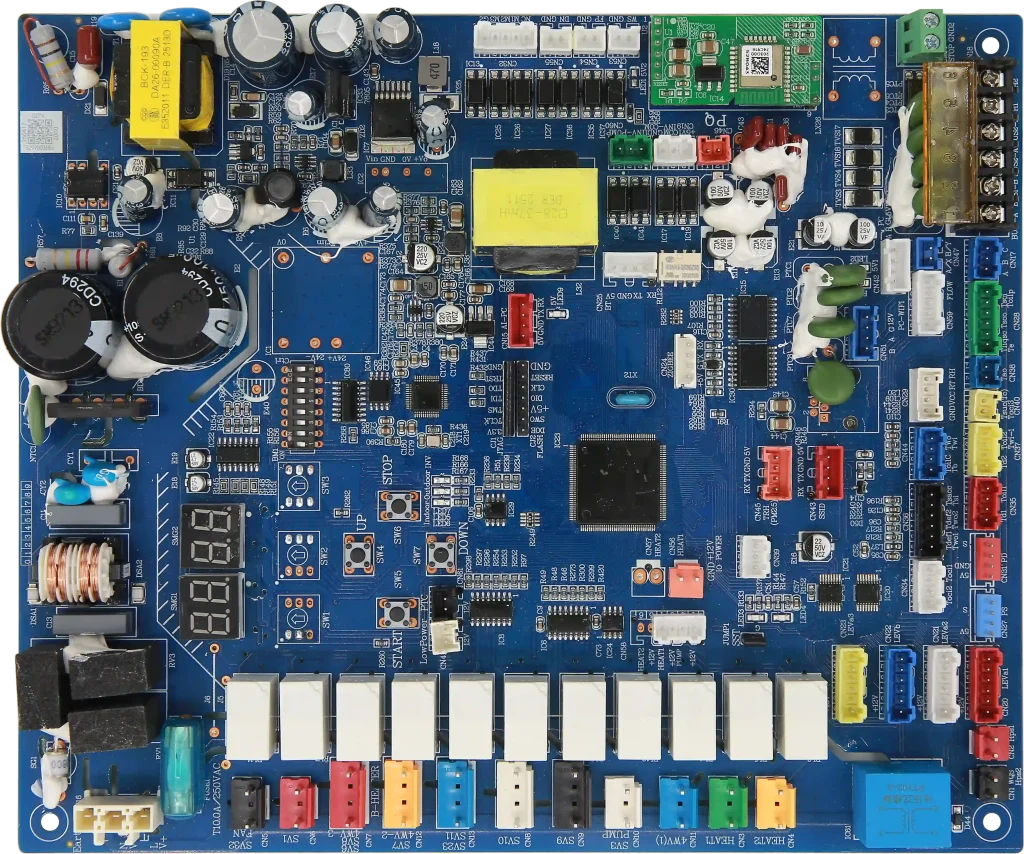

Home Appliance PCBA Manufacturer & Turnkey PCBA Assembly Services Comprehensive PCBA Solutions for Home Appliances Explore our top-tier PCBA solutions tailored for a variety of home appliances, including air conditioners, refrigerators, washing machines, and more. Why Choose Our Home Appliance PCBA Solutions? As a professional home appliance PCBA manufacturer, we provide turnkey PCBA assembly services…

Home Appliance PCBA Manufacturer & Turnkey PCBA Assembly Services

Comprehensive PCBA Solutions for Home Appliances

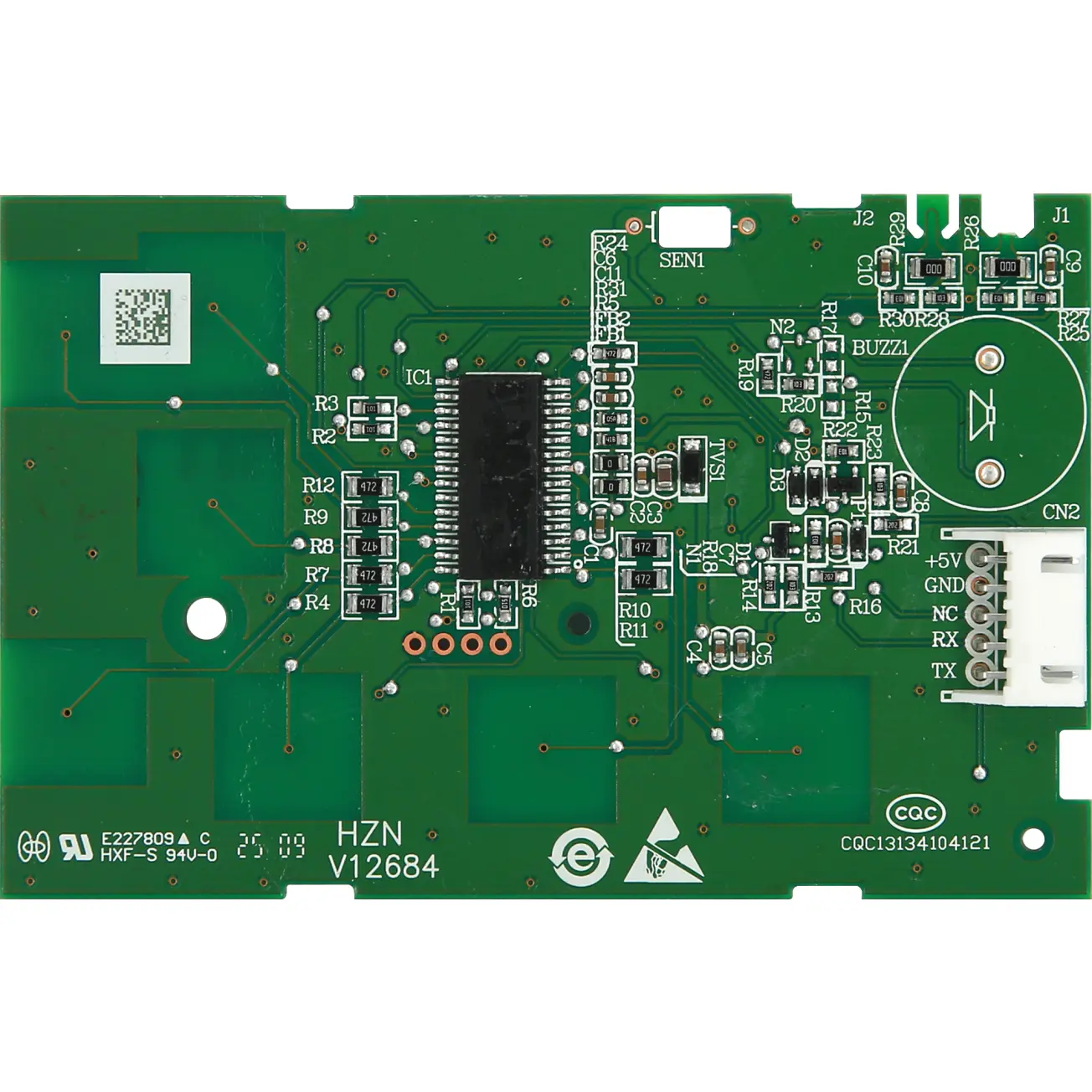

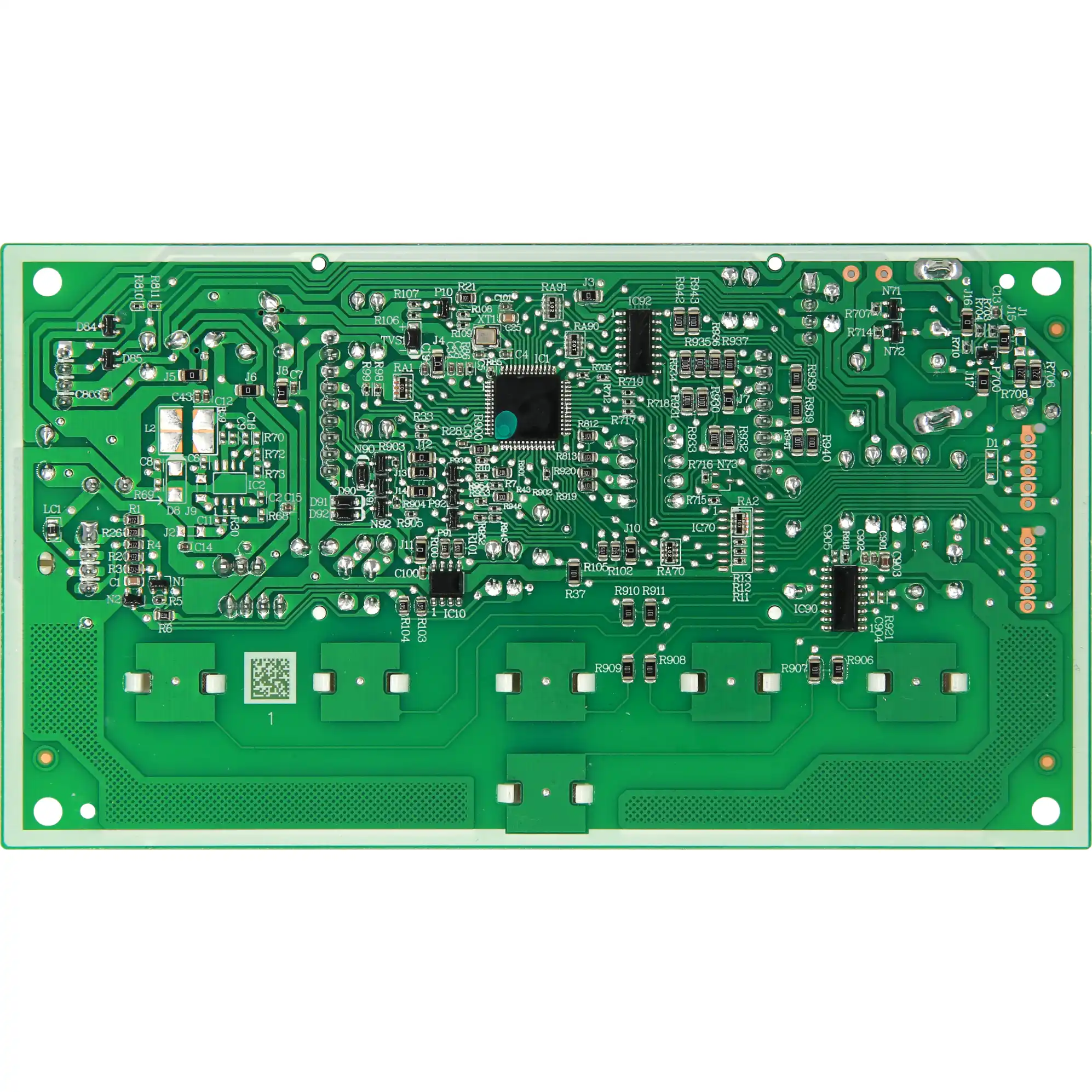

Explore our top-tier PCBA solutions tailored for a variety of home appliances, including air conditioners, refrigerators, washing machines, and more.

Why Choose Our Home Appliance PCBA Solutions?

As a professional home appliance PCBA manufacturer, we provide turnkey PCBA assembly services designed to meet the strict reliability and safety requirements of modern appliances. From control boards to power management modules, our solutions ensure stable operation, long service life, and cost efficiency.

With over 10 years of engineering experience, we help global home appliance brands reduce development risks and accelerate time to market.

One-Stop PCBA Service From Prototype to Mass Production

We offer a complete end-to-end PCBA service, covering:

- Circuit design optimization & design validation

- Component procurement and supply chain management

- SMT assembly, DIP insertion, and automated welding

- AOI, SPI, ICT, FCT functional testing

- Burn-in, aging tests, final assembly and delivery

Our turnkey model simplifies supplier management and guarantees consistent quality from prototype to mass production.

Reliable Performance:

Built for demanding home appliance applications, our PCBA assembly delivers consistent performance with validated reliability.

- High thermal stability for continuous operation

- Low power consumption through circuit optimization

- Long lifecycle proven by cycling tests & burn-in aging

Custom PCBA Design & Engineering Support:

From hardware to firmware readiness, our team builds application-specific PCBA for home appliances.

- Platforms: MCU / RTOS / Linux / Android solutions based on requirements

- IoT-ready: Wi-Fi / Bluetooth / Zigbee module integration

- Manufacturing-ready: automated SMT lines + SPI/AOI/ICT/FCT + MES traceability

Lower Total Cost for OEM/ODM PCBA Manufacturing:

We reduce hidden costs—rework, delays, quality escapes, and after-sales failures—with process control and validated reliability.

- Quality gates: SPI / AOI / ICT / FCT + burn-in aging

- Reliability validation: temperature cycling + long-term aging

- ISO-certified factory + MES traceability for consistent production

Faster EVT/DVT/PVT to Mass Production:

We support a smooth ramp from prototype to volume with turnkey PCBA capabilities.

- Design optimization + component sourcing for faster build readiness

- Automated SMT/DIP + functional testing + burn-in for stable yields

- Traceable production execution via MES across all lines

Technology-Driven OEM/ODM PCBA Execution:

We combine advanced production technology with engineering support to deliver consistent, scalable results.

- Automated SMT & assembly lines + MES traceability across all lines

- Comprehensive test equipment for electrical/environmental validation

- R&D center (60 engineers) for hardware/software/structure co-development

Factory Built for Scalable OEM/ODM Production:

We support fast ramp-up and stable mass production with controlled processes and advanced equipment.

- High-precision placement systems and automated welding

- Integrated testing and burn-in before shipment

- ISO-certified management and digital traceability

Manufactured in compliance with ISO 9001, ISO/TS 16949, ISO/TS 22163, and certified to UL, CE, ROHS standards.

Discover Our PCBA Features

Explore the extensive features of our PCBA solutions designed for a wide range of home appliance and smart device applications.

Quality Assurance

Our PCBA solutions undergo strict quality assurance processes, including AOI, functional testing, and reliability inspections, to ensure stable performance and long-term durability across various operating environments.

Customized Solutions

We provide fully customized PCBA solutions tailored to the specific electrical, structural, and functional requirements of each appliance model, supporting OEM and ODM projects from concept to mass production.

State-of-the-Art Technology

By leveraging advanced SMT technology and high-precision assembly equipment, our PCBAs enhance the performance of air conditioners, refrigerators, washing machines, and smart home devices.

Fast Turnaround

Our optimized production workflow ensures short lead times and rapid PCBA turnaround, helping customers accelerate product development cycles and achieve faster market launches.

Scalable Manufacturing

With flexible and scalable manufacturing capabilities, we efficiently support both low-volume prototyping and high-volume mass production, while maintaining consistent quality standards.

Comprehensive Testing

Each PCBA undergoes comprehensive electrical and functional testing to meet international industry standards, ensuring enhanced product reliability and appliance longevity.

-

What is PCBA?

PCBA stands for Printed Circuit Board Assembly. It refers to the complete process of mounting and soldering electronic components onto a printed circuit board, resulting in a fully functional electronic assembly.

-

What is the difference between PCB and PCBA?

A PCB is a bare circuit board without components, while PCBA is a finished board with all electronic components assembled and soldered, ready for use in electronic products.

-

What PCBA services do you provide?

We offer one-stop PCBA services including PCB fabrication, component sourcing, SMT assembly, DIP assembly, reflow and wave soldering, AOI inspection, functional testing, and mass production.

-

What testing methods are used for PCBA?

Our PCBA testing includes SPI, AOI, ICT, functional testing, and aging tests to ensure high quality, reliability, and stable performance of every assembled board.

-

Can customers supply their own components?

Yes, customers may provide their own components for PCBA assembly. We also offer full component procurement services to ensure cost efficiency and reliable supply chains.

-

What is the typical lead time for PCBA orders?

Lead time depends on board complexity, order quantity, and component availability. Prototype orders usually take a shorter time, while mass production lead times vary based on project requirements.

Leave Your Message

Reliable, Customized Solutions for Business Success

Sanshun is dedicated to offering customized business solutions that improve operational efficiency, product performance, and long-term competitiveness, helping companies achieve sustainable growth.