PCBA Relay Failure: Mitigating After-Sales Risk with Quality OEM Selection

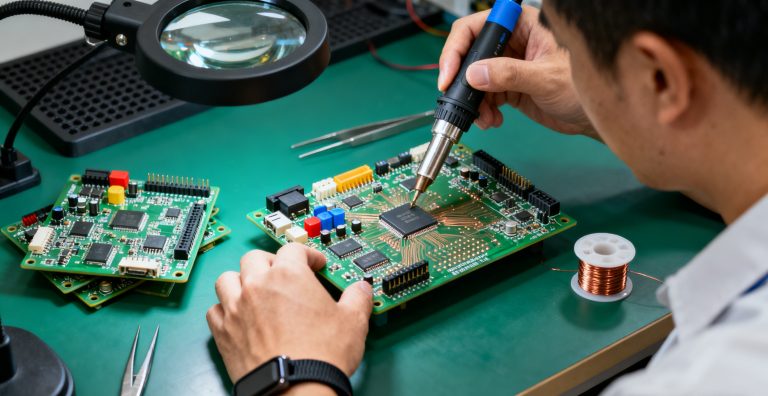

Their process includes rigorous inspection, environmental stress screening, and precise metrology, all designed to maximize relay lifespan and minimize after-sales risk.

Their process includes rigorous inspection, environmental stress screening, and precise metrology, all designed to maximize relay lifespan and minimize after-sales risk.

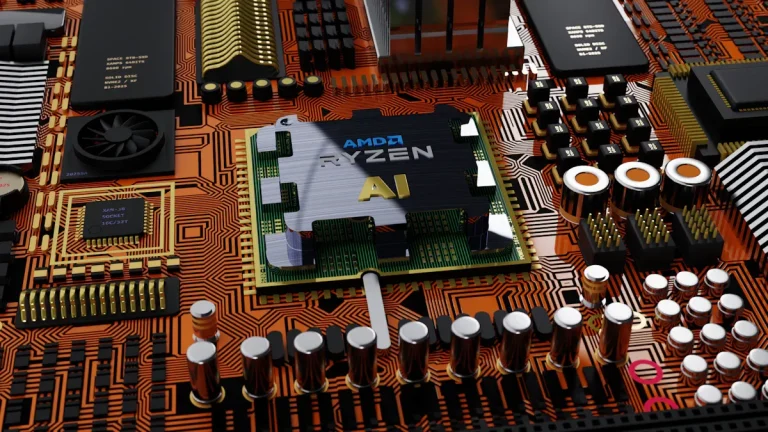

You gain a clear advantage when you choose PCBA China for your manufacturing needs in 2025. Global OEMs rely on this region because it leads the world, holding 59% of the global PCB production market.

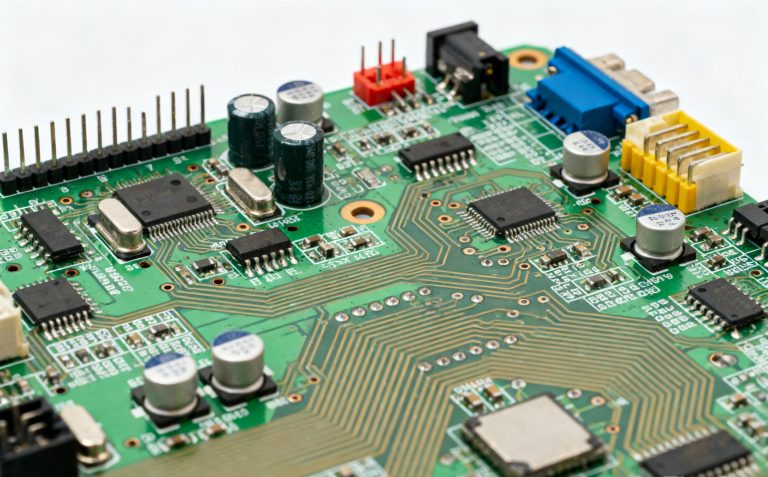

You see many European SMEs turning to Asia-based PCBA Suppliers because they seek lower costs, enhanced production flexibility, and superior quality. Rising labor expenses in Europe and unpredictable supply chain risks have forced you to rethink your manufacturing strategies.

You need a systematic approach to identify a reliable PCBA manufacturer in China. China PACB accounts for approximately 51% of global PCBA production, making it a key destination for PCBA sourcing. You should prioritize strict quality control and reliability testing. Leading manufacturers such as Sanshun and Next PCBA have earned customer trust through their consistent service and proven reliability.

You want the best when choosing a China PCBA Factory. Sanshun PCBA stands out with strong industry certifications, advanced technology, and an efficient supply chain. The company’s focus on zero-defect PACB production gives you confidence in every project. High-reliability sectors trust Sanshun PCBA for consistent quality and dependable results.