Key certifications every reliable SMT PCBA should have

Certifications provide essential proof that an SMT PCBA meets internationally recognized standards for quality, safety, and regulatory compliance.

Certifications provide essential proof that an SMT PCBA meets internationally recognized standards for quality, safety, and regulatory compliance.

Choosing the right PCBA Contract Manufacturing approach can define your product’s reputation and your company’s long-term competitiveness. A single strategic misstep in PCBA contract manufacturing decisions may expose you to quality failures, communication breakdowns, supply chain disruptions, or even intellectual property risks.

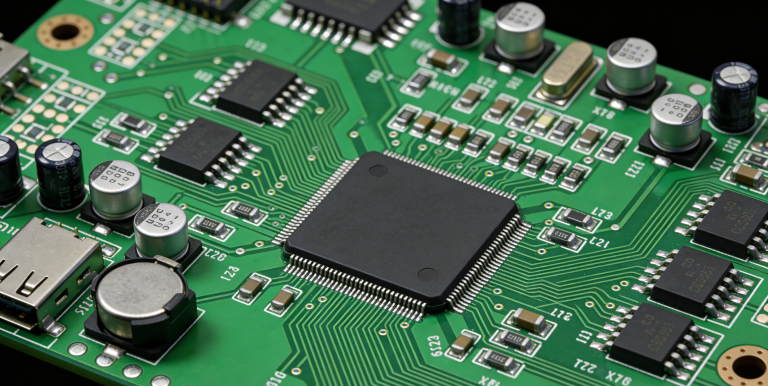

In electronic manufacturing, SMT PCBA can be produced using different assembly processes depending on product requirements, performance expectations, and application environments.

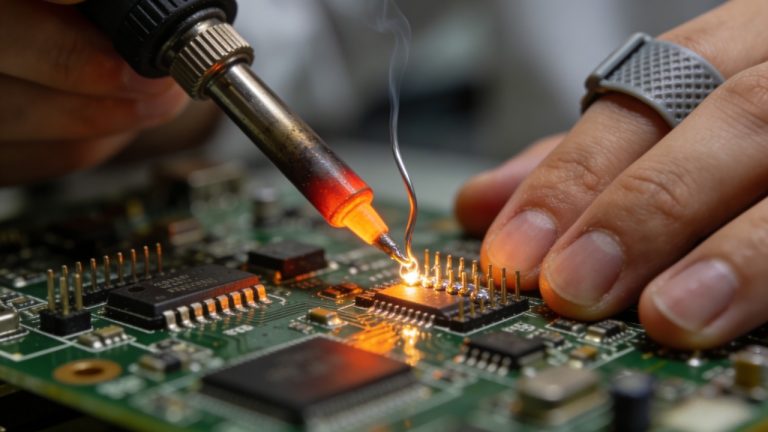

You often encounter SMT PCBA defects like solder bridging, tombstoning, solder balls, insufficient solder, missing components, cold solder joints, misalignment, and open joints in PCBA assembly.

For most OEMs, you will find that PCBA contract manufacturing delivers lower operational costs and mitigates major risks compared to in-house assembly. Key risk factors often cited by decision-makers include quality control, intellectual property security, and production scalability.

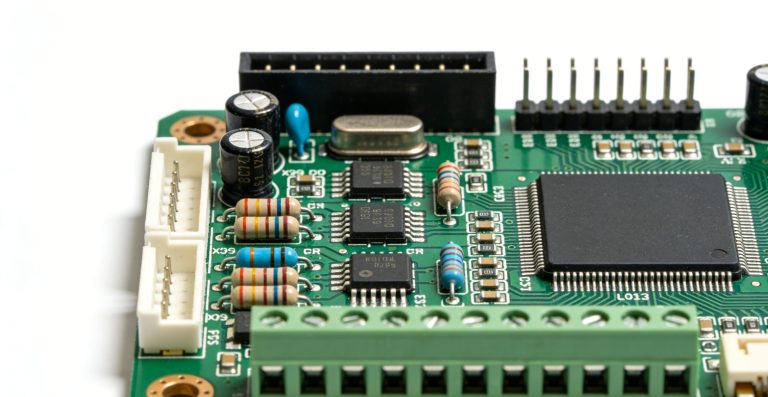

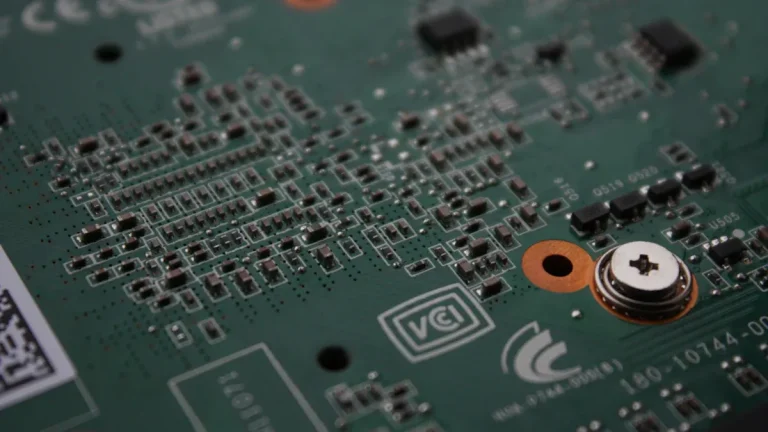

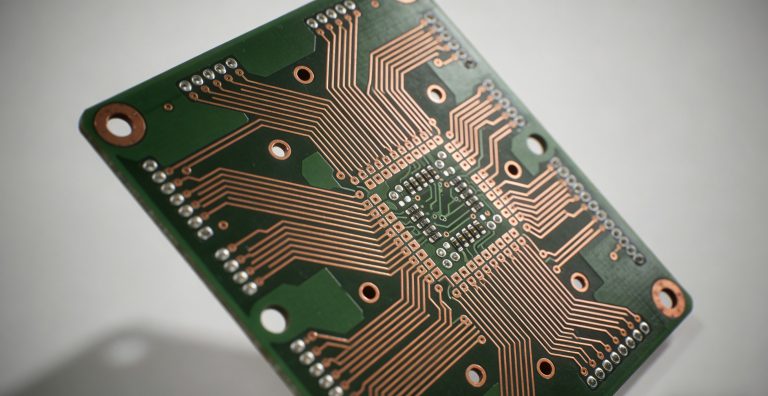

Surface mount technology (SMT) PCBA processes involve three essential steps: solder paste printing, component placement, and reflow soldering. These steps directly influence the quality and reliability of your SMT PCBA assemblies.

You face high stakes in PCBA contract manufacturing. Even a single flaw can compromise an entire product line, risking costly recalls and damaged reputations. ISO 9001 stands as the gold standard for minimizing these risks.

You face a critical decision when choosing between SMT PCBA and THT Assembly for your project.

You need a reliable PCBA Contract Manufacturing partner who consistently delivers high-quality results, protects your intellectual property, and responds to your requirements with precision.

SMT PCBA uses surface mount technology to assemble electronic components directly onto pcba. This method increases efficiency and allows for compact device designs. Unlike traditional through-hole assembly, surface mounting technology attaches components to the board surface.

Professional PCBA production forms the foundation of product reliability. You influence long-term durability at every stage, from sourcing components to final testing. If you overlook robust quality controls, you expose your products to early failures and costly repairs.

Selecting the right PCBA contract manufacturing partner shapes your product’s quality, overall reliability, and speed to market. You need to define your pcb assembly requirements and understand how a poor provider choice can increase costs and delays.